Method for manufacturing river channel dry land construction conditions by using flow self-adjusting siphoning type construction flow guide pipe

A construction diversion and siphon technology, applied in water conservancy projects, water conservancy engineering equipment, special data processing applications, etc., can solve the problems of long construction period, hidden dangers of river flood safety, and high construction and demolition costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

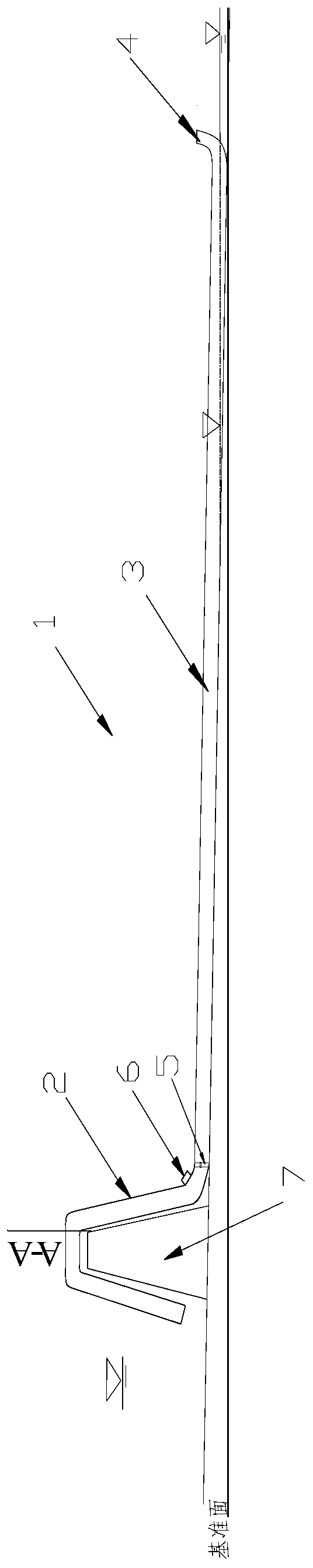

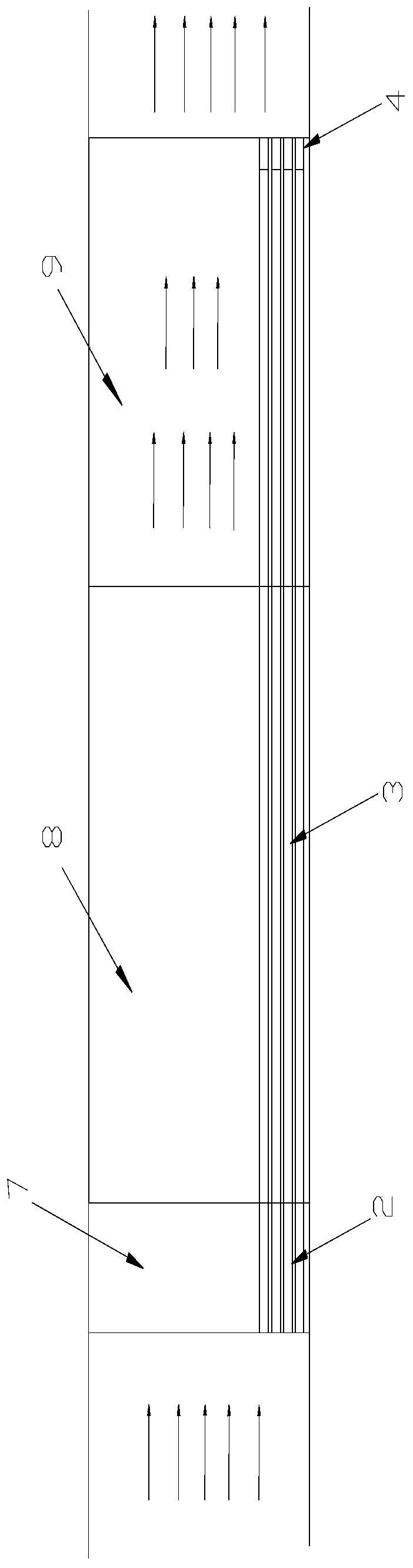

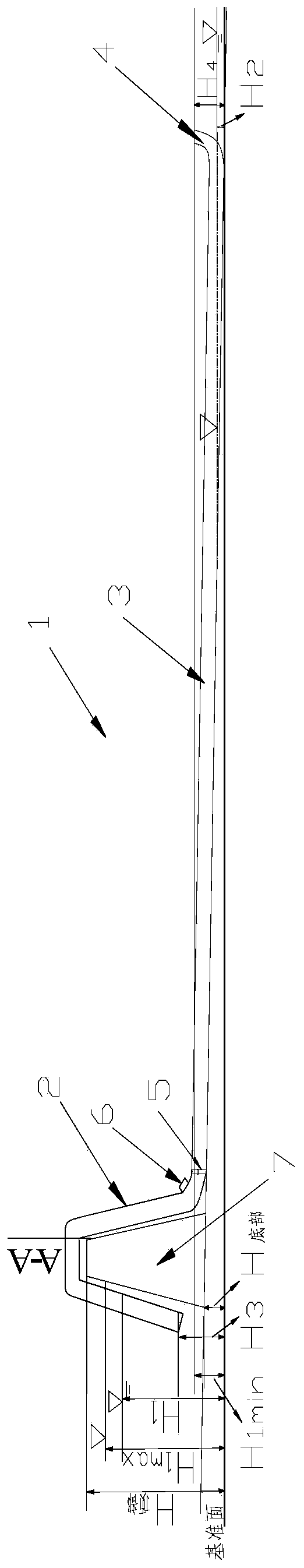

[0143] This embodiment takes a certain river channel in Chengdu City, Sichuan Province as an example to illustrate the method of using the flow self-adjusting siphon construction diversion pipe to manufacture the construction conditions of the dry land of the river channel provided by the present invention. In this embodiment, the schematic diagram of the layout of the siphon construction guide pipe is as follows Figure 1~2 shown.

[0144] It is planned to build a small bridge 300m downstream of a rubber dam (rubber dam is a specific water-retaining structure) in the river. The rubber dam is 3m high. The basic information of the river is shown in Table 1.

[0145] Table 1 Basic data table of river course

[0146] Channel width B(m) Channel roughness n River slope J 80 0.025 0.8‰

[0147] In the following calculations, the elevation data are all based on the horizontal plane at the end of the downstream river, that is, the riverbed at the end of the o...

Embodiment 2

[0271] In this embodiment, the engineering conditions involved are the same as in Embodiment 1, and the construction conditions of the dry river course are manufactured in the same way as in Embodiment 1, except that the diameter of the siphon construction diversion pipe used is 1.5m. , that is, the inner diameters of the hard pipe, the water delivery hose and the water outlet elbow used in this embodiment are equal to 1.5m.

[0272] Adopt the method identical with embodiment 1, each parameter that calculates is as follows:

[0273] The length of the water hose l 2 =1175m;

[0274] Inlet elevation H of siphon construction diversion pipe 3 =1.14m;

[0275] The outlet elevation H of the siphon construction diversion pipe 4 =1.44m;

[0276] The installation elevation H of the siphon construction diversion pipe A : 3.94m≤H A ≤8.00m;

[0277] The necessary installation quantity of siphon construction diversion pipe m=14;

[0278] In this embodiment, M=m=14.

[0279] In th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com