Adjacent rack rail mounting and adjusting appliance for rack rail railway

A technology for installation and adjustment of racks, which is applied in the directions of roads, tracks, paved tracks, etc., can solve the problems that the longitudinal pitch and other position parameters of two adjacent racks cannot be accurately and quickly detected, and the construction efficiency is low. Achieve the effect of improving work efficiency, convenient and fast movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

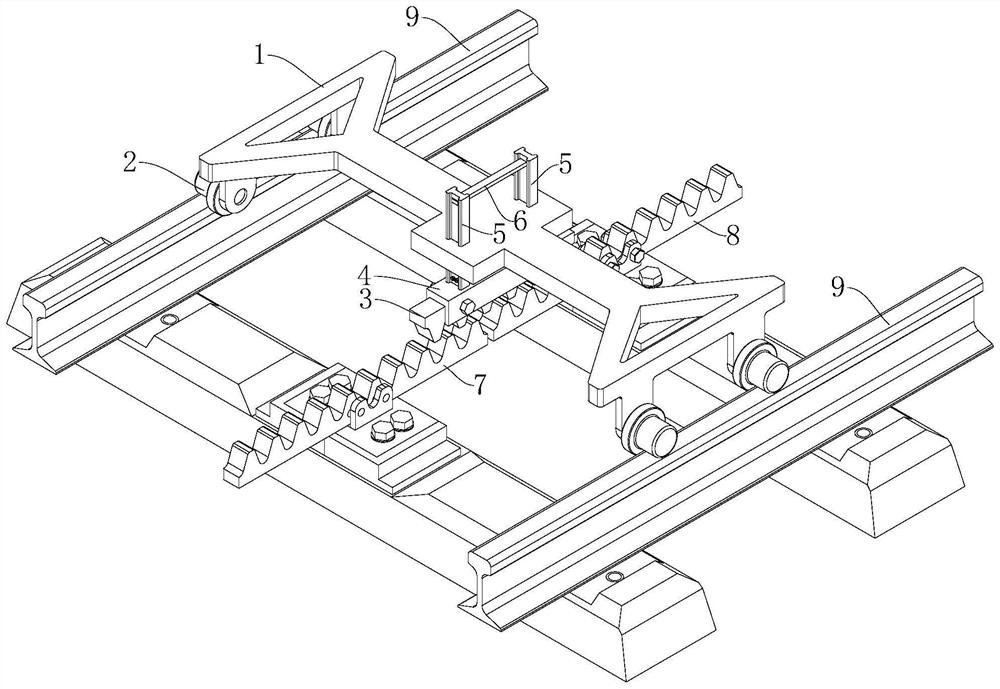

[0033] Adjacent rack rail installation adjustment device for a rack railway, such as Figure 1-Figure 4 , including the wheel hub 2 of the walking module, the frame 1 of the load-bearing module and the working module.

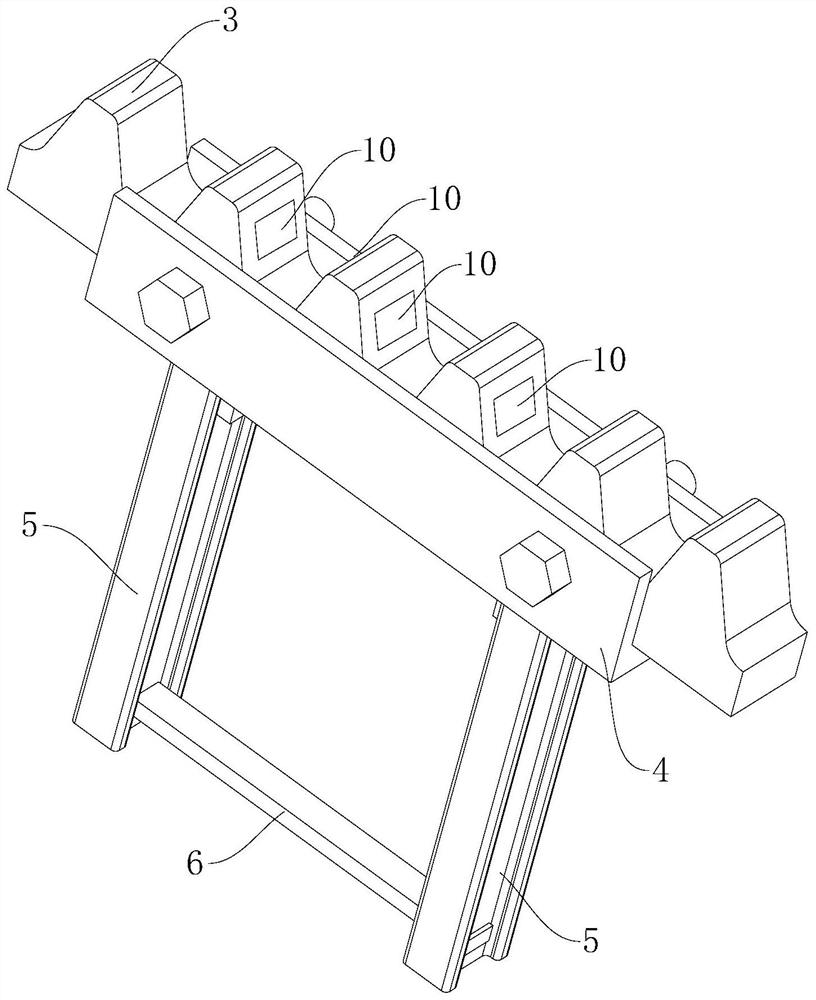

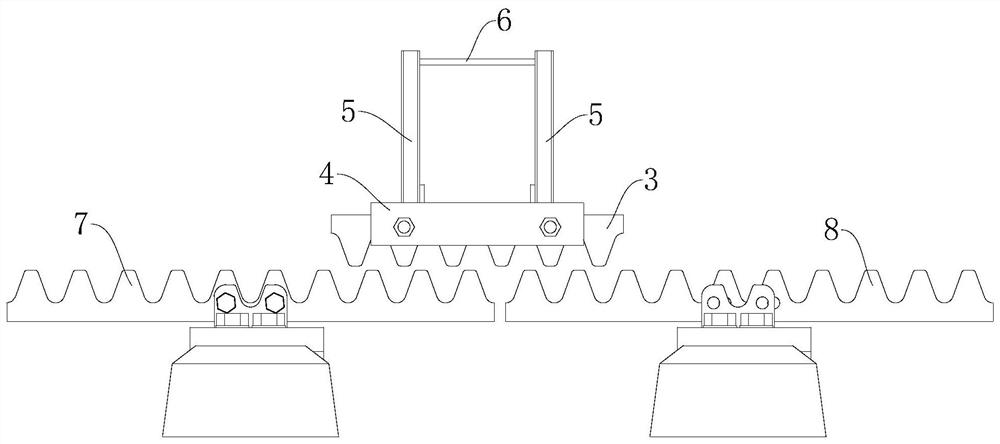

[0034] Specifically, such as figure 1 , 2 , the working module is located below the frame 1, corresponding to the position of the rack, and includes an engaging rack 3, a base 4 and two opposite guide rails 5. The meshing rack 3 is fixed in the through-slot structure of the base 4 by fastening bolts upside down, and the meshing rack 3 is used to simultaneously engage with the installation rack (that is, the rack): the first rack 7 and the second rack 8; Two oppositely arranged guide rails 5 are arranged on the two ends of the upper part of the base 4 along the length direction of the base 4, engraved with the same scale mark, and the two slide up and down through two through holes arranged longitudinally on the frame 1; The arrangement is to ensure that the ...

Embodiment 2

[0042] In the actual operation of the cog railway, the repeated action of the cog and the gear on the train will continuously increase the wear of the tooth surface of the cog, especially the teeth near the adjacent cog, which have high vibration frequency and fast wear; when the cog Tooth surface wear to a certain extent will affect the quality of driving operation, and then the rack needs to be replaced. In order to further quantitatively reflect the installation accuracy of the adjacent racks and detect whether the position accuracy of the racks meets the operating requirements after a period of operation, such as image 3 , on several teeth of the meshing rack 3 in embodiment 1, a laser distance measuring sensor 10 is embedded in the tooth surfaces on both sides of each tooth to detect the tooth surface of the meshing rack 3 to the meshing rack tooth surface the distance between. In this way, on the one hand, it can quantitatively reflect the degree of engagement between ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com