Supporting module for fused deposition modeling three-dimensional printing and generating method of supporting module

A supporting module and 3D printing technology, applied in the direction of additive processing, etc., can solve the problem that the supporting module 1 is difficult to remove, and achieve the effect of reducing the difficulty of dismantling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

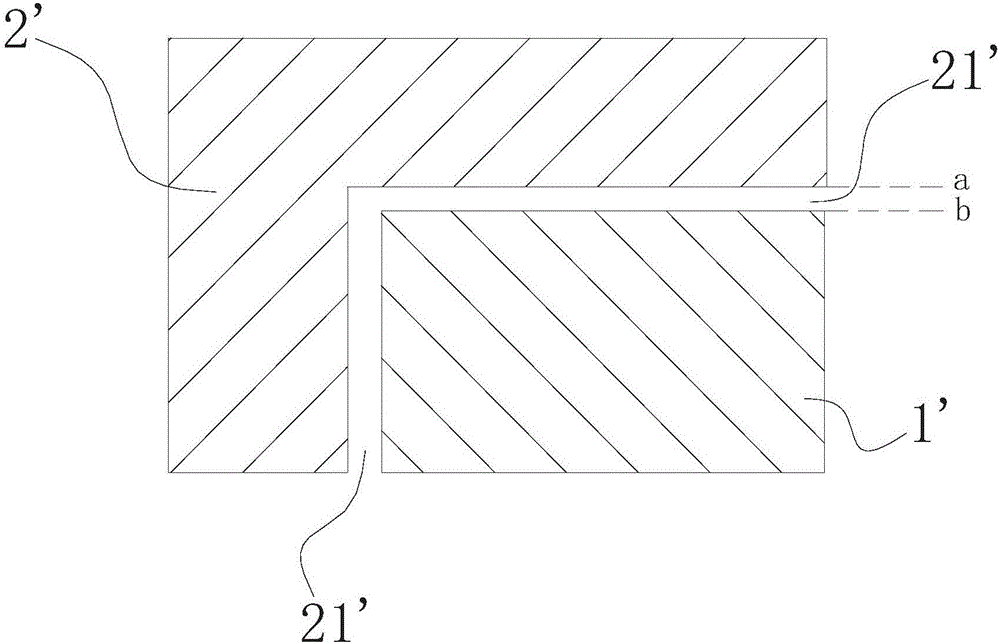

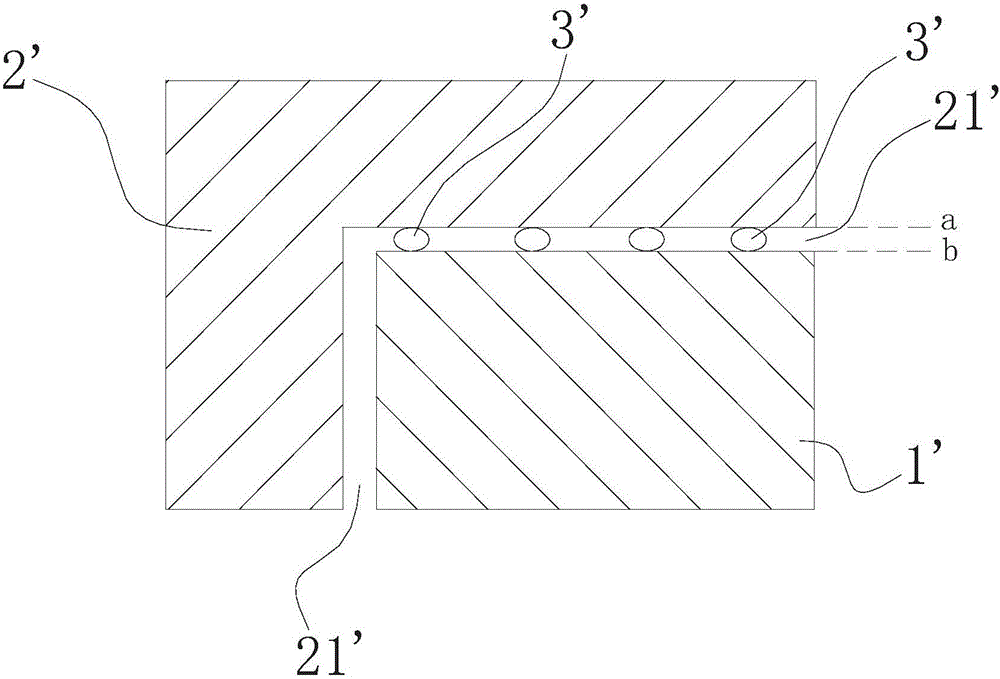

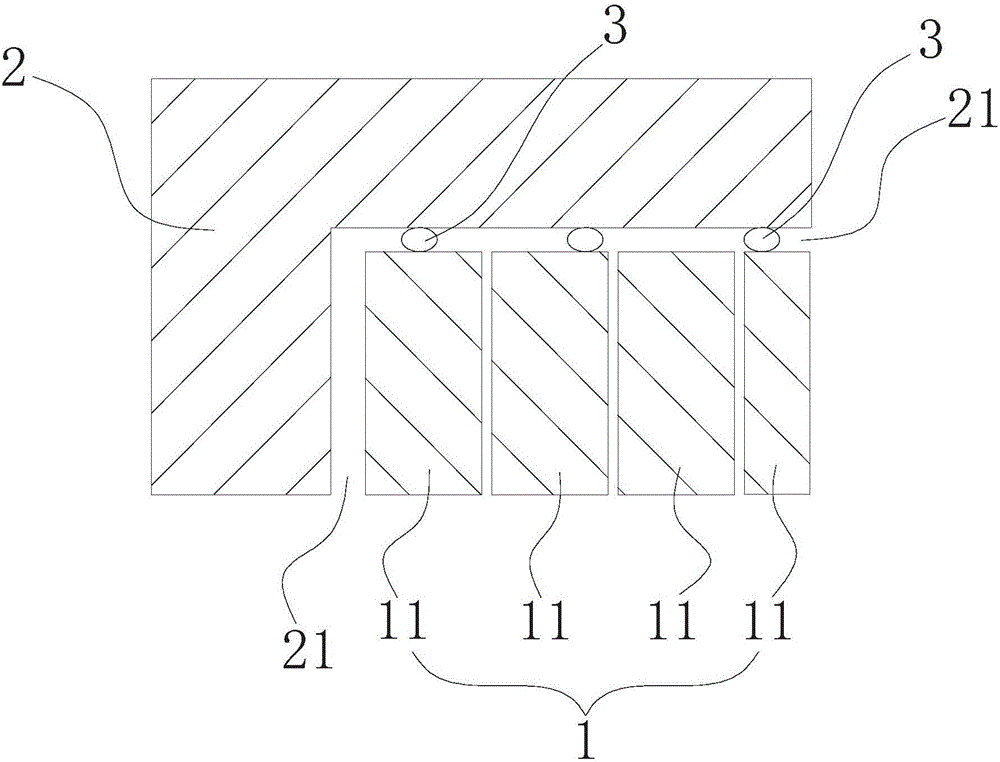

[0038] See image 3 with Figure 4 , which respectively show the support module of the fusion deposition molding 3D printing and the longitudinal sectional view of the model after printing and the cross-sectional view of the support module according to the first embodiment of the present invention. Model 2 has one or more overhangs. The supporting module 1 is arranged in a suspended part of the model 2 . image 3 Take a suspended part 21 of model 2 as an example for illustration. The support module 1 is arranged under the suspended part 21 of the model 2, and is used to provide multiple fixing points for the suspended part 21 during the process of printing the model 2 to support the suspended part 21. After the printing is completed, the support module 1 is removed from the model 2 The lower part of the floating part 21 is removed. exist image 3 with Figure 4In the shown embodiment, the suspended part whose vertical projection profile is rectangular and horizontal proj...

no. 2 example

[0053] See Figure 9 with Figure 10 , which respectively show the cross-sectional view of the support module of fusion deposition molding 3D printing according to the second embodiment of the present invention and the cross-sectional view of the array before the intersection of the array and the suspended part during the printing process. with the above Figure 4 The difference in the first embodiment shown in is that, as Figure 9 As shown, the supporting units 11 are arranged in a matrix, and the cross-section of each central supporting unit 112 is rectangular. Furthermore, in order to achieve the above Figure 9 The cross-section of the support module 1 is shown. In this embodiment, before the intersection of the array 12 and the suspended part 21, the cross-section of each support unit 11 is rectangular, and the support units 11 are arranged in a matrix, as shown in Figure 10 shown. This embodiment can also be implemented and will not be repeated here.

no. 3 example

[0055] See Figure 11 with Figure 12 , which respectively show the cross-sectional view of the support module of the fusion deposition molding 3D printing according to the third embodiment of the present invention and the cross-sectional view of the array before the intersection of the array and the suspended part during the printing process. with the above Figure 4 The difference in the first embodiment shown in is that, as Figure 11 As shown, the adjacent supporting units 11 are alternately arranged in front and back, and the cross-section of each central supporting unit 112 is triangular. Among them, the setting of positive and negative phases (refer to Figure 12 ) means that each support unit 11 with a triangular cross-section is in the opposite shape of its adjacent support units 11 up and down or left and right in the same plane. Taking a triangular cross-section of a support unit 11 as an example, it rotates 180° with the center of the triangle The triangle form...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com