Method for arranging wind power generation equipment in shallow water of intertidal zone

A technology of wind power generation equipment and installation method, which is applied to wind turbine components, wind energy power generation, wind turbines, etc., can solve problems such as difficulties, inability to enter the construction site for land installation equipment, and inability to enter the construction site, and achieves high installation efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

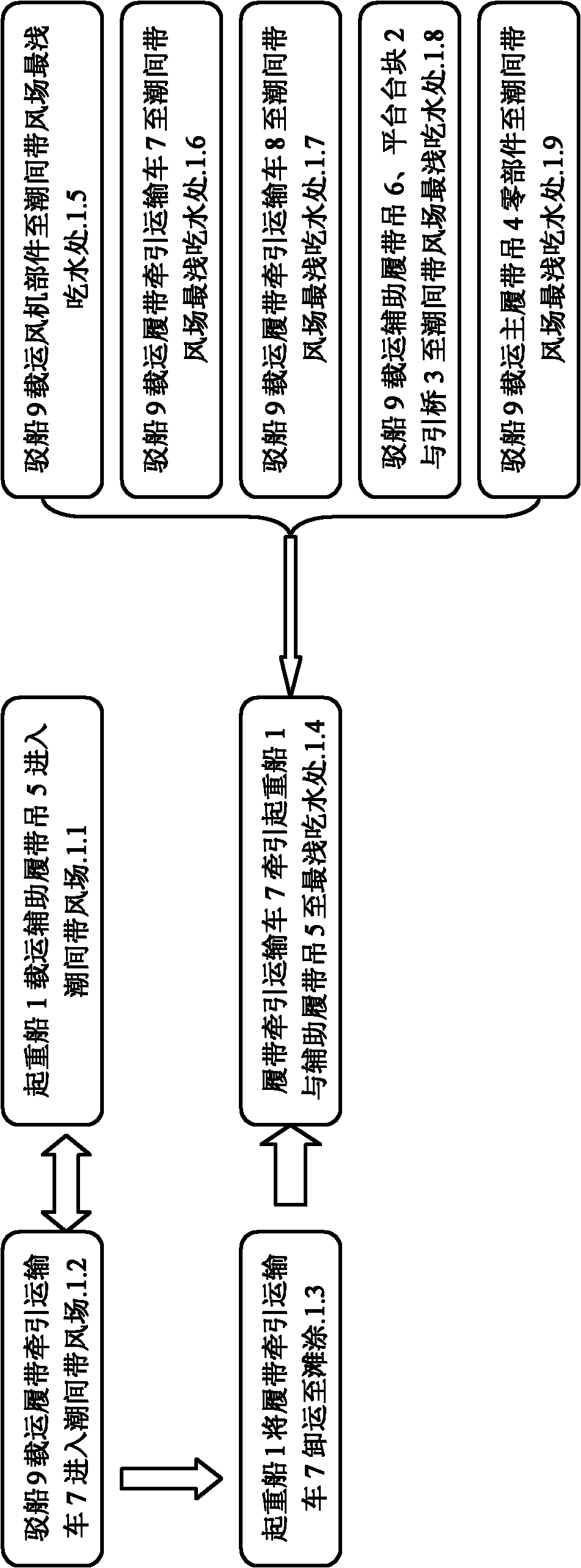

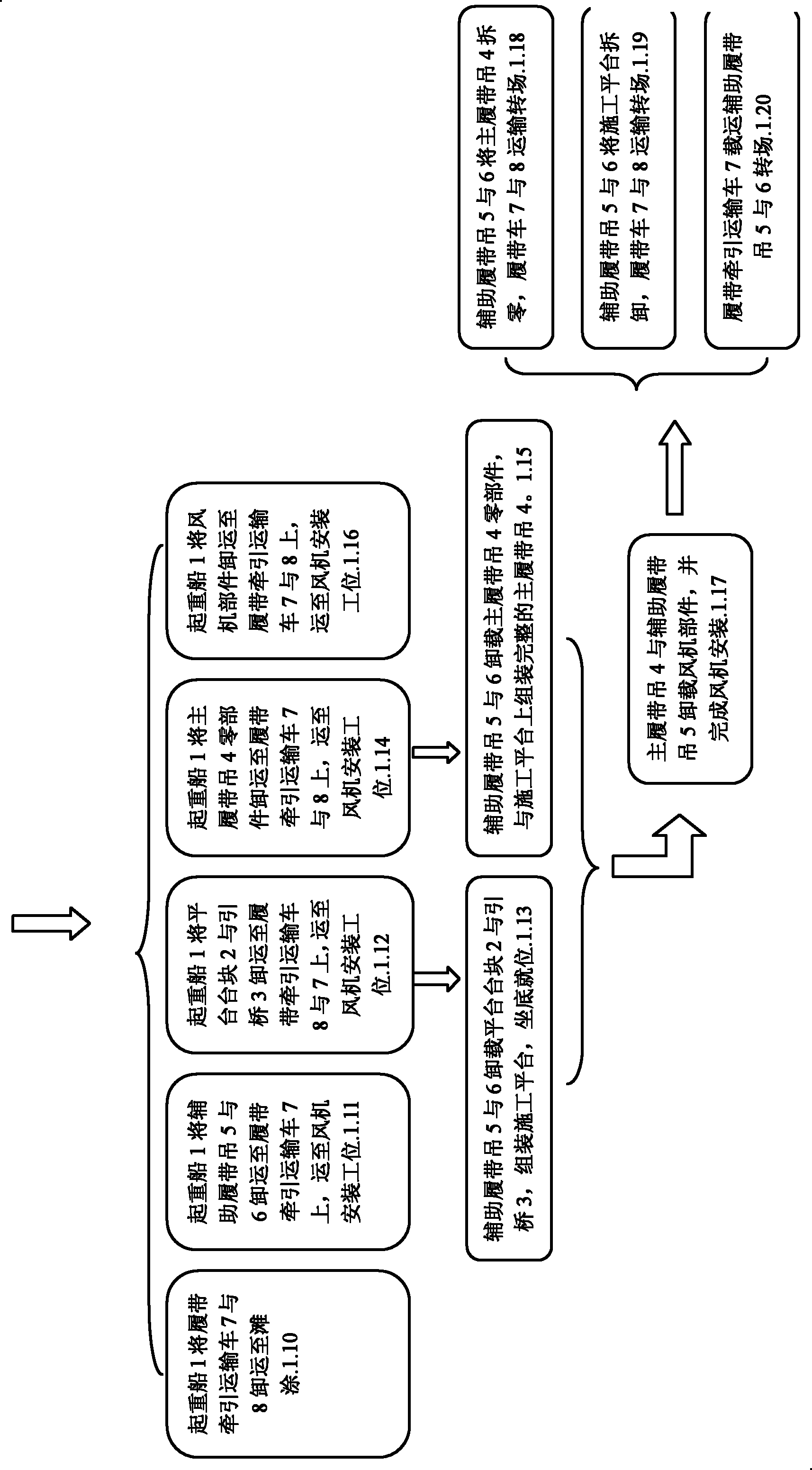

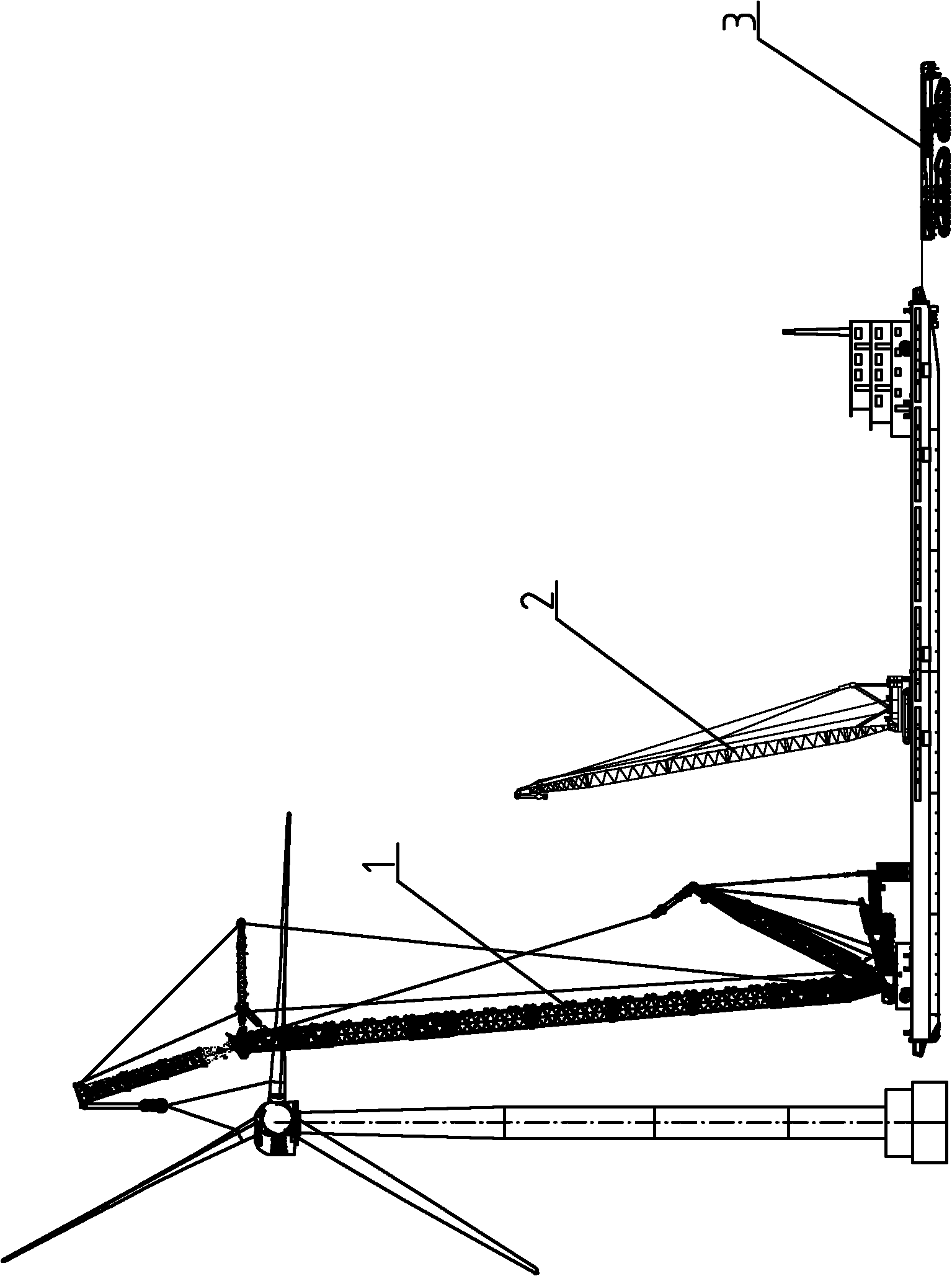

[0046] A construction method for transporting and installing wind power generation equipment in an intertidal zone with a water depth of 2m or less, characterized in that it includes the following steps:

[0047] (1) Crane ship 1 carries 260t auxiliary crawler crane 5 into the intertidal zone wind field by external force;

[0048] (2) The barge 9 carries the 150t crawler tractor transport vehicle I7 into the wind field in the intertidal zone, and berths the crane ship 1;

[0049] (3) The crane ship 1 unloads the 150t crawler tractor transport vehicle I7 onto the tidal flat;

[0050] (4) 150t crawler traction transport vehicle I7 tow crane ship 1 and 260t auxiliary crawler crane 5 to the shallowest draft;

[0051] (5) The barge 9 carries the wind turbine components to the shallowest draft of the wind field in the intertidal zone, and the 150t crawler tractor transport vehicle I7 tows the transport barge 9 to berth the crane ship 1;

[0052] (6) The barge 9 carries some 150t c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com