Quick installation type connecting mechanism

A plug-in mechanism and fast technology, applied in the direction of connection, coupling device, parts of the connection device, etc., can solve the problems of damaged thread profile, long installation time of threaded connection, easy automatic loosening, etc., and achieve a small number of windings , fast installation speed and stable connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

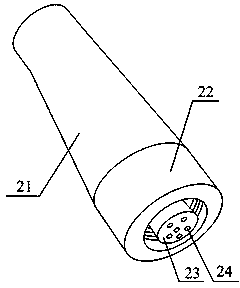

[0016] The plug of the present invention is used in conjunction with a socket with a screw cap. The general structure of the socket with screw cap in the prior art is as figure 2 Shown:

[0017] Described socket comprises socket shell 21, nut 22, cylindrical socket insulator 23, and the rear end of described nut 22 is connected with the front end of socket shell 21, and both are coaxial; Socket insulator 23 is positioned at socket shell 21 and Inside the nut 22 , the socket insulator 23 is provided with an insertion hole 24 , and the nut 22 is provided with internal threads.

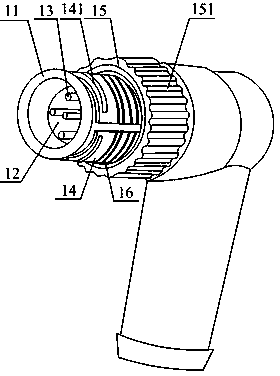

[0018] The structure of the quick installation type plug-in mechanism of the present invention is as follows: figure 1 As shown, it includes a hollow cylindrical plug housing 11, a cylindrical plug insulator 12 disposed in the plug housing 11, and a pin 13 inserted on the plug insulator 12; the plug housing 11 is also sheathed There is a retaining ring 14, the front end of the outer wall of the retai...

Embodiment 2

[0021] On the basis of Embodiment 1, the retaining ring 14 is also improved as follows in this embodiment:

[0022] The rear end of the outer wall of the retaining ring 14 is also sleeved with a locking ring 15, and the locking ring 15 is threadedly connected to the section where the connecting thread 16 is located, that is, the inner wall of the locking ring 15 is provided with a thread corresponding to the outer thread of the outer wall of the retaining ring 14. The length of the locking ring 15 is smaller than the length of the connecting thread 16 on the retaining ring 14 in the axial direction of the retaining ring 14, so the locking ring 15 can rotate on the retaining ring 14 and move along the axial direction of the retaining ring 14 . The locking ring 15 has three functions, one is to fix the retaining ring 14, the other is to limit the nut 22 during installation, and the third is to further stabilize the connection between the plug and the socket. When rotating in pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com