Production method of freeze-dried additive-free royal jelly powder product

A technology of royal jelly freeze-dried powder and a production method, which is applied in the directions of food freezing, food ingredients, food drying, etc., can solve the problems of difficulty in rapid overflow of water and increased energy consumption, and achieves the advantages of rapid sublimation, improved drying efficiency, and internal heat transfer effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

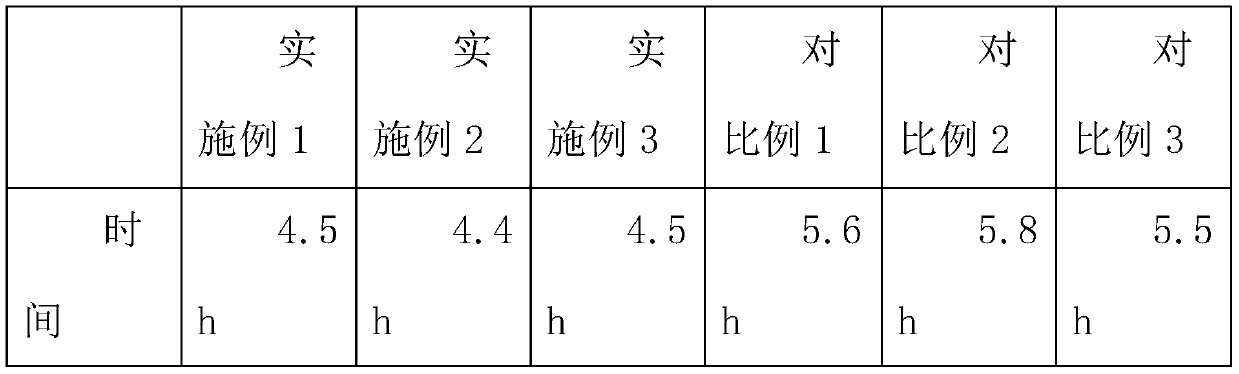

Examples

Embodiment 1

[0034] Removal of impurities: take royal jelly and use deionized water to adjust the water content of royal jelly to 25%. If the water content of the royal jelly raw material is higher than 25%, there is no need to add deionized water for adjustment, and it can be used directly; then the royal jelly is over 100 After mesh sieving, test its isoelectric point, then adjust the pH to the isoelectric point of royal jelly, and then place the adjusted royal jelly in a refrigerator at a temperature of 2℃;

[0035] Carrier preparation: mix agar and water into an agar solution with a mass concentration of 10g / L, then mix the dilute acetic acid solution with a mass fraction of 3% and the agar solution at a mass ratio of 1:5 for 10 minutes, then pour it into the indentation In the mold, transfer the mold to a refrigerator at a temperature of 2°C and let it stand until it freezes into a concave-shaped gel sheet with a thickness of 1mm;

[0036] Pre-freezing: Place the royal jelly on the surface...

Embodiment 2

[0040] Removal of impurities: take royal jelly and use deionized water to adjust the water content of royal jelly to 27%. If the water content of the royal jelly raw material is higher than 27%, there is no need to add deionized water for adjustment, and it can be used directly; then the royal jelly is over 200 After mesh screening, test its isoelectric point, then adjust the pH to the royal jelly isoelectric point, and then place the adjusted royal jelly in a refrigerator at a temperature of 3℃;

[0041] Carrier preparation: agar and water are prepared into an agar solution with a mass concentration of 15g / L, and then a 4% dilute acetic acid solution and agar solution are mixed in a mass ratio of 1:8 for 50 minutes, and then poured into the indent In the mold, transfer the mold to a refrigerator at a temperature of 3°C and let it stand until it freezes into a concave-shaped gel sheet with a thickness of 1.5mm;

[0042] Pre-freezing: Put the royal jelly on the surface of the gel sh...

Embodiment 3

[0046] Removal of impurities: take royal jelly and use deionized water to adjust the water content of royal jelly to 30%. If the water content of the royal jelly raw material is higher than 30%, there is no need to add deionized water for adjustment, and it can be used directly; then the royal jelly is over 500 After mesh screening, test its isoelectric point, then adjust the pH to the royal jelly isoelectric point, and then place the adjusted royal jelly in a refrigerator at a temperature of 4℃;

[0047] Carrier preparation: mix agar and water into an agar solution with a mass concentration of 20g / L, and then mix a 5% dilute acetic acid solution and agar solution at a mass ratio of 1:10 for 60 minutes, then pour them In the mold, transfer the mold to a refrigerator at a temperature of 4℃ and let it stand until it freezes into a concave-shaped gel sheet with a thickness of 2mm;

[0048] Pre-freezing: Place the royal jelly on the surface of the gel sheet and pre-freeze it for 3 hour...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com