Performance test system for high-performance combined sealing ring of reciprocating machinery

A combined sealing and testing system technology, applied in fluid tightness testing, machine/structural component testing, mechanical equipment, etc., to achieve the effect of friendly operation interface, high test parameters, and reduced impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

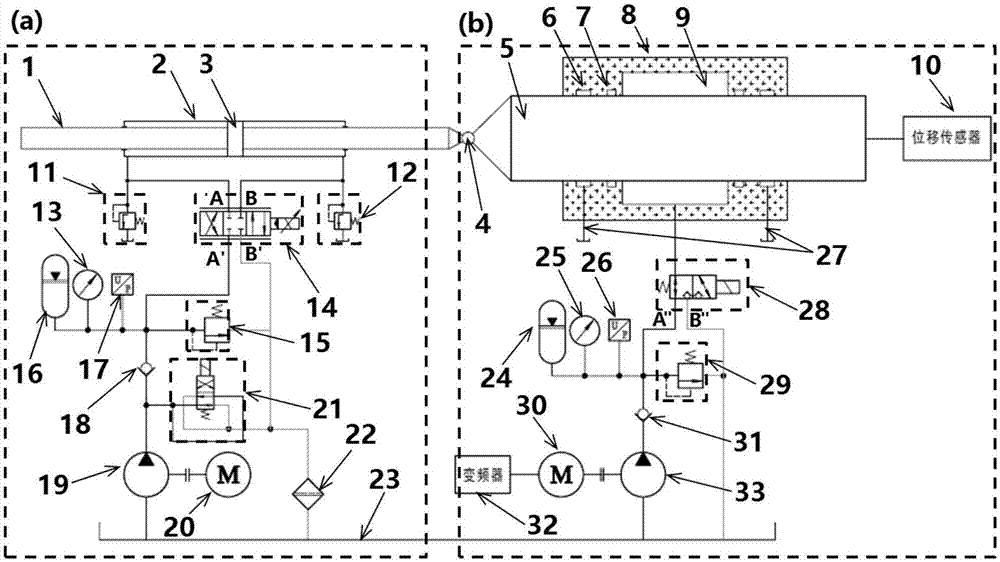

[0048] refer to figure 1 , a high-performance combined sealing ring performance test system for reciprocating machinery, including a reciprocating power system (a) and a sealed chamber hydraulic system (b); the reciprocating power system (a) includes a piston rod 1, a servo cylinder 2 and a piston 3; The sealed chamber hydraulic system (b) includes a cylinder 5, a test cylinder 8, a combined sealing ring 7, a displacement sensor 10 and a ball joint 4; one end of the piston rod 1 passes through the servo cylinder 2 horizontally , the middle part of the piston rod located in the inner cavity of the servo cylinder 2 is provided with a piston 3, and the piston 3 divides the inner cavity of the servo cylinder 2 into a left cavity and a right cavity;

[0049] The other end of the piston rod 1 is connected to the actuator 5 through the spherical joint 4, and the reciprocating motion of the piston rod 1 drives the actuator 5 to reciprocate at the same speed; The actuator cylinder 5 p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com