Vertical gasket taking whole machine robot

A robot and gasket technology, applied in the field of parts assembly, can solve the problems of affecting the NVH effect of the engine, the stability of the gasket is not long enough, and the gasket cannot be placed directly, and achieves a simple structure, long-lasting stability, and guaranteed surface quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, and the implementation scope of the present invention is not limited thereto.

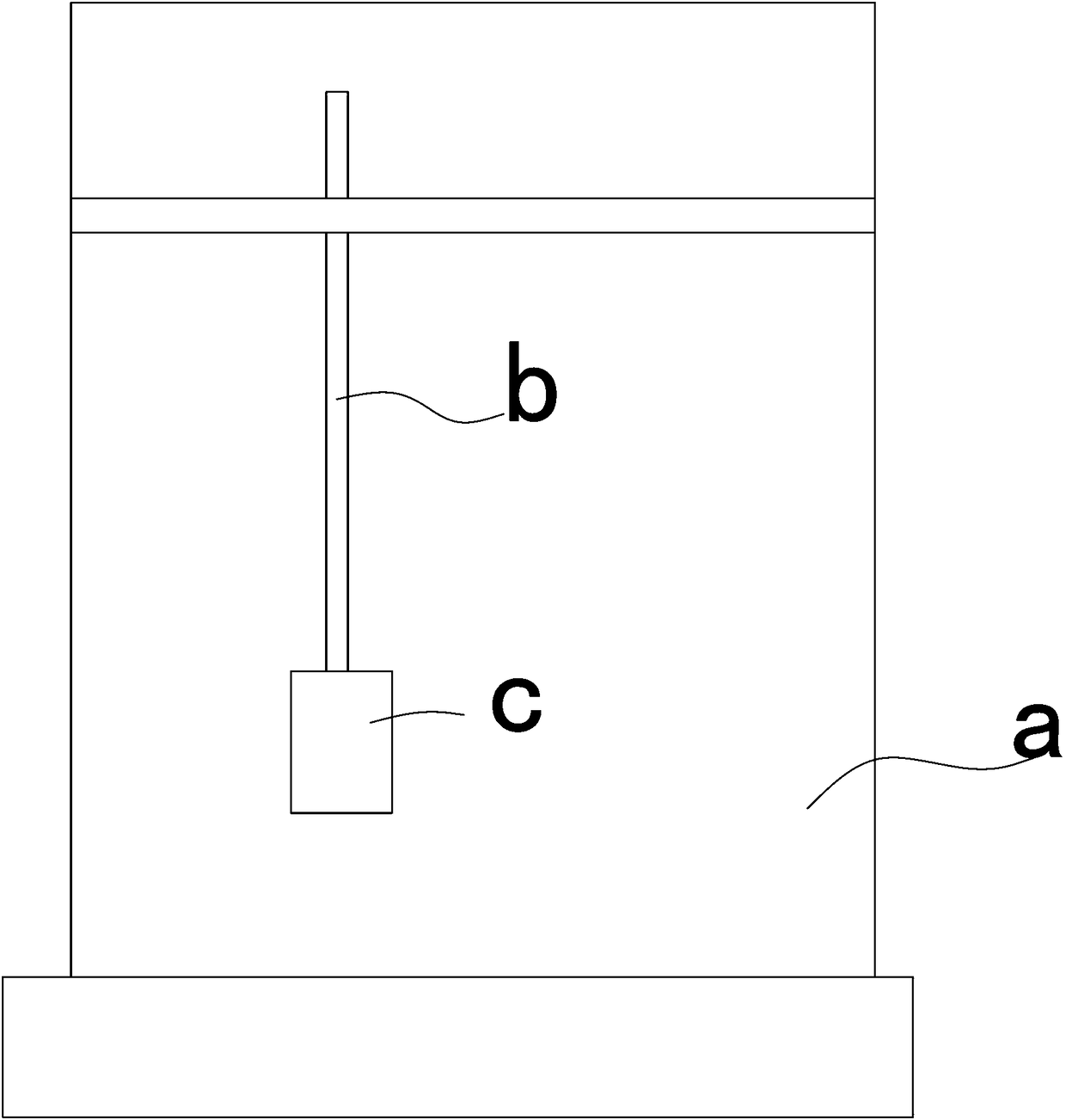

[0022] Such as Figure 1 to Figure 8 As shown, a kind of vertical belt gasket described in this embodiment takes the whole machine robot,

[0023] It includes a workbench a, on which a moving arm b that can move along the X-axis and Y-axis in a vertical plane is provided, and a pick-up mechanism c is provided at the free end of the moving arm.

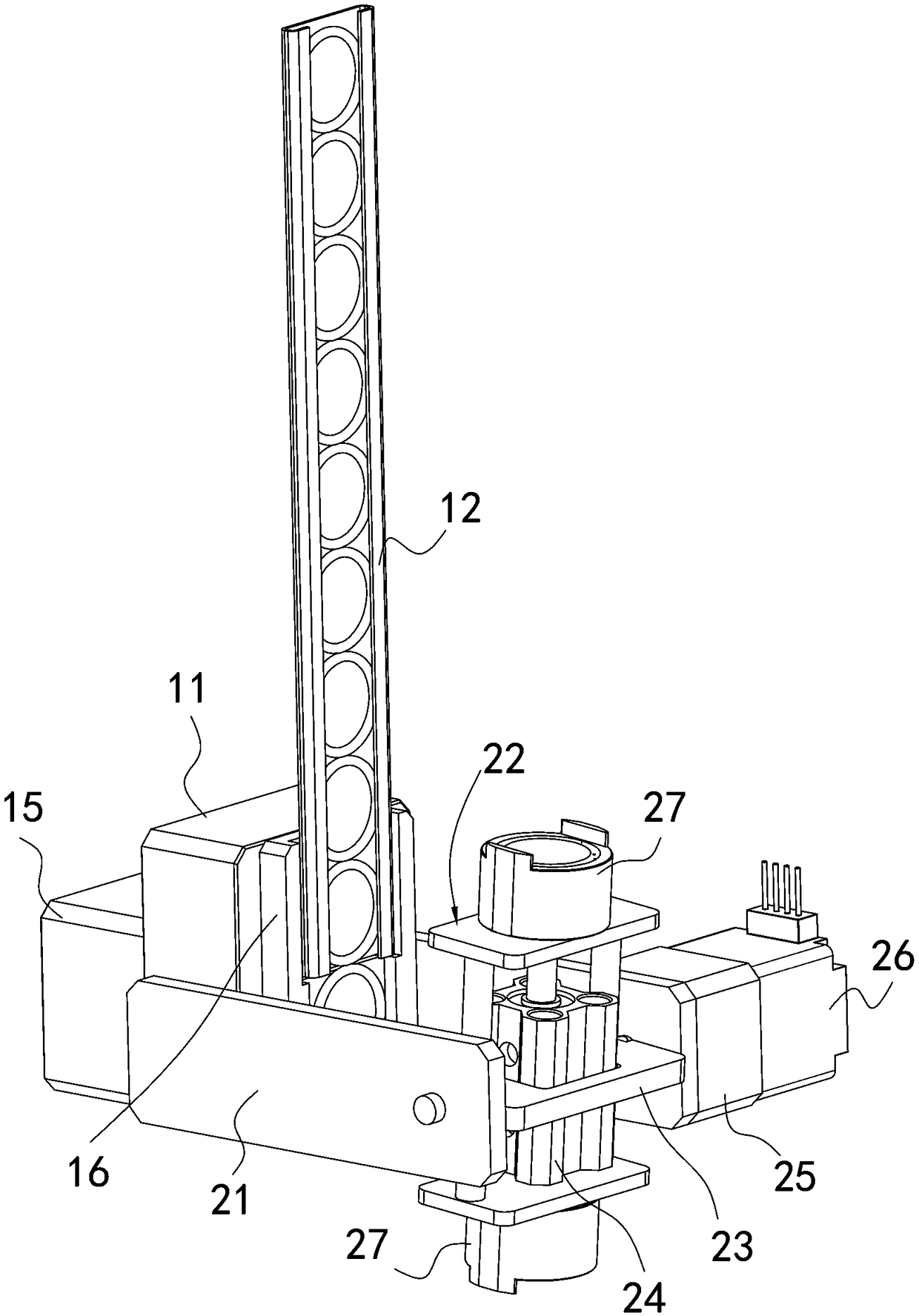

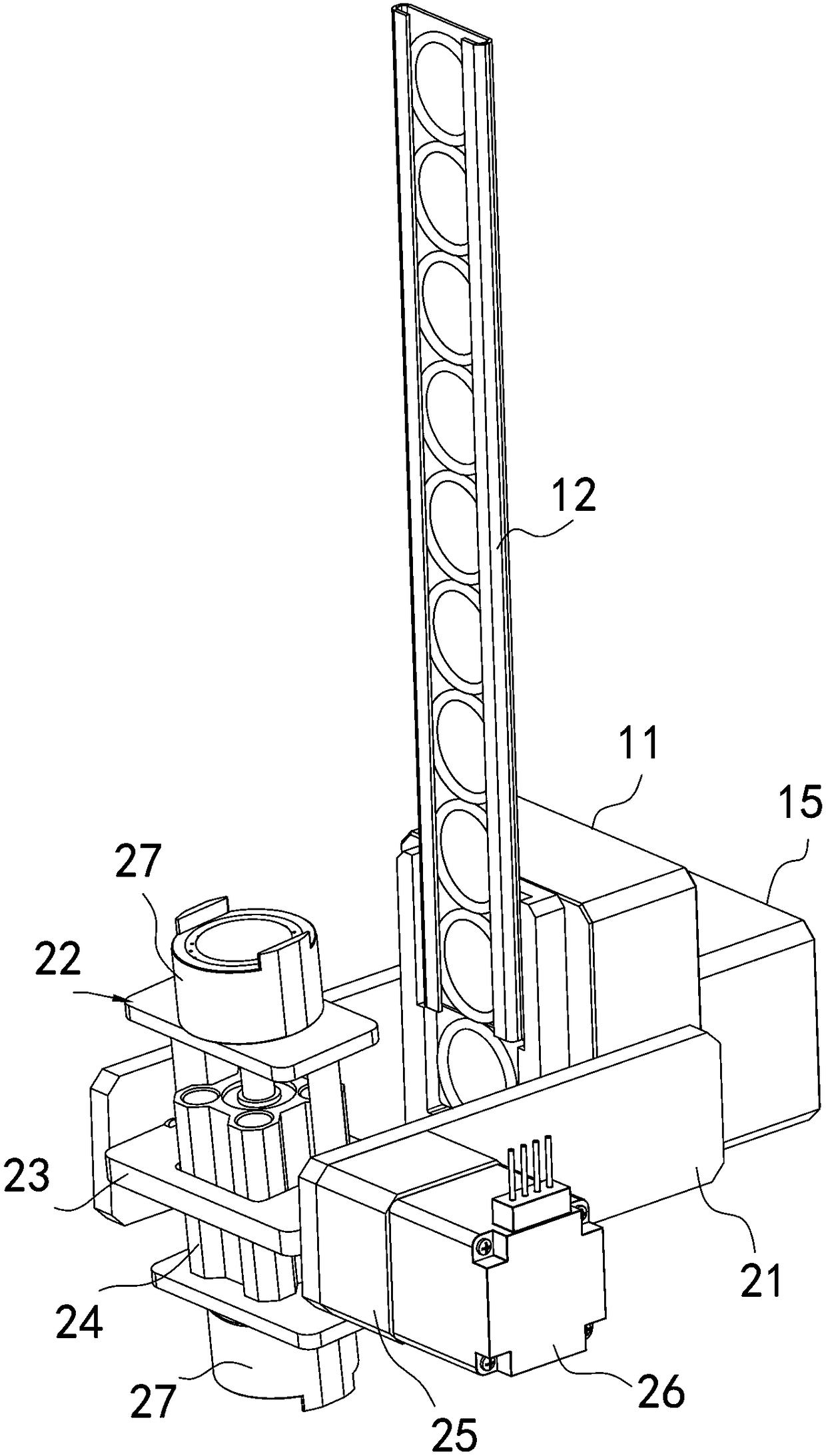

[0024] The taking mechanism c includes a feeding assembly and a rotating discharging mechanism, and the rotating discharging mechanism is connected with the feeding assembly;

[0025] The feeding assembly includes a fixed block 11, a feeding chute 12, a sliding ejector block 13, a return spring 14 and a spring cover 15, the fixed block 11 is provided with a first square hole, and the sliding ejector block 13 is loca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com