Mould casting magnesium alloy

A magnesium alloy, die-casting technology, applied in the field of die-cast magnesium alloy, to achieve the effects of no cracks and defects, good casting performance, good creep performance and corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The die-cast magnesium alloy of the present invention can be used for: automotive parts around the engine, such as structural parts around the engine, such as cylinder blocks, cylinder heads, cylinder head covers, oil pans, oil pump bodies, oil pump covers, feed pipes, and tanks , such as boxes around the engine such as transmission boxes, shift boxes, chain box slip-in boxes, hinge covers and oil pump covers.

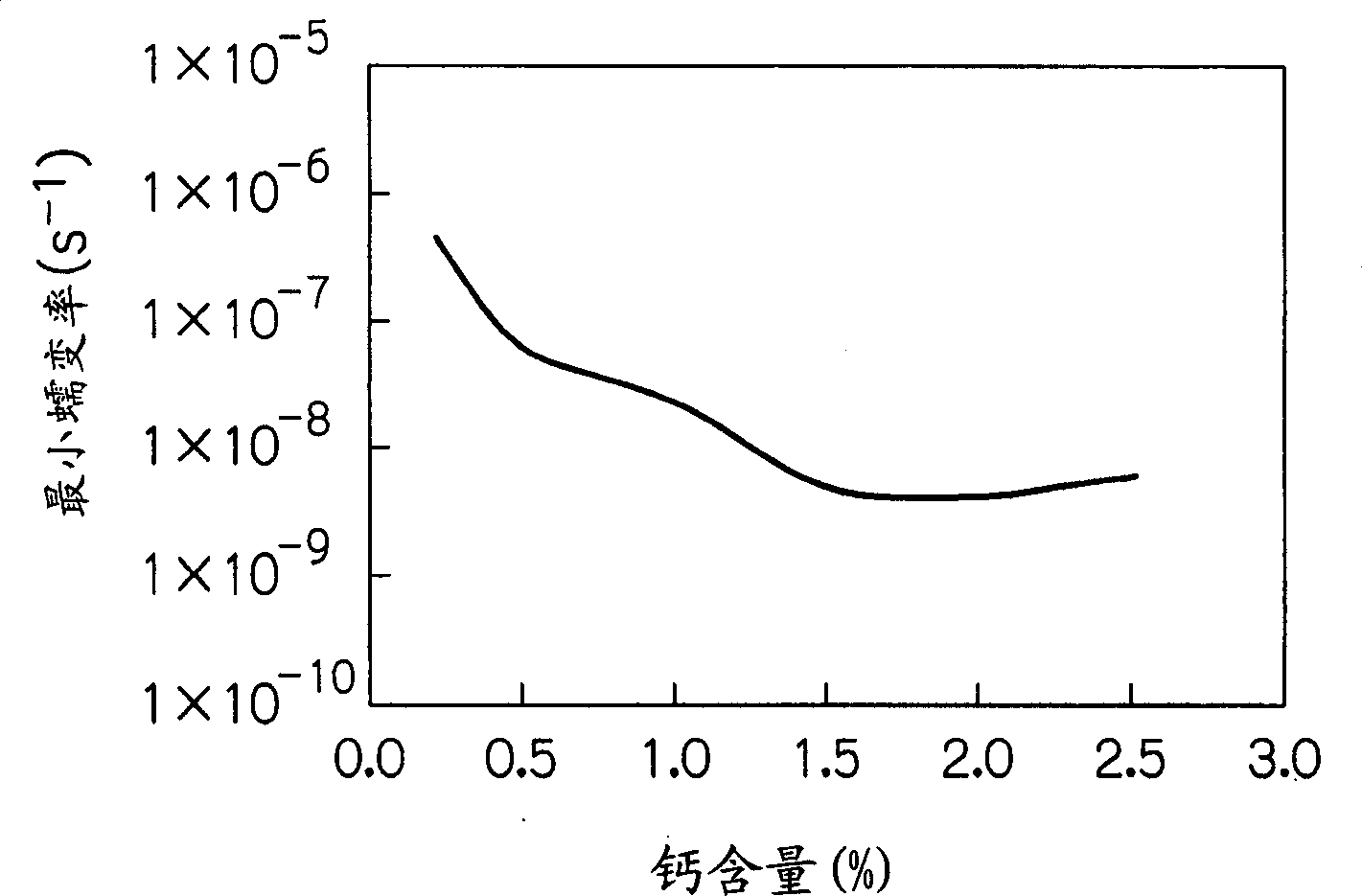

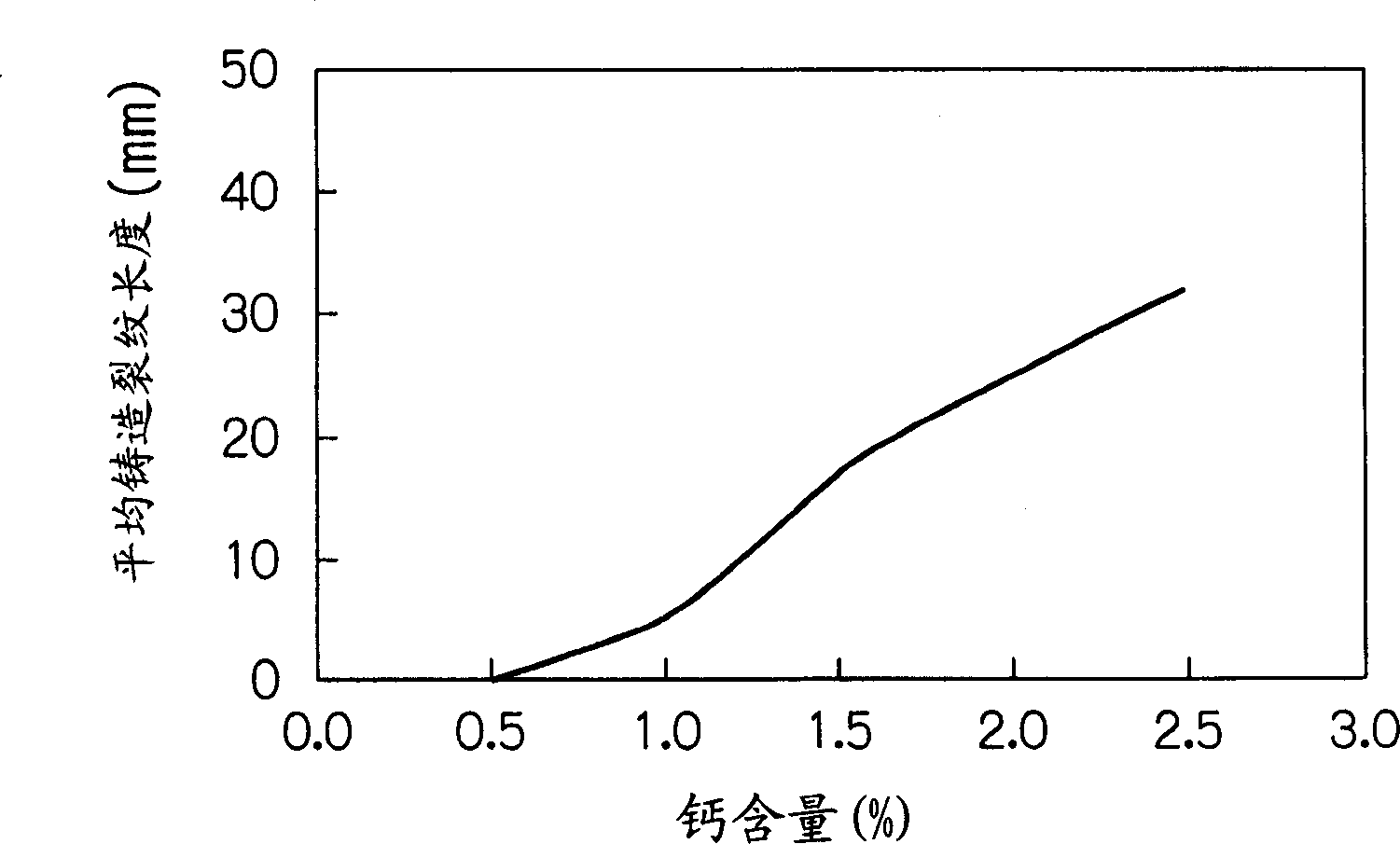

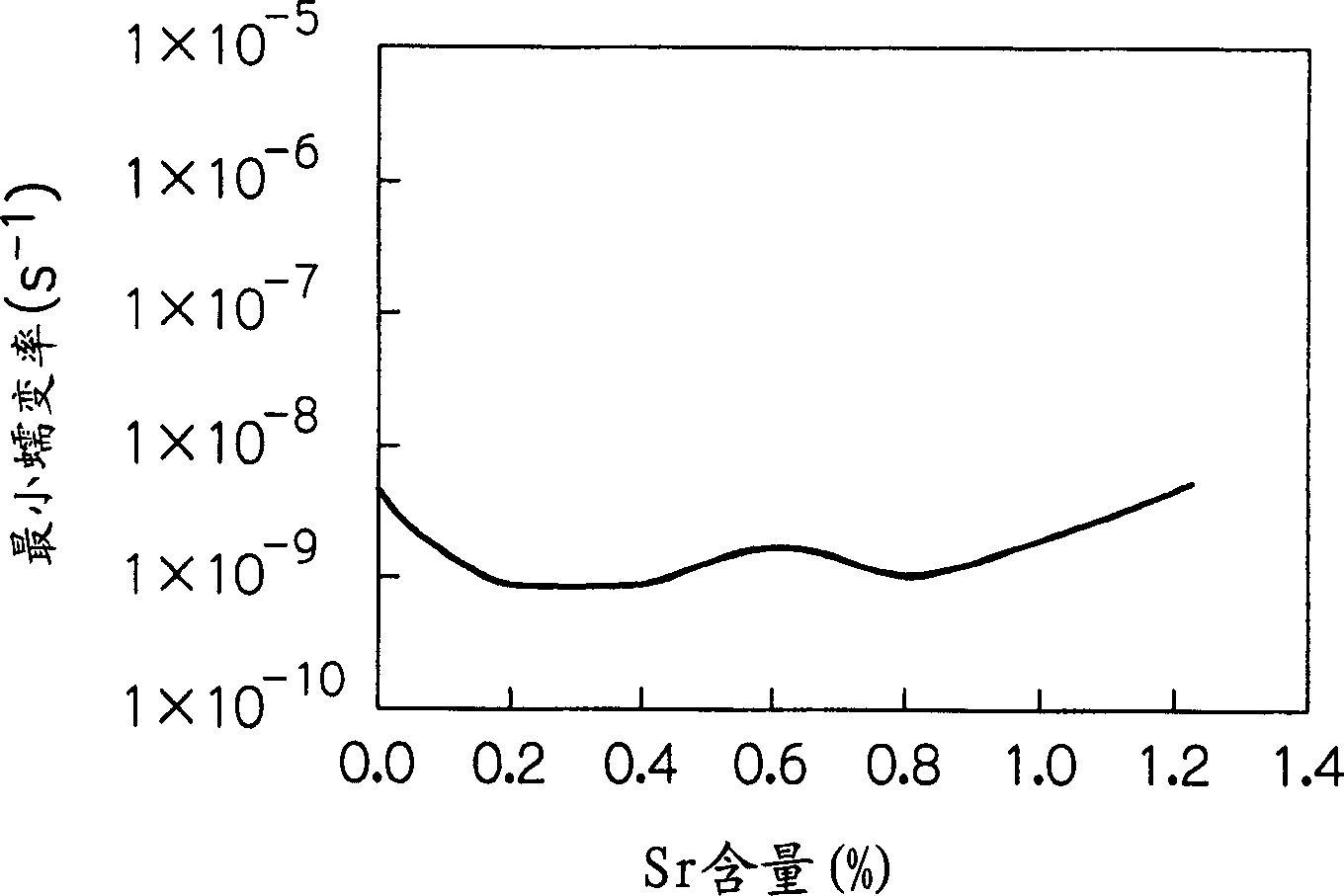

[0047] The aluminum content is limited to "1.5 to 6% by weight" based on the results of the tests described below.

[0048] When the content of aluminum is not more than 6% by weight, most of the aluminum infiltrates into the matrix of magnesium in solid state. The tensile strength of the alloy increases due to solution hardening. Moreover, the creep properties of the alloy are improved due to the network phase structure of the Al-Ca compound crystallized at the grain edges due to the combination with Calcium. Aluminum also improves the castability of the allo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com