An electrical control switch structure

A technology of electrical control and switch structure, applied in the direction of electrical switches, circuits, electrical components, etc., can solve the problems of lack of overall unity and relative stability, difficult for users to recover, and appearances that are not related to each other.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to have a further understanding and understanding of the structural features of the present invention and the achieved effects, the preferred embodiments and accompanying drawings are used for a detailed description, as follows:

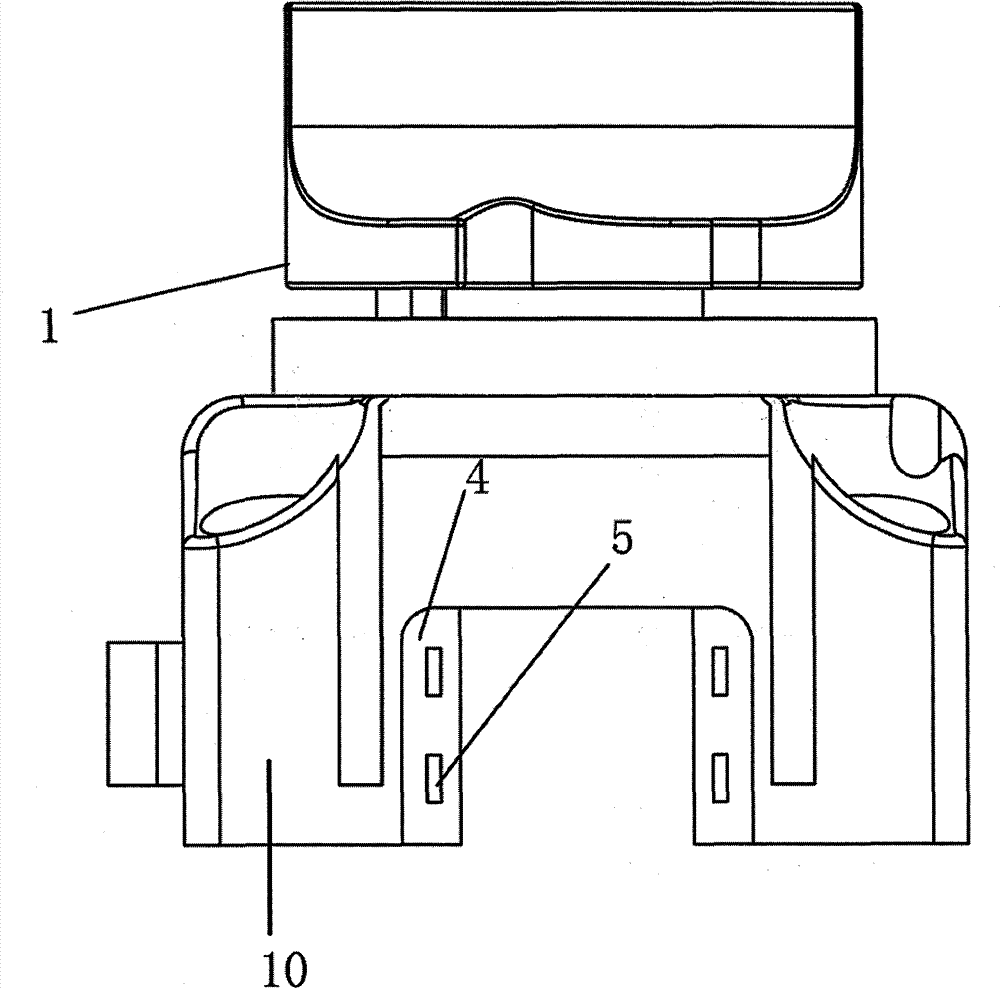

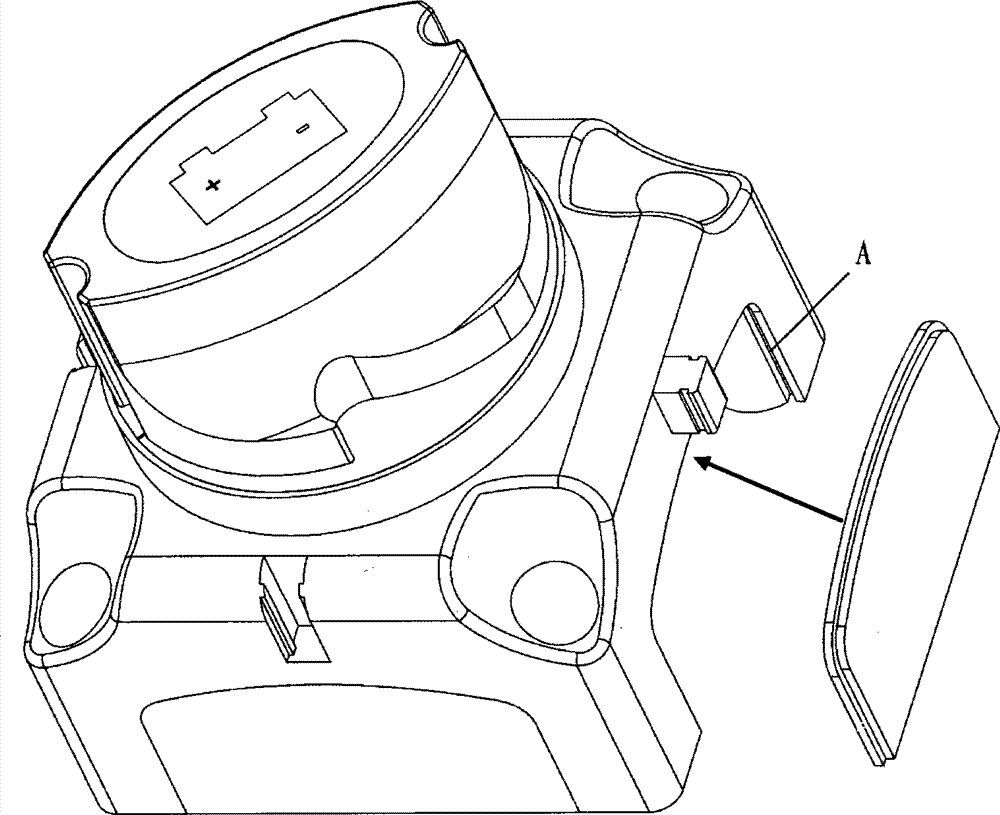

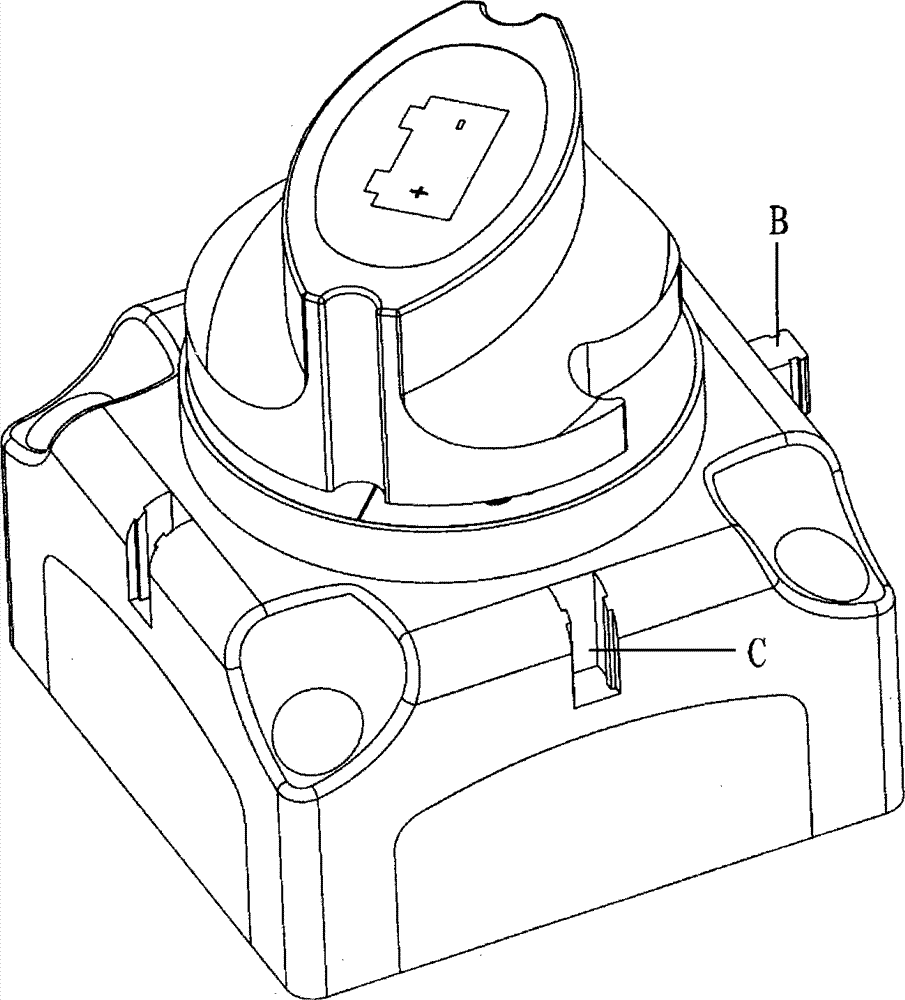

[0028] In order to better manage the wires inside the electrical control switch, a movable switch door needs to be set on one side of the electrical control switch, and image 3 , Figure 4 It is the installation structure diagram of the wire slot of the electrical control switch of the present invention, as shown in the figure. The structure of the electrical control switch mainly adopts a "press buckle" wire slot structure, including an electrical control switch 1 and a cover plate 2 installed on the first side 10 of the electrical control switch 1, and the cover plate 2 is provided with a bayonet The column 3 and the first side 10 of the electrical control switch 1 are provided with a bayonet surface 4 , the bayonet surface 4 is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com