Tertiary reheating power generation system

A thermal power generation system and reheater technology, applied in the direction of machines/engines, steam engine devices, mechanical equipment, etc., can solve problems such as poor operating economy, increased heating area of the boiler body, consumption of high-temperature pipelines in the furnace volume, and large investment costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

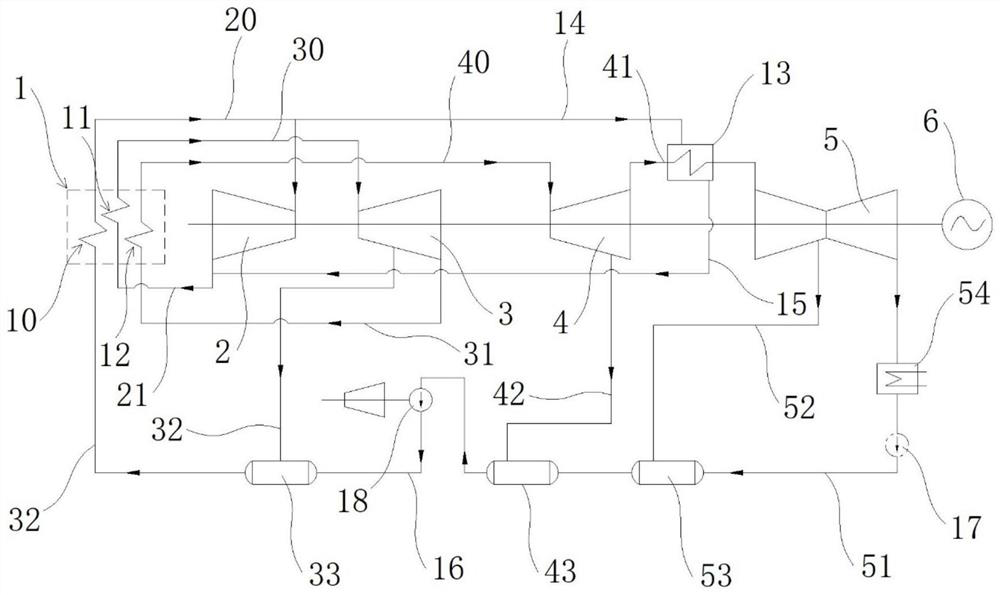

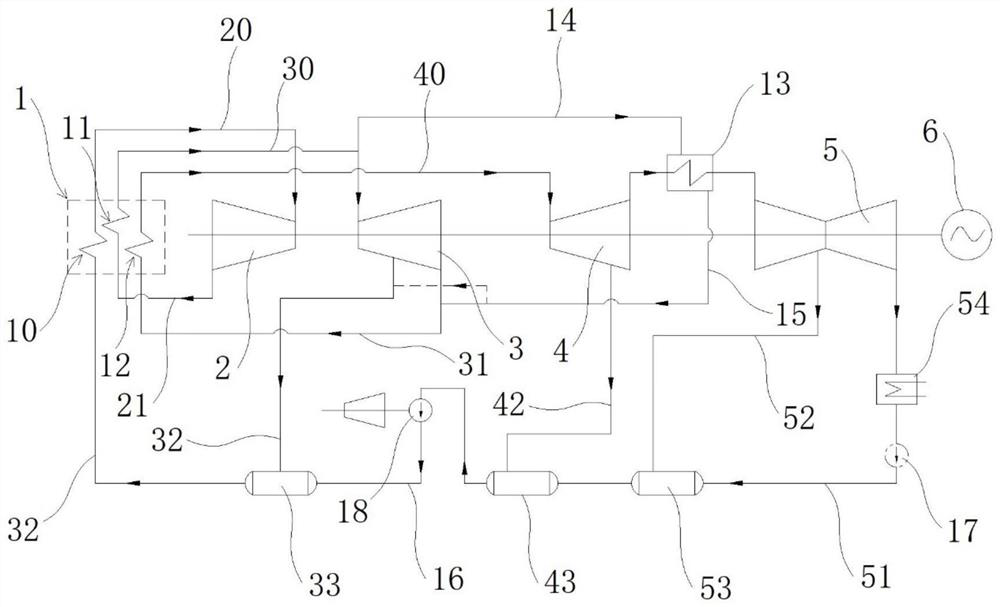

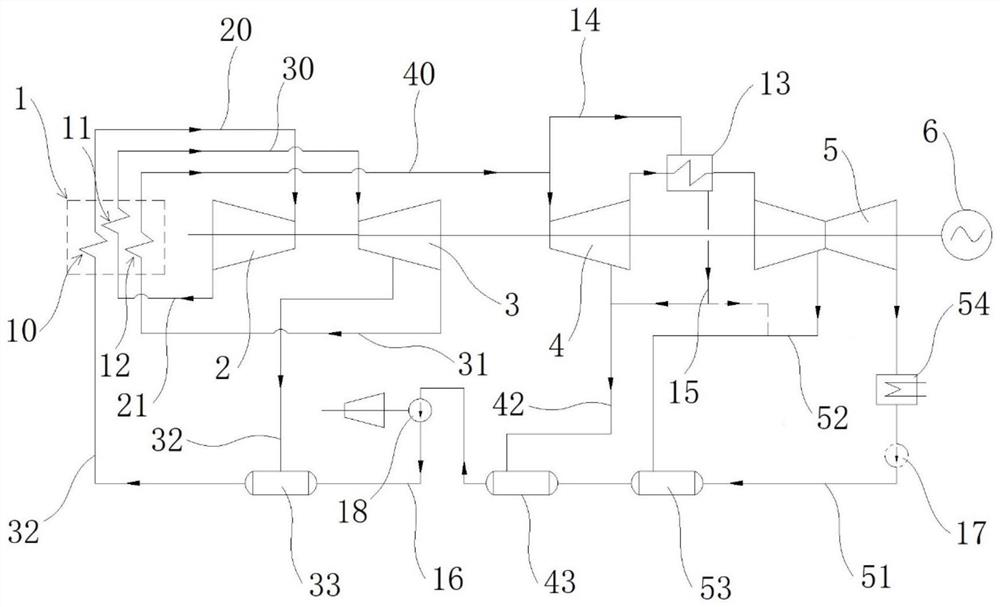

[0037] Specific embodiment 1 of the triple reheat power generation system of the present invention, such as figure 1 As shown, the three-time reheat power generation system includes boiler 1, ultra-high pressure cylinder 2, high-pressure cylinder 3, medium-pressure cylinder 4, low-pressure cylinder 5 and generator 6, ultra-high pressure cylinder 2, high-pressure cylinder 3, medium-pressure cylinder 4, and low-pressure cylinder 5 are all connected to the generator 6; the boiler 1 is equipped with a primary reheater 11 and a secondary reheater 12, the steam inlet of the boiler 1 and the ultra-high pressure cylinder 2 is connected with a main steam pipeline 20, and the primar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com