A prefabricated exterior wall structure based on bim technology

A prefabricated and exterior wall technology, applied to walls, building components, building structures, etc., can solve problems such as long construction period, loose and falling exterior wall bricks, and achieve the effect of reducing the difficulty of demolition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

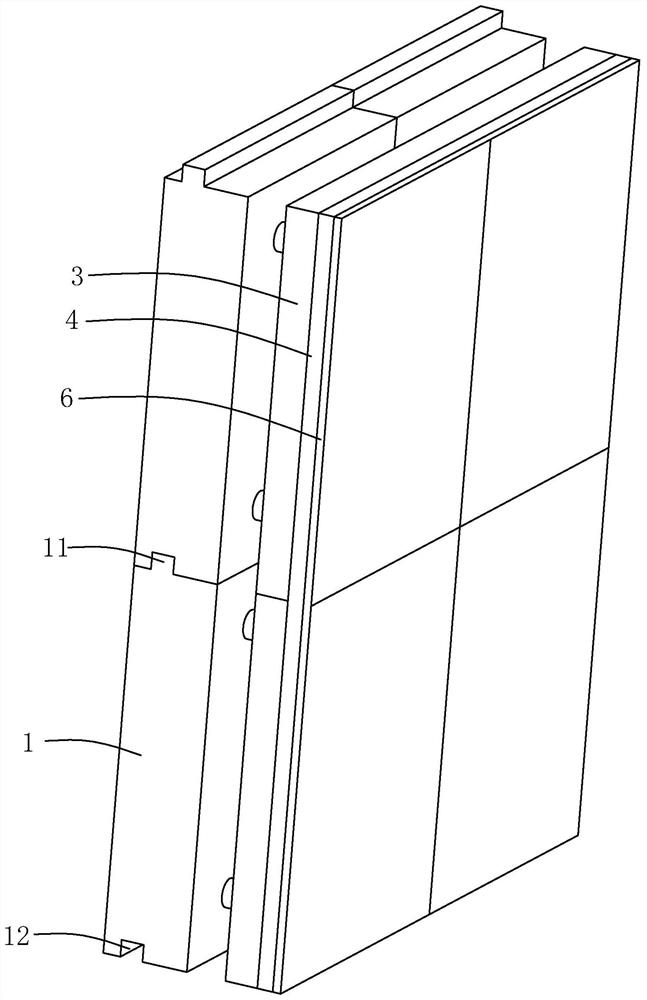

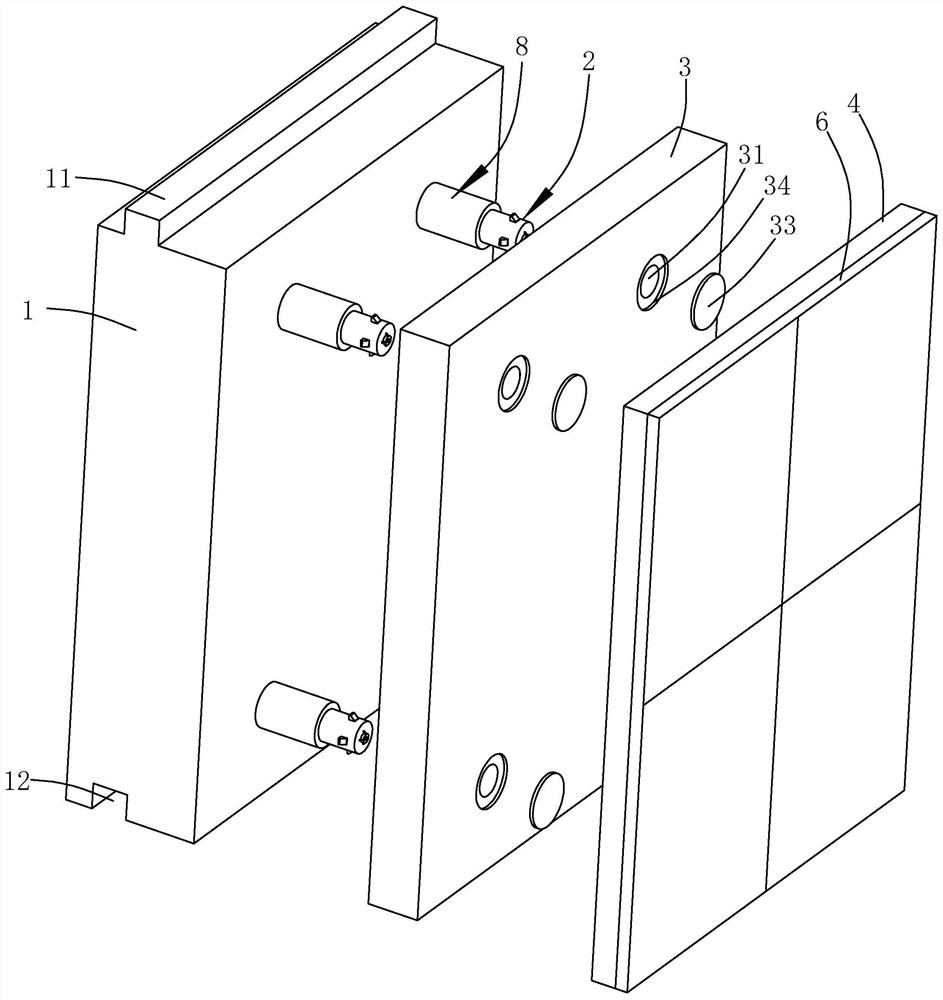

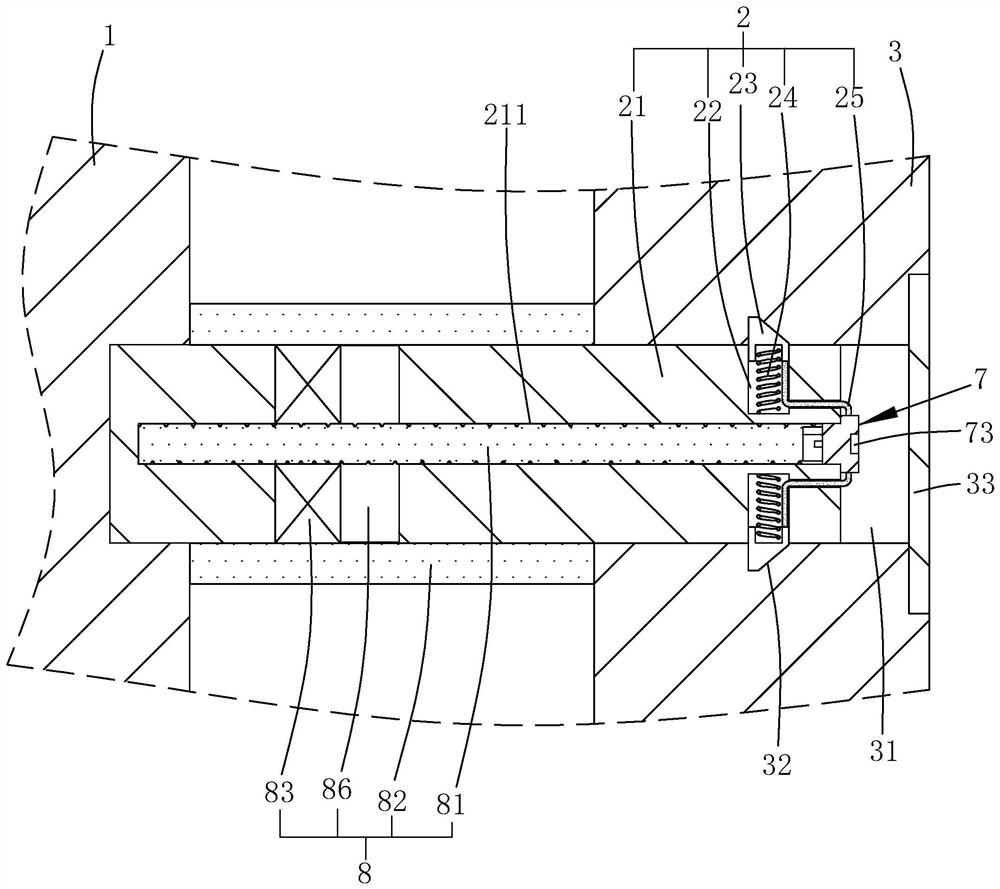

[0038] refer to figure 1 and figure 2 , is a prefabricated exterior wall structure based on BIM technology disclosed in the present invention, which is convenient for later maintenance. The assembled exterior wall structure includes an exterior wall body formed by splicing several exterior wall panels 1. The upper end of the exterior wall panel 1 is integrally formed with a waterproof anti-sill 11, and the lower end of the exterior wall panel 1 is provided with a positioning groove 12 adapted to the waterproof anti-sill 11. ; Among the two vertically adjacent exterior wall panels 1, the waterproof anti-sill 11 on the lower exterior wall panel 1 is inserted into the positioning groove 12 on the upper exterior wall panel 1, and the waterproof anti-sill 11 and the positioning The cooperation of the groove 12 ensures that the wall surface of the outer wall body is smooth.

[0039] A connection plate 3 is connected to the outside of each exterior wall panel 1 through four suspen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com