Motor shell assembling and magnetizing process

A motor casing and process technology, which is applied in the field of motor casing assembly and magnetization technology, can solve the problems of unfavorable brushless DC fan mute effect, residual magnetic force, and large electromagnetic sound.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described below in conjunction with specific embodiments.

[0039] A motor casing assembly and magnetization process, which includes the following steps, specifically:

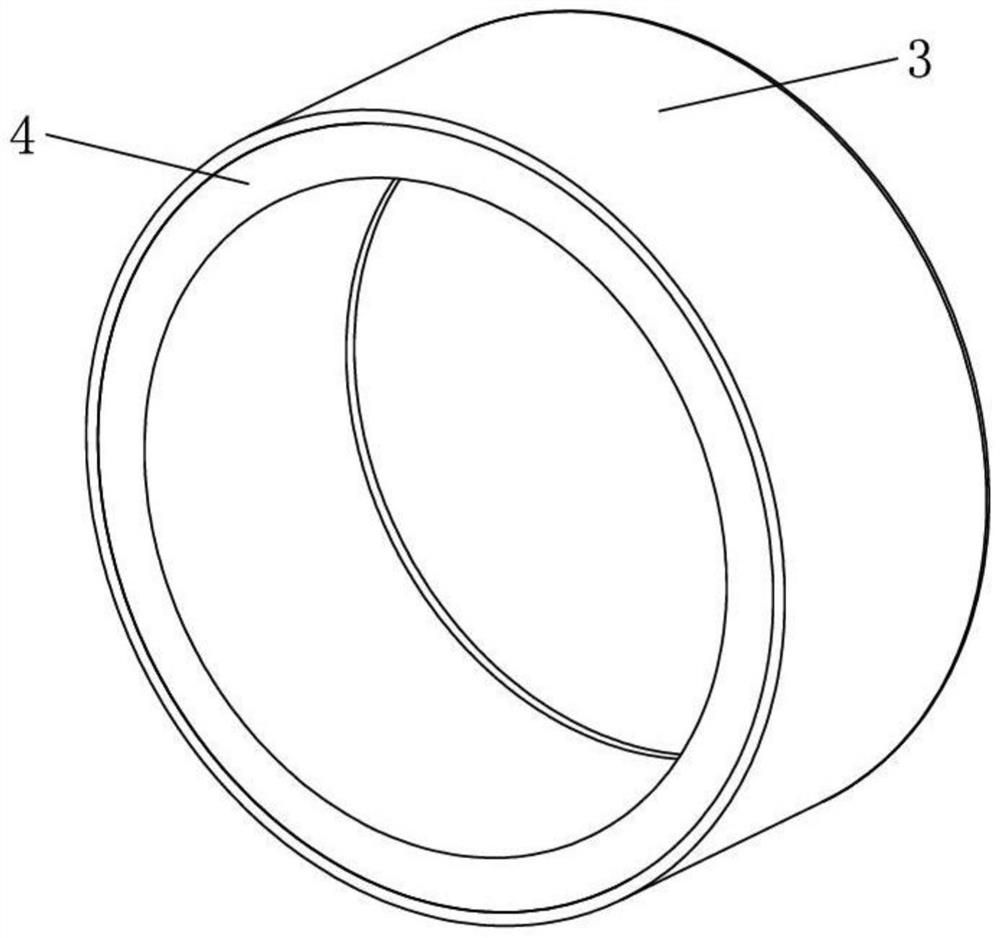

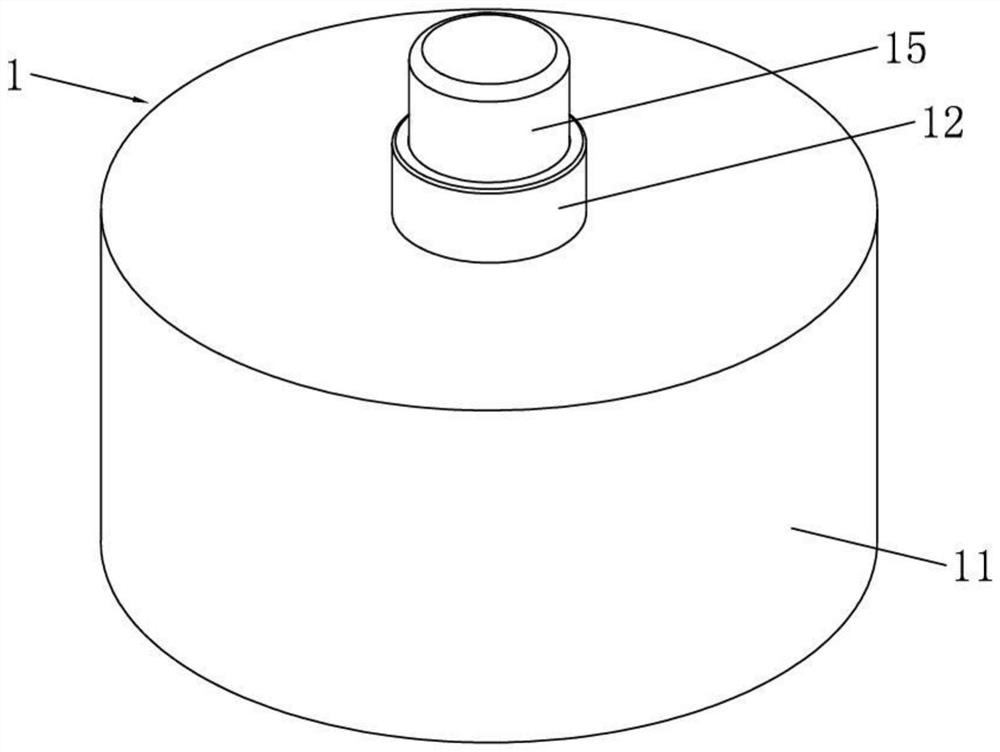

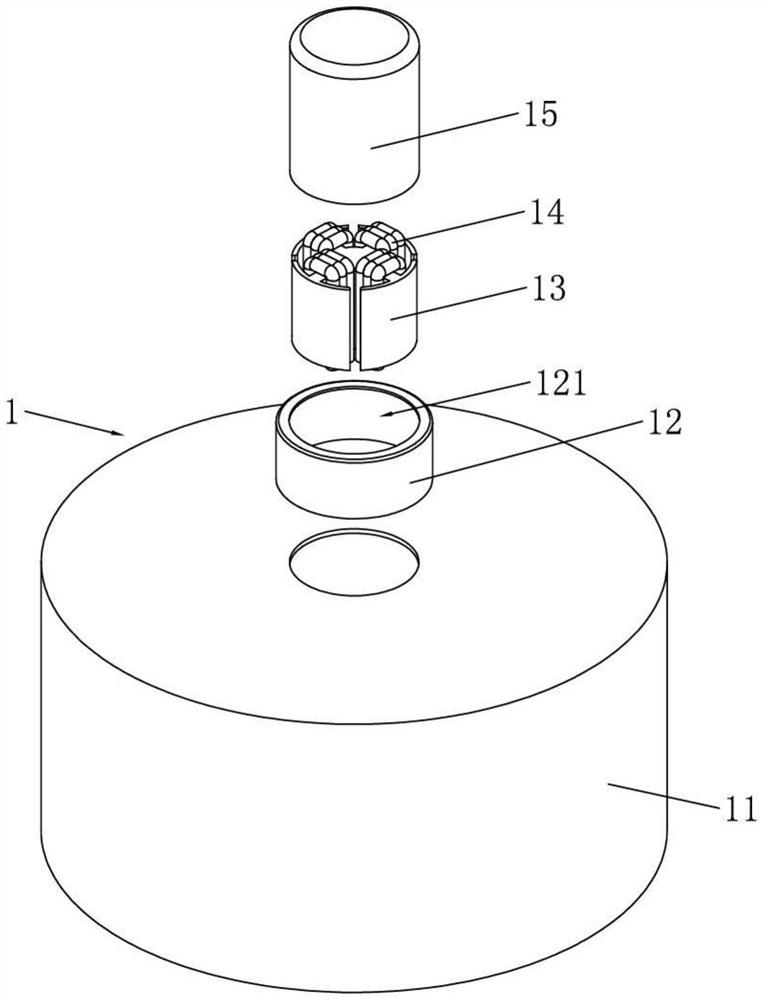

[0040] a. Preparation of triangular waveform charging head 1: as figure 2 and image 3 As shown, the magnetizing head 1 includes a fixed seat 11, a magnetizing assembly installed on the upper end of the fixed seat 11, the magnetizing assembly includes a fixed sleeve 12 installed in the middle of the upper surface of the fixed base 11, and the fixed sleeve 12 The core part of the core is provided with an upward-opening sleeve accommodating chamber 121, and the sleeve accommodating chamber 121 of the fixed sleeve 12 is embedded with a magnetically conductive steel winding frame 13, and the magnetically conductive steel winding frame 13 is wound with a coil Winding 14; the upper end of the fixed sleeve 12 is provided with an insulating adhesive layer 15 for covering the mag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com