Floating spar for supporting production risers

a technology of production risers and floating spars, which is applied in special purpose vessels, sealing/packing, and borehole/well accessories. it can solve the problems of large methods, high construction costs, and large weight of deepwater wells

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

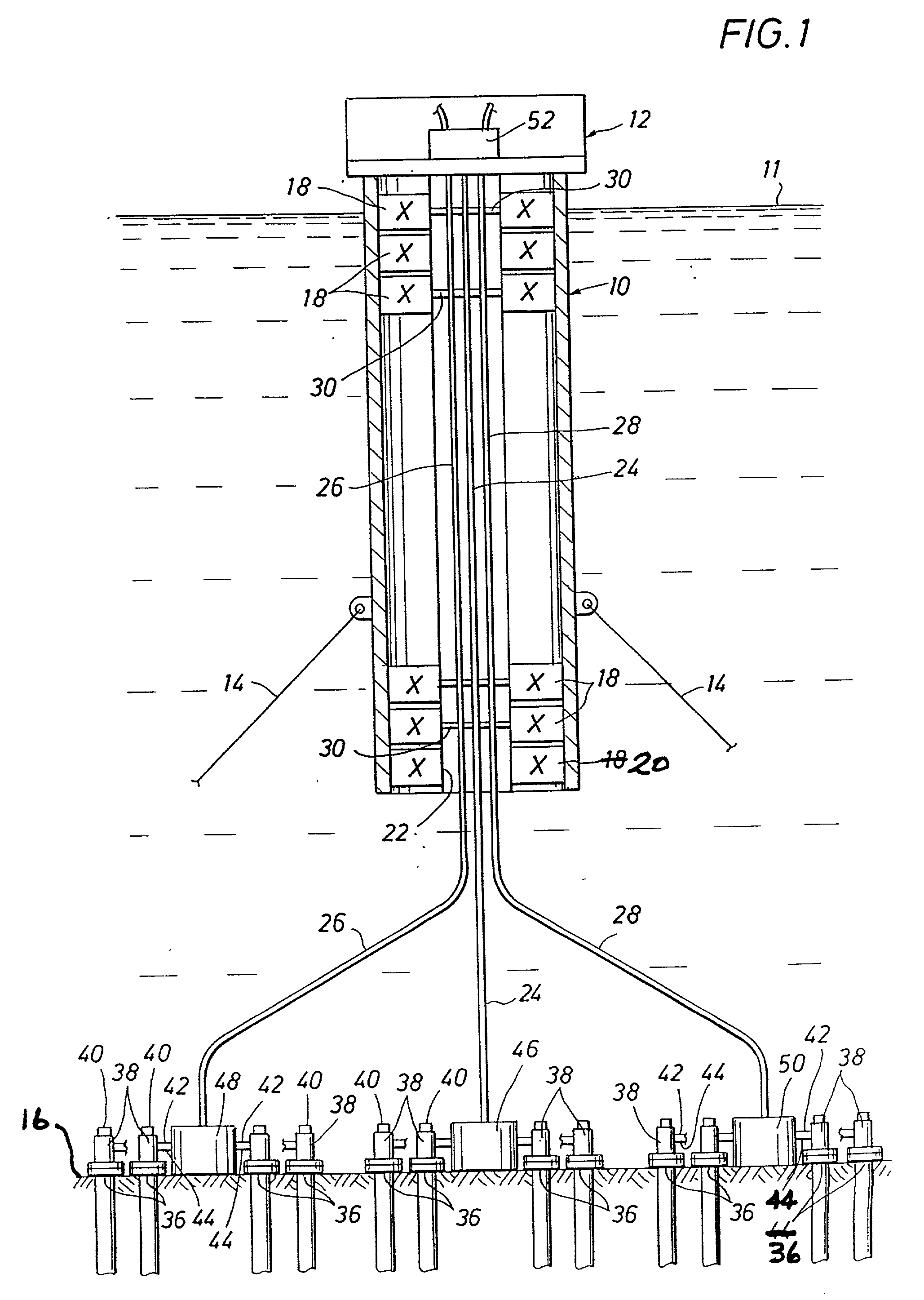

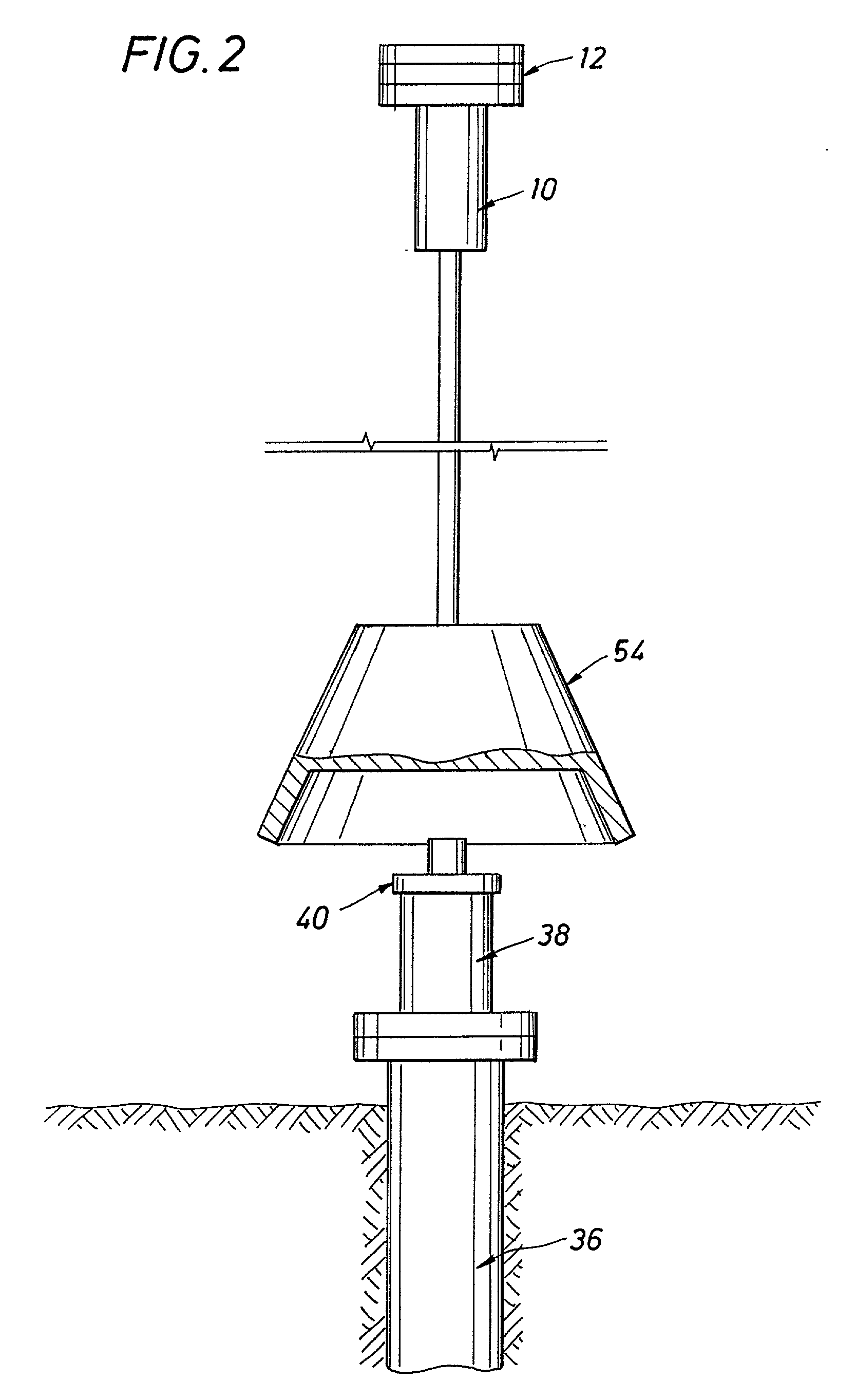

[0020] Referring to the drawings a floating spar or caisson is generally indicated at 10 having a production platform 12 with a plurality of decks mounted thereon above the sea level 11. Spar 10, for example, may be about 700 feet in length and about 75 feet in diameter, with the water depth over about 2000 feet. Mooring lines 14 are secured to anchor piles (not shown) on sea floor 16 for anchoring of spar 10. Six (6) or eight (8) mooring lines 14 are preferably utilized for mooring of spar 10. Buoys which comprise buoyancy tanks or chambers 18 are mounted within spar 10 along with ballast chambers 20. An axial bore or slot 22 is provided in spar 10 through buoyancy tanks 18 and ballast chambers 20 to receive a plurality of production risers 24, 26, 28. Test and umbilical lines may also be provided within spar 10. Suitable support members 30 on spar 10 within riser bore 22 support production risers 24, 26 and 28.

[0021] Mounted on sea floor 16 are a plurality of subsea wellheads 36. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com