Device for improving welding quality of large-size pipeline easily

A technology for welding quality and pipelines, which is applied in the direction of welding accessories, welding connection methods, tubular objects, etc., can solve the problems of reducing the service life of pipelines, achieve the effect of tightly protecting gas and improving welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

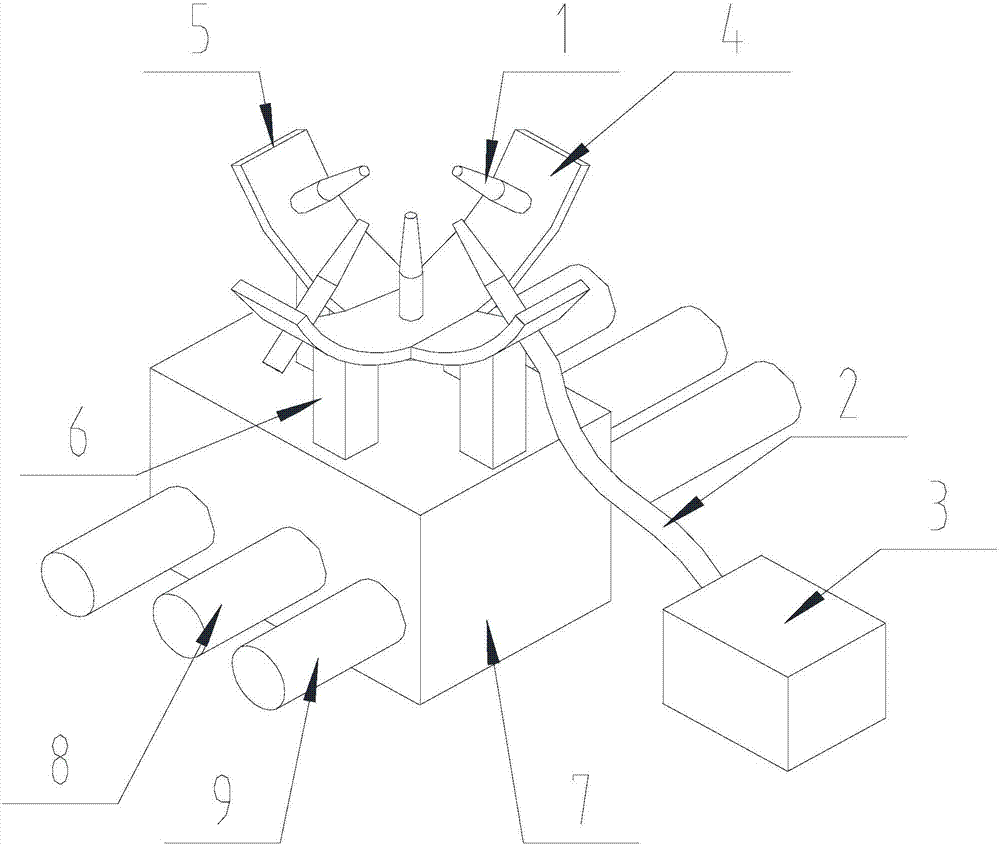

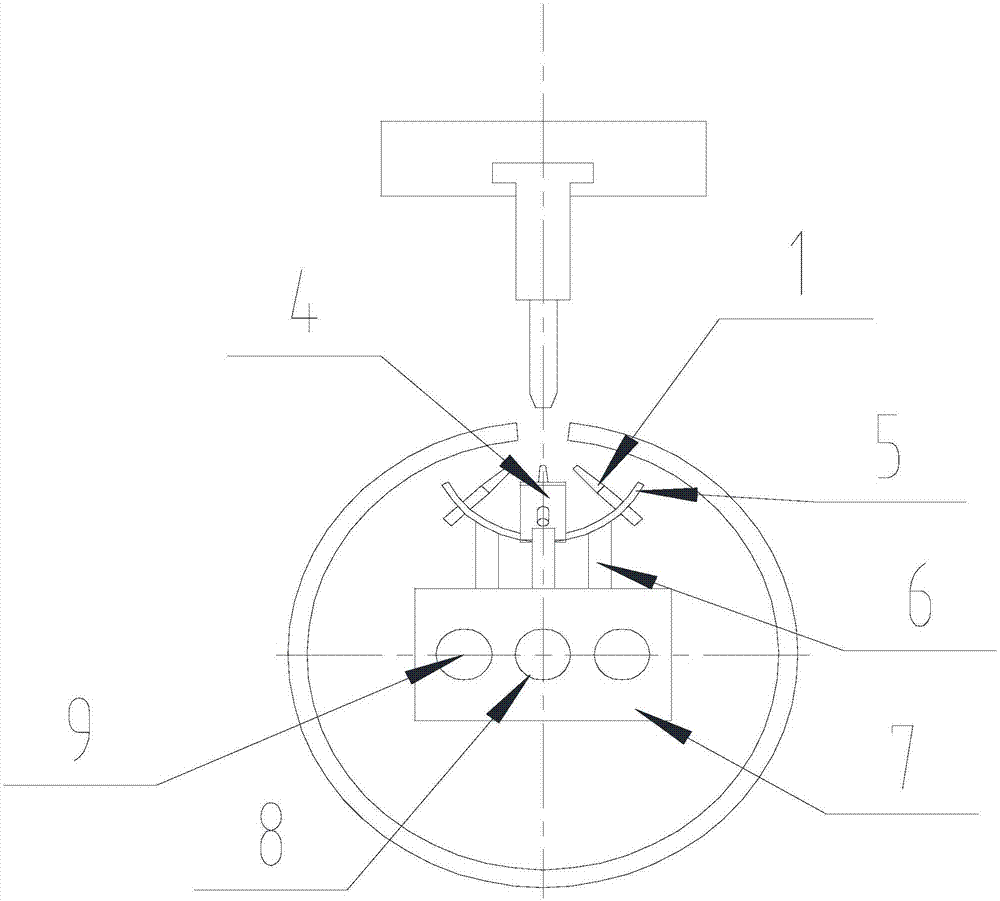

[0022] Such as Figure 1-Figure 2 As shown, the present invention is beneficial to the device for improving the welding quality of large-scale pipelines, including a horizontal plate 4, a connecting assembly, a driving assembly, and gas nozzles 1, gas pipelines 2 and gas storage tanks 3 communicated in sequence, and the gas nozzles 1 have several , and arranged in a row on the horizontal plate 4, and the extension lines of the gas jet ends of the gas nozzles 1 meet at one point; the connecting assembly is connected to the end of the horizontal plate 4 away from the gas nozzle 1, and the driving assembly is connected to the connecting assembly , and can drive the connected components to move back and forth.

[0023] When in use, the whole device is installed in the central hole of the pipeline to be welded. When the welding torch starts welding, the driving device is started and the shielding gas nozzle 1 is ejected at the same time. With the movement of the welding torch, the ...

Embodiment 2

[0025] The present invention is based on embodiment 1, and the present invention is further described.

[0026] Such as Figure 1-Figure 2 As shown, the present invention is beneficial to the device for improving the welding quality of large pipelines, the horizontal plate 4 is an arc plate, the gas nozzle 1 is evenly arranged on the inner concave surface of the horizontal plate 4 along the circumferential direction of the horizontal plate 4, and the gas nozzle 1 The paint spraying gas ends are all close to the axis of the cross plate 4. Setting the horizontal plate 4 as an arc plate can shorten the distance between the gas nozzle 1 and the intersection point of the horizontal plate 4 away from its radial centerline, so that the distance from each gas nozzle 1 to the intersection point is as uniform as possible, so that the weld seam can be obtained closer protective gas.

[0027] Further, a vertical plate 5 is also included, the shape of the vertical plate 5 is consistent w...

Embodiment 3

[0029] The present invention is based on embodiment 1, and the present invention is further described.

[0030] Such as Figure 1-Figure 2 As shown, the present invention is beneficial to the device for improving the welding quality of large-scale pipelines. The connecting assembly includes a connecting column 6 and a moving block 7. One end of the connecting column 6 is understood from the end of the horizontal plate 4 away from the gas nozzle 1. The connecting column 6 The other end is connected with moving block 7.

[0031] Further, the drive assembly includes a motor, a screw 8 parallel to each other and a limit rod 9, and a threaded hole cooperating with the screw 8 and a limit block cooperating with the limit rod 9 are provided on the moving block 7, the The motor drives the screw rod 8 to rotate, and drives the moving block 7 to move along the axis of the screw rod 8 . During installation, detachably fix the two ends of the screw rod 8 and the two ends of the stop rod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com