Generator torque control methods

a technology of generator torque and control method, which is applied in the direction of motors, wind energy generation, dynamo-electric machines, etc., can solve the problems of generators that cannot the generator is unable to export power to the supply network, and the drive train of serious mechanical oscillations of wind turbines, etc., to achieve a rapid reduction of the dbr and the associated actuator or switchgear, the effect of significantly reducing the dbr

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

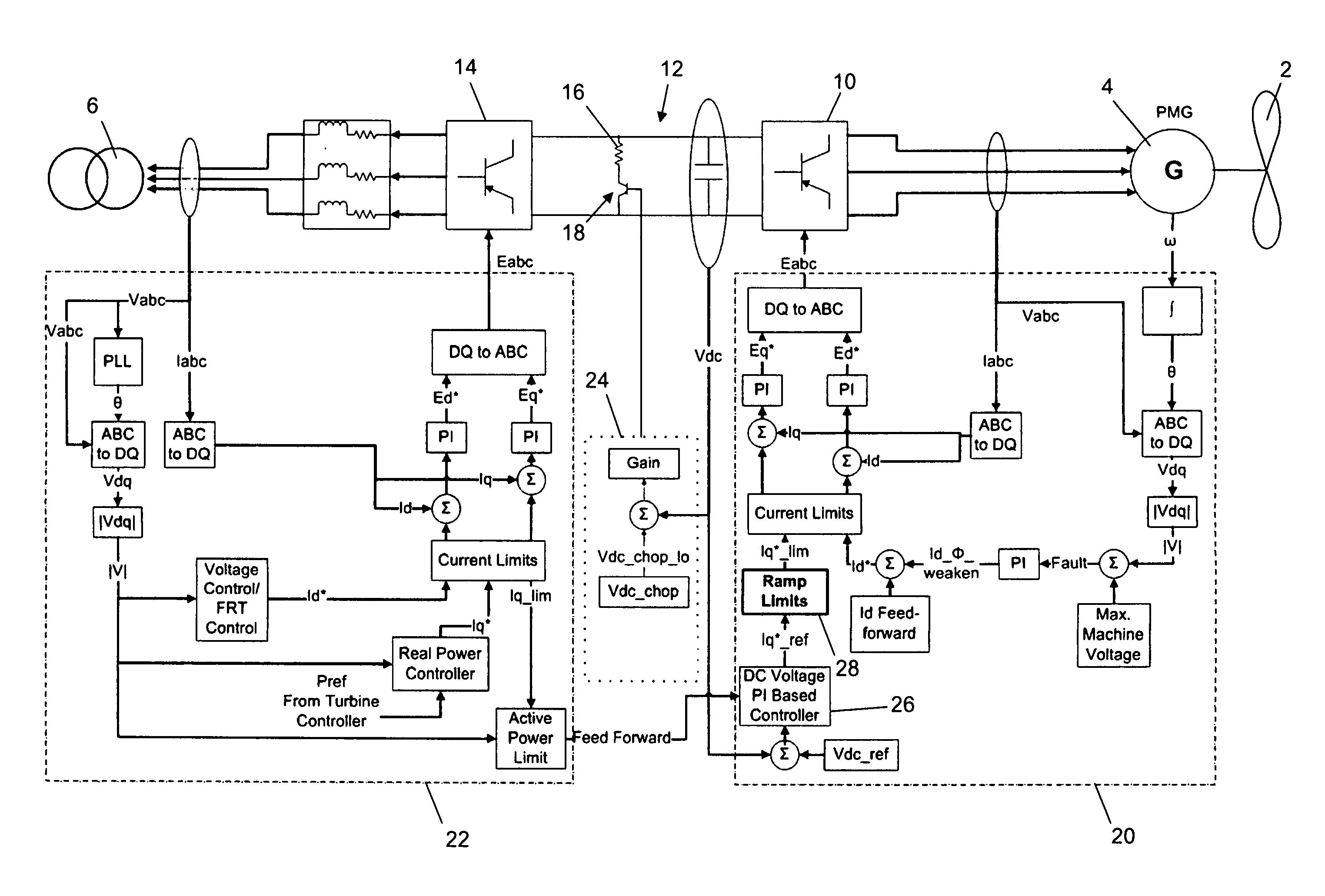

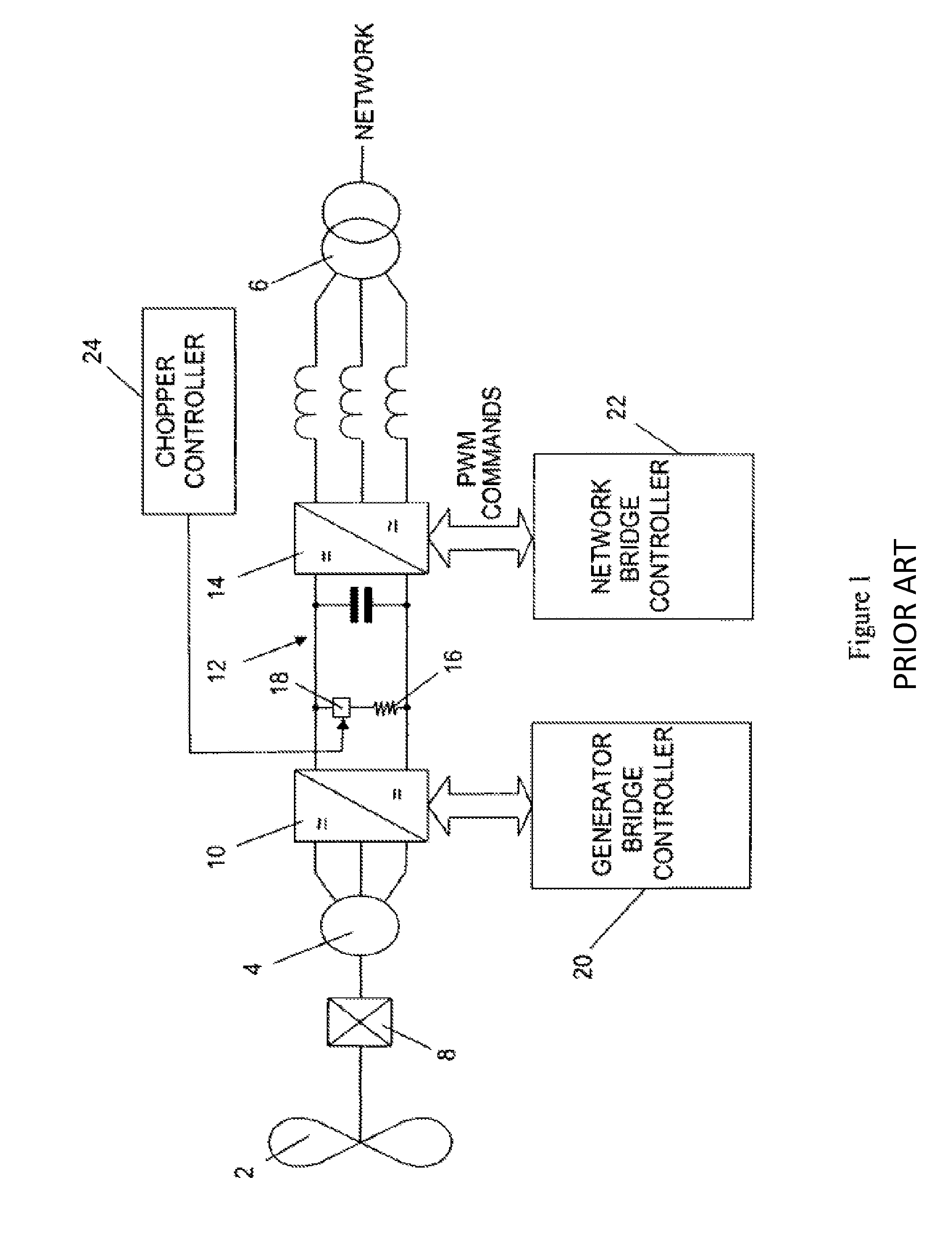

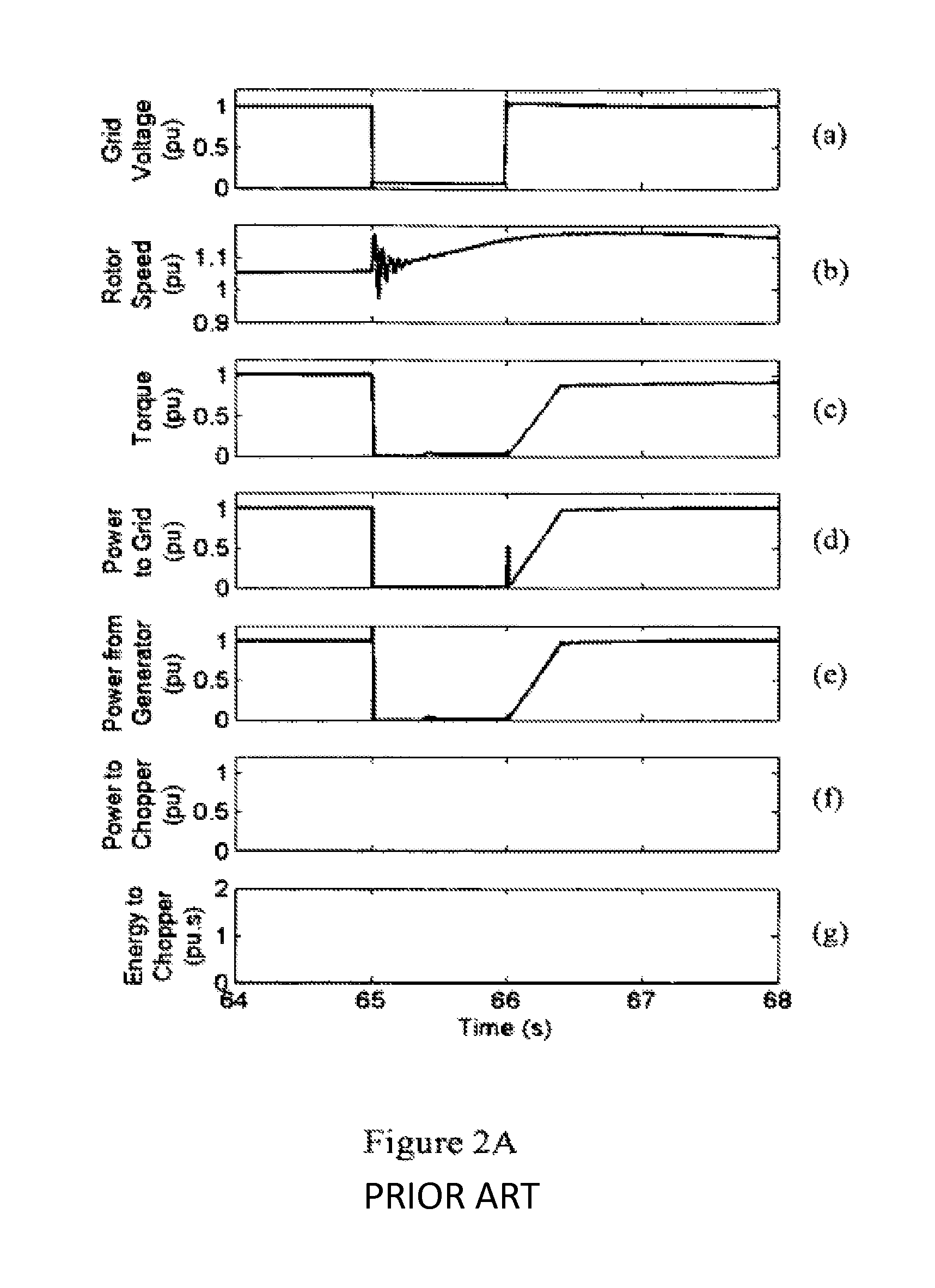

[0045]The generator torque control method of the present invention is best understood with reference to FIGS. 2C and 2D. Each Figure includes a series of seven graphs labelled (a) to (g) as described above and which show how the operational parameters of the wind turbine and power converter assembly of FIG. 1 vary in a pu or “per unit” system during a grid fault where the grid voltage in the supply network dips to zero for one second. FIG. 2C shows how the operational parameters vary in a situation where the generator torque is made to decrease as soon as the grid fault is detected. FIG. 2D shows how the same operational parameters vary in a situation where the generator torque is held substantially constant for 0.5 s before it is made to decrease.

[0046]It can be seen from graphs (a) of FIGS. 2C and 2D that the grid voltage undergoes a step reduction from 1 to 0 at time t=65 s, remains at 0 for one second and recovers with a step increase from 0 to 1 at time t=66 s. For the reasons ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com