Method for preparing permanent magnet iron core

A magnetic core and iron core technology are applied in the field of electromagnet-type transverse magnetic field heat treatment furnaces to achieve the effects of saving equipment and production costs, high magnetic field strength, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

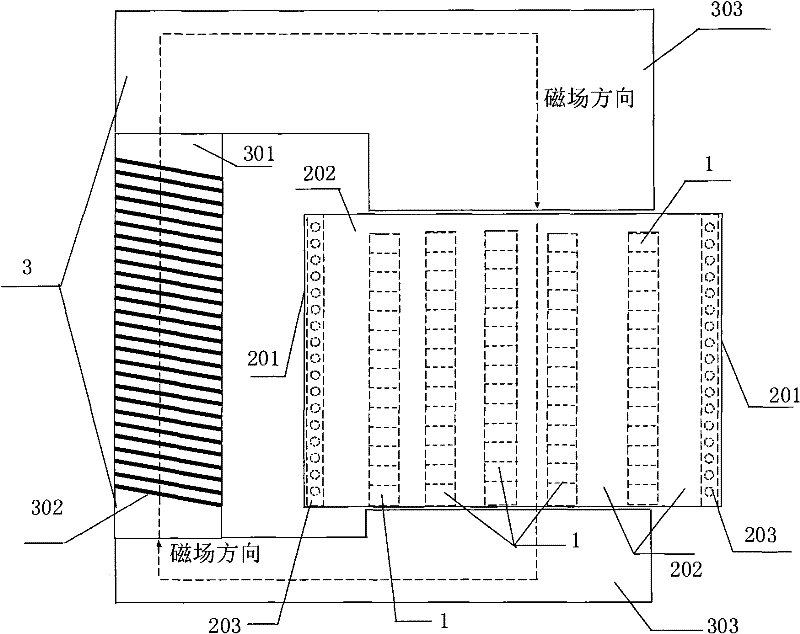

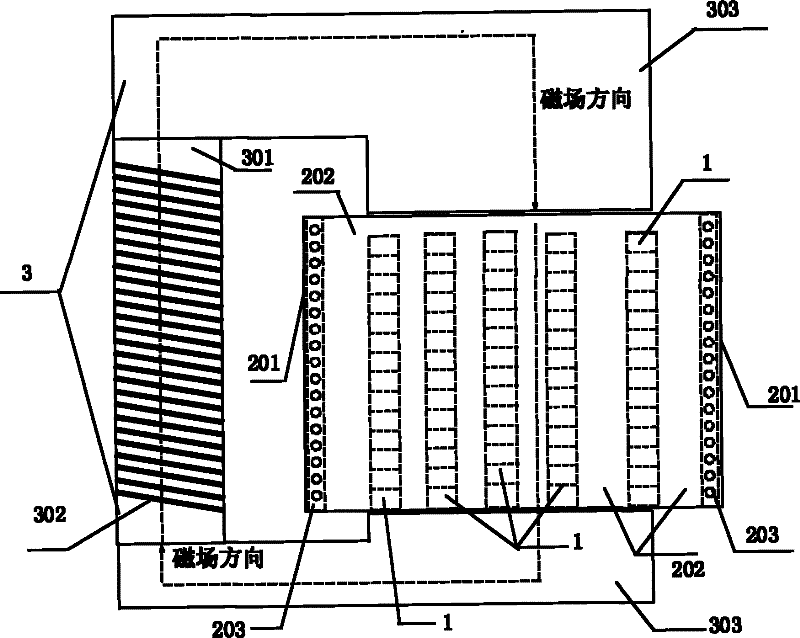

[0030] Such as figure 1 As shown, the electromagnet type transverse magnetic field heat treatment equipment includes a heating furnace 2 and an electromagnet 3. The direction of the magnetic field generated by the two magnetic poles 303 of the electromagnet is parallel to the vertical direction of the heating furnace.

[0031] The structure of the heating furnace includes a furnace wall 201 and a furnace 202 formed by the furnace wall; a heating element 203 is arranged inside the furnace wall. The size of the hearth is Φ400mm×600mm.

[0032] The so-called electromagnet includes a yoke 301 and a coil 302, and the coil is wound around the yoke. The material of the yoke is pure iron.

[0033] The formula for calculating the magnetic field strength H generated by the electromagnet is:

[0034] H=N×I / L=k×I

[0035] Among them, N is the number of turns of the energized coil, I is the magnetizing current, and L is the air gap length of the electromagnet. The value of the consta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Curie point | aaaaa | aaaaa |

| Curie point | aaaaa | aaaaa |

| Curie point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com