Overall thermal hydraulics performance simulator for engineered safety system of reactor

A technology of comprehensive performance and safety system, which is applied in the field of thermal and hydraulic comprehensive performance experiments of new-type reactor special safety systems, can solve the problems of inaccurate data and single function, and achieves a wide range of parameters, high design parameters, regulation and control. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

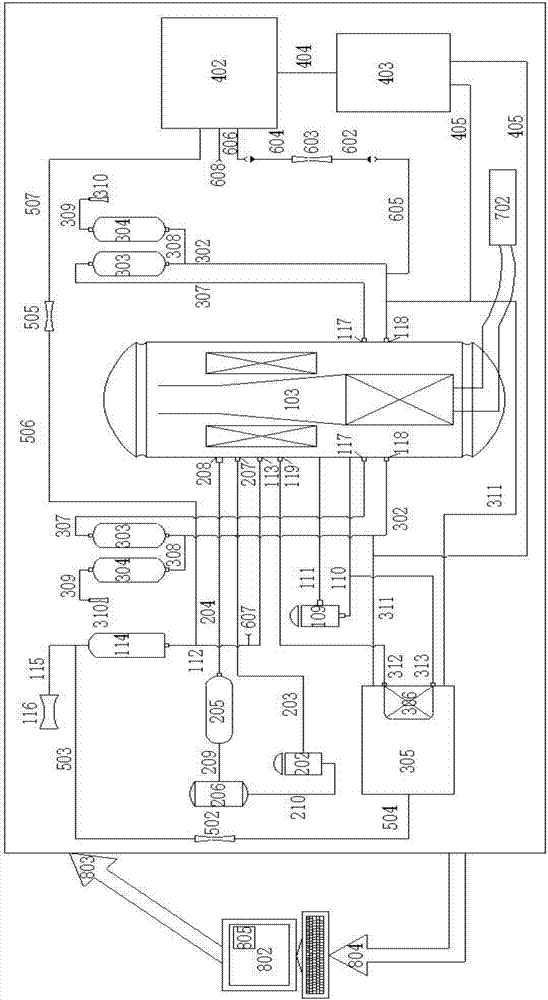

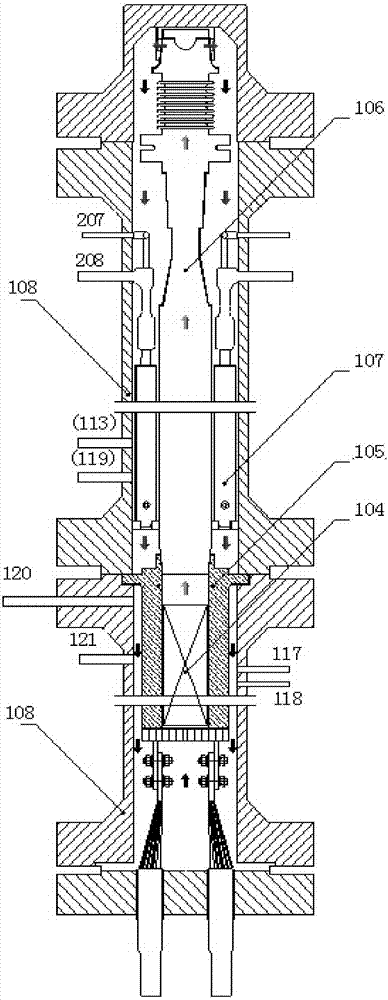

[0024] Such as Figures 1 to 2 As shown, the thermal-hydraulic comprehensive performance simulator of the special safety system of the reactor of the present invention includes a coolant experimental system, a steam condensation system, a passive safety injection and waste heat discharge experimental system, and a recirculation experimental system for coolant simulation experiments. , pressure relief experimental system, loss of water accident experimental system, power supply system, and thermal parameter acquisition and control system, coolant experimental system, steam condensation system, DC power supply system and thermal parameter acquisition and control system to complete the normal operation of the simulated reactor Nuclear heat release process, coolant forced circulation flow, pressure control adjustment and steam output; passive safety injection and waste heat discharge experimental system, coolant experimental system, steam condensation system, DC power supply system...

Embodiment approach

[0026] The first method: through the inlet quick-release pipeline 602 and the outlet quick-release pipeline 603 in the loss of water accident experimental system respectively connecting the pipeline 605 and the pipeline 606 to realize the experimental simulation of the whole transient process of the direct injection pipeline when the loss of water accident occurs.

[0027] First, the coolant experiment system, steam condensation system, DC power supply system and thermal parameter acquisition and control system jointly complete the nuclear heat release process, coolant forced circulation flow, pressure control adjustment and steam output during the normal operation of the simulated reactor.

[0028] Then the thermal parameter acquisition and control system outputs the control signal of the loss of water accident, controls the DC power supply system to change according to the decay heat curve, the main pump 109 gradually stops running according to the emergency shutdown situation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com