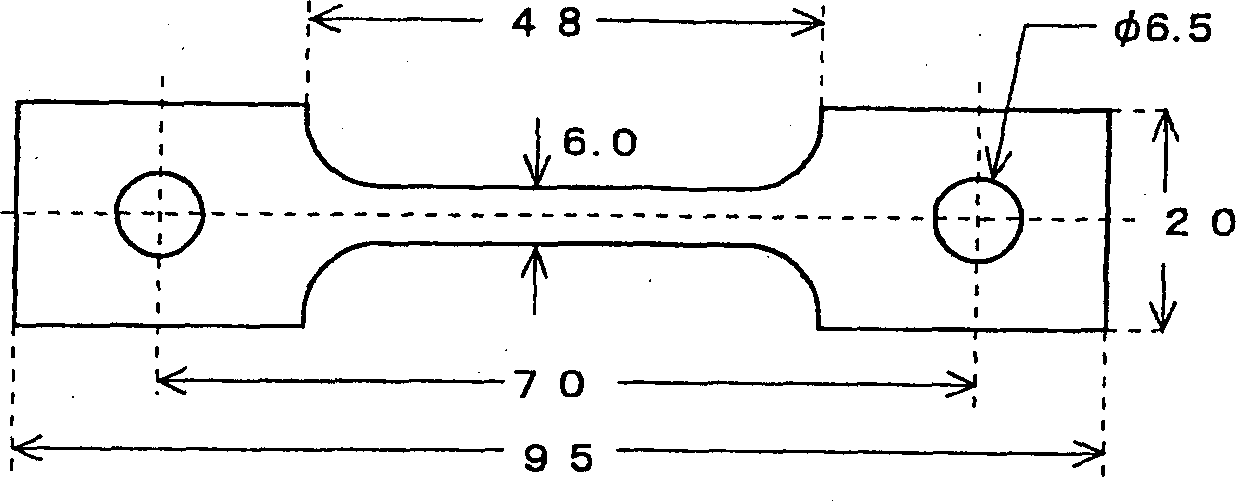

Method for producing platinum material reinforced with dispersed oxide

A dispersion-enhanced, oxide technology, applied in manufacturing tools, glass manufacturing equipment, glass furnace equipment, etc., can solve the problem of not being able to further improve the creep strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

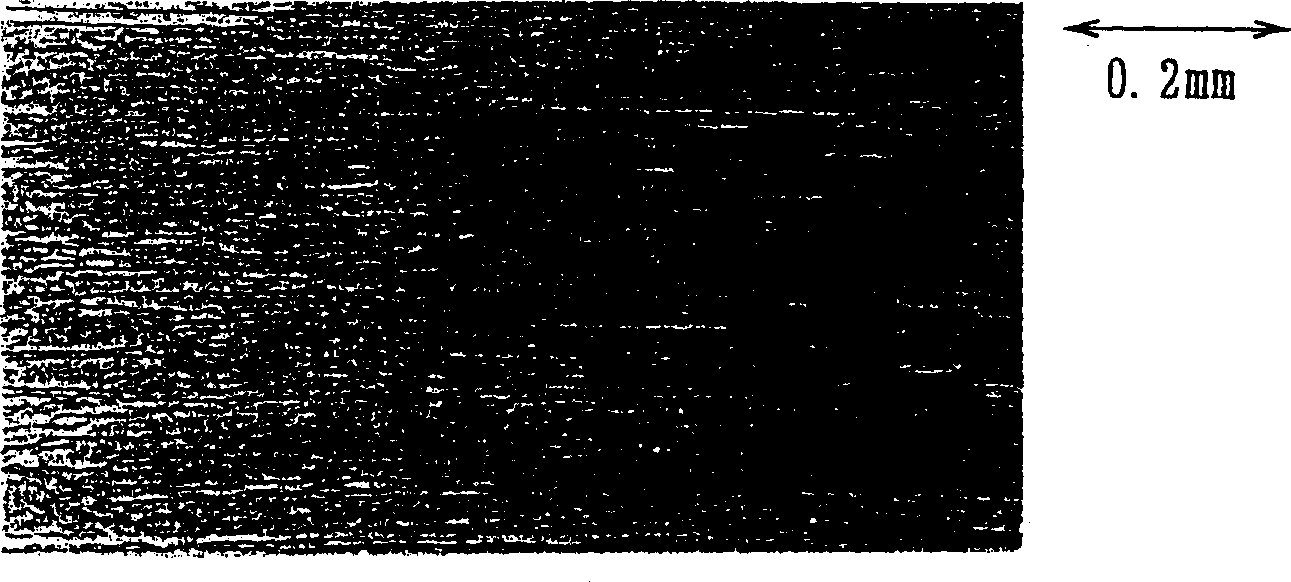

Examples

Embodiment 1

[0034] In this Example 1, Pt powder having a particle size of about 0.6 µm was used. Add urea solution to the mixture of platinum powder suspension and zirconium nitrate solution to form platinum powder loaded with zirconium hydroxide, so as to make platinum material. The Pt powder used here is prepared in such a way that it contains a specific surface area of about 23m 2 / g of Pt powder and CaCO 3 The suspension was subjected to ball milling, the suspension was heated at a high temperature of 1100° C., the material obtained after heating at high temperature was poured into water, and treated with nitric acid.

[0035] Pour 1kg of platinum powder into 1.5kg of pure water to prepare platinum powder suspension. Add Zr(NO 3 ) 4 solution (4.56 g, concentration: 96.66%), and a mixed solution was prepared. Heat this mixed solution to boil.

[0036] After boiling, an aqueous urea solution (4.0 g) was added to the mixed solution to adjust the pH of the solution to 7.0. After ...

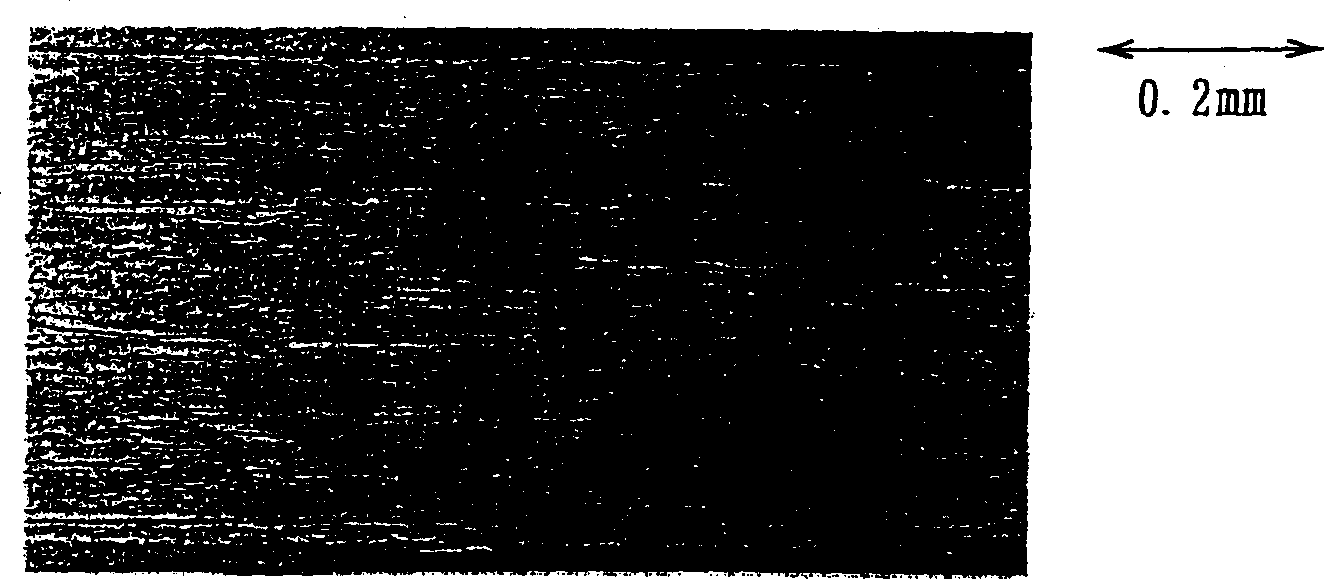

Embodiment 2

[0042] In Example 2, the same Pt powder as described in Example 1 was used, while zirconium nitrate solution and urea solution were added to the platinum powder suspension to form platinum powder loaded with zirconium hydroxide, thus preparing platinum material.

[0043] Specifically, 1 kg of platinum powder is poured into 1.5 kg of pure water to prepare a platinum powder suspension. Add Zr(NO 3 ) 4 A mixture of a solution (4.56 g, concentration: 96.66%) and an aqueous urea solution (urea; 4.0 g). The mixture was heated to 90°C and maintained. After confirming that the pH was 7.0 by urea hydrolysis during the hold at 90°C, the mixture was further incubated at 90°C for about 30 minutes, and then the heating was stopped.

[0044] This process makes the Zr(NO 3 ) 4 Converted to precipitated Zr(OH) 4 . Precipitated Zr(OH) 4 supported on Pt particles in a mixed solution.

[0045] The mixed solution was filtered to collect platinum powder loaded with zirconium hydroxide. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com