Compositions curable with actinic energy ray

An active energy ray and composition technology, applied in the field of active energy ray-curable compositions, can solve problems such as insufficient developability and insufficient sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0224] Examples and comparative examples are given below to describe the present invention more specifically.

[0225] In addition, hereinafter, "part" means a mass part, and "%" means a mass %.

manufacture example 1

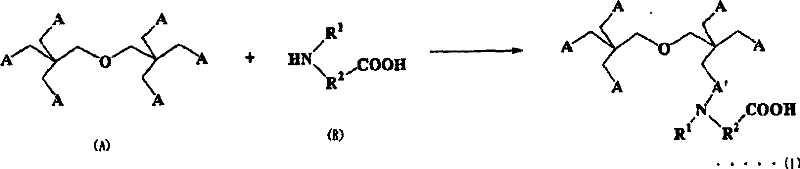

[0226] ○ Production Example 1 [Preparation of (a-1)]

[0227] In a 500-milliliter glass flask equipped with a stirring device, a thermometer, and a water-cooled condenser, add 110 g of ethanol, 100 g of an acrylate mixture containing dipentaerythritol five and six acrylates in a ratio of 30:70 (mass ratio) [hydroxyl value 36 mgKOH / g, hereinafter referred to as "g1"], drop into 10g proline at room temperature, and react for 4 hours. The reaction was carried out under air atmosphere.

[0228] As a result, a solution containing 50% (a-1) (hereinafter referred to as a1) having an acid value of 45 mgKOH / g (in terms of solid content) as a solid was obtained.

manufacture example 2

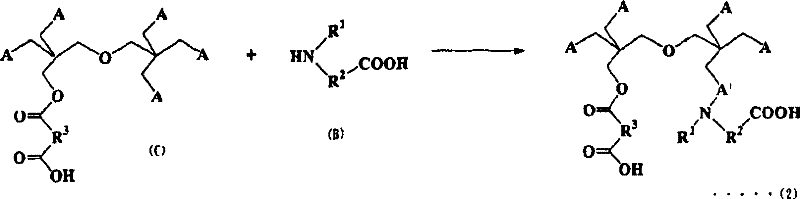

[0229] ○ Production Example 2 [Preparation of (a2-1)]

[0230] In the same flask as in Production Example 1, 16 g of succinic anhydride, 250 g of g1, and 0.13 g of a methalone-hydroquinone complex were charged, and the temperature was raised to 85°C. 1.3 g of triethylamine was thrown in as a catalyst, and it was made to react for 4 hours. The reaction was performed in a mixed atmosphere of air / nitrogen to obtain a compound having an acid value of 34 mgKOH / g (hereinafter referred to as "h1").

[0231] Next, in another flask, add 103 g of DMDG [manufactured by Nippon Emulsifier Co., Ltd., trade name DMDG, hereinafter referred to as "DMDG"], 100 g of g1, put 2.6 g of ethanolamine at room temperature, and react under air atmosphere 4 hours.

[0232] As a result, 50% (a2-1) (hereinafter referred to as "a2") having an acid value of 33 mgKOH / g (in terms of solid matter) and a hydroxyl value of 23 mgKOH / g (in terms of solid matter) was obtained as a solid matter. solution.

[0233...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com