A textile winding device

A winding device and winding technology, which are applied in the directions of transportation and packaging, thin material handling, and filamentary material transportation, can solve the problems of increasing labor costs, increasing economic costs, and single structure, and achieve rapid disassembly and assembly lines. The effect of increasing the working speed and improving the uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

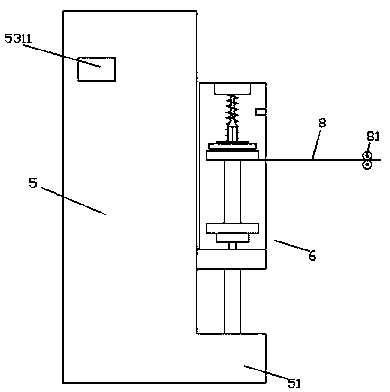

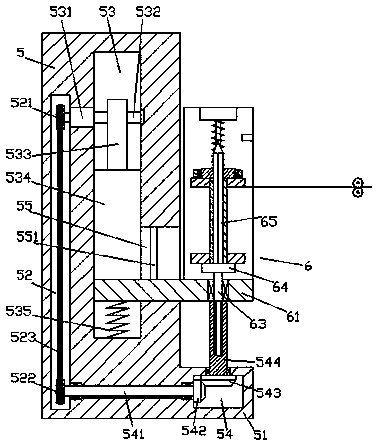

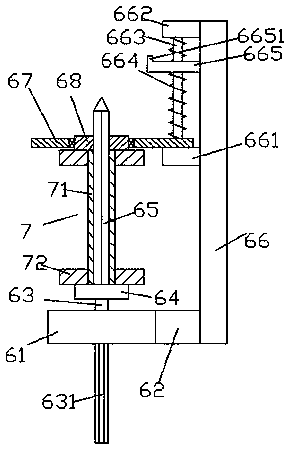

[0023] Such as Figure 1-Figure 6 As shown, a textile winding device of the present invention includes a body 5 and a guide wheel 81 arranged on the right side of the body 5 and arranged symmetrically up and down. The bottom of the right end surface of the body 5 is provided with a boss portion 51, A winding mechanism 6 is provided above the boss portion 51. The winding mechanism 6 includes a bottom plate 61 extending left and right, a connecting block 62 fixed on the right rear side of the bottom plate 61, and a connecting block 62 fixed to the connecting block 62. A straight plate 66 extending upward at the rear end and a winding base 64 arranged above the bottom plate 61. A first rotating shaft 63 is fixed at the bottom of the winding base 64, and the bottom of the first rotating shaft 63 penetrates The bottom plate 61 is rotatably connected with the bottom plate 61, the bottom of the first rotating shaft 63 is fixed with an external spline shaft 631 extending downward, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com