A disassembly device with buckle structure

A buckle structure and disassembly device technology, which is applied in the direction of connecting components, thin plate connections, mechanical equipment, etc., can solve the problems of prying the clamping plate 30, difficulty in disassembly work, inconvenience, etc., and achieves labor-saving operation, simple structure, and simple production. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

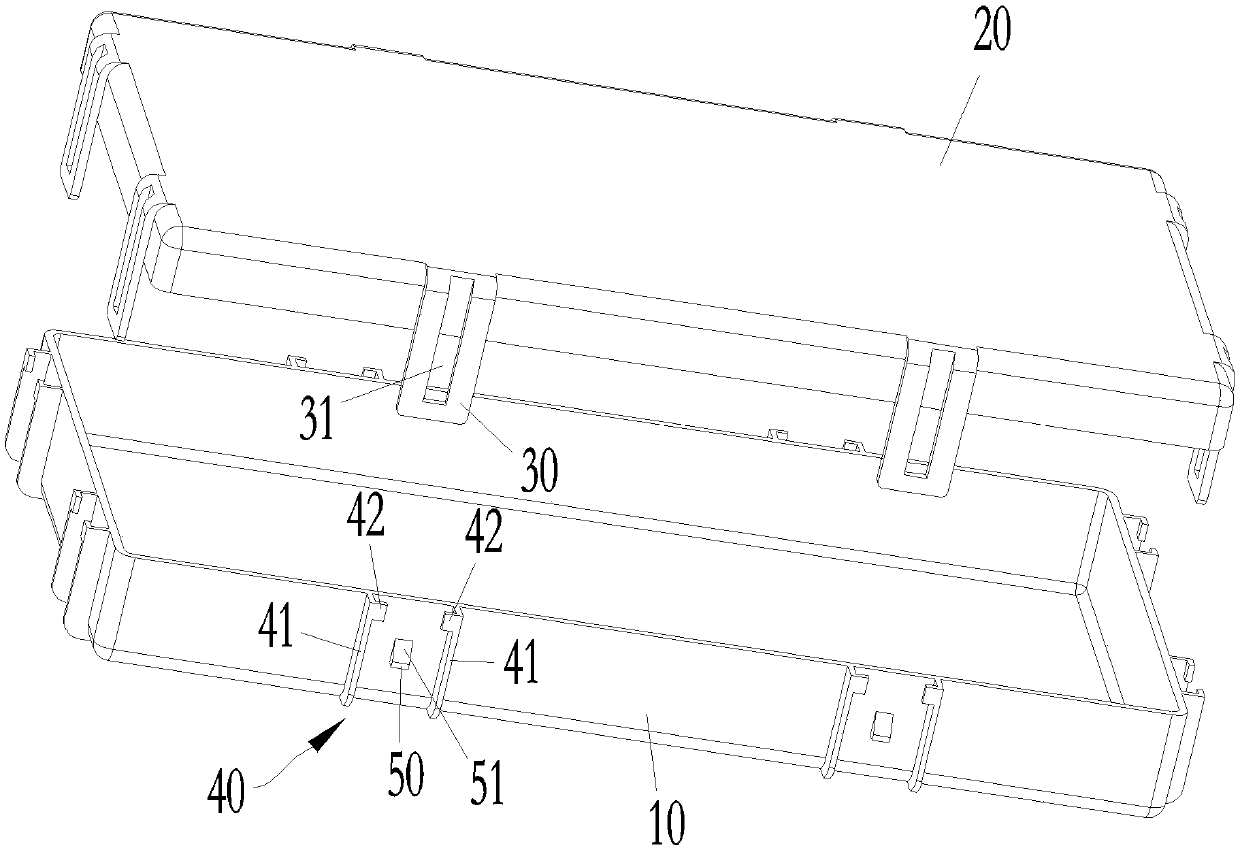

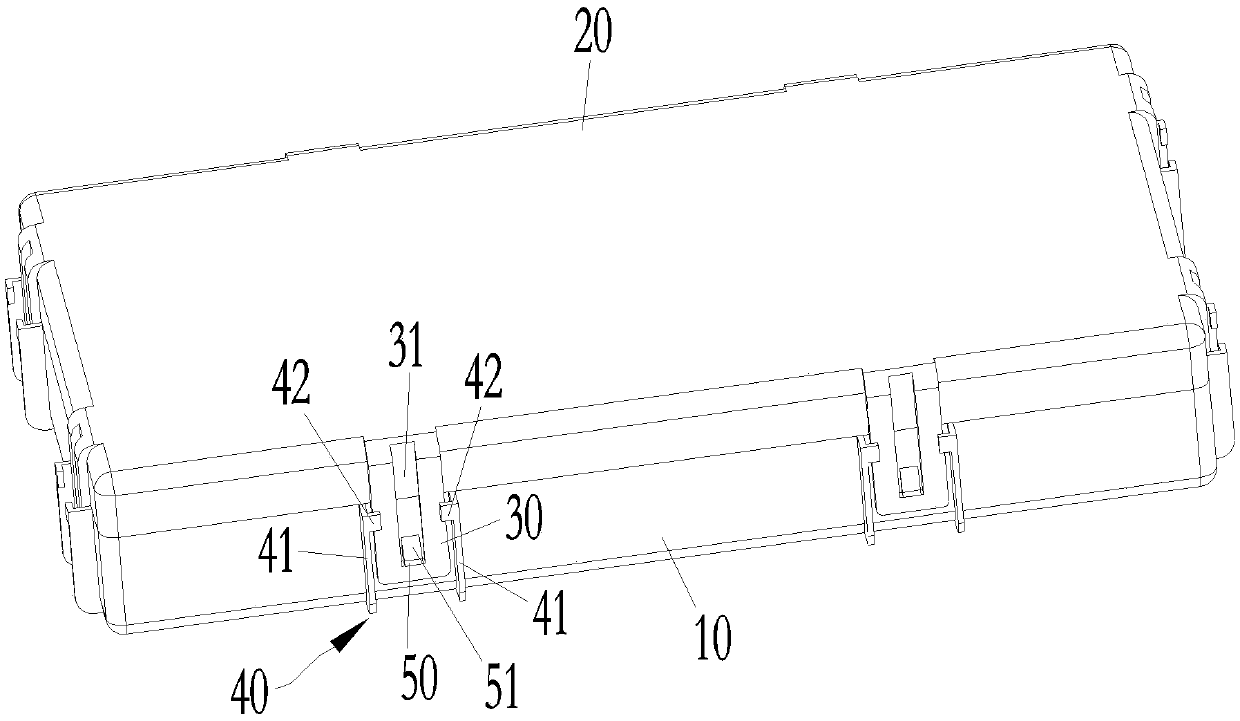

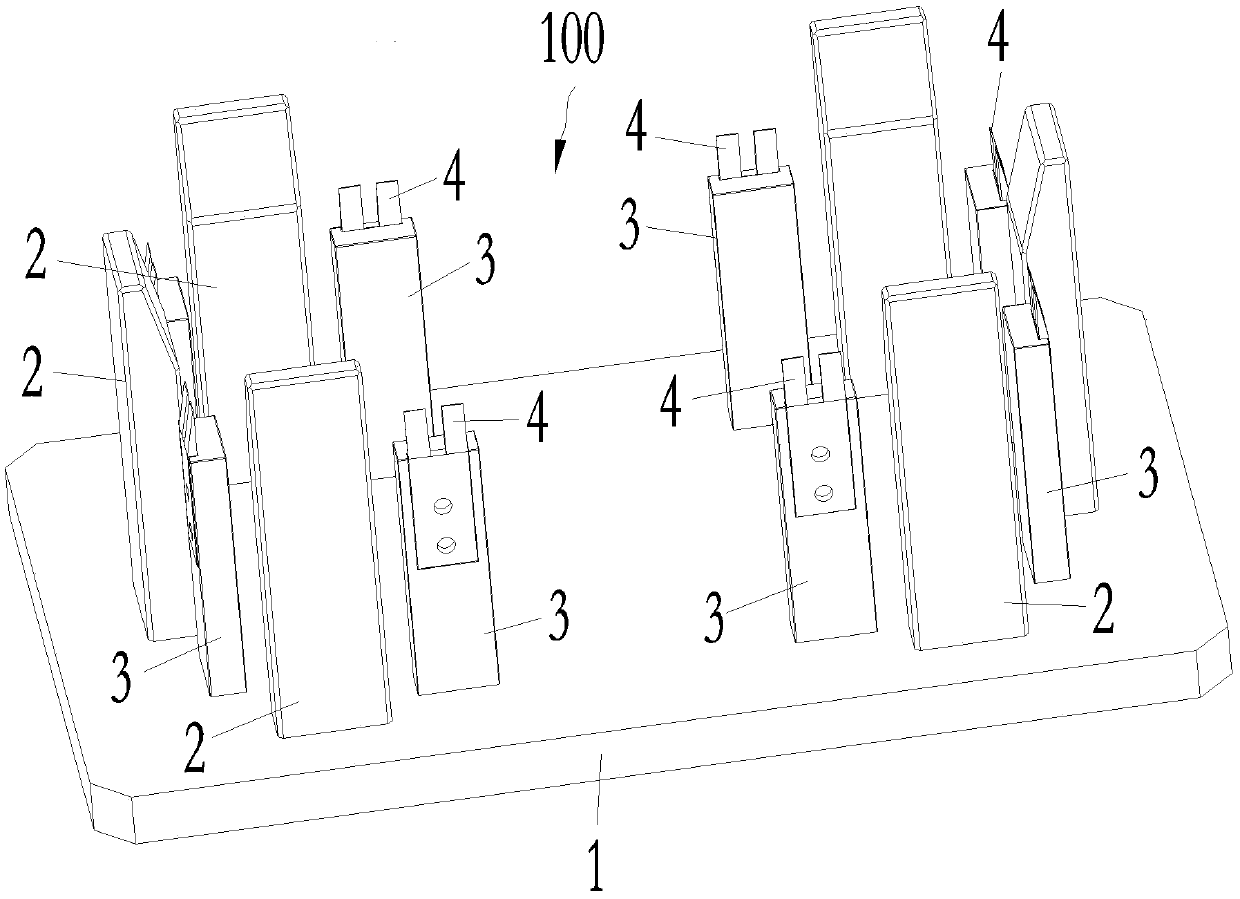

[0010] Such as image 3 , Figure 4 As shown, the dismounting device of a buckle structure includes a base 1, and a plurality of limiting columns 2 arranged on the base 1, and a space 100 for inserting the lower casing 10 is formed in the limiting columns 2, each The limit column 2 is in contact with the walls of the lower casing 10 inserted into the space 100 to form a limit to the lower casing 10, and the base 1 is also provided with a support 3 for supporting the inserted lower casing from the bottom. The outer side of the top of 3 is provided with disassembly head 4 opposite to each buckle structure position. The disassembly head 4 is a wedge-shaped structure with a thin top and a thick bottom. When the product is inserted into the space 100, the disassembly head 4 can be inserted into the upper shell between the clamping plate and the outer wall of the lower case. When the dismounting head is inserted to a certain depth, the dismounting head 4 of the wedge-shaped struct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com