Elastic screwing mechanism in full-automatic assembly system for adjusting pin of cupboard

An assembly system and a technology for adjusting feet, which is applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve problems such as motion error, manufacturing error, and positioning error, and achieve the effect of strong flexibility and stable and consistent assembly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

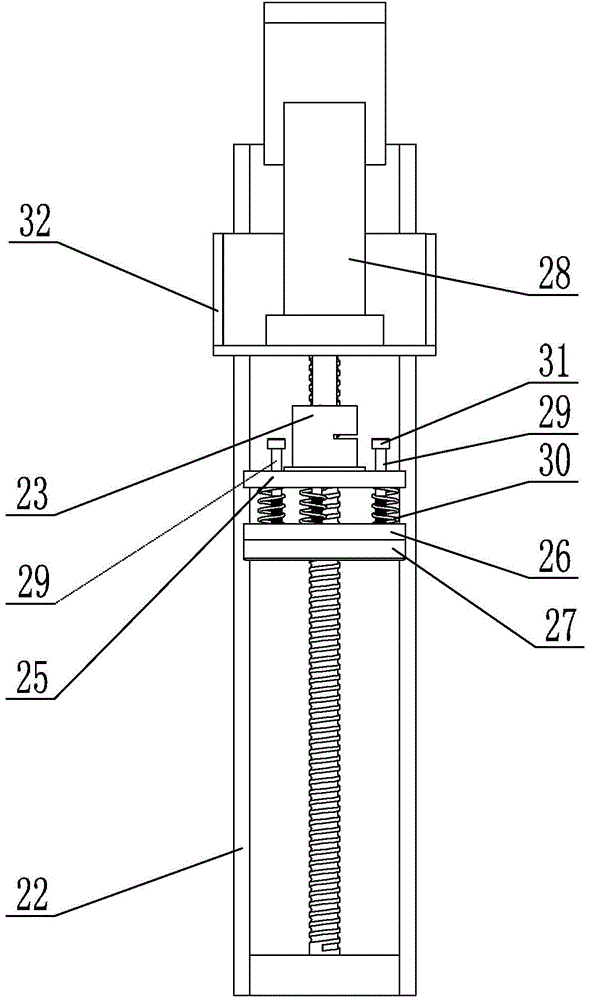

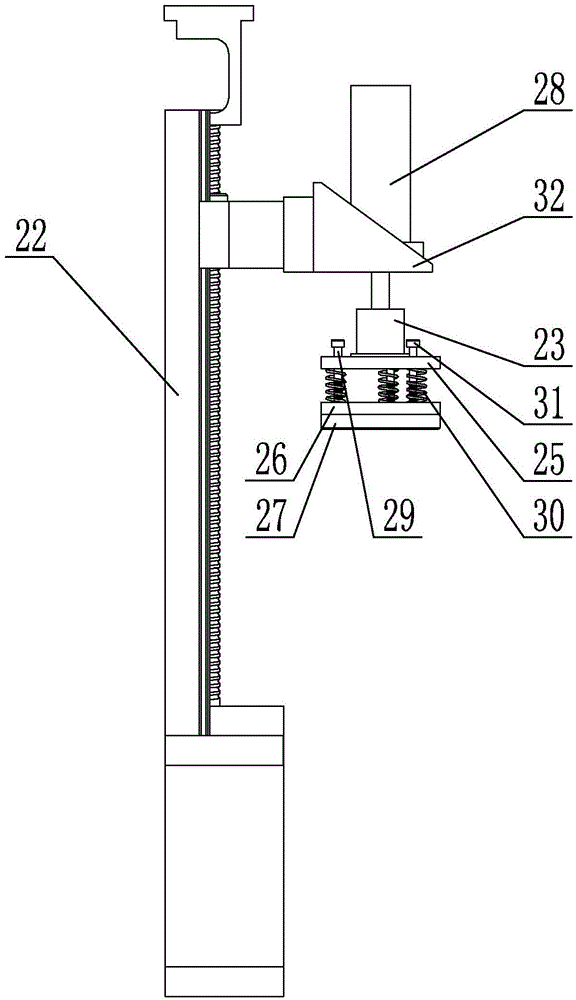

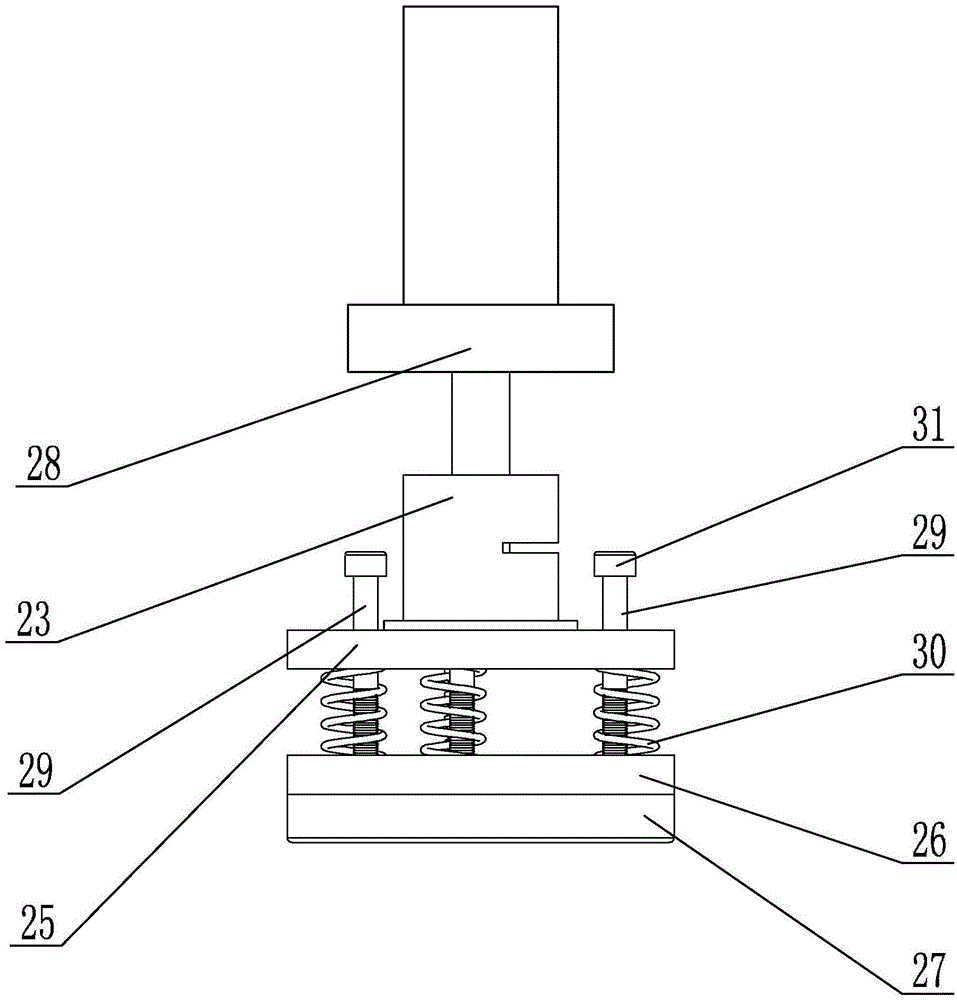

[0009] Specific implementation mode one: combine figure 1 , figure 2 and image 3 Describe this embodiment, the elastic screwing mechanism in the fully automatic assembly system for cabinet adjustment feet described in this embodiment includes a linear slide 22, a coupling 23, a screw cover upper cover body 25, a screw cover lower cover Body 26, buffer pad 27, motor 28, a plurality of guide posts 29 and a plurality of springs 30, the linear slide table 22 is vertically arranged, and one side of the moving slider in the described linear slide table 22 is fixedly connected with a motor 28, so The output shaft of the motor 28 passes through the coupling 23 and is fixedly connected with the upper cover body 25 of the screw cover, and the lower cover body 26 of the screw cover is arranged under the upper cover body 25 of the screw cover, and the plurality of guide posts 29 They are all vertically arranged and slidably connected between the upper cover body 25 of the screw cover ...

specific Embodiment approach 2

[0013] Specific implementation mode two: combination figure 1 , figure 2 and image 3 This embodiment is described. In this embodiment, the lower end surface of the screw cap lower body 26 is fixedly bonded with a buffer pad 27 . The buffer pad 27 is connected with the lower surface of the lower cover body 26 of the screw cap by gluing. Components not mentioned in this embodiment are the same in structure and connection relationship as in Embodiment 1.

specific Embodiment approach 3

[0014] Specific implementation mode three: combination figure 1 , figure 2 and image 3 This embodiment will be described. In this embodiment, the buffer pad 27 is a silicone pad. Silicone pads are finished products sold in the market, with low cost. Silicone pads have the characteristics of silicone, with certain tension, flexibility, excellent insulation, pressure resistance, high temperature resistance, low temperature resistance, stable chemical properties, environmental protection and safety, and no peculiar smell. specialty. Components not mentioned in this embodiment are the same in structure and connection relationship as those in Embodiments 1 and 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com