Energy-saving low-discharge heating boiler

A heating boiler, low-emission technology, used in water heaters, fluid heaters, lighting and heating equipment, etc., can solve the problems of tube sheet cracking and tube bursting in water and fire tube boilers, and the original emission of boiler dust is concentrated. The problems of high height and complicated water tube boiler process can achieve the effect of easy complete removal, easy split assembly, and easy bulk packaging.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

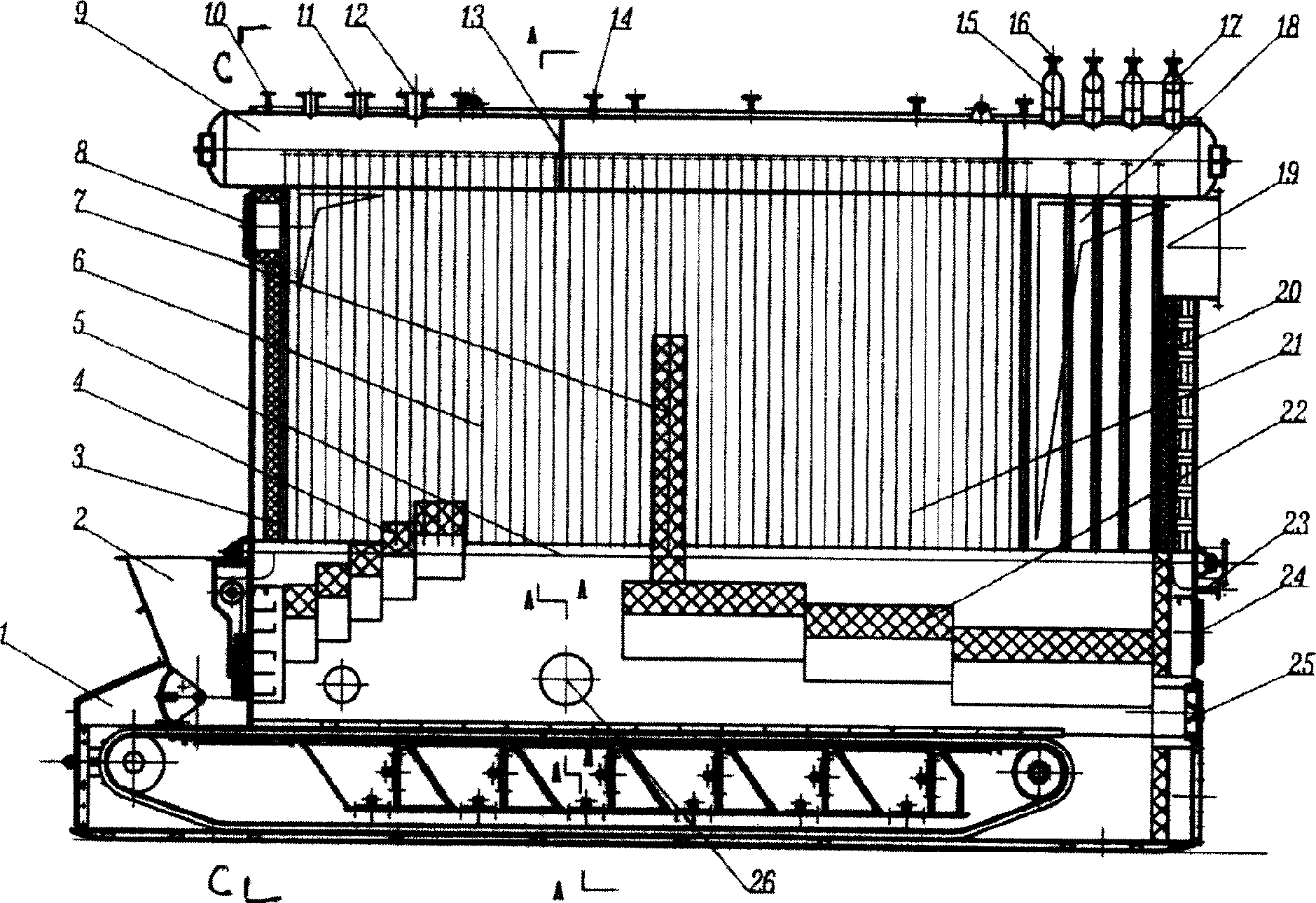

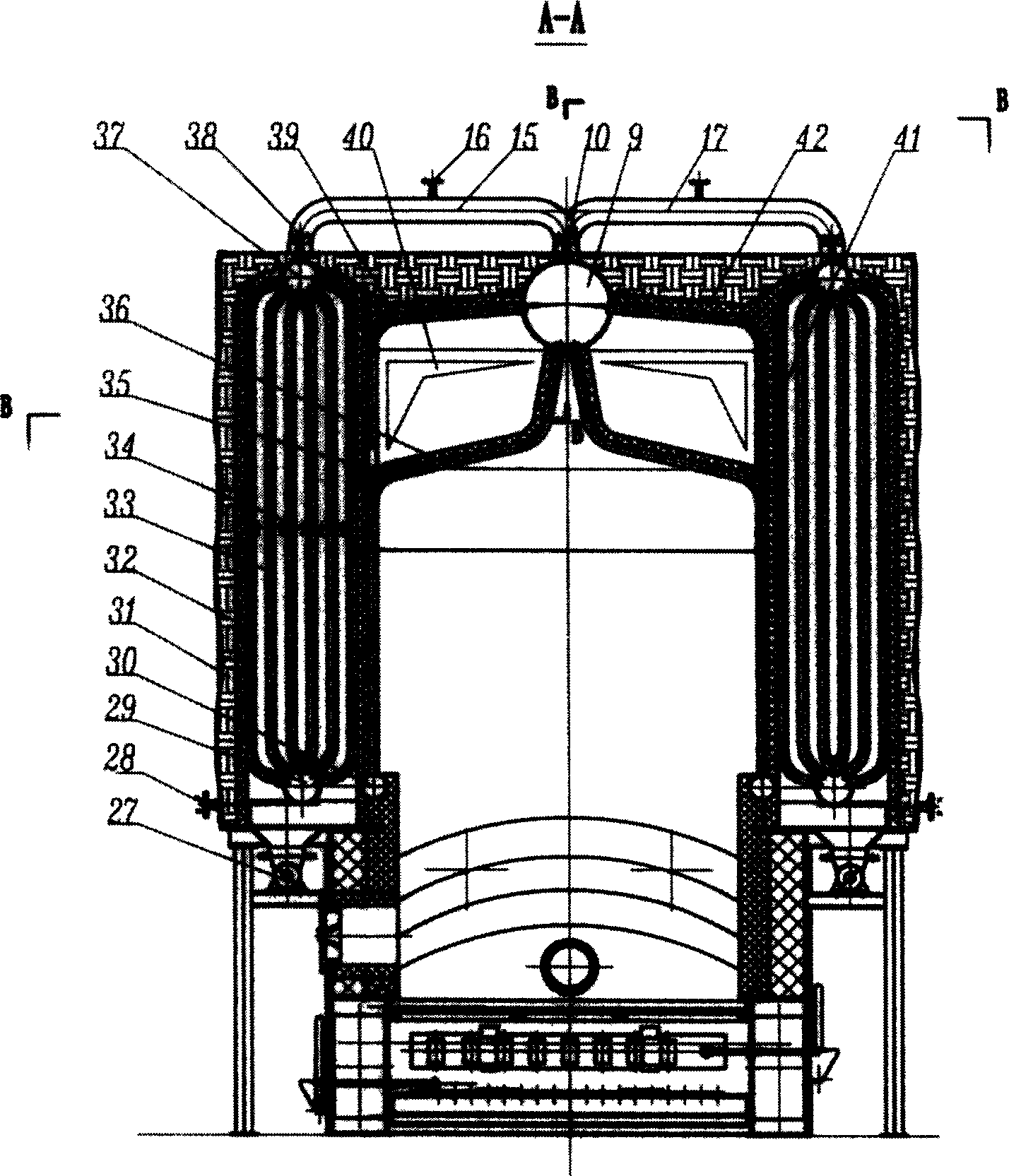

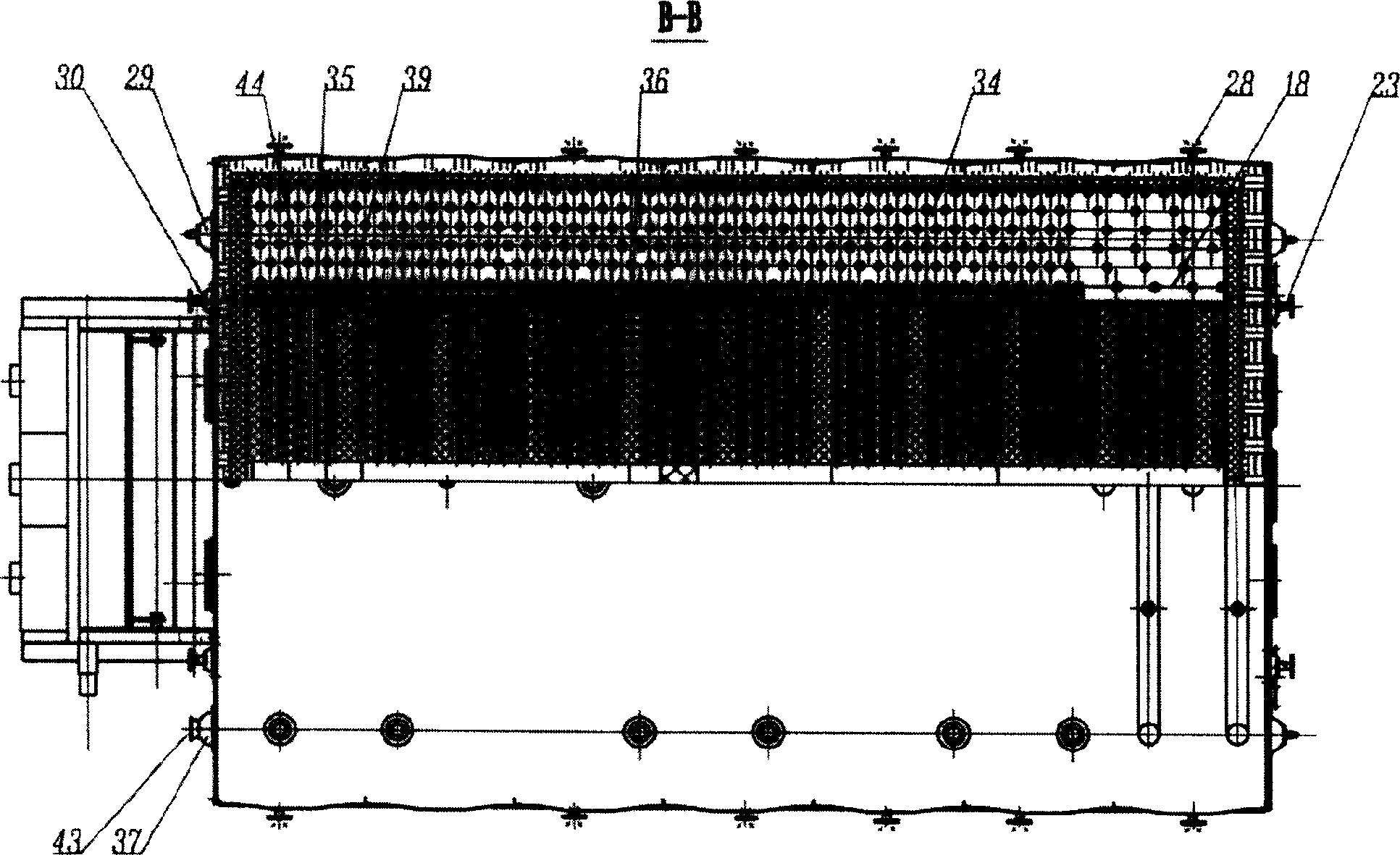

[0011] Below in conjunction with accompanying drawing, the utility model is described in detail.

[0012] A heating boiler with low energy consumption and low emissions, comprising an upper central header (drum) 9, a lower header 30, side upper and lower headers 37, 29, a water wall tube bundle 35, a three-return tube rack 39, and a convection tube bundle 33 Wait. The water wall tube bundle 35 and the three-pass tube frame 39 are connected with the upper central header (drum) 9 and the lower header 30 . The convection tube bundle 33 is connected with the side upper and lower headers 37, 29, the side upper header 37 is connected with the upper central header (drum) 9 through the communication pipes 15, 17 to form the boiler body, and the front wall 3 is respectively constructed on the furnace body, The rear wall 20, the side wall 41, the outer wall 32, the hearth ceiling 36, the three-pass ceiling 42, and the outsourcing after filling the heat preservation material 31 is conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com