High-temperature-resistant and water-cooling-free roll and preparation method thereof

A water-free, high-temperature-resistant technology, applied in the field of metallurgy, can solve the problems of water-free cooling roll sticking to steel and low cost-effectiveness of water-free cooling roll materials, so as to improve corrosion resistance, anti-oxidative accumulation and anti-adhesion performance, and improve high temperature Effects of strength and corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

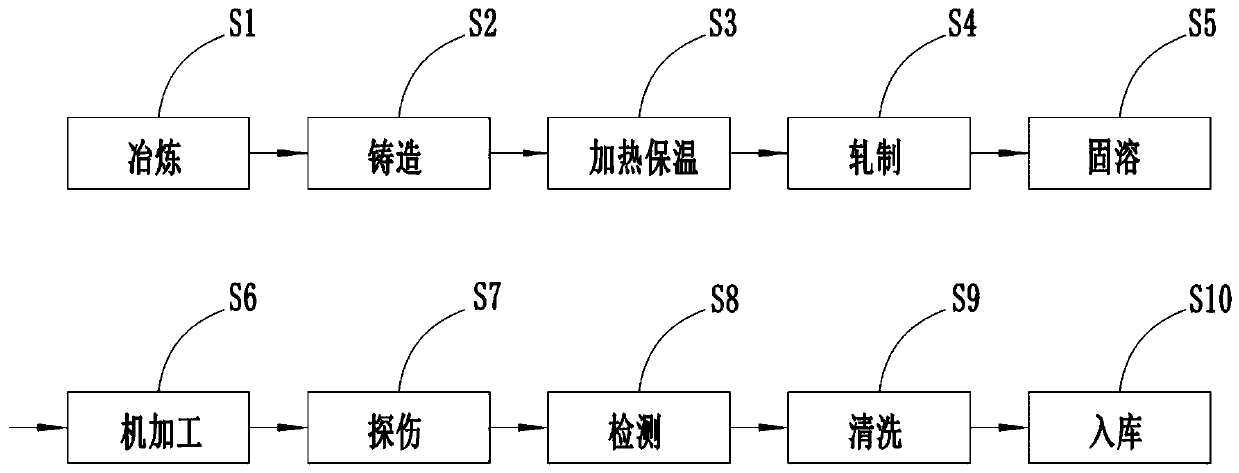

[0034] The present invention also provides a method for preparing a high temperature resistant waterless chill roll, comprising the following steps:

[0035] 1) Smelting: Ferrosilicon, electrolytic manganese, nickel, micro-carbon ferrochrome, ferromolybdenum, vanadium, iron, aluminum, ferrotungsten, ferrotitanium, ferroniobium, ferrochromium nitride, and A3 waste are smelted in an intermediate frequency induction furnace. After the content of each element is measured by the direct reading spectrometer, the molten steel is tapped;

[0036] 2) Casting: The molten steel is subjected to centrifugal casting to obtain ingots. Centrifugal casting can change the crystallization process of metals. The waterless chilled rollers of centrifugal casting have better mechanical and physical properties.

[0037] 2) Heating and heat preservation: heat the ingot to 1200°C in a heating furnace and keep it warm for 6 hours;

[0038] 3) Forging: the ingot is forged into a round steel billet throu...

Embodiment 1

[0048] A high temperature resistant waterless chill roll, by weight percentage: C0.3, Si0.5, Mn0.2, Ni0.5, Cr30-31, Mo2.1, V0.15, Al4.5, W1.3, Ti0. 1, Nb0.15, N0.08, the balance is Fe and other unavoidable impurity elements.

[0049] A preparation method of a high temperature resistant waterless chill roll, comprising the following steps:

[0050] 1) Smelting: Ferrosilicon, electrolytic manganese, nickel, micro-carbon ferrochrome, ferromolybdenum, vanadium, iron, aluminum, ferrotungsten, ferrotitanium, ferroniobium, ferrochromium nitride, and A3 waste are smelted in an intermediate frequency induction furnace. After the content of each element is measured by the direct reading spectrometer, the molten steel is tapped;

[0051] 2) Casting: Centrifugal casting of molten steel to obtain ingots;

[0052] 2) Heating and heat preservation: heat the ingot to 1200°C in a heating furnace and keep it warm for 6 hours;

[0053] 3) Forging: the ingot is forged into a round steel billet...

Embodiment 2

[0062] A high temperature resistant waterless chill roll, by weight percentage: C0.5, Si0.8, Mn0.4, Ni1.5, Cr31, Mo2.3, V0.3, Al6.0, W1.8, Ti0.2, Nb0.2, N0.15, the balance is Fe and other unavoidable impurity elements.

[0063] A preparation method of a high temperature resistant waterless chill roll, comprising the following steps:

[0064] 1) Smelting: Ferrosilicon, electrolytic manganese, nickel, micro-carbon ferrochrome, ferromolybdenum, vanadium, iron, aluminum, ferrotungsten, ferrotitanium, ferroniobium, ferrochromium nitride, and A3 waste are smelted in an intermediate frequency induction furnace. After the content of each element is measured by the direct reading spectrometer, the molten steel is tapped;

[0065] 2) Casting: Centrifugal casting of molten steel to obtain ingots;

[0066] 2) Heating and heat preservation: heat the ingot to 1200°C in a heating furnace and keep it warm for 6 hours;

[0067] 3) Forging: the ingot is forged into a round steel billet throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com