Compact liquid-tube vacuum tube water heater compatible with phase change heat storage function

A technology of vacuum tube water heater and phase change heat storage, which is applied in the field of solar thermal energy, can solve the problems that it is difficult to form a secondary natural circulation water heater, the parts of the water heater are damaged, and it is difficult to install a phase change heat storage device, so as to achieve weight reduction and liquid circulation. The effect of short path and high heat collection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

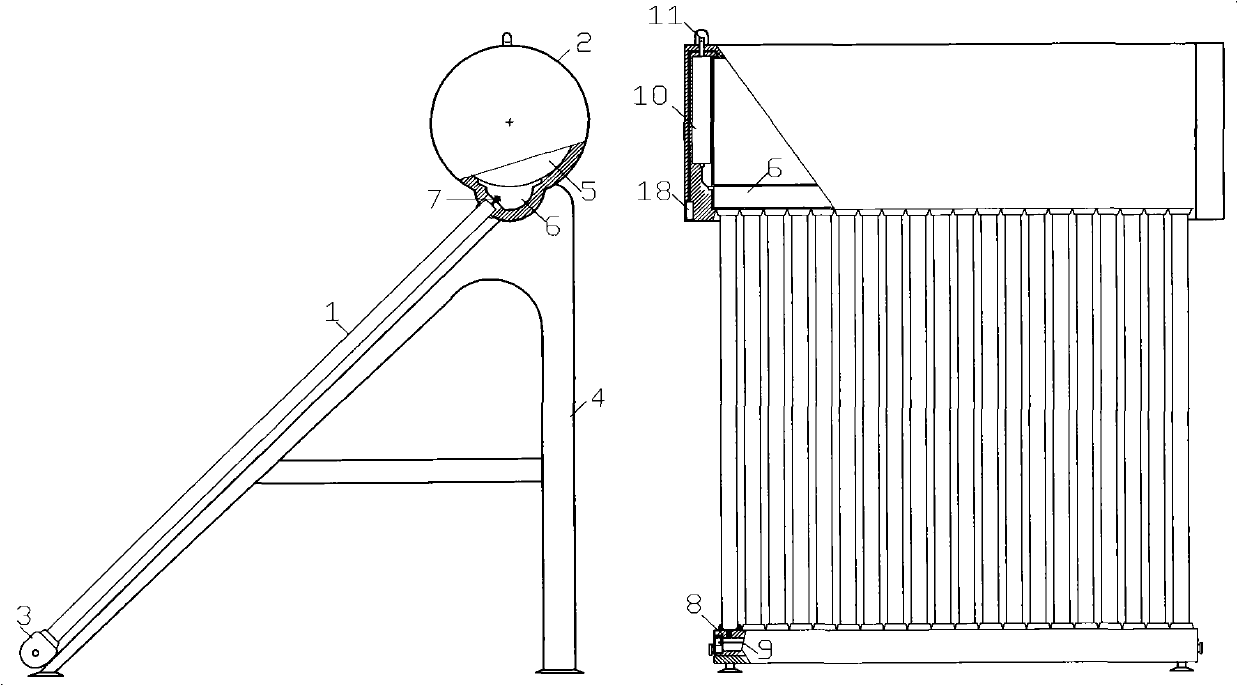

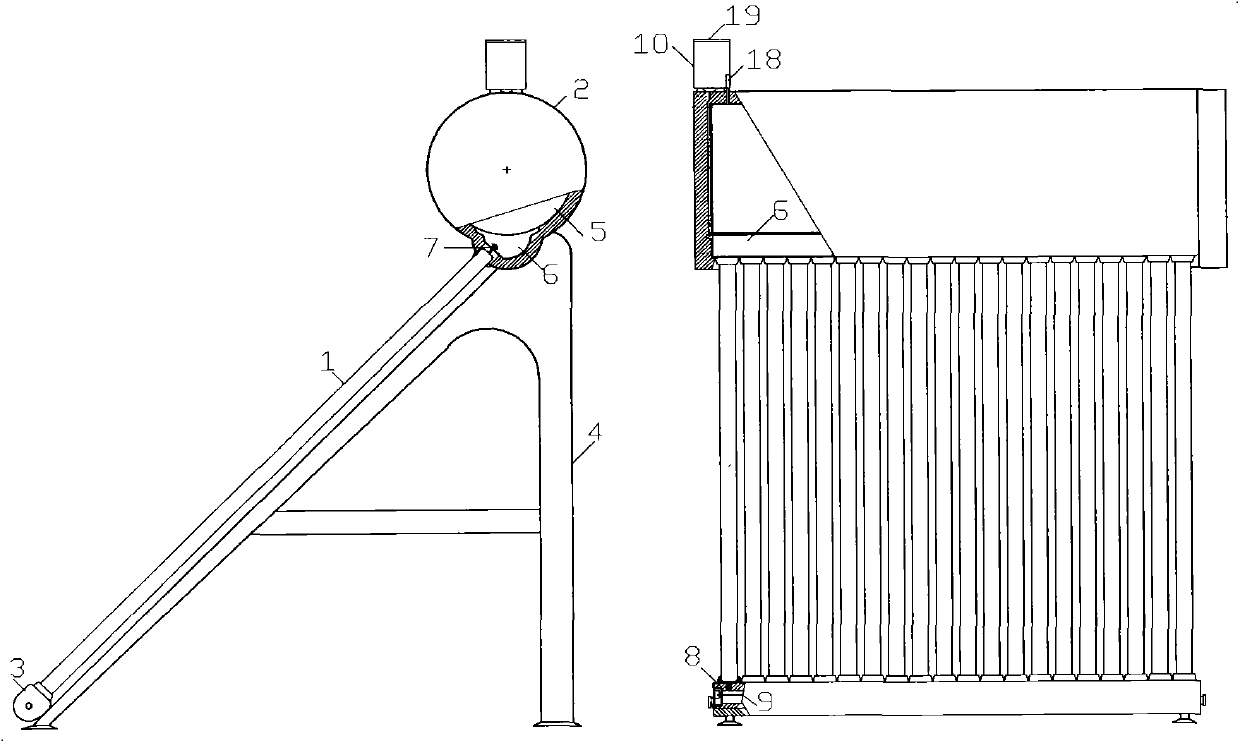

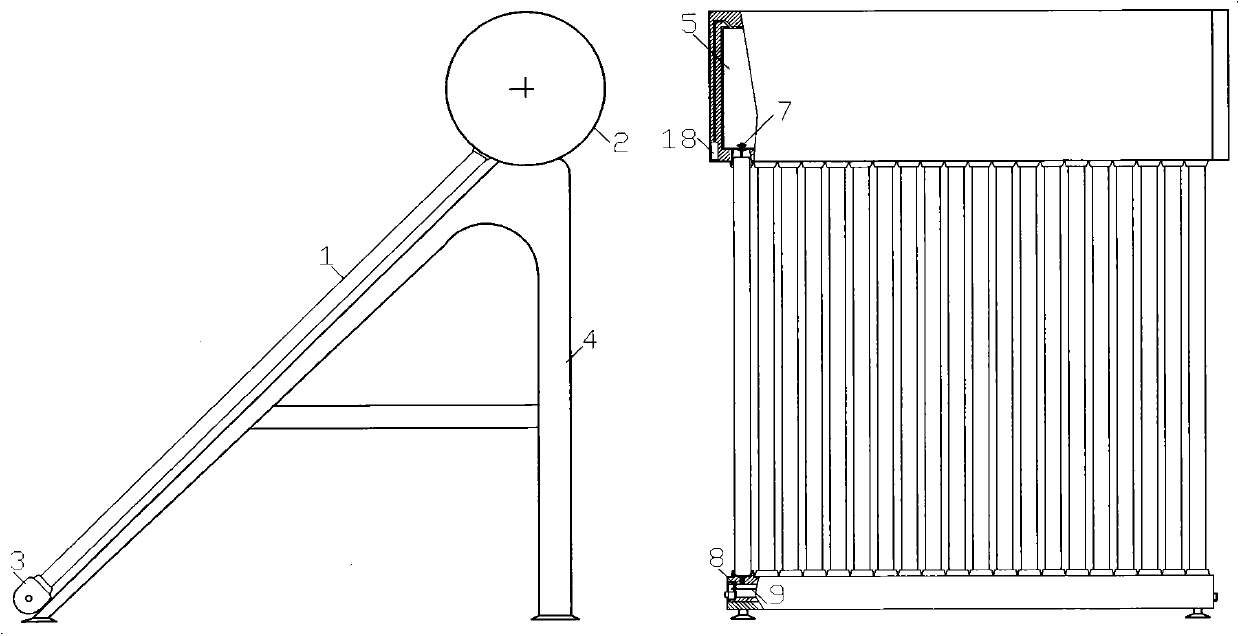

[0038]figure 1 , figure 2 It is an embodiment of the secondary circulation water heater of the present invention. In the figure, the thermal insulation water tank (2) is on the top, and the multifunctional header (3) is on the bottom, which are respectively fixed on the bracket (4), and the heat transfer liquid ( 16) The upper end communicates with the heat transfer liquid pipe interface (7) of the jacketed heat exchanger (6), the lower end communicates with the inline header (8) of the multifunctional header (3), and the electric heating tube (9) is installed in the header (8) In the flow channel, the pressurized liquid replenisher (10) is installed on the side of the heat preservation water tank (2) higher than the jacket heat exchanger (6), the lower end is connected with the jacket heat exchanger (6), and the upper end is connected to the overpressure Protection and de-expansion device (11). Take off the overpressure protection and de-expansion device (11), and heat-cond...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com