Cylindrical high-temperature biomass hot blast furnace

A biomass and hot blast stove technology, used in air heaters, fluid heaters, lighting and heating equipment, etc., can solve the problems of burnout burnout, rupture of heat exchange tubes, unacceptable problems, etc., and achieve less ash on the wall area. , the effect of alleviating rupture and reducing equipment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be further described below in conjunction with specific examples, but the protection scope of the present invention is not limited thereto.

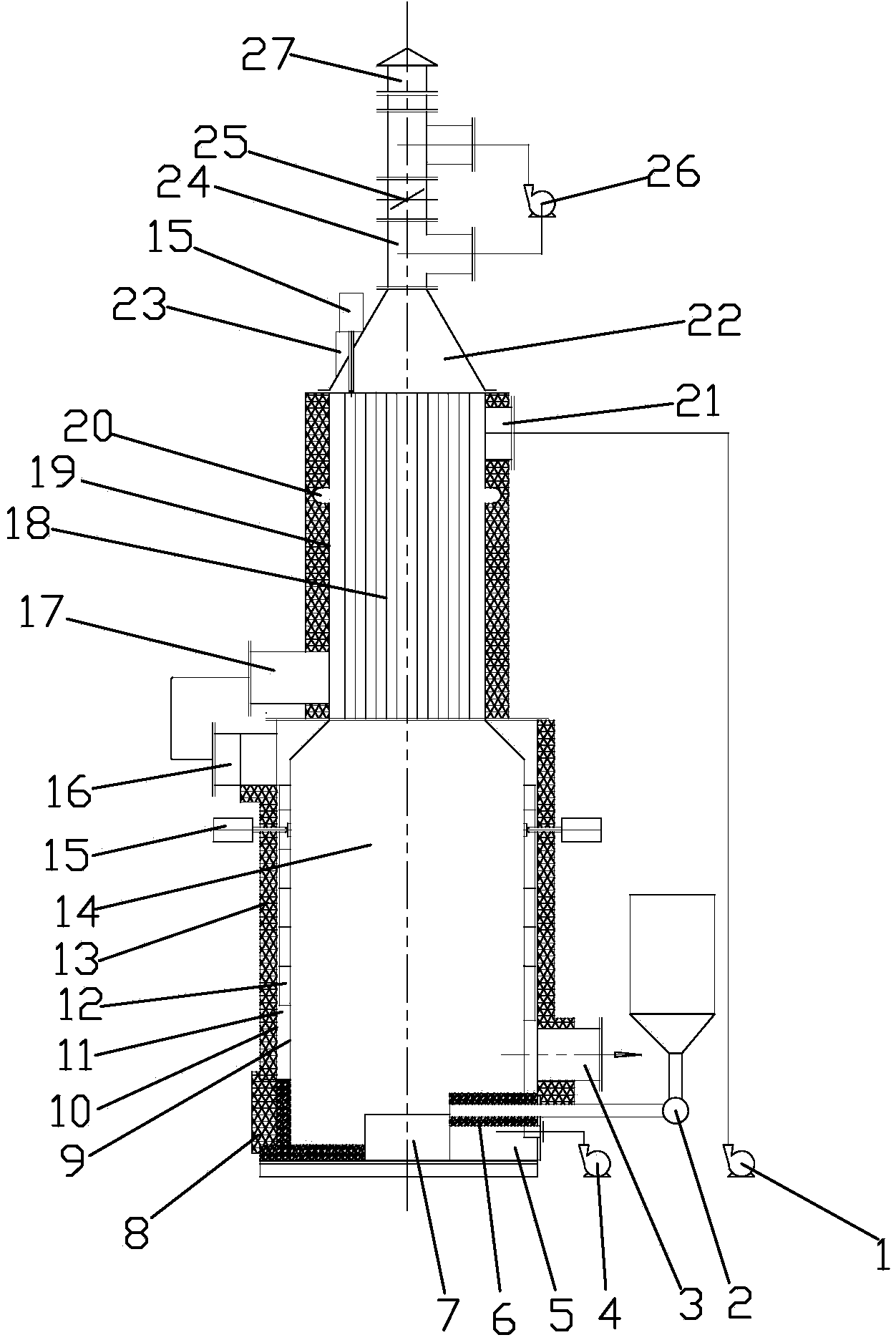

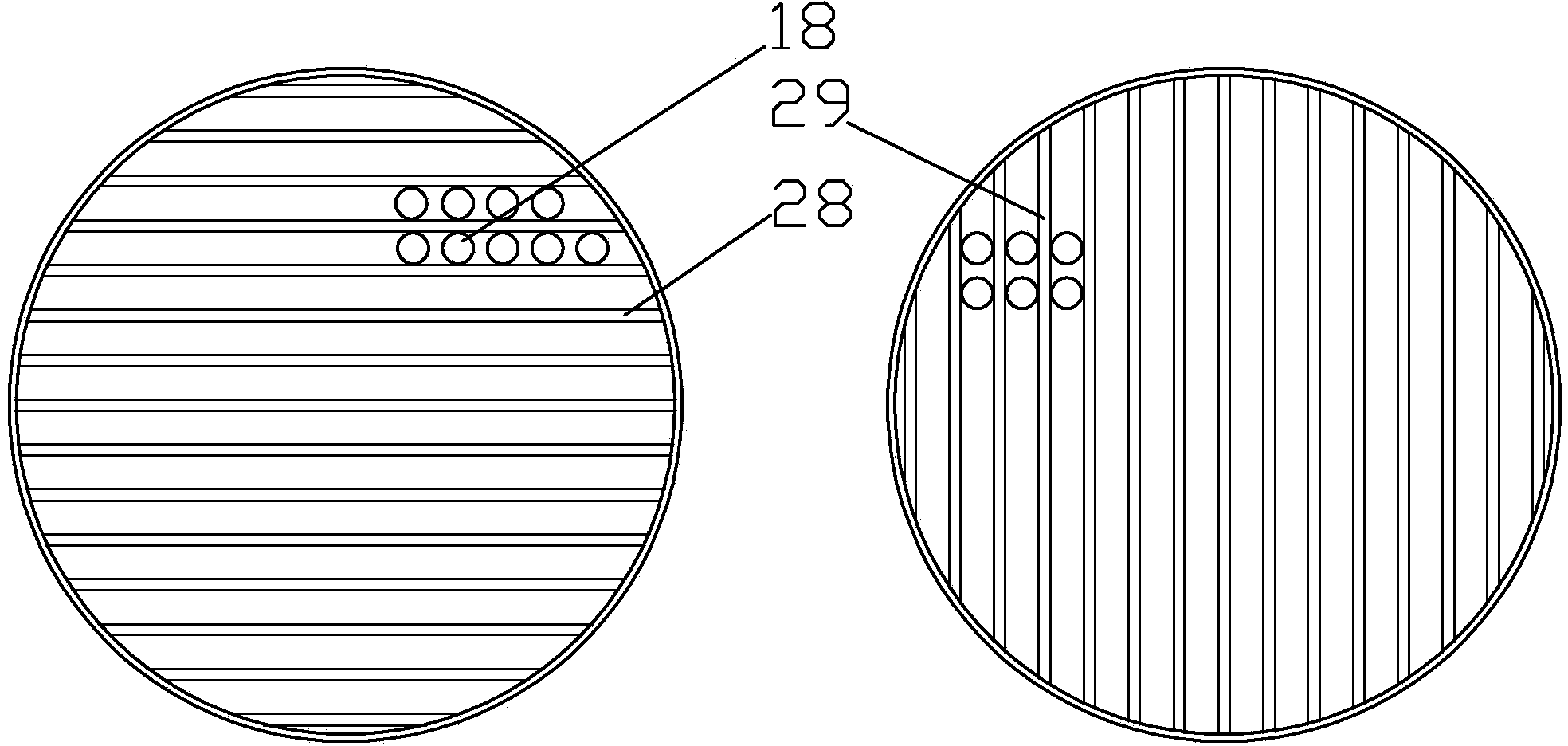

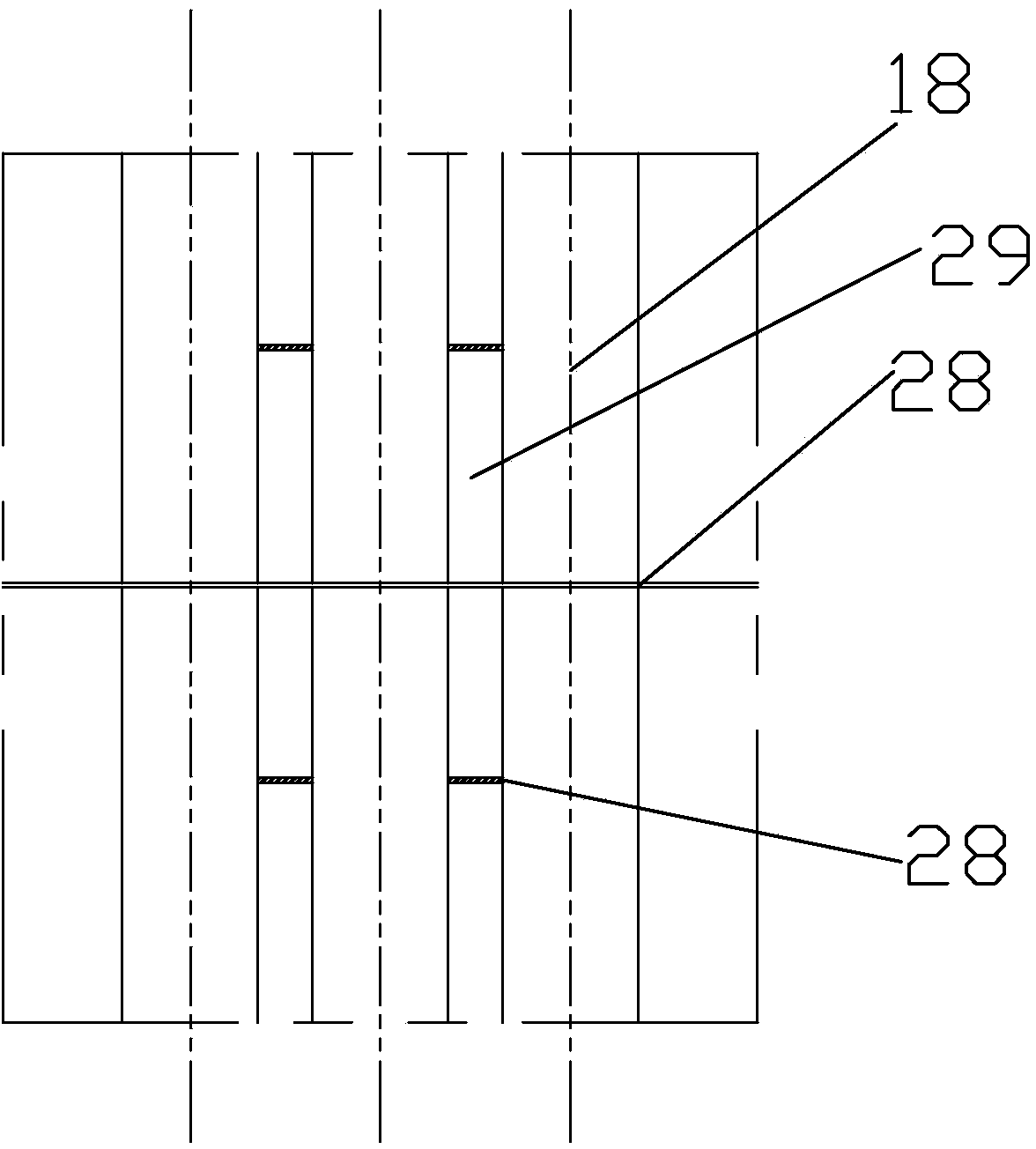

[0047] Such as figure 1 As shown, the cylindrical high-temperature biomass hot blast stove of the present invention includes a cylindrical heat exchanger and a cylindrical furnace section, the cylindrical heat exchanger is vertically installed on the upper part of the cylindrical furnace section, and the cylindrical heat exchanger is a convection heat transfer section , the cylindrical furnace section is a radiation heat transfer section; a biomass burner assembly is installed at the center of the bottom of the cylindrical furnace section, and a slag removal door 8 is installed on the left side of the bottom of the cylindrical furnace section, and the cylindrical furnace section and the cylinder heat exchange Electromagnetic vibrators 15 are installed on the top of the cylindrical heat exchanger, an uppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com