Heating furnace waste heat combined cycle recovery system

A technology of combined cycle and recovery system, which is applied in lighting and heating equipment, furnaces, waste heat treatment, etc., can solve the problems of high operating costs and increased investment, and achieve the goals of reducing energy consumption, saving costs, and fully utilizing waste heat Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

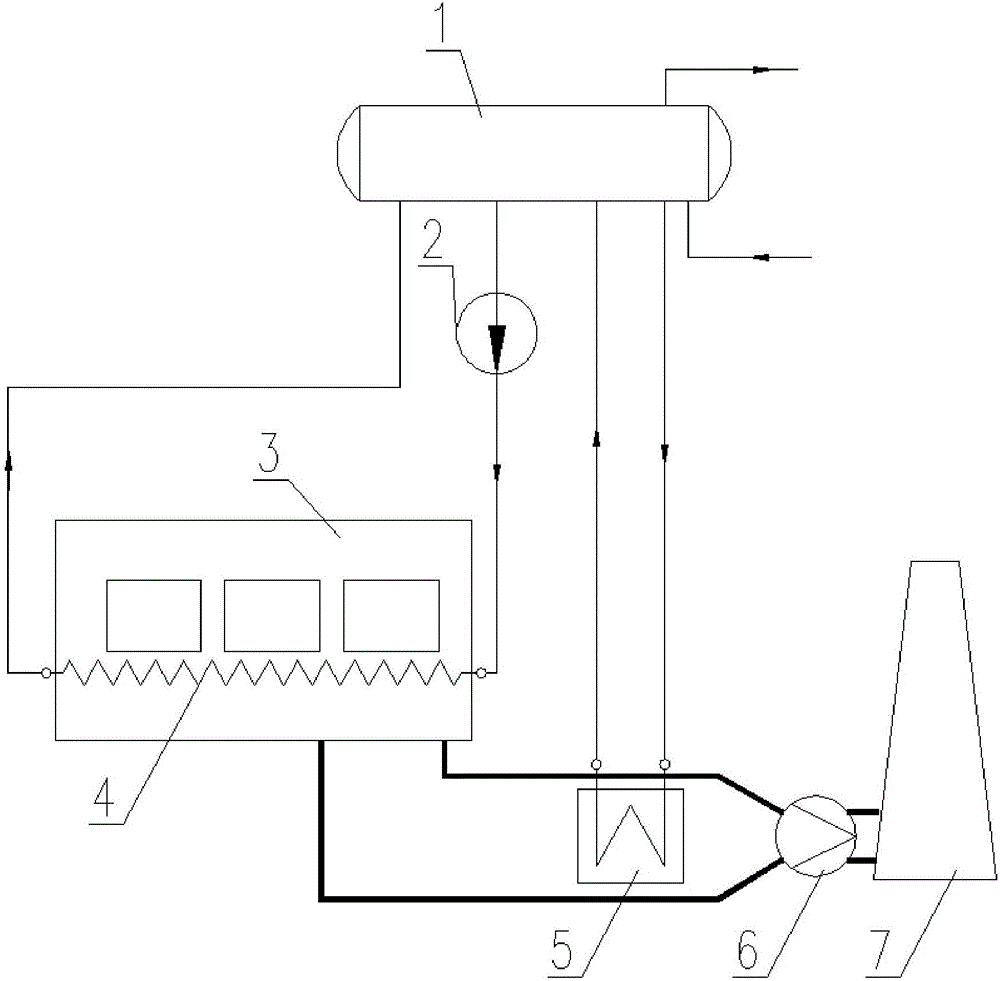

[0017] Such as figure 1 As shown, the waste heat resources recovered by the heating furnace waste heat combined cycle recovery system in this embodiment include two parts: the waste heat of the cooling water beam in the furnace of the heating furnace and the waste heat of the high-temperature flue gas in the tail flue of the heating furnace. A vaporization cooling mechanism 4 is arranged in the hearth of the heating furnace 3 to absorb the waste heat of the water beam at the bottom of the furnace. A flue gas heat exchange mechanism 5 is arranged in the tail flue to absorb the waste heat of the flue gas. The end of the tail flue is connected with the induced draft fan 6, and the induced draft fan 6 is connected with the chimney 7.

[0018] In this embodiment, the heating furnace waste heat combined cycle recovery system includes a vapor-water separation mechanism 1 , a vaporization cooling mechanism 4 , a flue gas heat exchange mechanism 5 and a cycle power mechanism 2 . The ...

Embodiment 2

[0028] On the basis of the above-mentioned embodiments, the vaporization cooling mechanism of the heating furnace waste heat combined cycle recovery system in this embodiment includes a cooling water beam, and one end of the cooling water beam is provided with an inlet of the vaporization cooling mechanism, and the cooling water beam The other end is provided with an outlet of the vaporization cooling mechanism.

[0029] In this embodiment, the water in the steam-water separation mechanism 1 is pumped into the cooling water beam through the circulating power mechanism. On the one hand, the water is used to cool the cooling water beam, and on the other hand, the water absorbs the waste heat in the cooling water beam to produce soda The mixture enters the steam-water separation mechanism 1, which not only ensures the safety of the heating furnace operation, but also utilizes the waste heat.

Embodiment 3

[0031] On the basis of Example 2, the cooling water beam includes an outer tube of the water beam and a core beam coaxially arranged with the outer tube of the water beam in the outer tube of the water beam; one end of the outer tube of the water beam is sealed, and the other One end is sealed and connected with the outer wall of the water beam core tube; one end of the water beam core tube is openly arranged in the water beam outer tube, and the other end is arranged outside the water beam outer tube; the water beam core tube is arranged on The outer end of the water beam outer tube is provided with an inlet of a vaporization cooling mechanism, and the end of the water beam outer tube close to the inlet of the vaporization cooling mechanism is provided with an outlet of a vaporization cooling mechanism.

[0032] In this embodiment, the cooling water of the water girder enters from the middle and flows out from the periphery, so that the water girder can be cooled evenly, and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com