Disassembling and assembling tool for clamping jaw of loading and unloading machine

A loading and unloading machine and gripper technology, which is applied in the field of nuclear power, can solve the problems of personnel falling, small area space, and long working time, and achieve the effects of safe disassembly and assembly work, reduced exposure dose, and reduced working time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

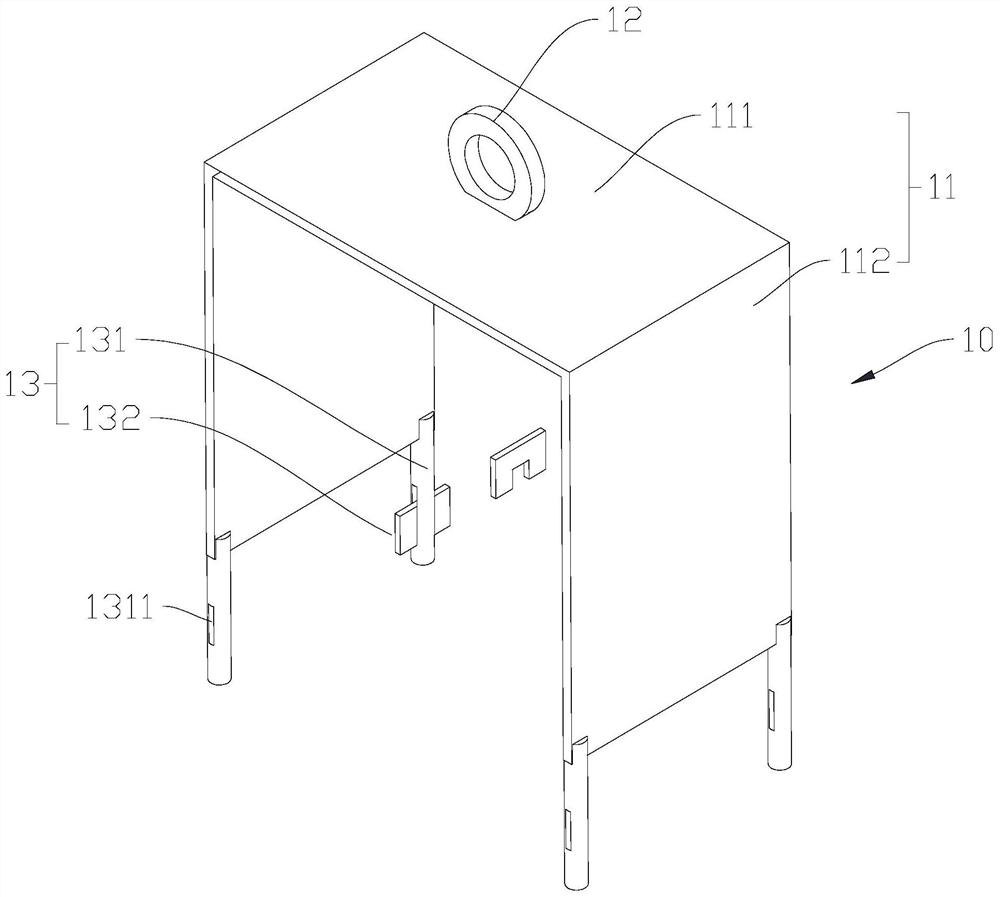

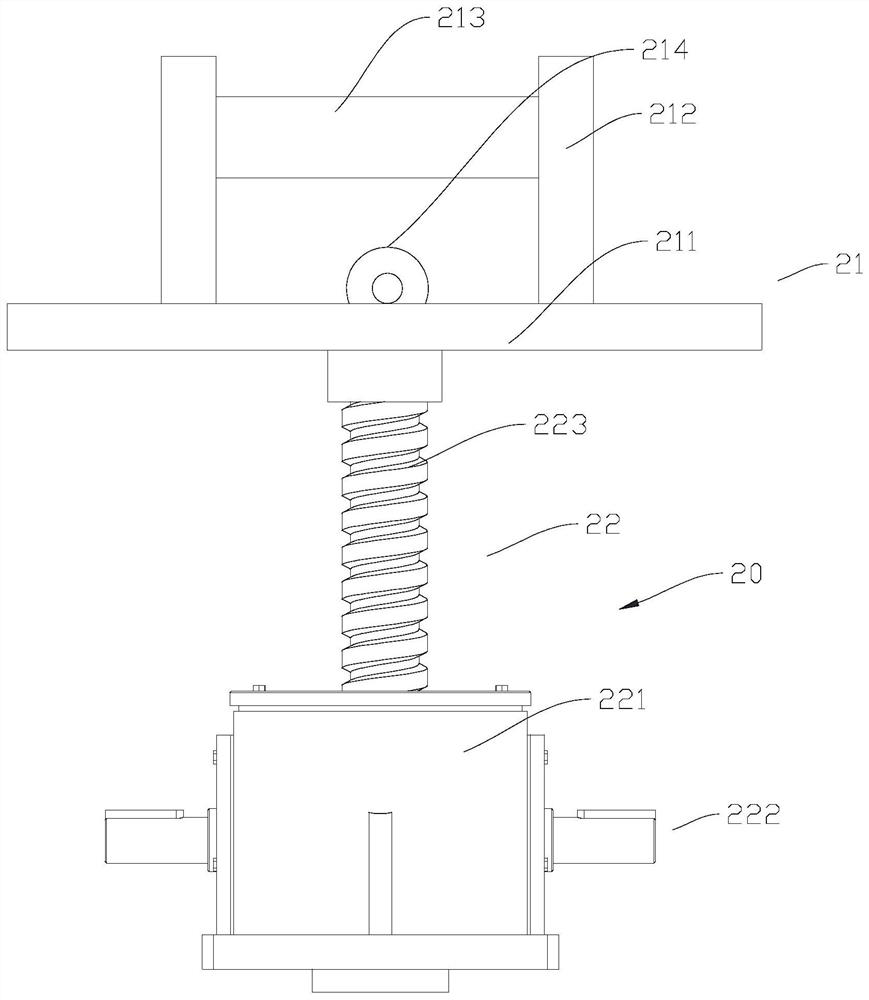

[0032] figure 1 and figure 2 Some preferred embodiments of the dismantling tool for loading and unloading machine jaws according to the invention are shown. The disassembly and assembly tool for the jaws of the loading and unloading machine can quickly and safely realize the disassembly and assembly work of the jaws of the loading and unloading machine, reduce the working time of personnel, and reduce the exposure dose of personnel.

[0033] The disassembly tool can include a sling 10 and a base 20; the sling 10 can be detachably connected to the upper part of the jaws of the loading and unloading machine, so that after opening the outer cover of the jaw container, the inclusions can be lifted out separately, thus eli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com