Multi-roll-core structure of lithium battery and assembly method of multi-roll-core structure

A lithium battery, winding core technology, applied in secondary batteries, structural parts, battery pack components, etc., can solve problems such as short circuit of lithium batteries, and achieve the effect of avoiding short circuit, improving process adaptability, and avoiding the risk of short circuit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

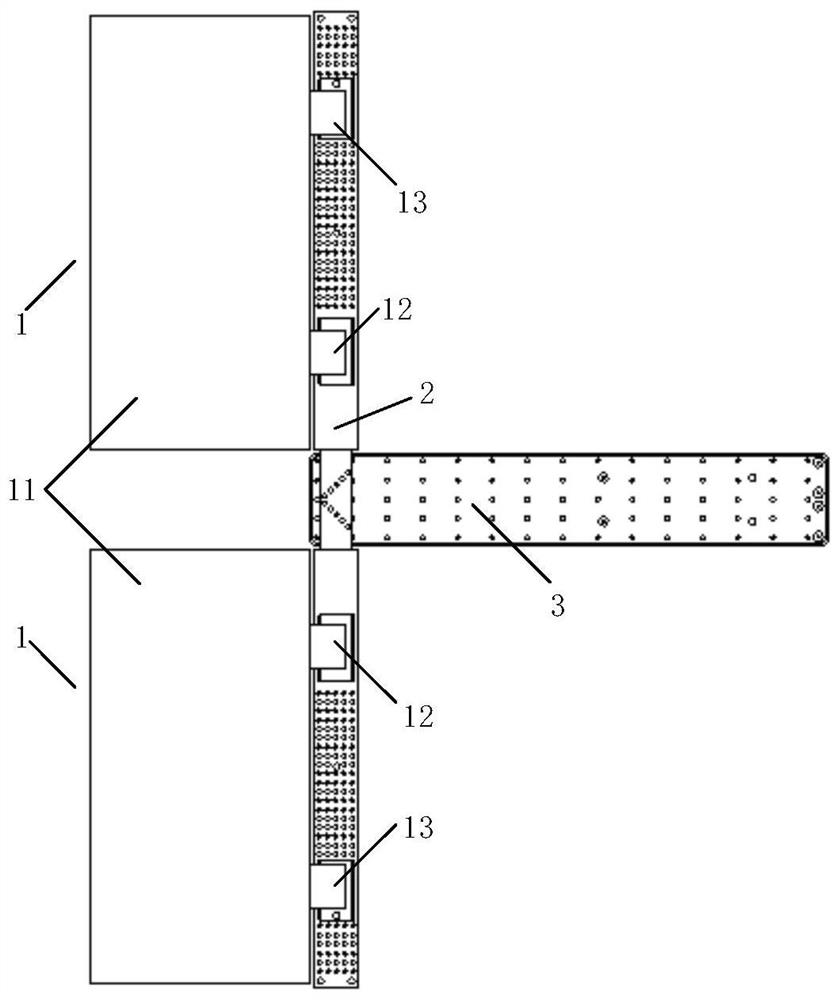

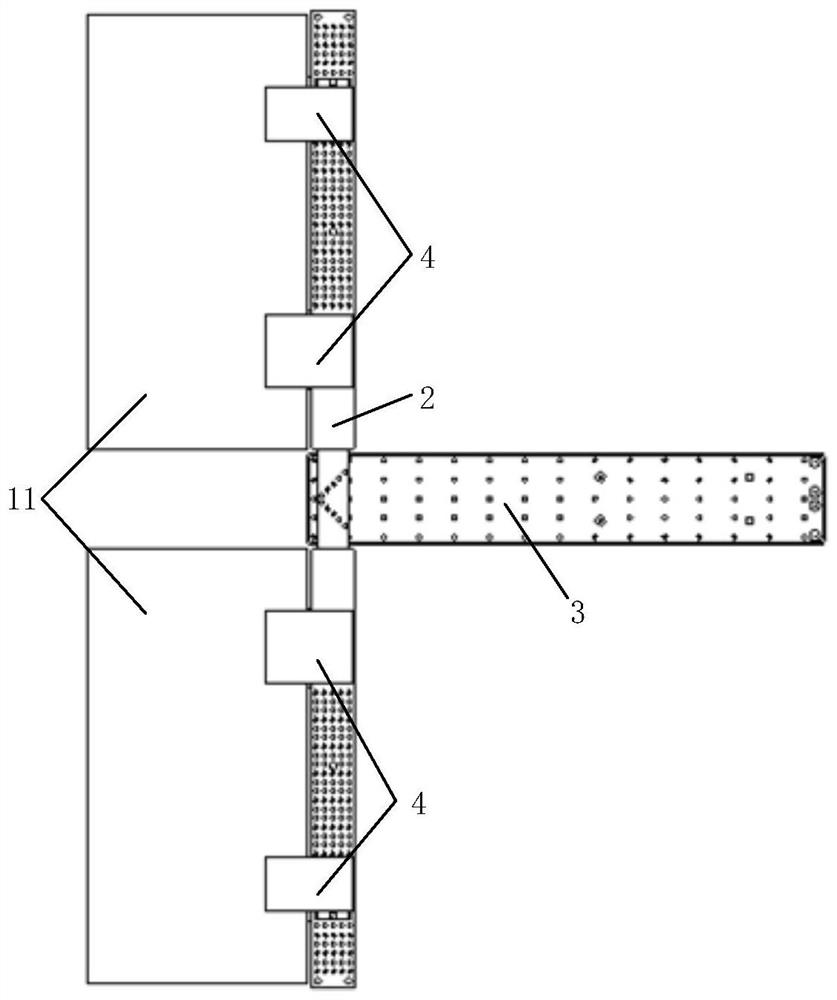

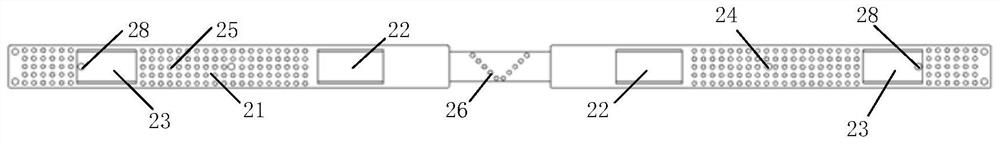

[0093] refer to figure 1 with figure 2 , a lithium battery multi-core structure disclosed in the present invention comprises two core assemblies 1, a connection assembly 2, a cover plate assembly 3, an insulating tape 4 and an aluminum shell (not shown); the core assembly 1 is connected to The component 2 is fixed, the connecting component 2 and the cover component 3 are fixed, the insulating tape 4 is wrapped on the joint between the core component 1 and the connecting component 2, the core component 1, the connecting component 2 and the cover component 3 are fixed and combined and inserted Inside the aluminum shell, the cover assembly 3 is fixed to the aluminum shell.

[0094] refer to figure 1 , the winding core assembly 1 includes a winding core body 11 and a pole lug, and the pole lug includes a positive pole lug 12 and a negative pole lug 13; the positive pole lug 12 and the negative pole lug 13 are respectively fixed on the two ends of the same end face of the windin...

Embodiment 2

[0110] refer to Figure 15 with Figure 16 , the same as the first embodiment, the difference is that the number of winding core assemblies 1 in this embodiment is three, one of the two connecting plates 21 of the connecting assembly 2 is welded and fixed with two winding core assemblies 1, and the other is welded and fixed There is a winding core assembly 1 .

[0111] The assembly method of a multi-roll core structure of a lithium battery disclosed in this embodiment is the same as that of Embodiment 1, except for step S2;

[0112] S2: Install the winding core assembly 1 on the connection assembly 2, one of the two connection plates 21 of the connection assembly 2 is welded and fixed with two winding core assemblies 1, and the other is welded and fixed with one winding core assembly 1, and the winding core assembly 1 The positive tab 12 on the top is welded and fixed to the positive connecting piece 22 on the connection assembly 2, and the negative tab 13 is welded and fixe...

Embodiment 3

[0114] refer to Figure 17 with Figure 18 , the same as the first embodiment, except that the number of winding core assemblies 1 in this embodiment is four, and the two connecting plates 21 of the connecting assembly 2 are respectively welded and fixed with two winding core assemblies 1 .

[0115] The assembly method of a multi-roll core structure of a lithium battery disclosed in this embodiment is the same as that of Embodiment 1, except for step S2;

[0116] S2: Install the winding core assembly 1 on the connecting assembly 2, the two connecting plates 21 of the connecting assembly 2 are respectively welded and fixed with two winding core assemblies 1, the positive pole lug 12 on the winding core assembly 1 and the positive pole on the connecting assembly 2 The connecting piece 22 is welded and fixed, and the negative electrode ear 13 and the negative electrode connecting piece 23 are welded and fixed; the insulating tape 4 is pasted on the welding area between the tab a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com