Conveying structure for keyboard middle plate and assembling device with conveying structure

A technology for assembling devices and transmission structures, which is applied in the direction of electrical components, electric switches, circuits, etc., can solve the problems of increasing the workload of operators, affecting assembly efficiency and assembly quality, and achieving the effects of avoiding damage to the shell and good buffering effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

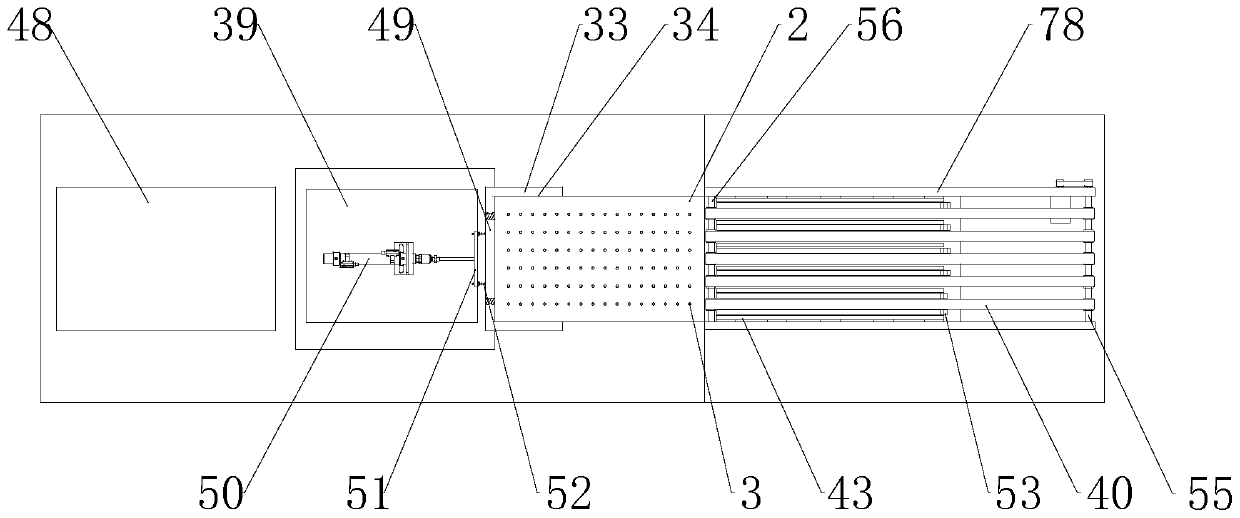

[0083] like Figure 1 to Figure 5 As shown, the transmission structure for the middle board of the keyboard includes a supporting base 1;

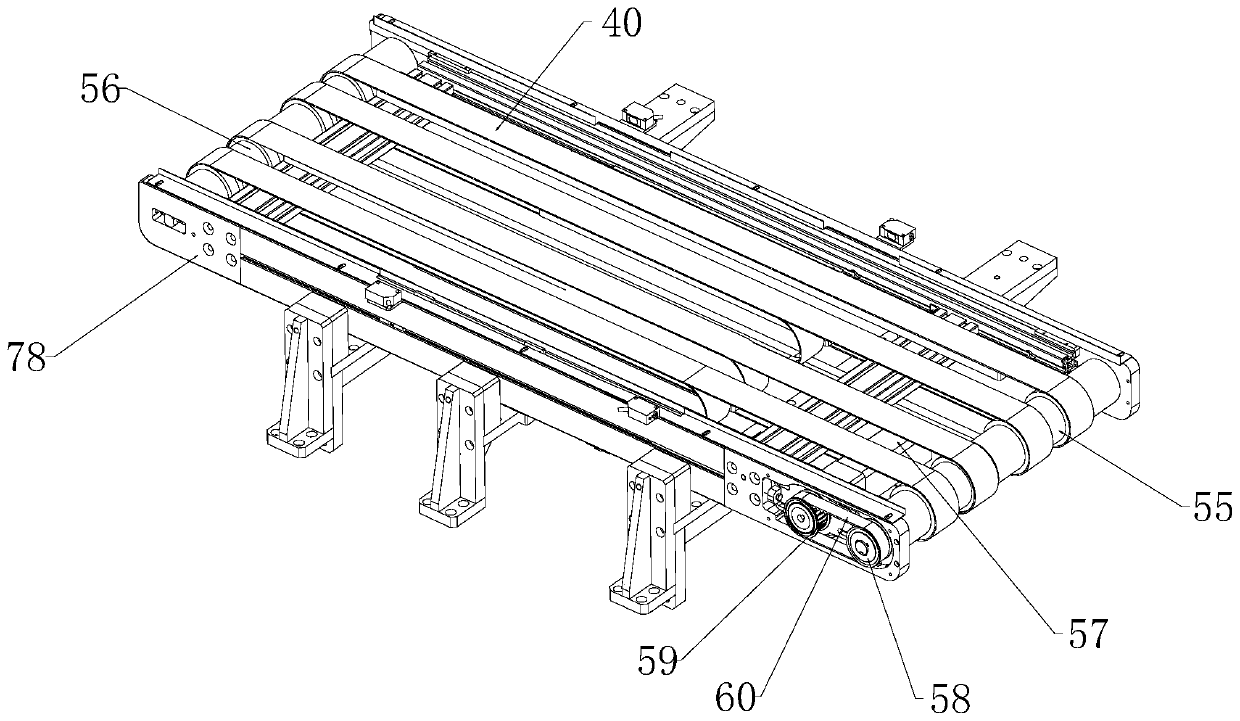

[0084] A middle plate transmission frame 78 is installed on the support base 1, and a plurality of spaced transmission belts 40 are arranged on the middle plate transmission frame 78, and a belt driving device for driving the transmission belt 40 is also installed on the middle plate transmission frame 78;

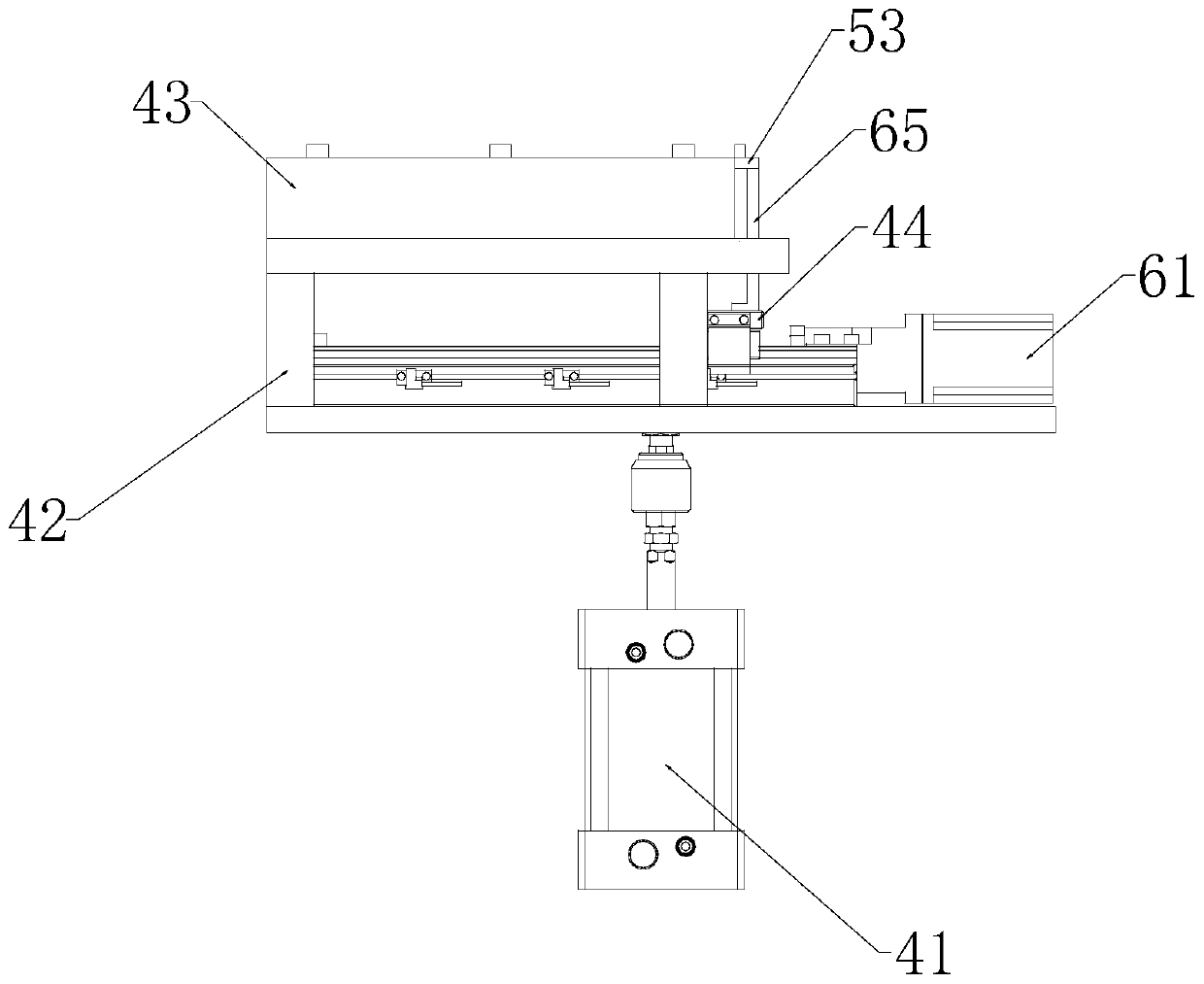

[0085] The supporting base 1 is also equipped with a feeding supporting drive device 41, the output end of the feeding supporting driving device 41 is connected with a feeding support frame 42, and the feeding supporting driving device 41 acts on the feeding supporting frame 42, so that: the feeding support The frame 42 can move up and down relative to the conveyor belt 40;

[0086] The feeding support frame 42 is provided with several feeding support rods 43 arranged in a staggered manner with the conveyor belt 40, and the top of the...

Embodiment 2

[0097] like Figure 1 to Figure 15 A keyboard mid-board assembling device, characterized in that: it includes the transmission structure for the keyboard mid-board as described in any one of Embodiment 1;

[0098] The lower positioning plate 2 located at the output end of the middle plate transmission frame 78 is also installed on the support base 1,

[0099] The lower positioning plate 2 has a lower adsorption cavity, and the top of the lower positioning plate 2 is provided with several lower adsorption holes 3 communicating with the adsorption cavity, and the lower positioning plate 2 is also provided with a lower adsorption connection hole 4 communicating with the adsorption cavity. ;

[0100] An upper positioning drive device is also installed on the support base 1, the output end of the upper positioning drive device is connected with an upper positioning mounting plate 5, and several upper positioning components are arranged on the upper positioning mounting plate 5;

...

Embodiment 3

[0108] This embodiment makes the following further limitations on the basis of Embodiment 2: the inner wall of the movable cylinder 8 is provided with a connecting assembly;

[0109] The connection assembly includes an upper limit ring 13, a lower limit ring 14 located below the upper limit ring 13 and a locking ring 15 between the upper limit ring 13 and the lower limit ring 14, the locking ring 15 can rotate relative to the upper limit ring 13, The middle part of the lower limit ring 14 has an insertion opening 16, and the middle part of the locking ring 15 has a locking opening 17 with a non-circular section;

[0110] A rotating bar-shaped opening 19 is provided on the side wall of the movable cylinder 8, and a locking handle 20 extending through the rotating bar-shaped opening 19 and capable of moving relative to the rotating bar-shaped opening 19 is extended on the locking ring 15;

[0111] The outer surface of the upper end of the upper adsorption member 11 is provided w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com