A mold and prefabrication method suitable for producing assembled underpass tunnel frames by long-line matching method

A long-term matching and assembly technology, applied in the direction of molds, etc., can solve the problems of high cost, high construction risk, and low precision of component prefabrication

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

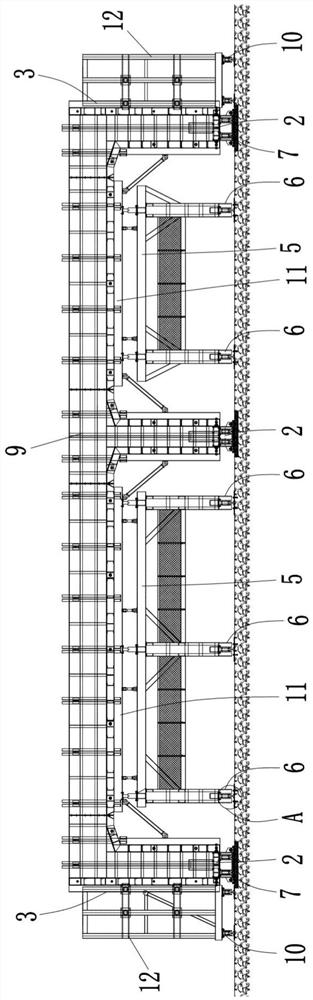

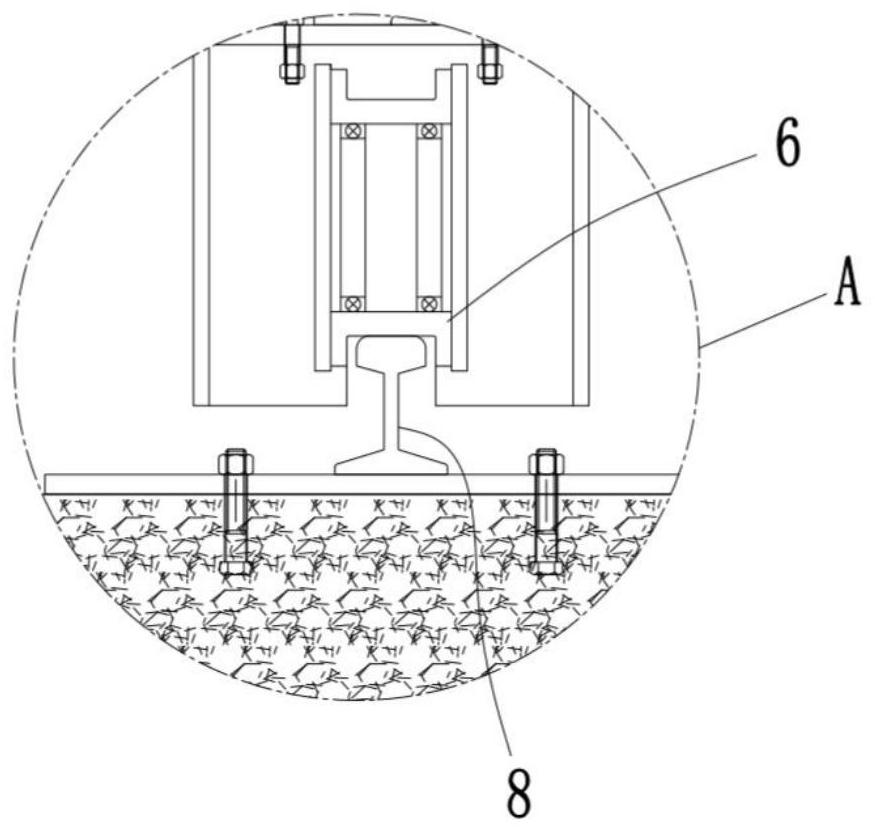

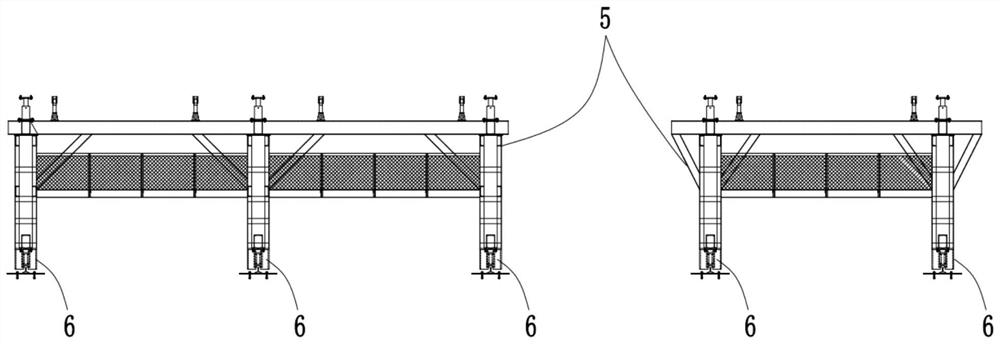

[0051] Example 1, such as Figure 1-8 Shown:

[0052] A mold suitable for producing an assembled underpass tunnel frame by the long-line matching method, including a bottom mold assembly 2 adapted to the bottom of a frame segment 1, and an inner mold assembly 11 adapted to the inner wall of the frame segment 1 , a side mold assembly 3 adapted to the outer walls on both sides of the frame segment 1 and an end mold assembly adapted to both ends of the frame segment 1, and an inner mold for supporting the inner mold assembly 11 The bracket 5 is provided with a driving device for driving the inner mold assembly 11 to switch between the pouring position and the disengagement position on the inner mold bracket 5, and the first walking assembly 6 is also arranged on the inner mold bracket 5, so The first walking assembly 6 is used to provide the movement of the inner mold support 5 along the length direction of the frame.

[0053] In this scheme, the frame segment 1 is formed by di...

Embodiment 2

[0068] Example 2, such as Figure 1-8 as shown,

[0069] A prefabrication method for prefabrication of a tunnel frame segment 1 using the mold described above,

[0070] Three work areas are sequentially numbered along the length direction of the track 8 to form: the first work area, the second work area and the third work area. The prefabrication method of this embodiment includes the following steps set in sequence:

[0071] Step 1. Prefabrication of the first frame segment 1 in the first working area: assemble the bottom mold assembly 2, the side mold assembly 3, the end mold assembly and the inner mold assembly 11 in the first working area to form a The pouring cavity with the same shape as the first frame segment 1, in which the pre-embedded components are installed and the concrete is poured;

[0072] Step 2. Prefabrication of the first frame segment 1 in the second working area: After the frame segment 1 in step 1 is hardened, the end formwork assembly and the side for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com