Steam generator primary-side structure capable of alleviating backflow of U-shaped pipes

A steam generator and U-tube technology, which is applied in nuclear power generation, climate sustainability, reactors, etc., can solve the problems of local backflow, differences in fluid dynamic characteristics, etc., and achieve the effect of improving performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

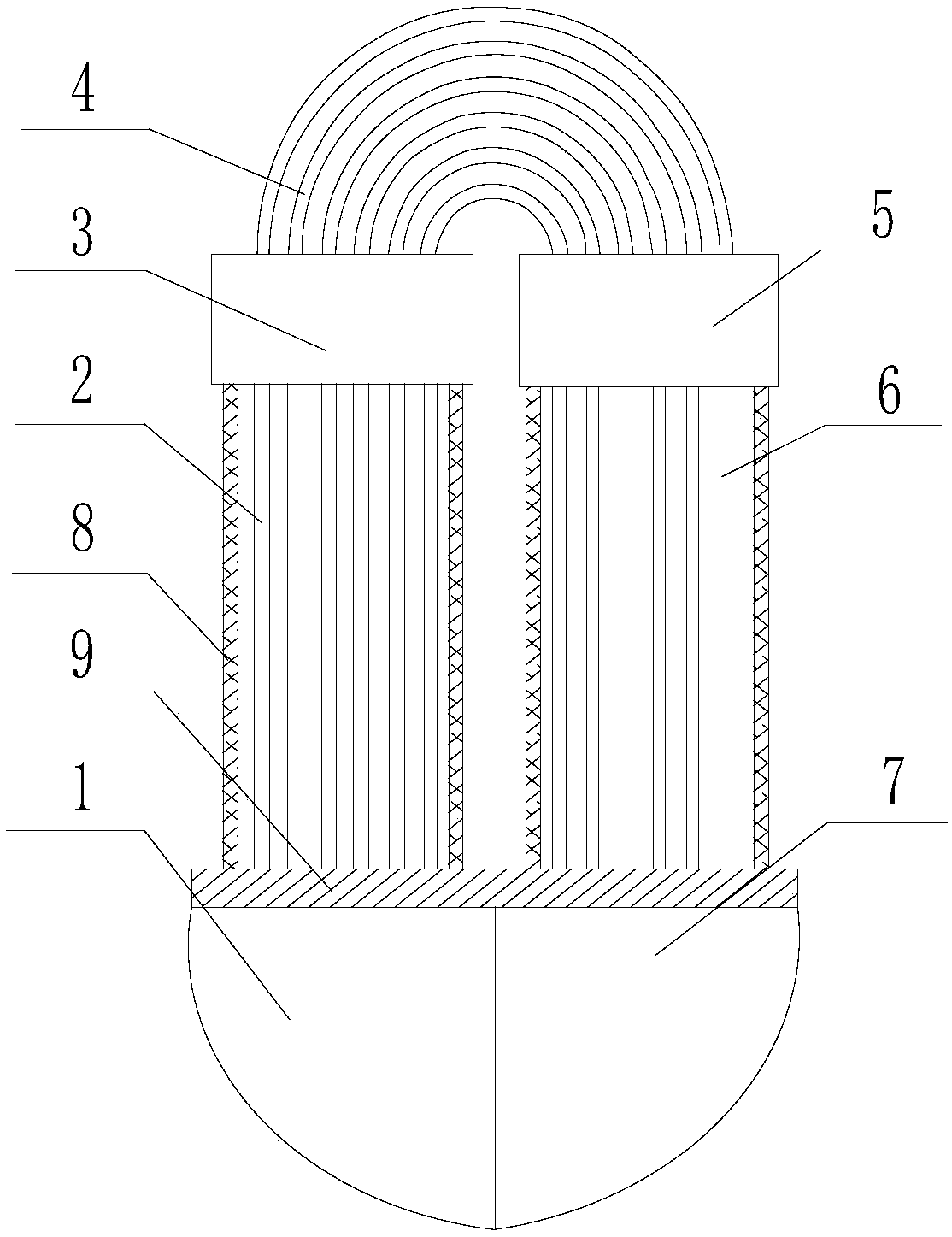

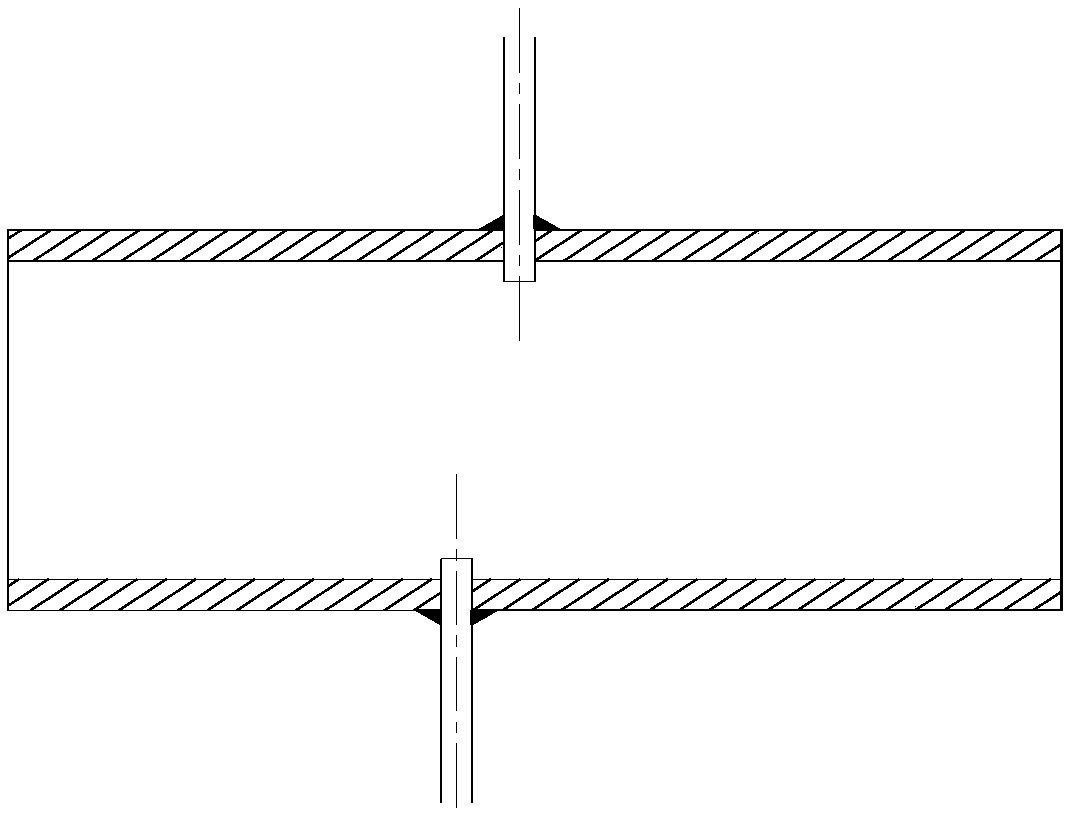

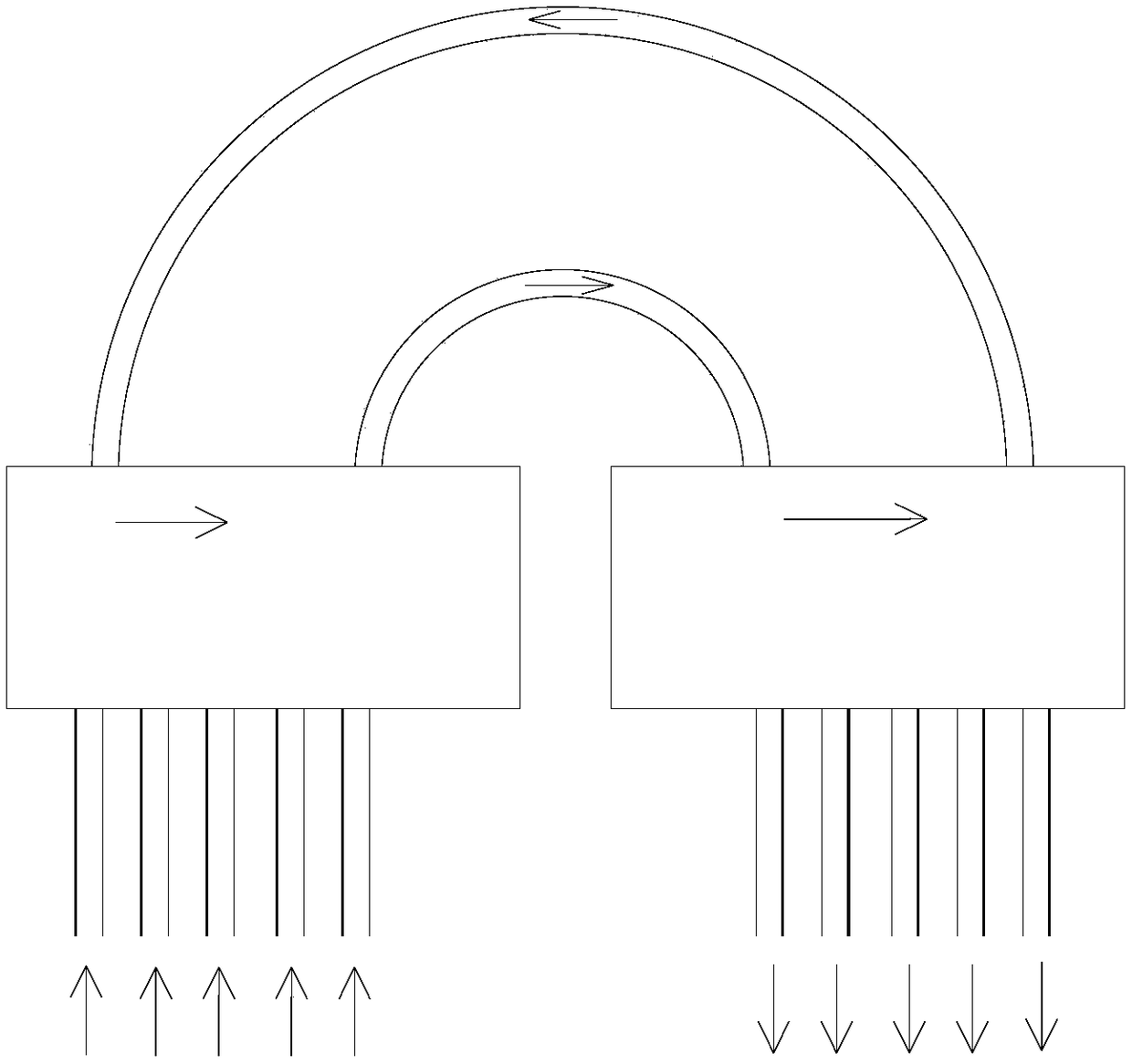

[0032] Such as Figure 1 to Figure 3 As shown, a steam generator primary side structure that can relieve U-shaped tube backflow includes several U-shaped tubes arranged in parallel, and the U-shaped tube includes an inlet straight pipe section 2, a curved section 4 and an outlet straight pipe section 6. The inlet end and the outlet end of the curved section 4 are respectively connected to the outlet end of the inlet straight pipe section 2 and the inlet end of the outlet straight pipe section 6, and the outlet end of the inlet straight pipe section 2 and the inlet end of the curved section 4 pass through the inlet intermediate header 3 connection, the inlet end of the outlet straight pipe section 6 is connected to the outlet end of the curved section 4 through the outlet intermediate header 5, specifically, the outlet end of the inlet straight pipe section 2 is inserted into the lower part of the inlet intermediate header 3, and the curved The inlet end of section 4 is inserte...

Embodiment 2

[0041] Such as Figure 1 to Figure 3 As shown, this embodiment is based on Embodiment 1. Two support columns 8 are arranged between the tube sheet 9 and the inlet intermediate header 3, and two support columns are arranged between the tube sheet 9 and the outlet intermediate header 5. Column 8.

[0042] In this embodiment, the bottom of the support column 8 is welded to the upper end surface of the tube plate 9 , and the top of the support column 8 is welded to the bottom of the inlet intermediate header 3 and the bottom of the outlet intermediate header 5 . By setting the support column 8, the installation stability of the inlet intermediate header 3 and the outlet intermediate header 5 is improved.

Embodiment 3

[0044] Such as Figure 1 to Figure 3 As shown, this embodiment is based on embodiment 1, the length of the outlet end of the inlet straight pipe section 2 and the inlet end of the curved section 4 inserted into the inlet intermediate header 3 is 2-3cm; the inlet end of the outlet straight pipe section 6 , The length of the outlet end of the curved section 4 inserted into the outlet middle header 5 is 2-3cm.

[0045] In this embodiment, the lengths of the inlet intermediate header 3 and the outlet intermediate header 5 are set to 2-3 cm by inserting the inlet straight pipe section 2 , the curved section 4 and the outlet straight pipe section 6 . The mixing effect of the airflow in the inlet intermediate header 3 and the outlet intermediate header 5 can be improved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com