Transmission chain for use in engine

A technology of transmission chain and engine, applied in the direction of transmission chain, engine element, machine/engine, etc., can solve chain breakage, fatigue failure of chain tensile force, damage to the durability of inner link plate 510 and outer link plate 550, etc. problem, to reduce friction and improve durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0034] Hereinafter, an engine transmission chain 100 as a first embodiment of the present invention will be described based on the drawings.

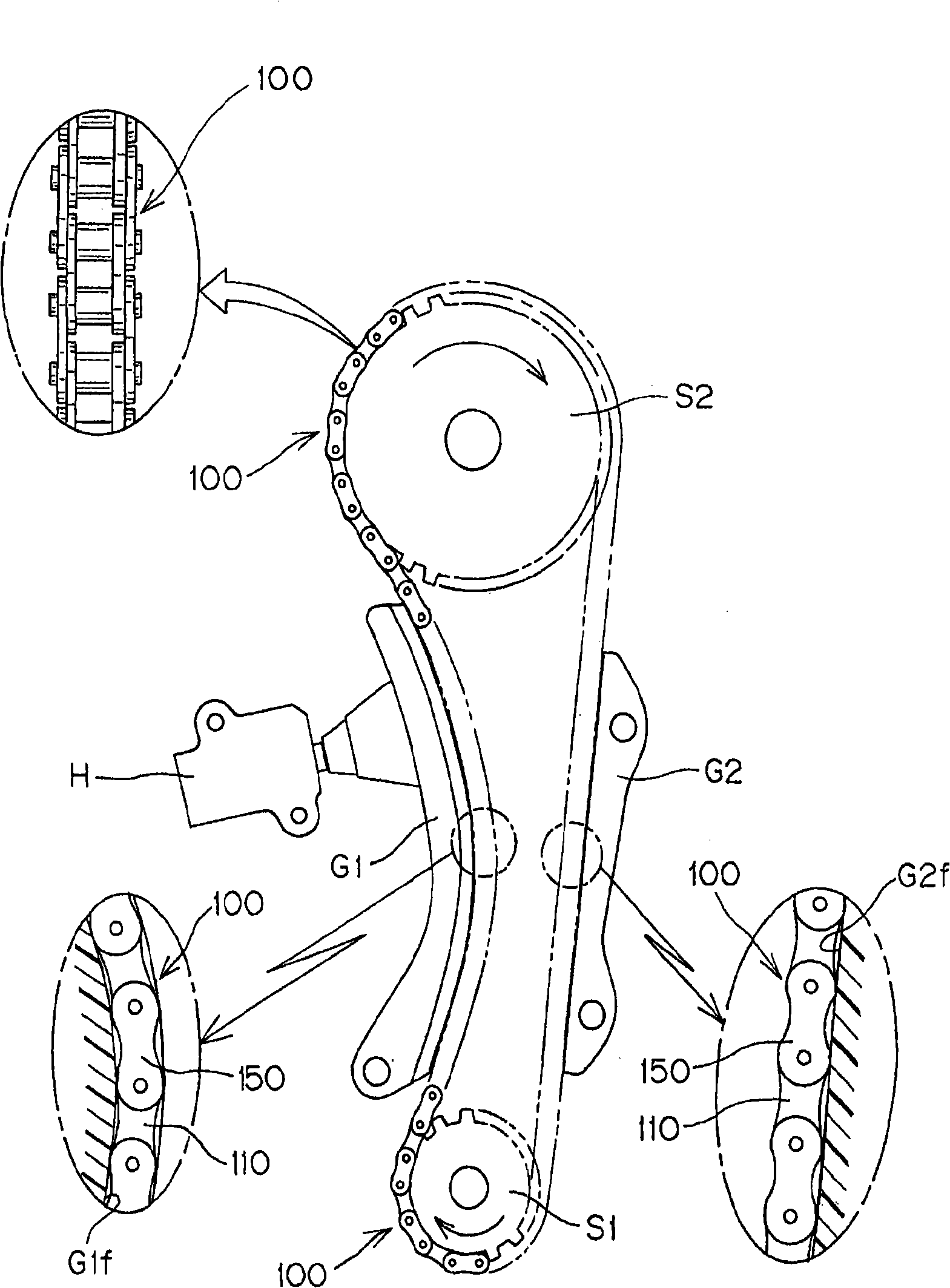

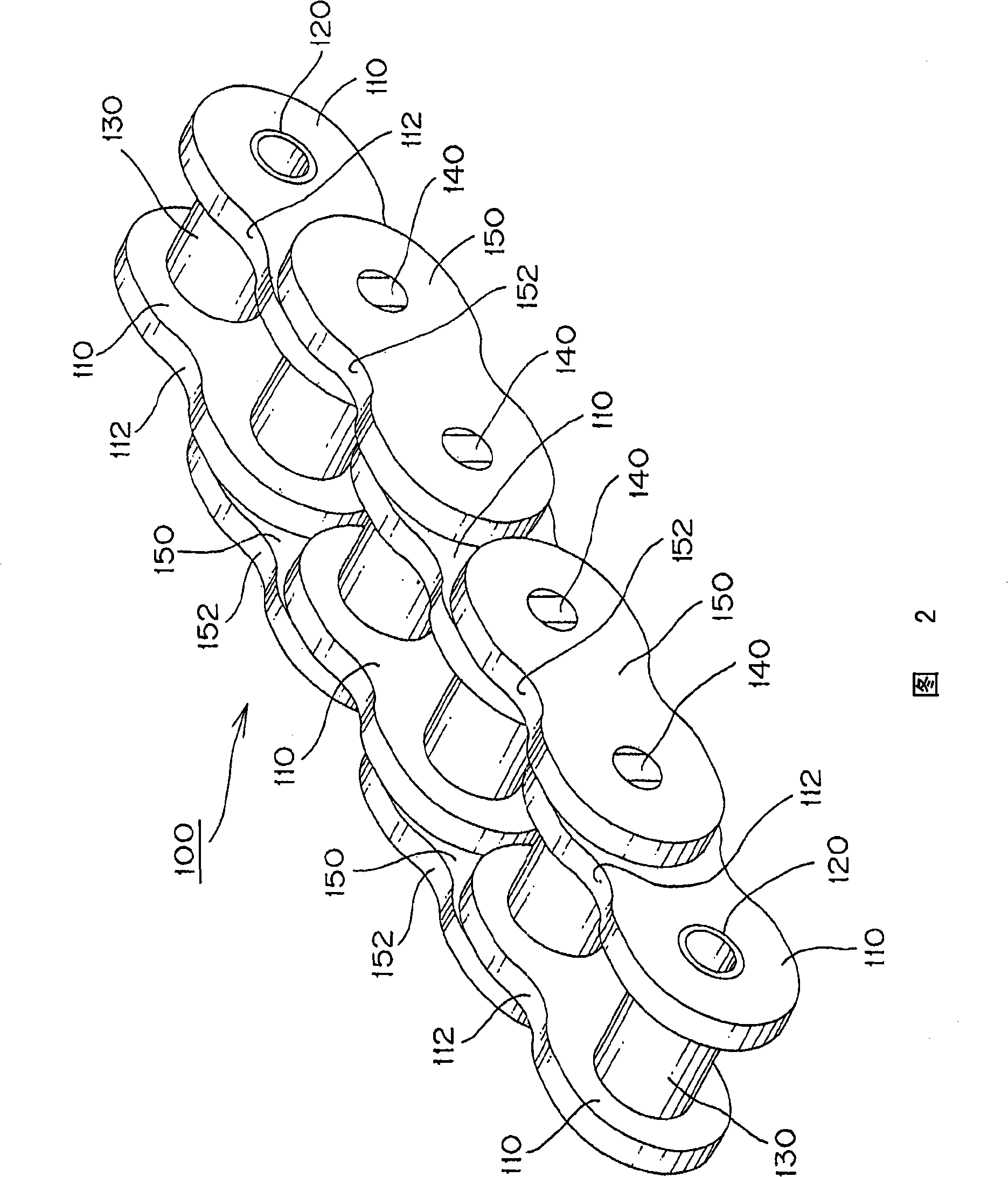

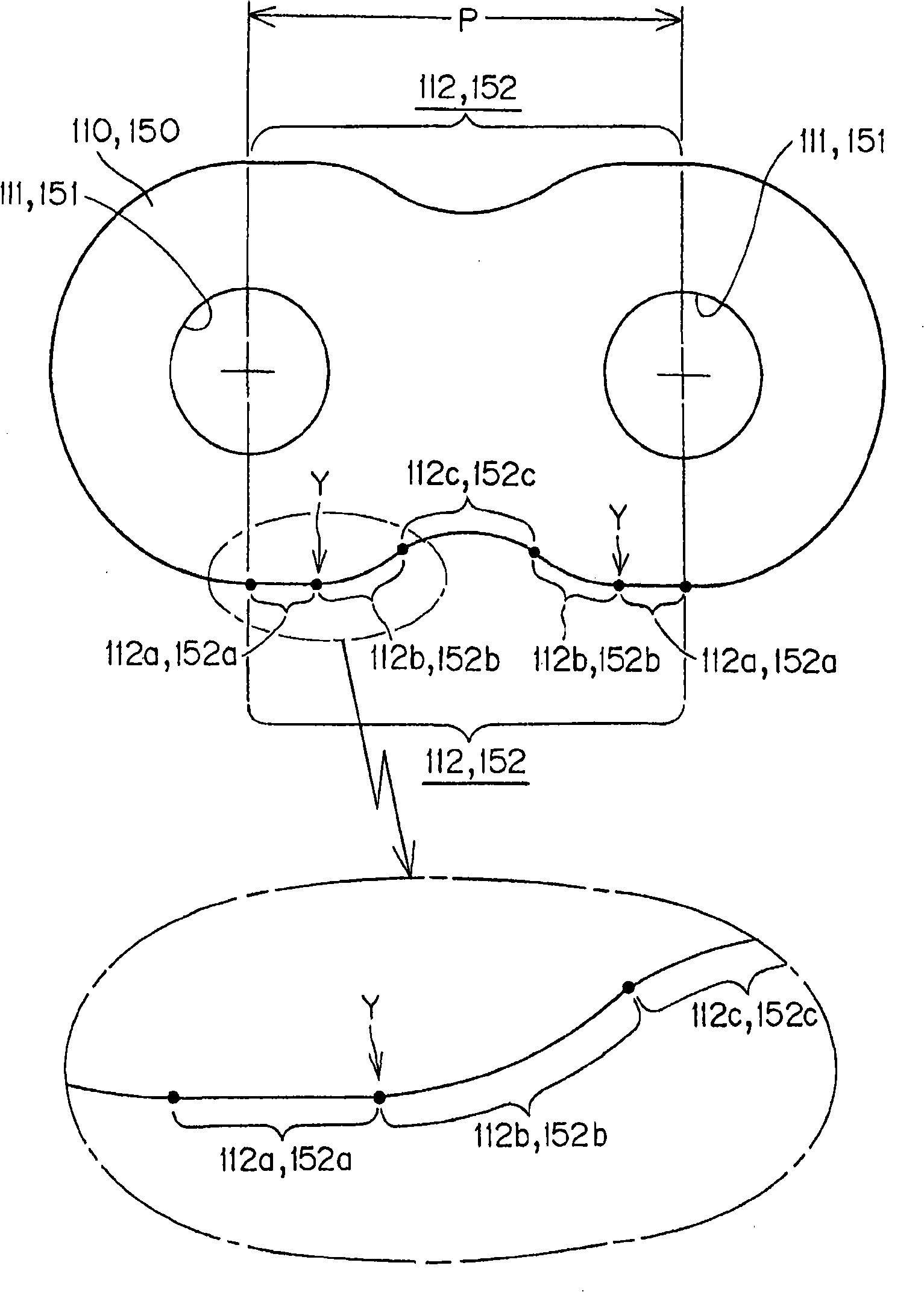

[0035] here, figure 1 It is a use state diagram using the power transmission chain for the engine as the first embodiment of the present invention, and Fig. 2 is figure 1 The partial perspective view of the transmission chain for the engine shown, image 3 is a side view showing an inner panel and an outer panel, Figure 4 is a plan view showing the state of sliding contact with the flat guide surface of the chain guide, Figure 5 is a plan view showing the state of sliding contact with the raised curved guide surface of the chain guide, Image 6 It is an explanatory view showing the state of sinking of the plate into the raised curved guide surface of the chain guide.

[0036] First of all, the engine drive chain 100 as the first embodiment of the present invention is a timing drive chain used in a timing drive system in an autom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com