First House II

a technology of first house and roof, applied in the field of first house ii, can solve the problems of inability to prepare such large components, long time allowable for erection, and centuries-old post and beam framing, and achieve the effect of high tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

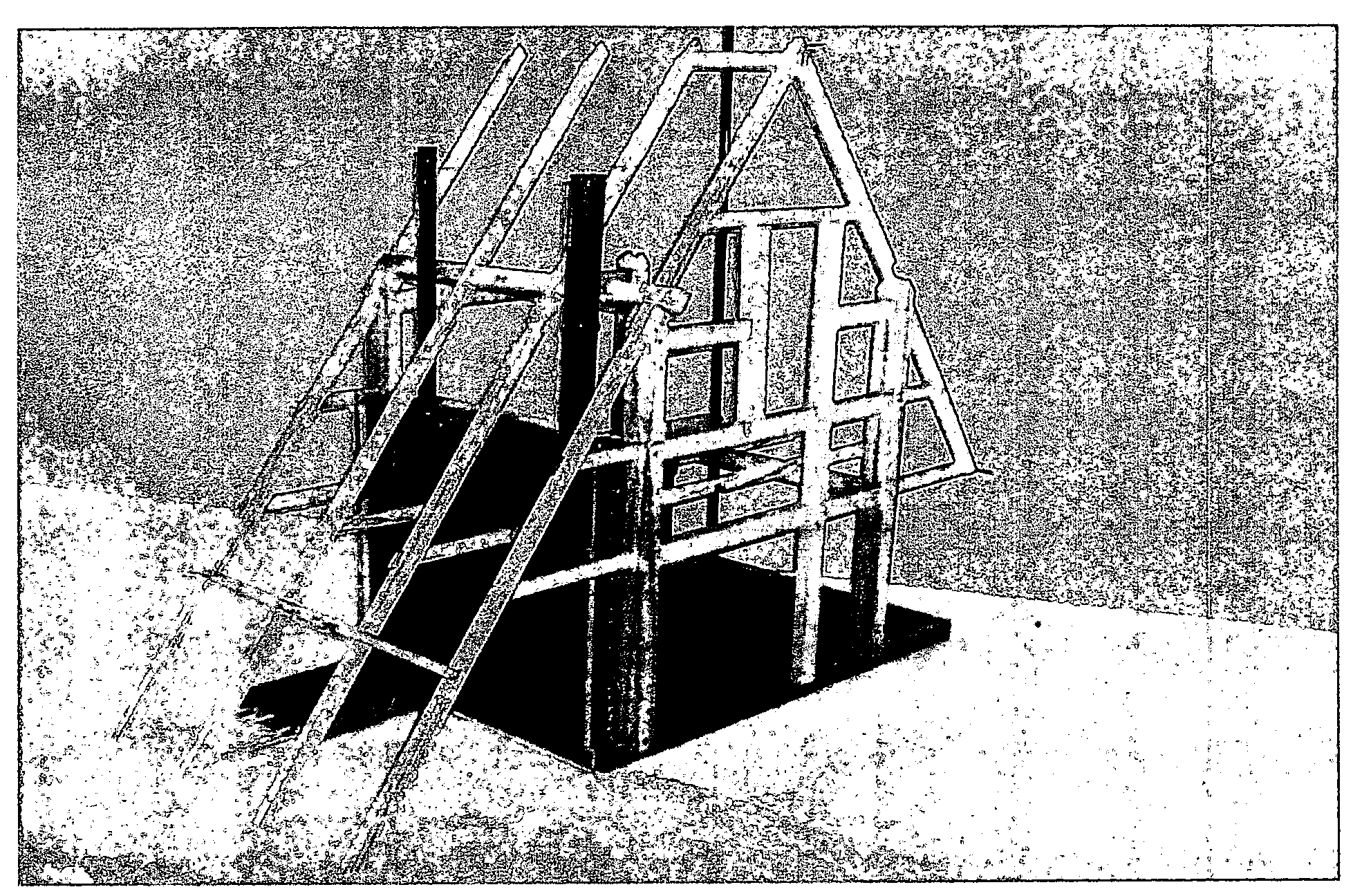

[0033]The invention is explained along with the process of making and using the invention in the sequential series of photographic figures. In this section is a short description of each phase of construction in a step by step sequence. As each dual view figure is explained, the distinguishing characteristics of what is invented and new or improved are explained in the explanation of each figure as they appear in the construction process. The best mode of carrying out the invention is set forth pictorially in this description.

[0034]FIG. 1A and FIG. 1B appear on a single sheet of paper as FIG. 2A and FIG. 2B through FIG. 22A and FIG. 22B appear.

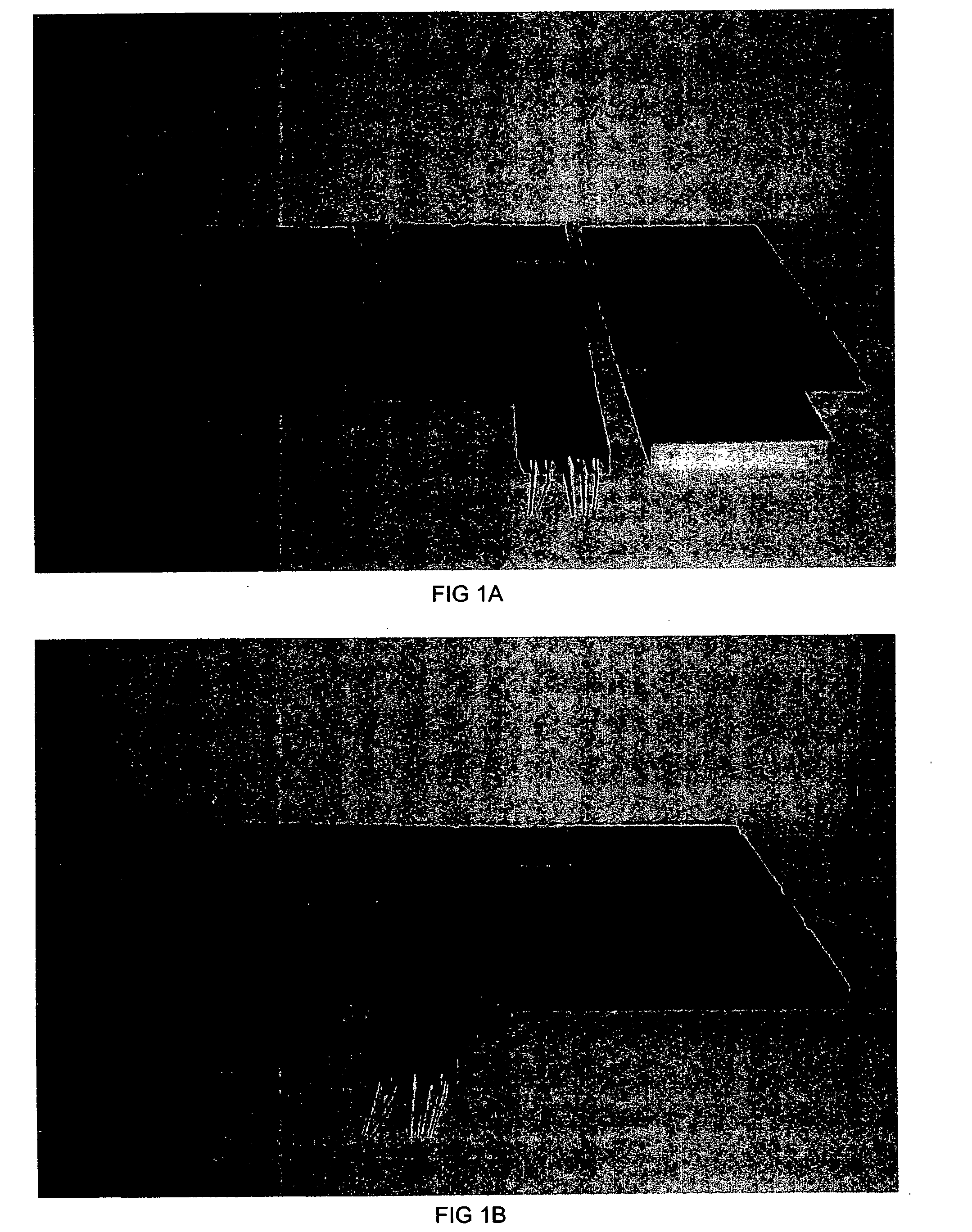

FIG. 1A

[0035]Depicts the three-bay decking options. Middle is the utility core consisting of three reinforced concrete slabs (grey) covered with single glazed quarry tile (green) and wood, with pre-drilled utility holes. One section is not cut to length on site to provide for grey water drainage (white tubes with green stripes). Note: The on-s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com