Patents

Literature

47results about How to "Achieving separation of work" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

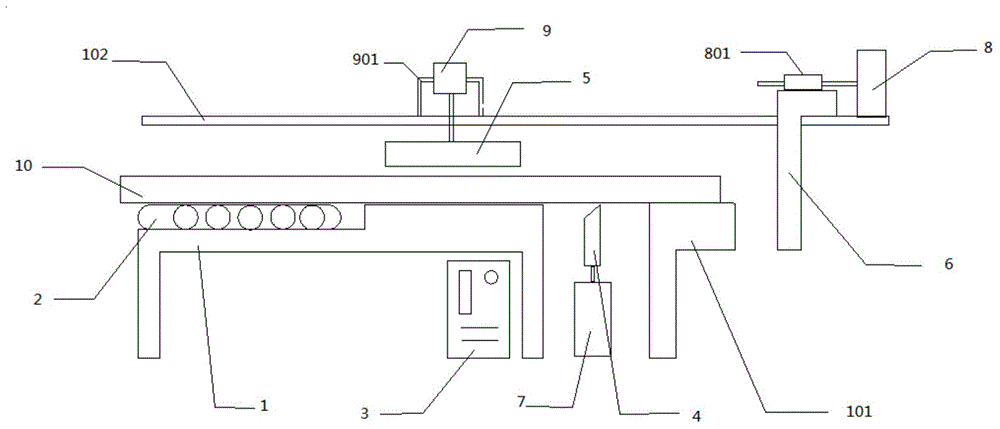

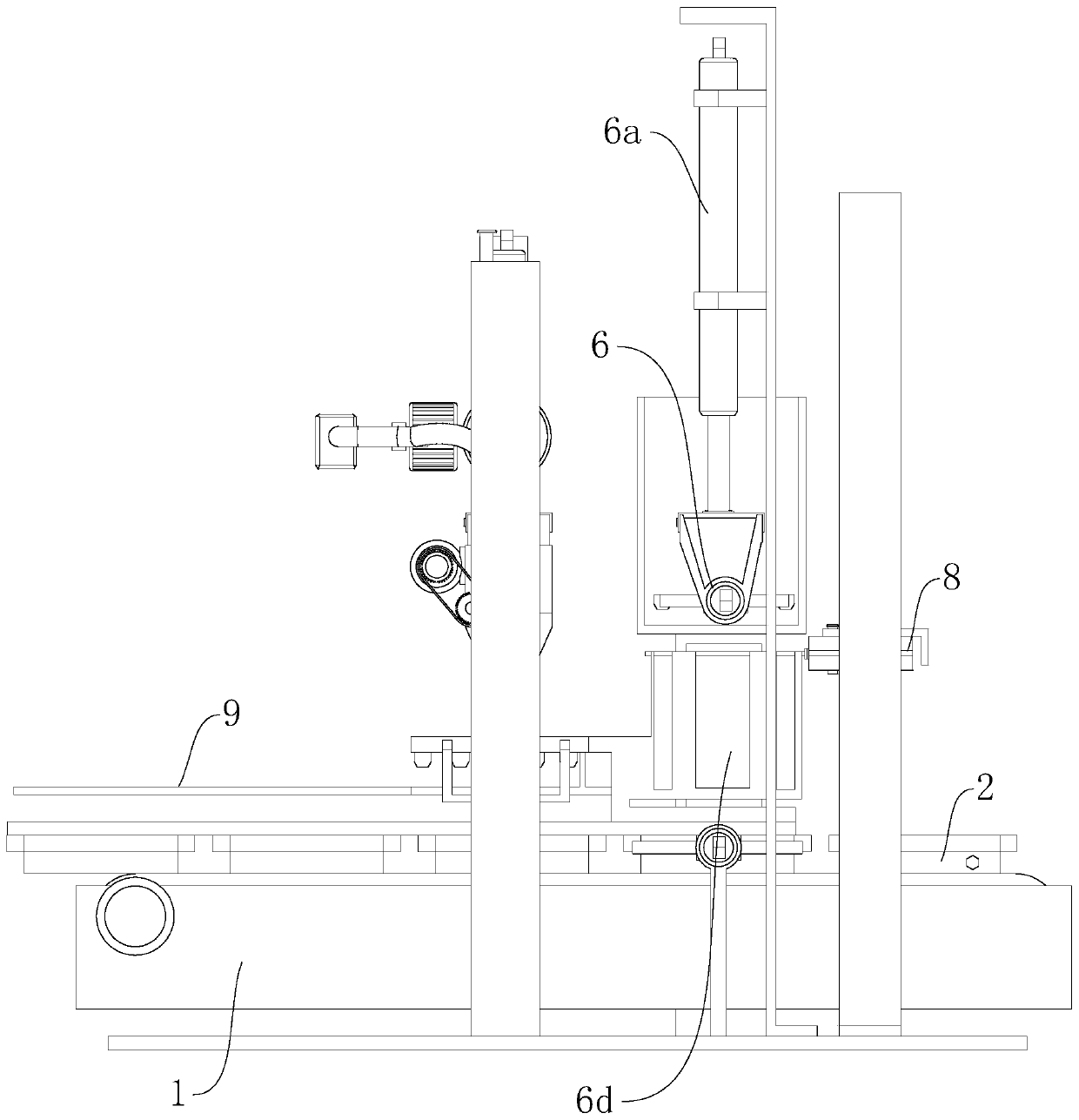

Plate shearing machine

InactiveCN104439486AAchieving separation of workEasy to separateMetal-working feeding devicesShearing machinesControl systemEngineering

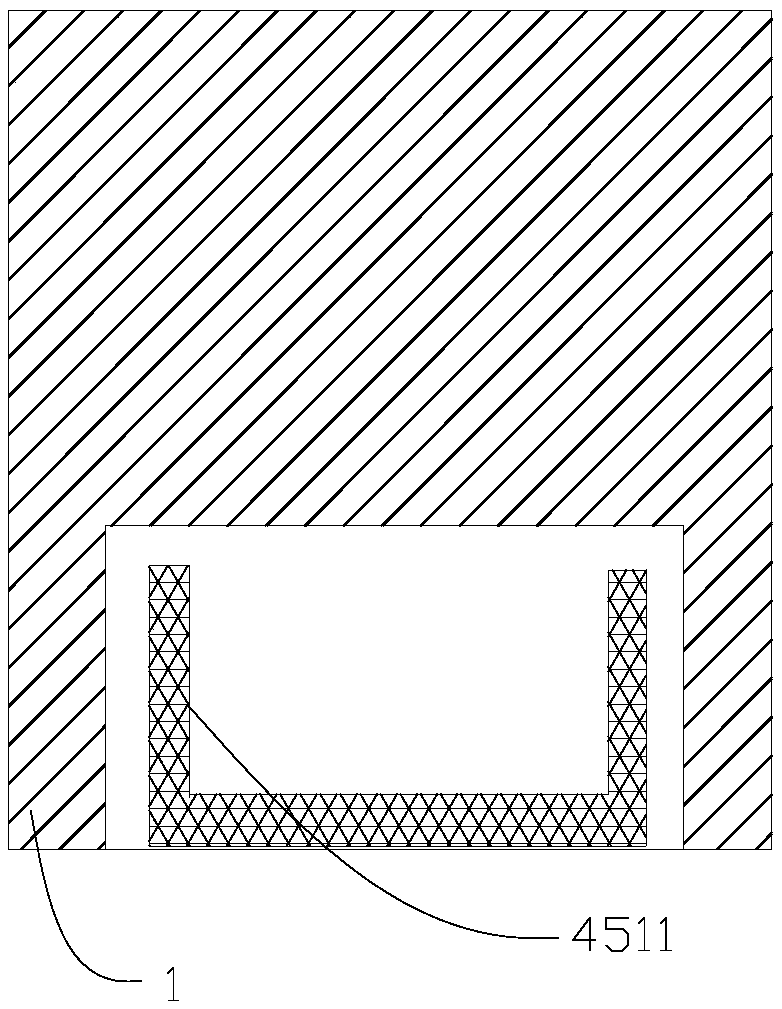

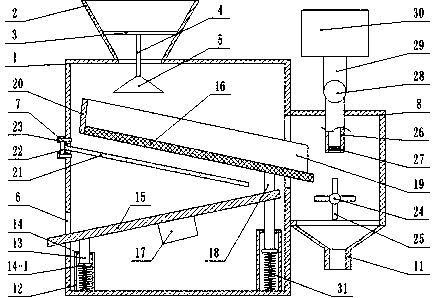

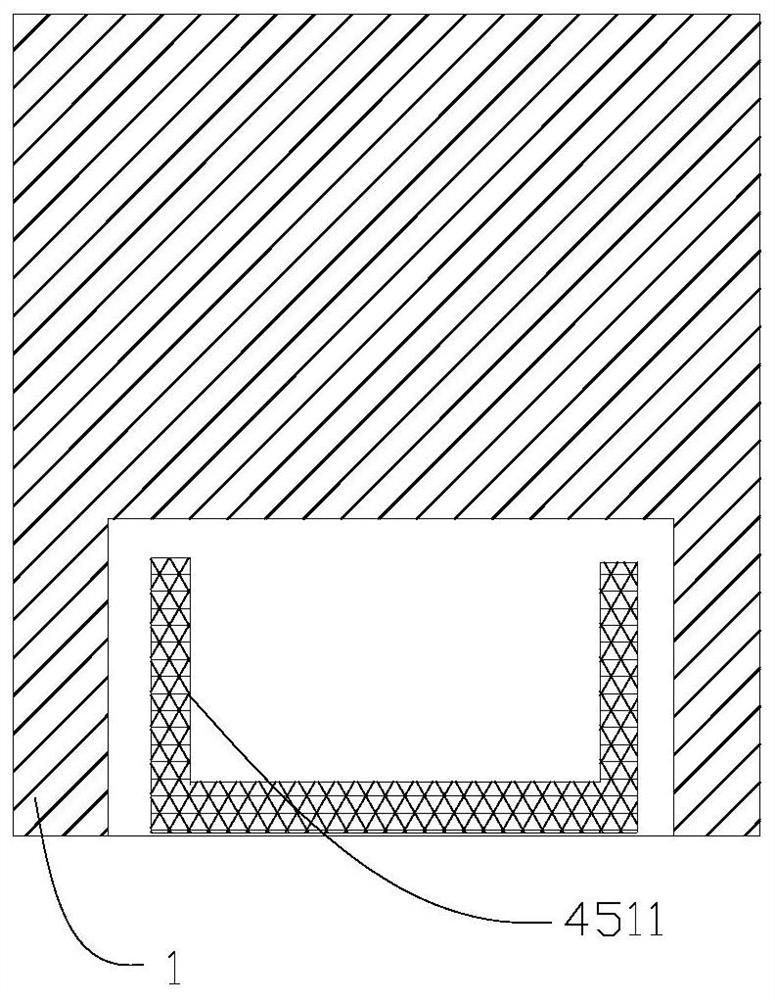

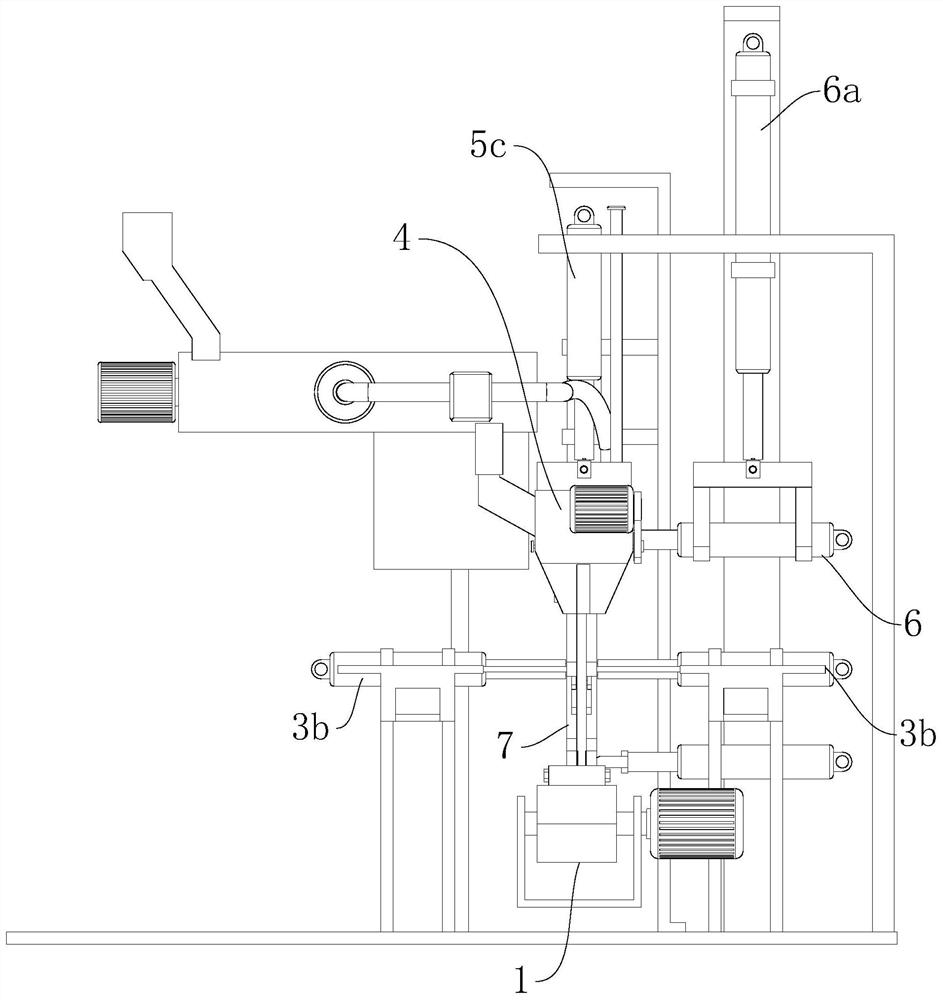

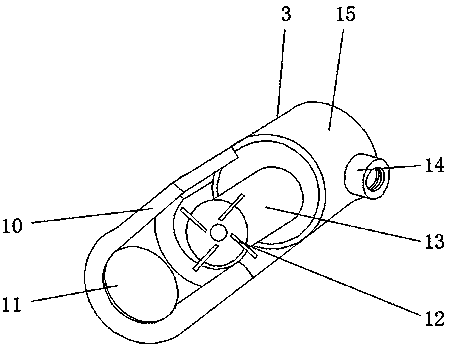

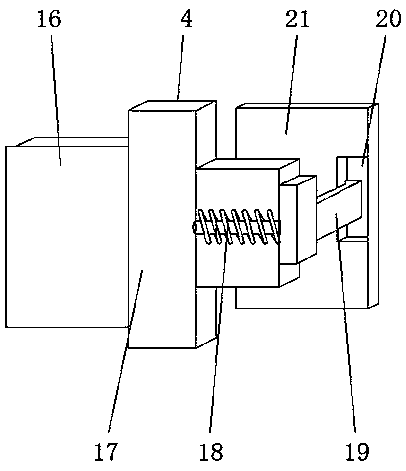

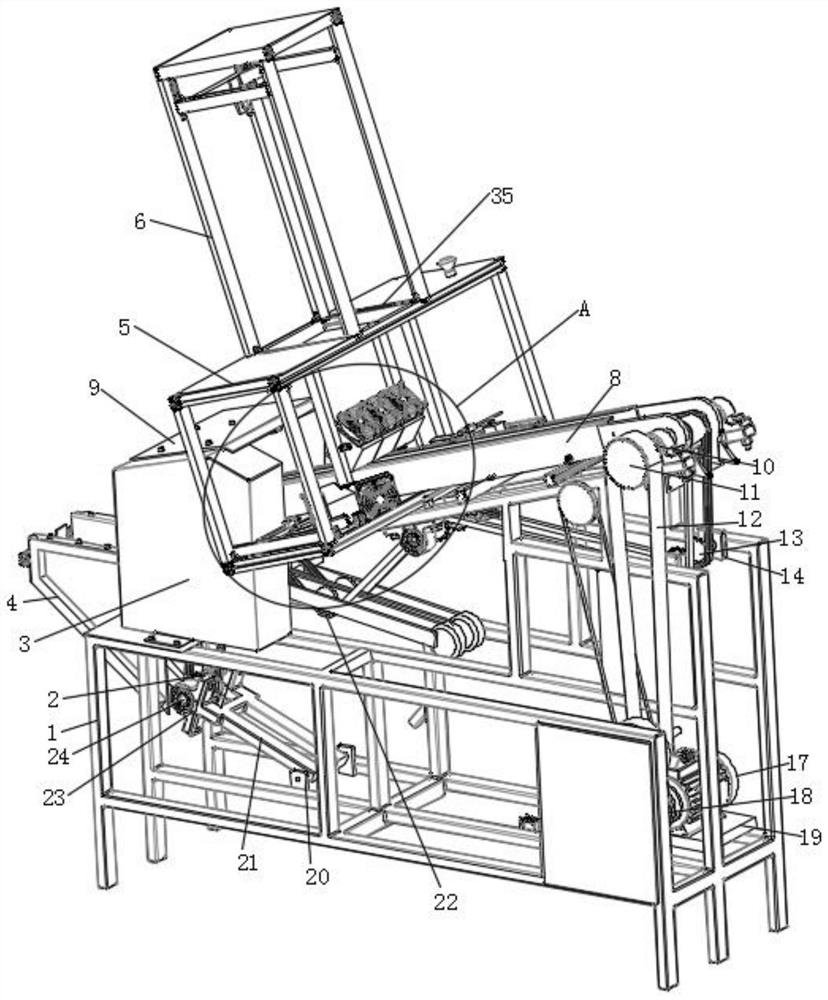

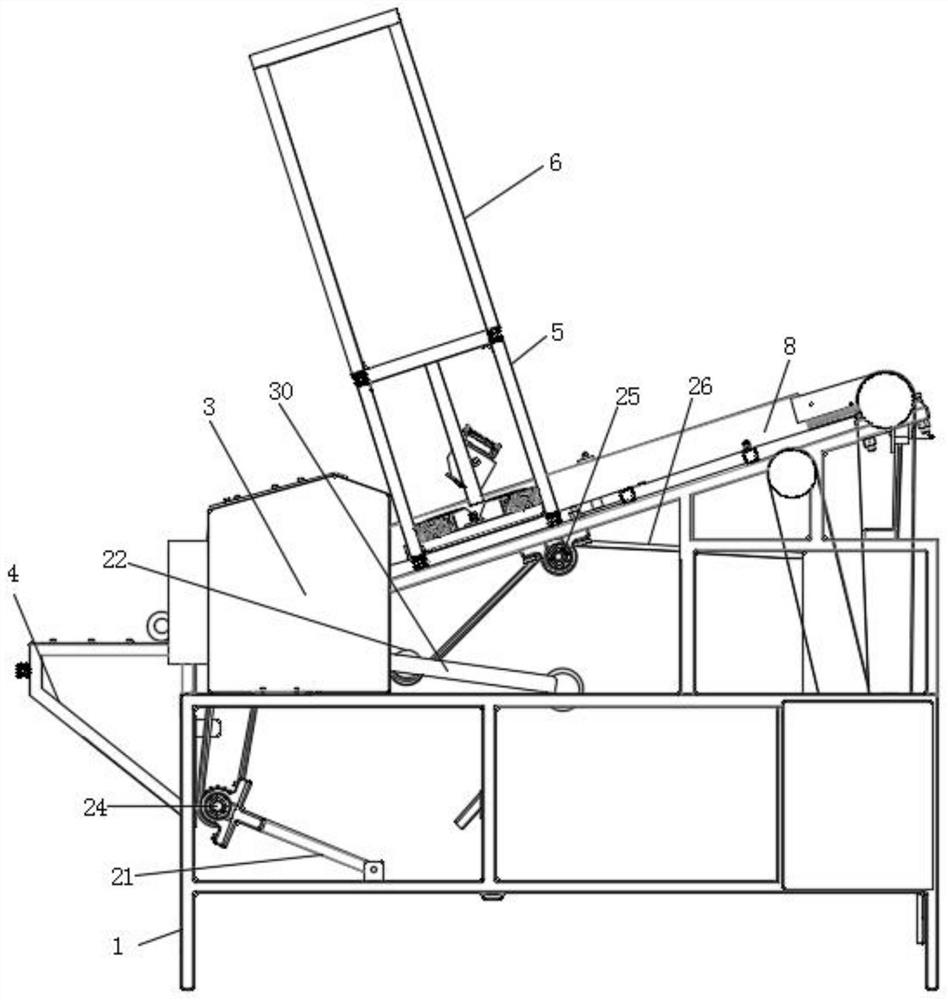

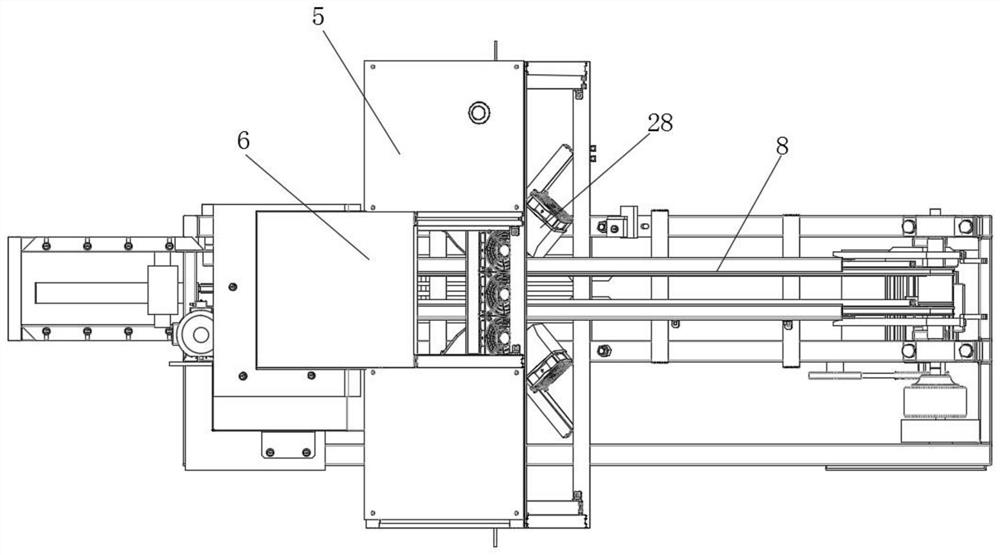

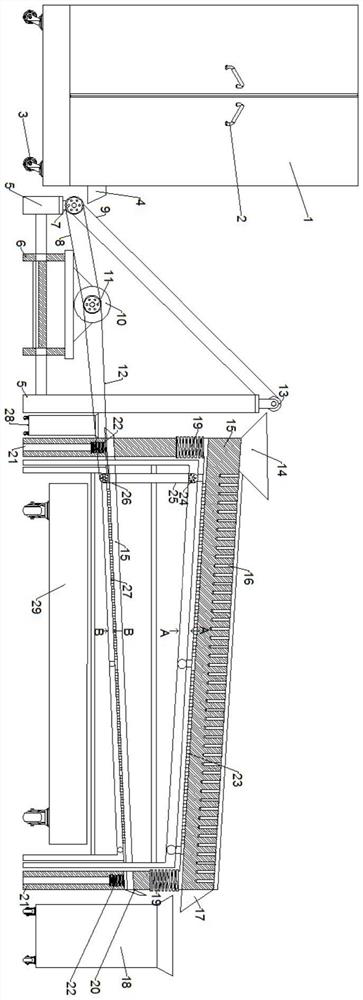

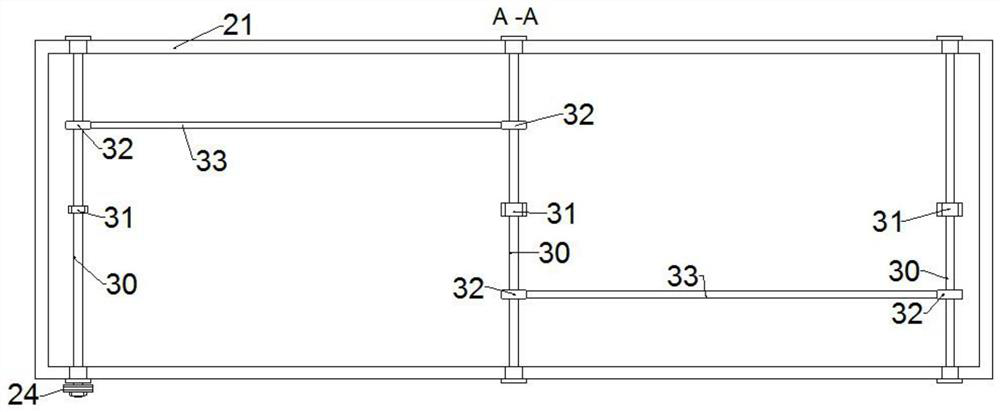

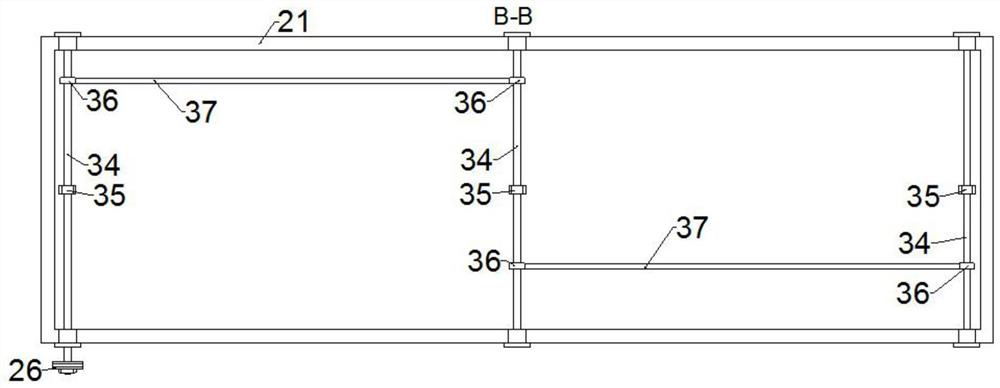

The invention relates to a plate shearing machine. The plate shearing machine comprises a supporting part, a conveying belt, a cutter part, a fixing and pressing system, a crane fixing system and a control cabinet. The conveying belt is arranged on a first support. The cutter part is arranged on the right of the first support and composed of a first hydraulic oil cylinder and a cutter head, and the cutter head can be pushed by the first hydraulic oil cylinder to move. The fixing and pressing system is composed of a second hydraulic oil cylinder and a pressing block and arranged on an upper support, and the pressing block can be pushed by the second hydraulic oil cylinder to move. The crane fixing system comprises a first stepping motor, a crane part and a stopping block and arranged on the upper support. The control cabinet is arranged below the first support. The plate shearing machine can shear metal plates and adjust the shearing length by itself according to the size of the needed metal plates, and controls system operation through the control cabinet. Shearing is convenient and fast, work efficiency is improved, and the production cost is lowered.

Owner:扬州固诚机床有限公司

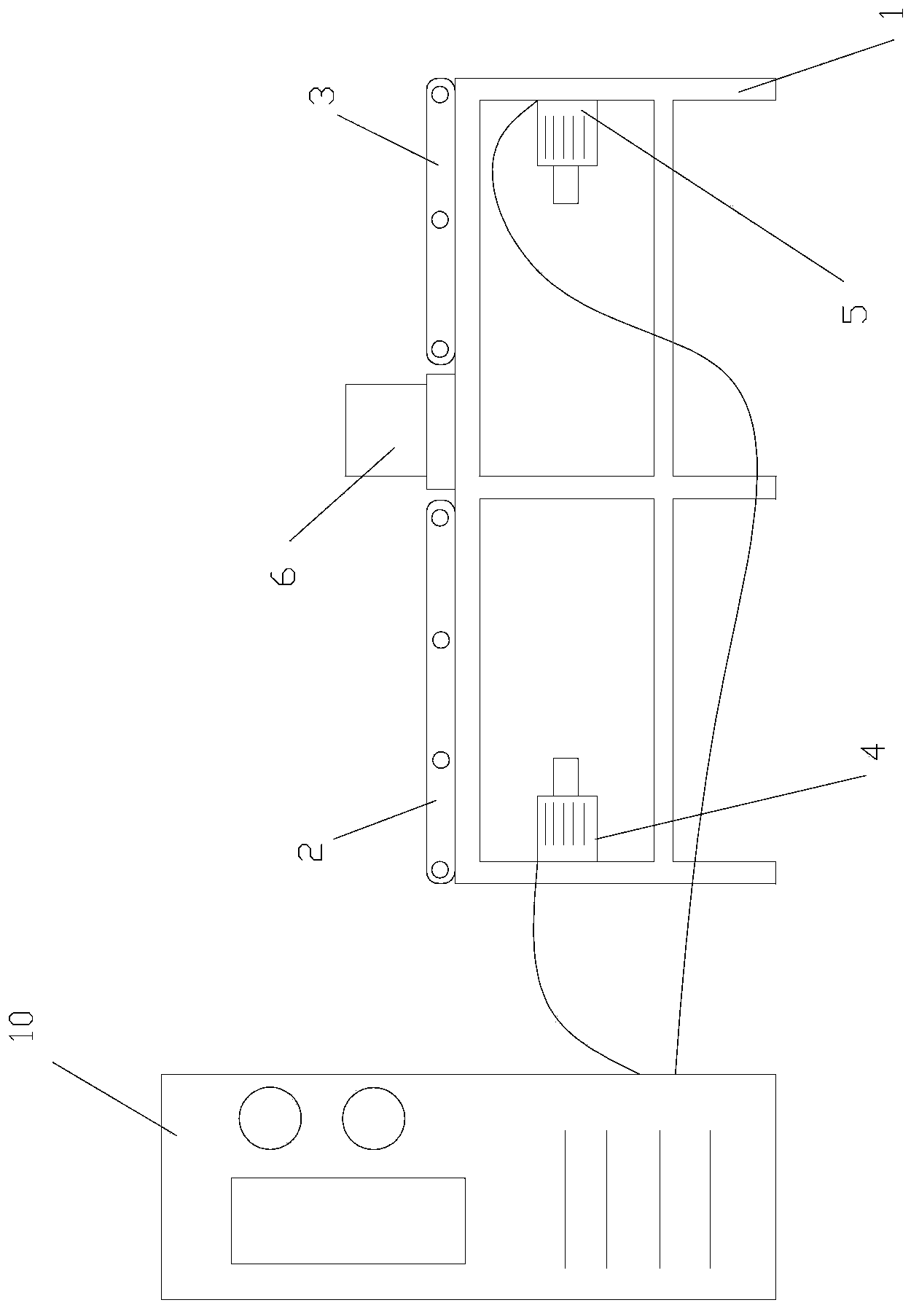

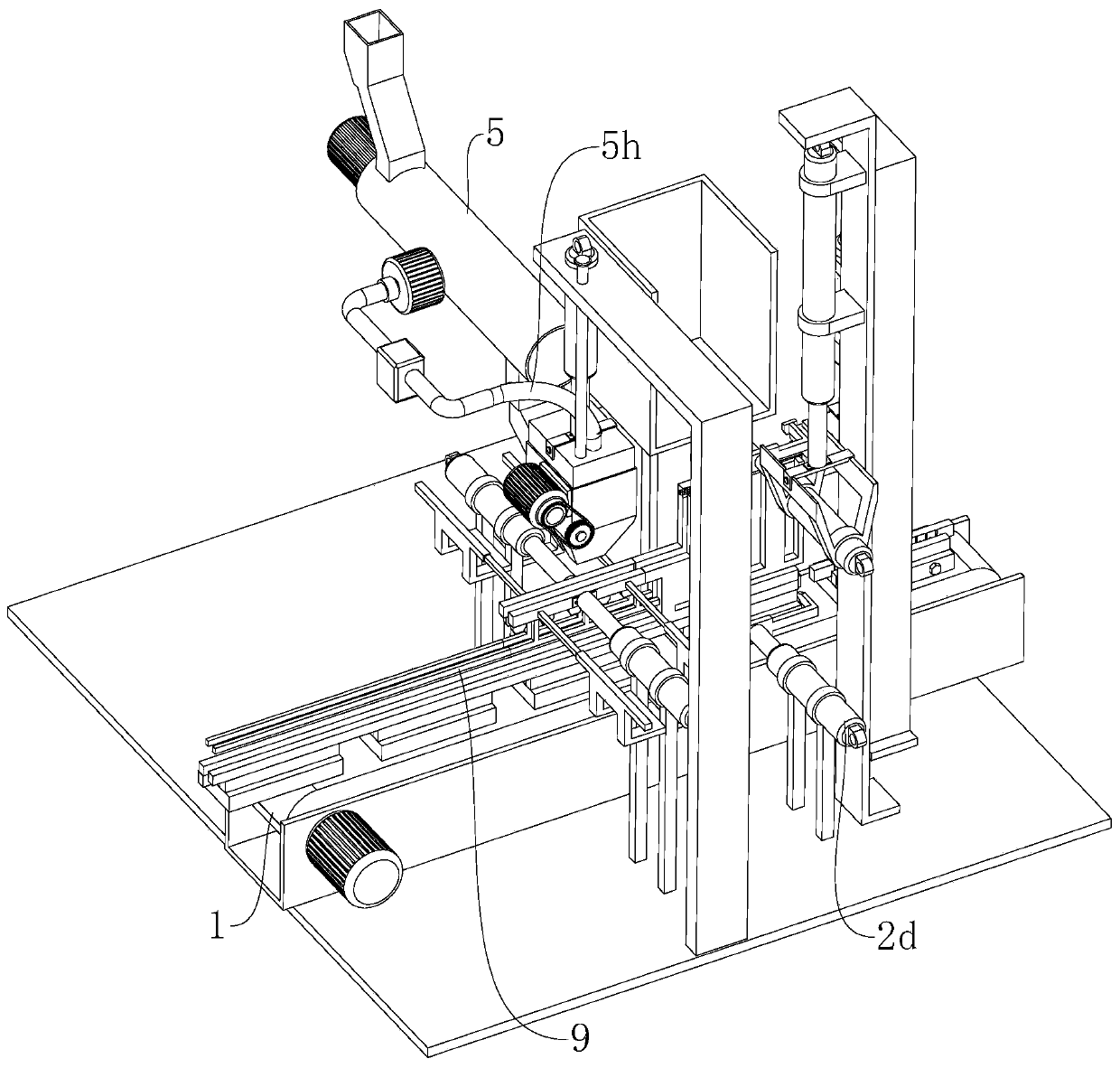

Plate shearing machine

InactiveCN103624313AAchieve separationAchieving separation of workShearing machinesShearing machine accessoriesConveyor beltEngineering

The invention provides a plate shearing machine. According to the technical scheme, the plate shearing machine comprises a body and a shearing device which is located above the body. The plate shearing machine is characterized by further comprising a first conveyor belt and a second conveyor belt. The first conveyor belt and the second conveyor belt are located above the body. The first conveyor belt and the second conveyor belt are located at the two ends of the shearing device respectively. A first motor is arranged on the body and connected with the first conveyor belt. A second motor is arranged on the body and connected with the second conveyor belt. The plate shearing machine has the advantages that separating metal plates can be achieved with the shearing machine; in addition, as a distance measuring device is added, the plates with different lengths can be easily cut and adjusted; a traditional conveyor belt is divided into the two conveyor belts, the plates can be successively separated after being cut and utilization of follow-up equipment is facilitated.

Owner:天津宏泰空调净化设备有限责任公司

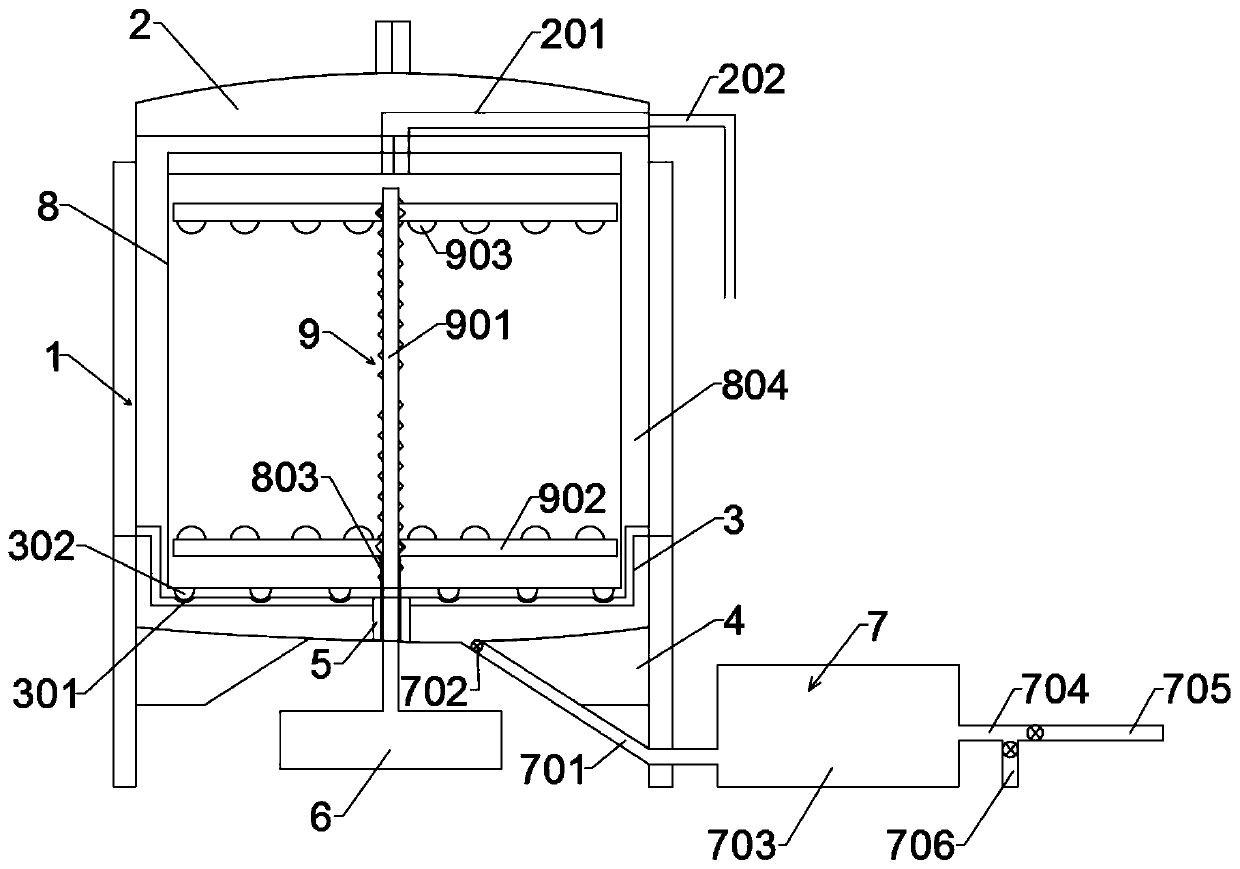

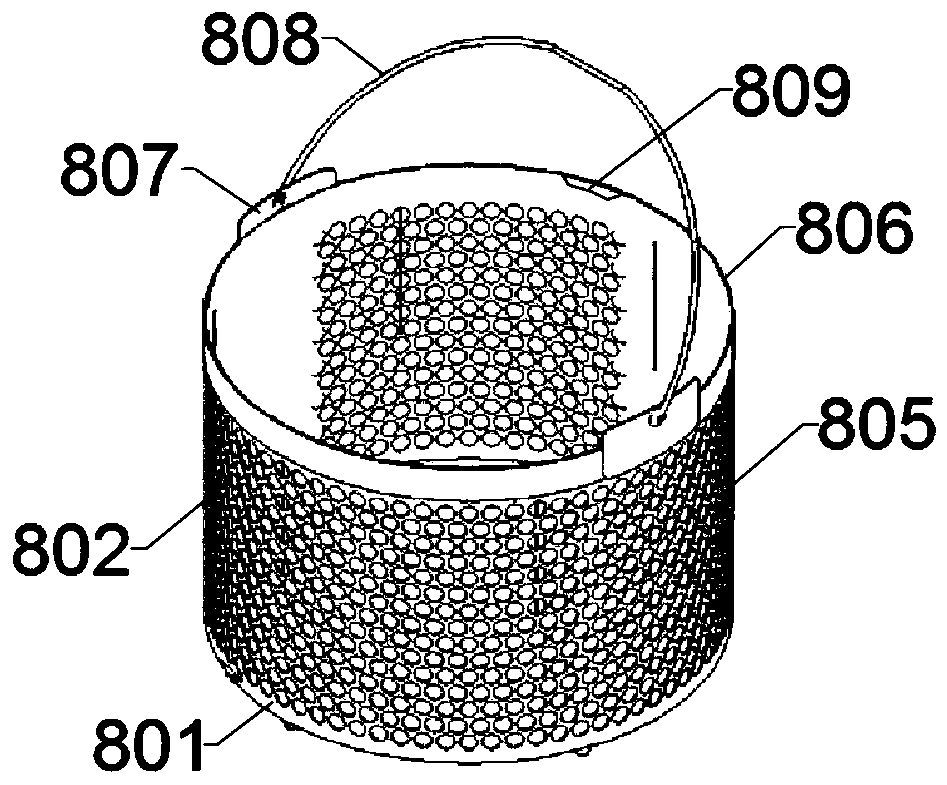

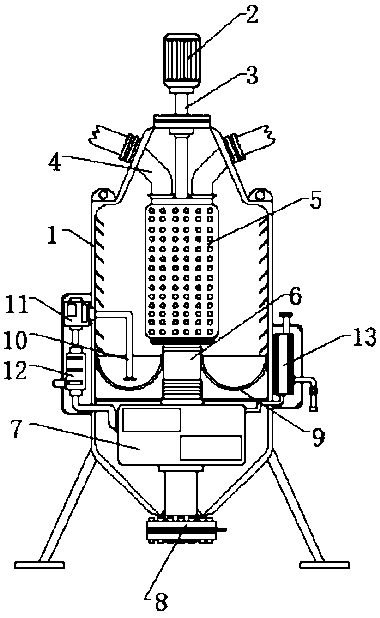

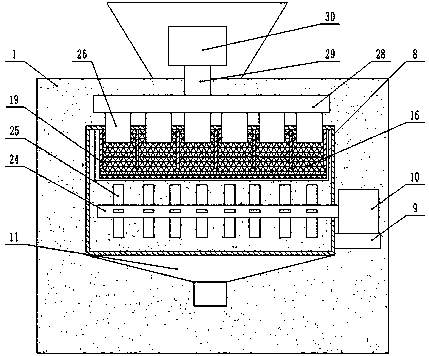

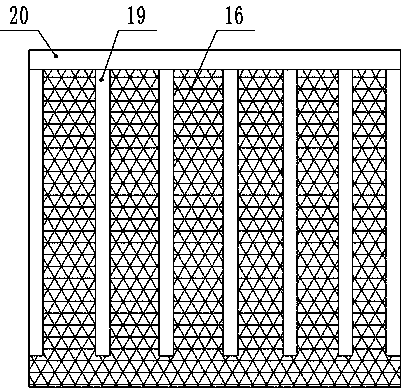

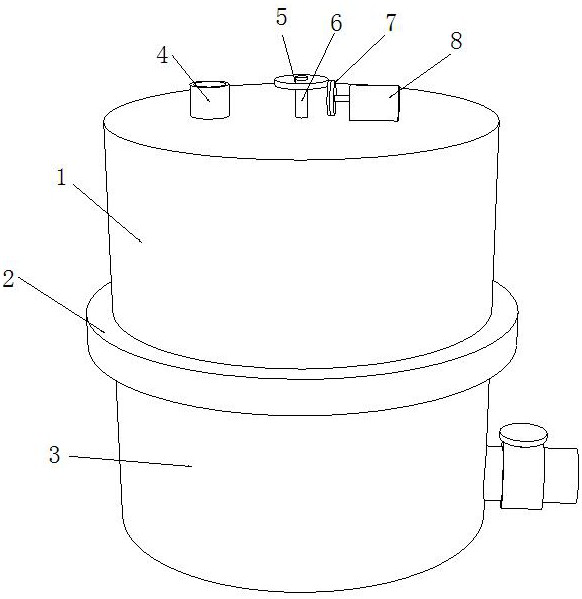

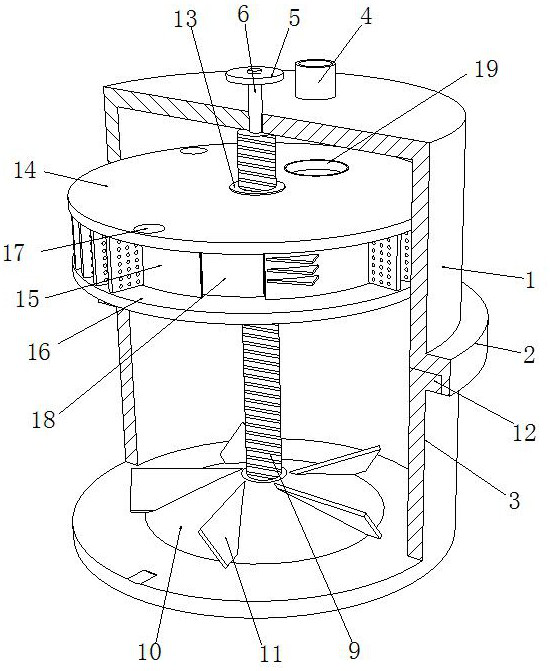

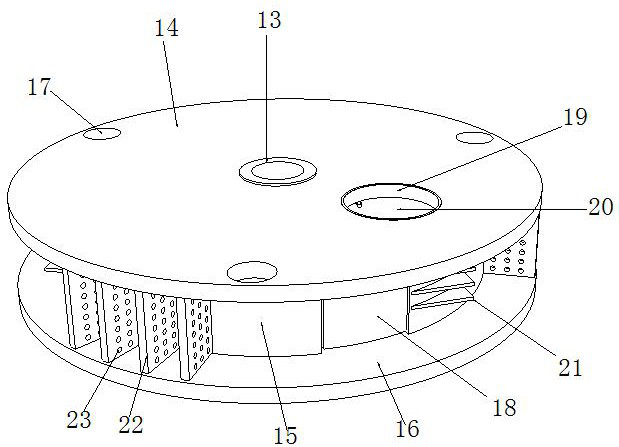

Decoction equipment for traditional Chinese medicine decoction pieces

PendingCN110538076ASmall apertureHigh hole densityPharmaceutical product form changeBiochemical engineeringKeel

An embodiment of the invention discloses decoction equipment for traditional Chinese medicine decoction pieces. The decoction equipment comprises a pan body and a pan lid, wherein a holding seat is fixedly mounted on the inner side wall of the pan body, a heating source is arranged on the bottom edge of the pan body, a power clamp seat is arranged in the center of the holding seat and driven by apower source arranged at the bottom of the pan body, a discharging mechanism is arranged on the bottom side surface of the pan body, an inner filter net is arranged on the holding seat and consists ofsupport keels and a porous liner, the support keels are arranged on the holding seat, a transfer base clamped with the power clamp seat is arranged in the bottom center of the porous liner, and a stirring mechanism is clamped on the transfer base. By arrangement of the inner filter net and the stirring mechanism, separation and dewatering of medicine liquid and medicine dregs are realized, so that the decoction effect and decoction yield are increased.

Owner:北京和利康源医疗科技有限公司

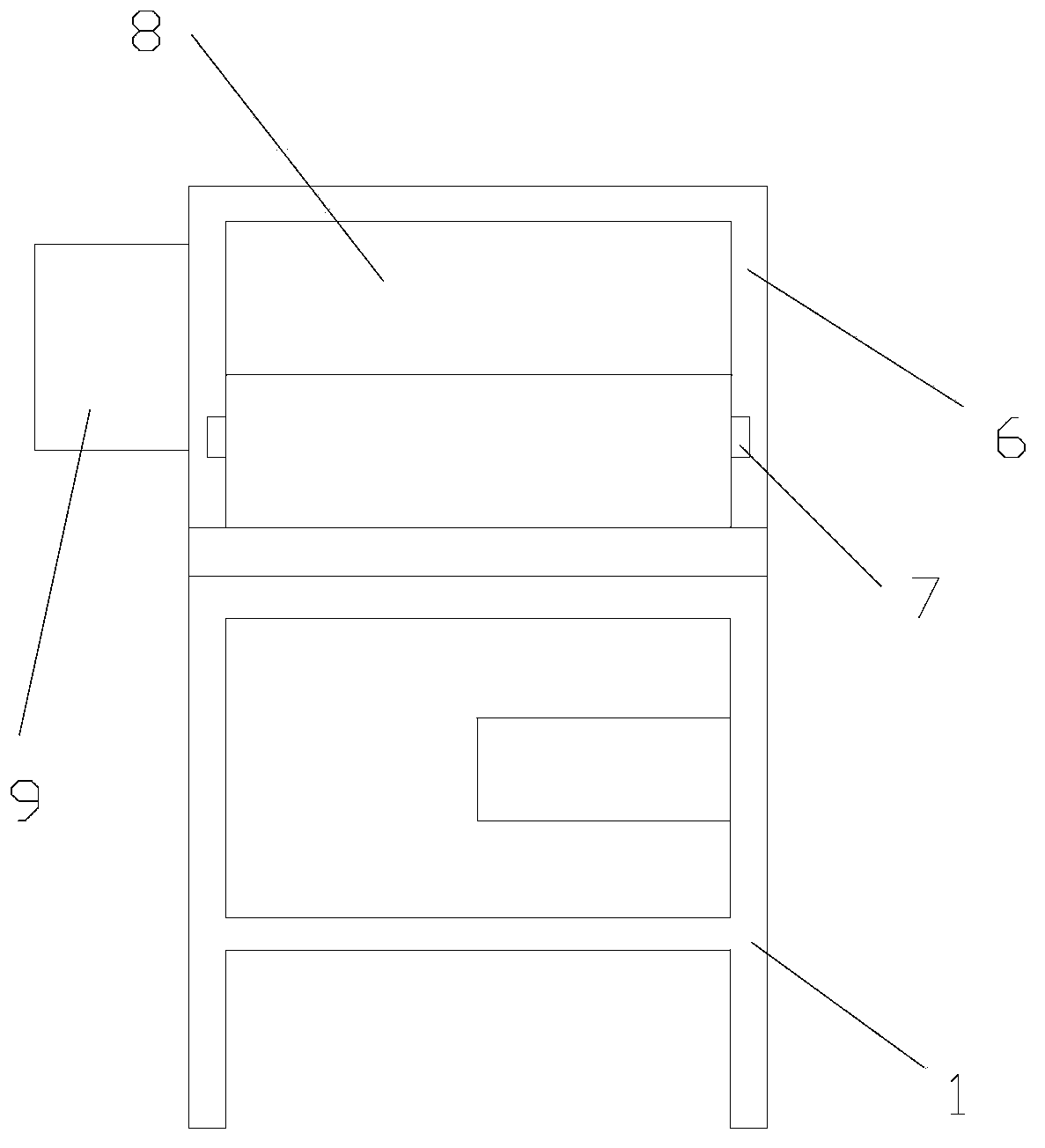

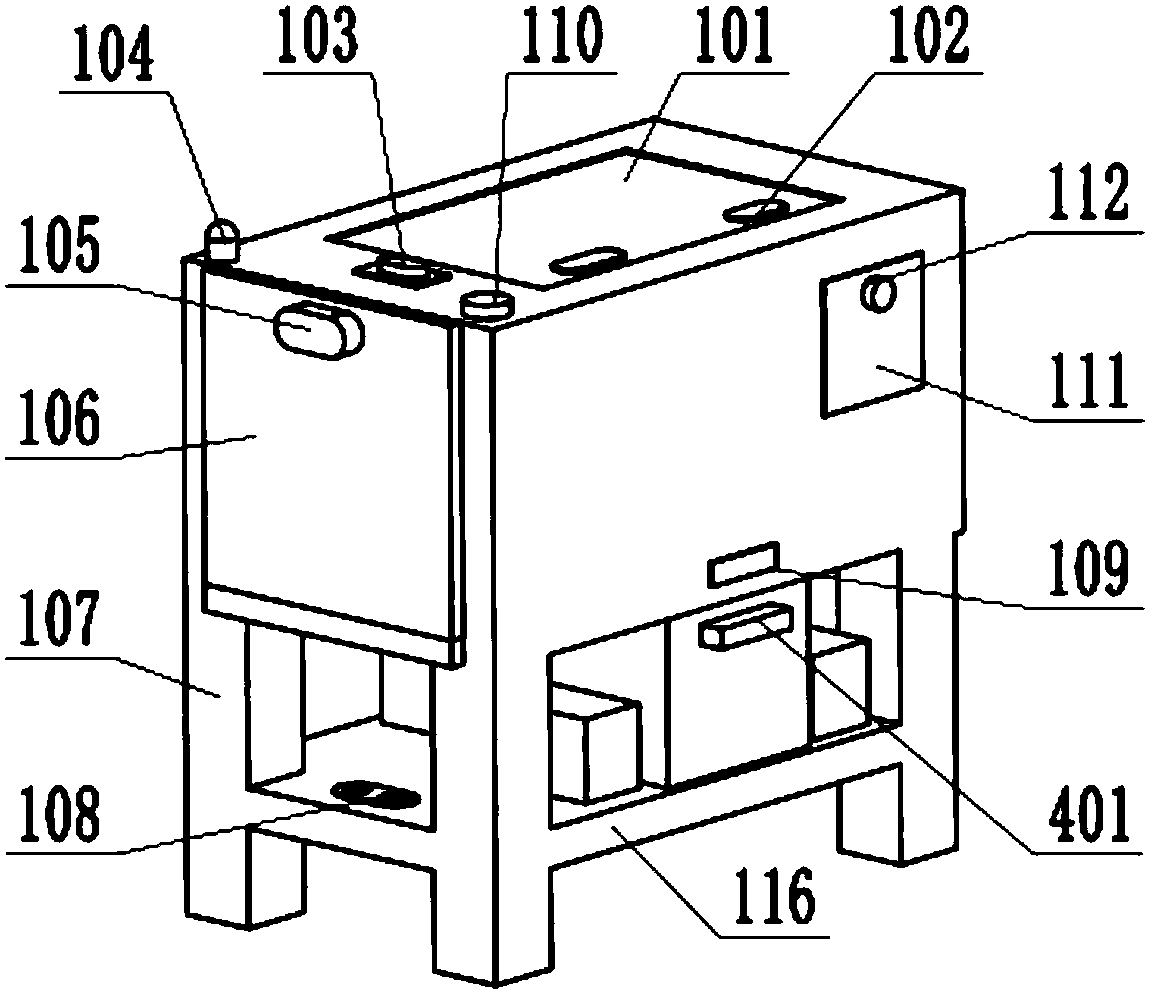

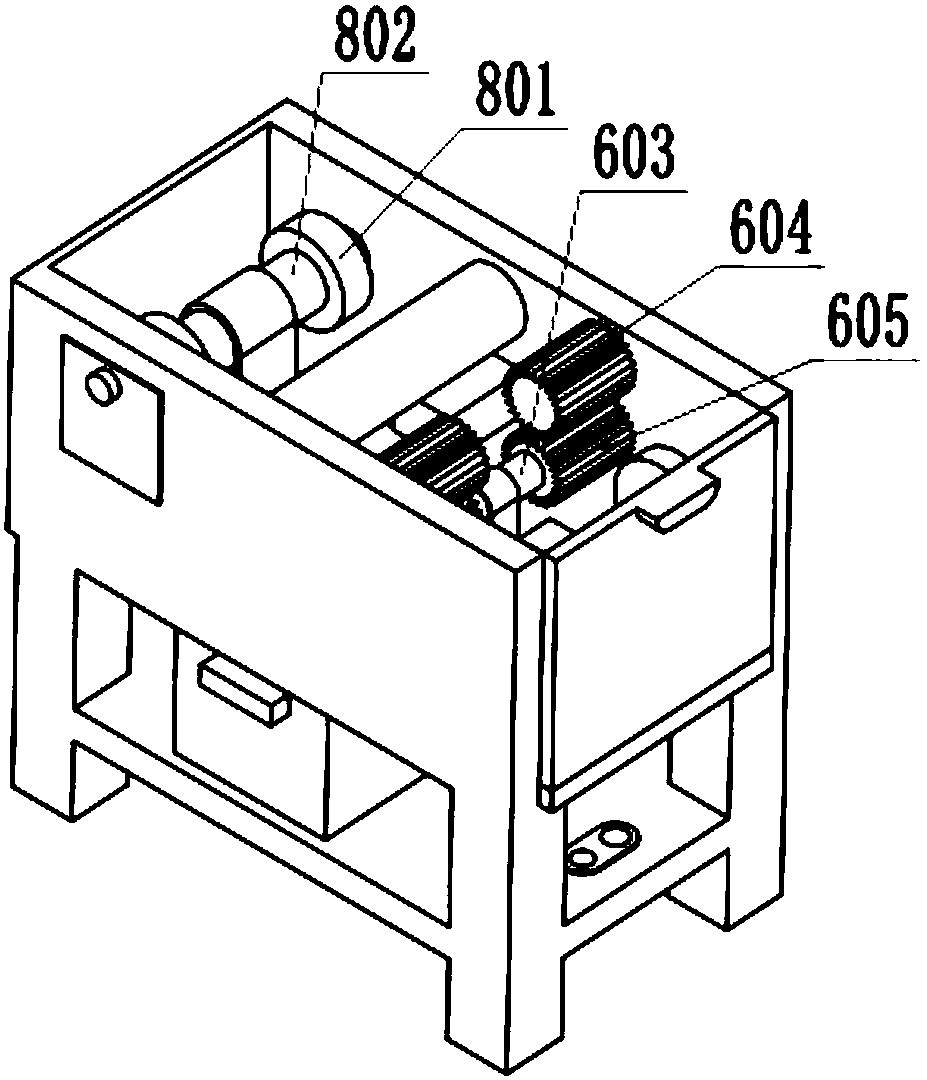

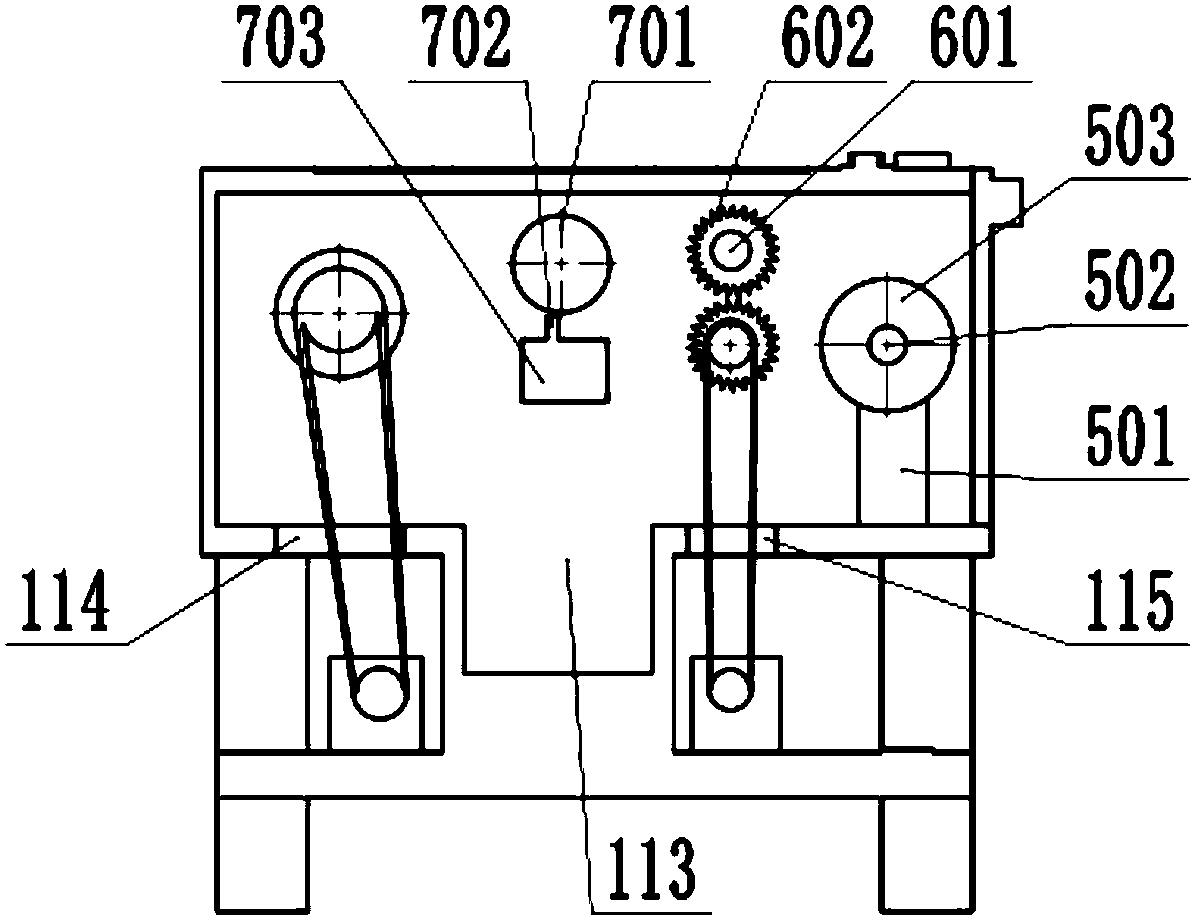

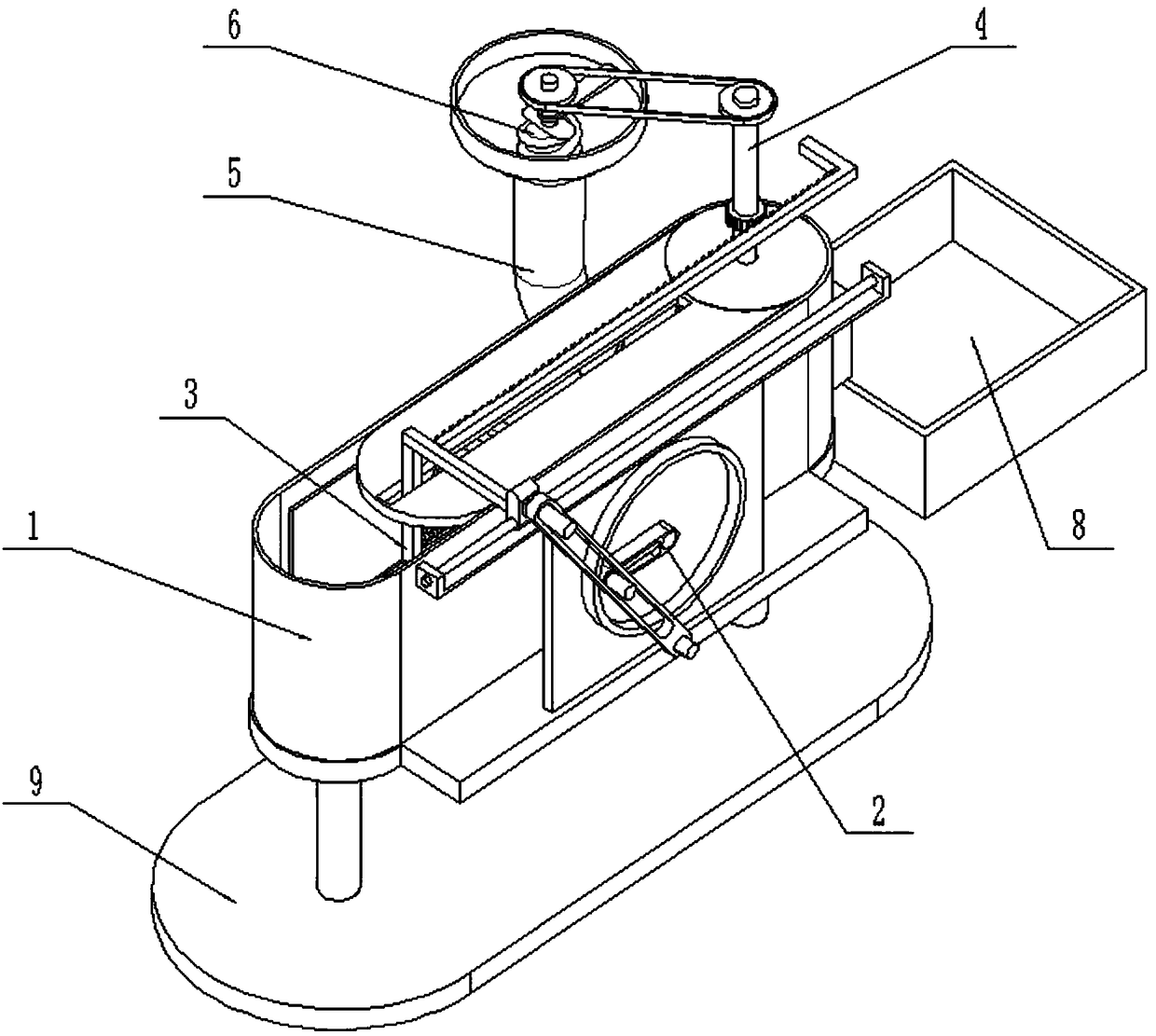

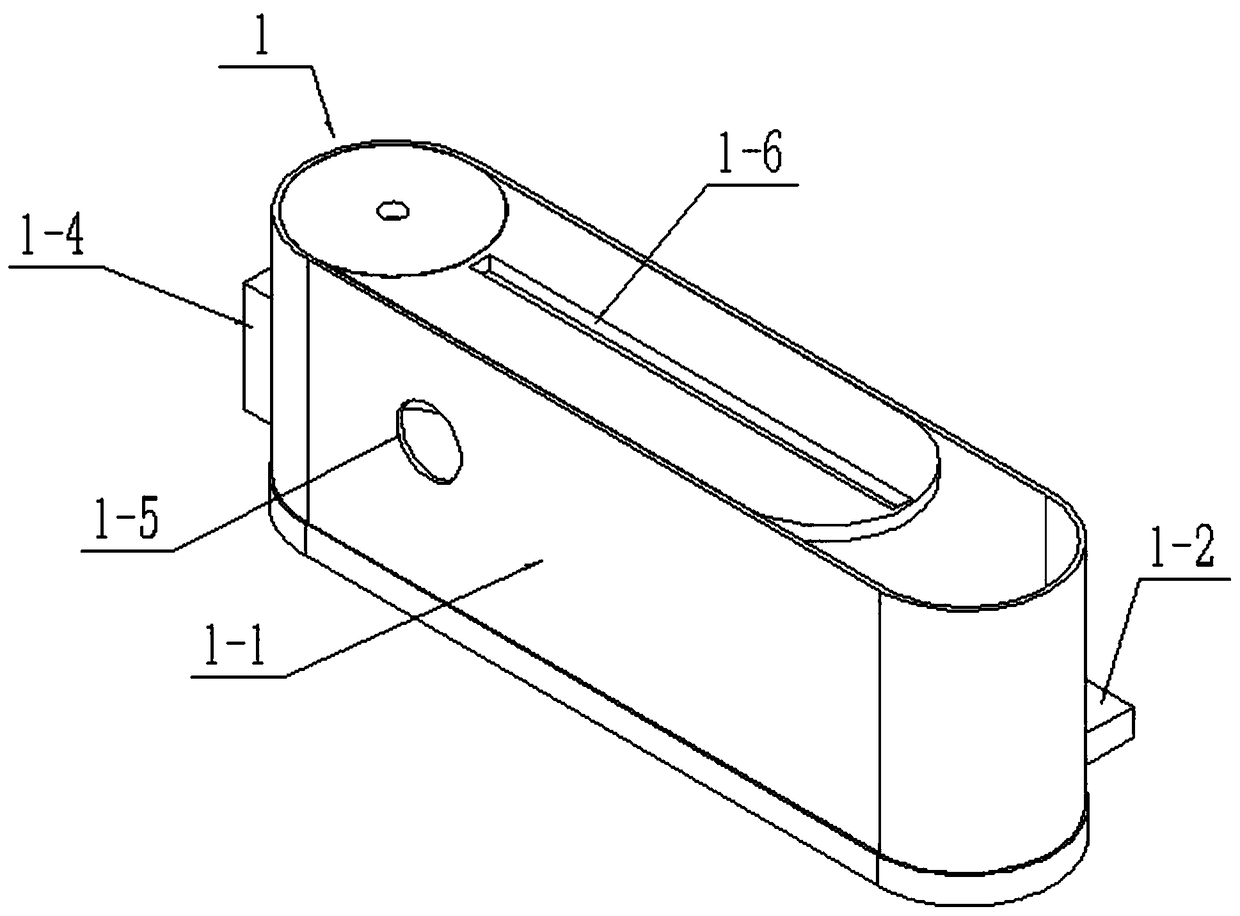

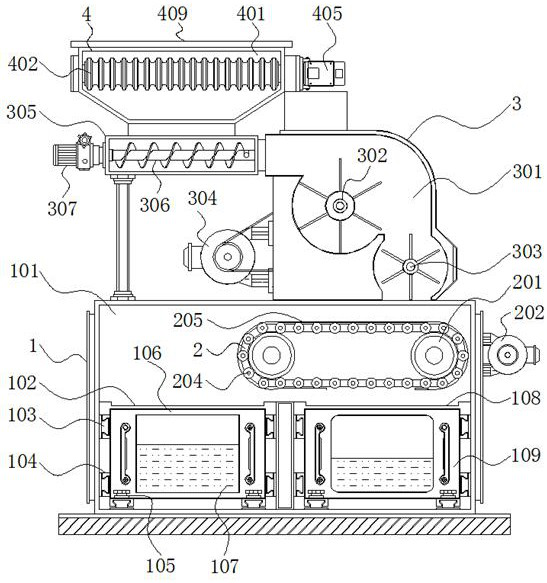

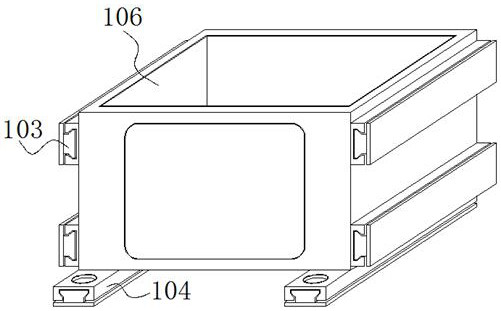

Recycling device of wire and cable dedicated for power distribution cabinet

InactiveCN107845454ASave pay-off speedImprove securityBasic electric elementsApparatus for removing/armouring cablesEngineeringElectric power

The invention discloses a recycling device of a wire and cable dedicated for a power distribution cabinet. The recycling device is composed of a chassis, a pay-off unit, a crushing unit, a separatingunit, a take-up unit and first and second motors arranged at the lower end of the chassis. Support legs are arranged at the lower end of the chassis. A baffle is arranged among the support legs. A front reel change door is arranged at one side of the chassis. A door handle is arranged on the front reel change door. The pay-off unit is arranged in the front reel change door. The crushing unit is arranged at one side of the pay-off unit. The separating unit is arranged at one side of the crushing unit. The take-up unit is arranged at one side of the separating unit. Rear reel change doors are arranged on chassis walls on the two sides of the take-up unit. The recycling device not only realizes the separation of a wire core from a wire sheath, but also realizes automation in the entire process. The separation devices are all located inside the chassis and the safety is improved.

Owner:佛山市欧能电气设备有限公司

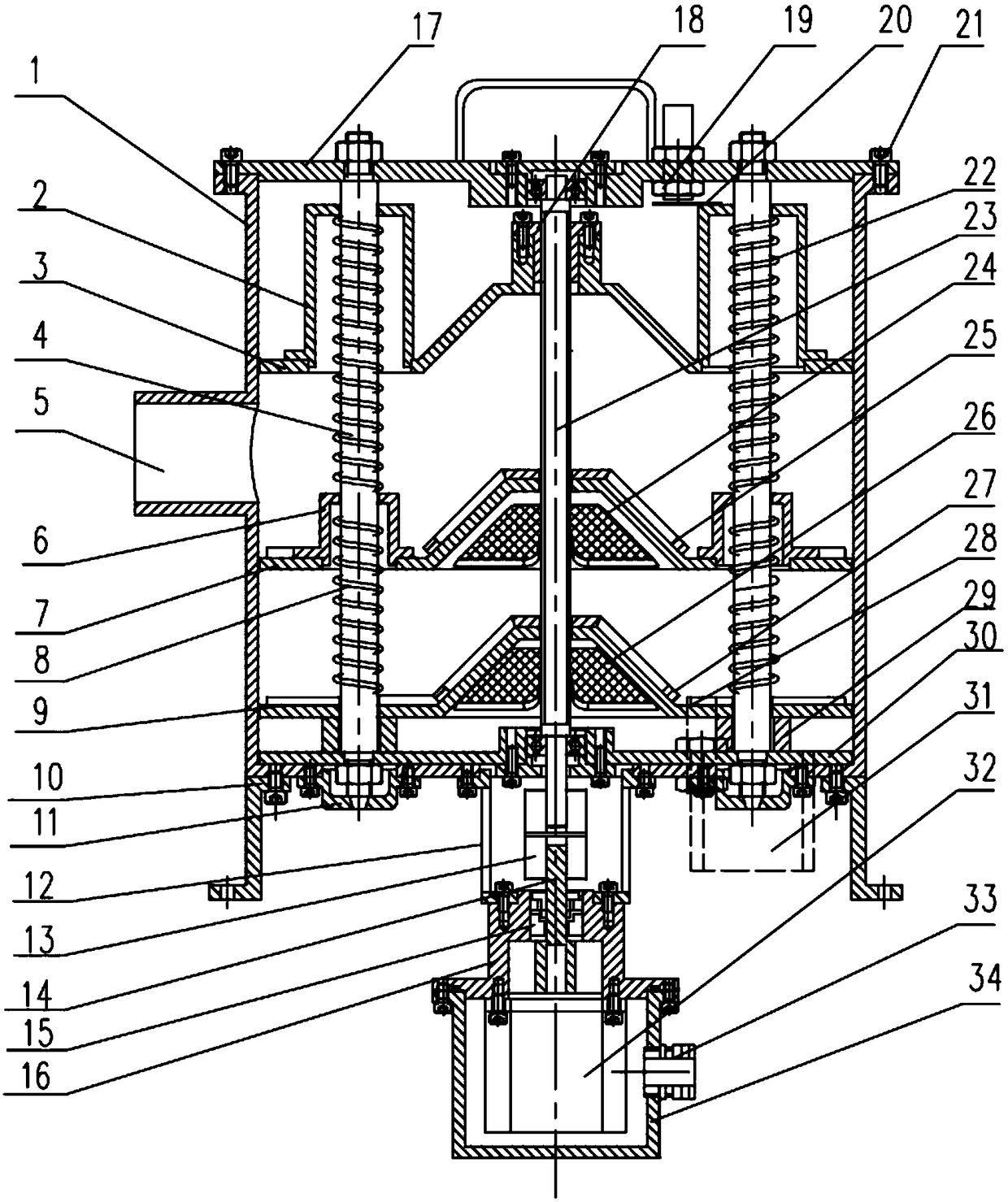

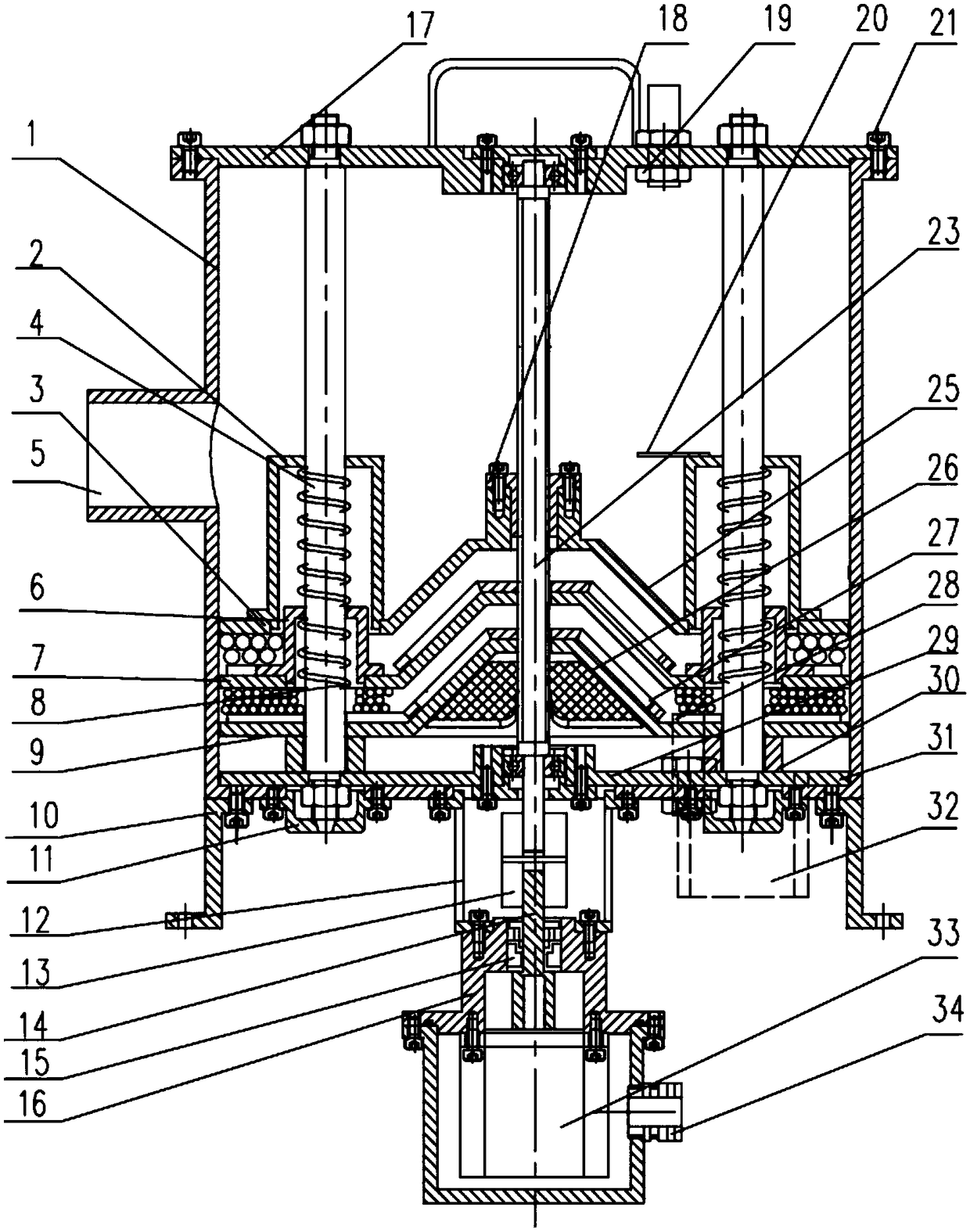

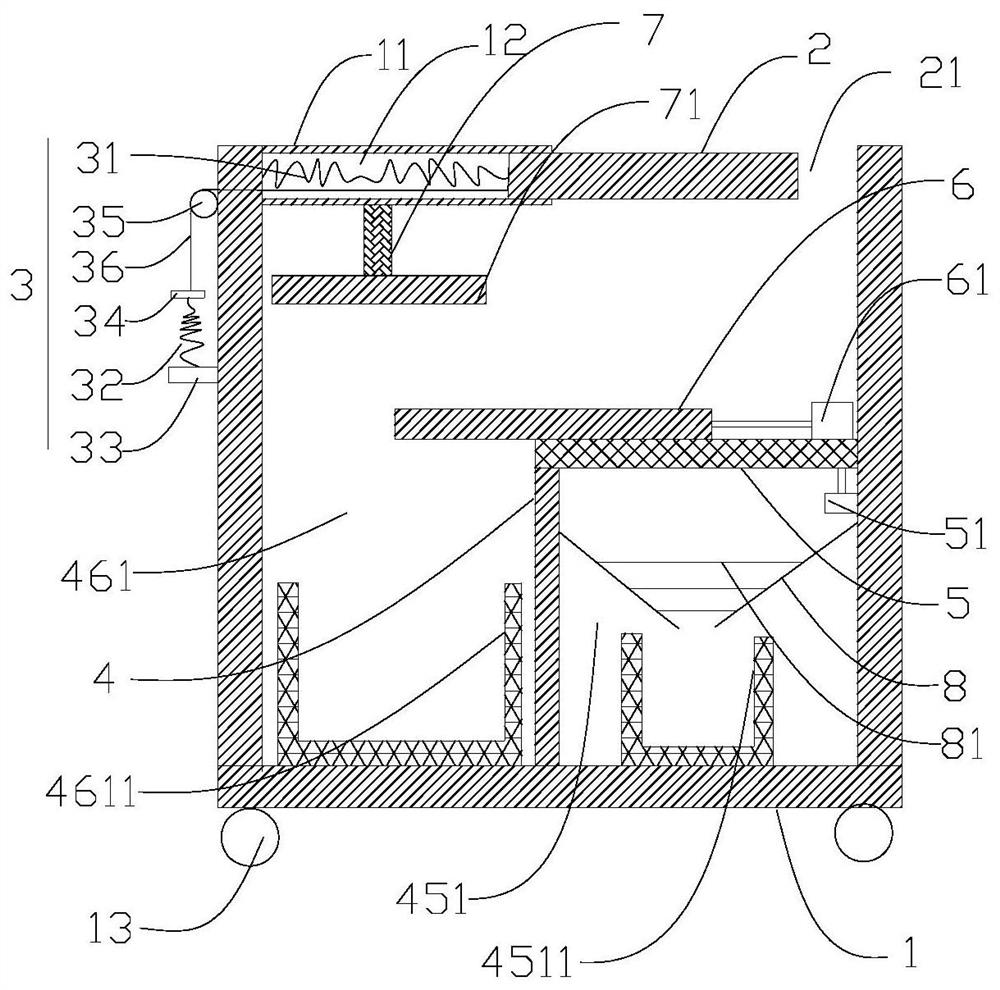

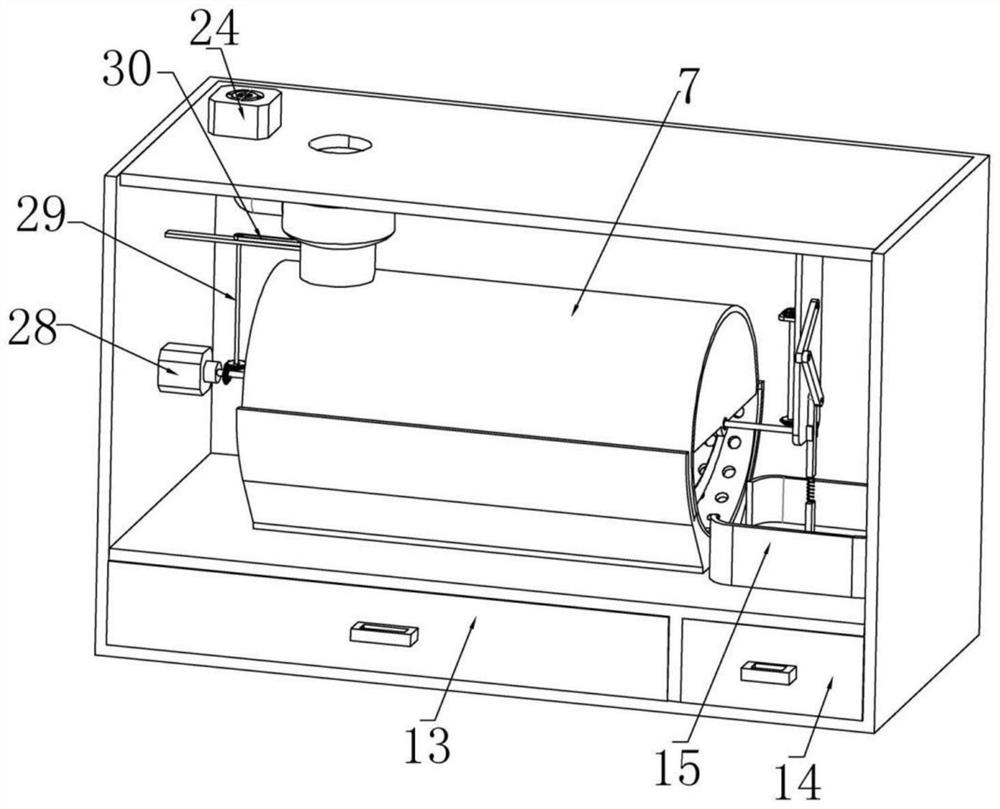

Solid-liquid separation device for chemical production

InactiveCN109200667ADischarge fullyHigh degree of separationFiltration circuitsMoving filtering element filtersPipetteDrive motor

The invention discloses a solid-liquid separation device for chemical production. The device comprises a filter and a dryer. The filter is installed at a vertical axis position inside the machine body, a driving motor is installed at the top of the machine body, the driving motor is in drive connection with the filter through a driving main shaft, feed pipes are installed on both sides of a truncated cone at the upper part of the machine body, the feed pipes are communicated with the filter, the outlet of the dryer is communicated with a discharge valve through a pipeline, a liquid collectingtank is installed outside a feed delivery pipe, a circulating pump is installed in a protection cover mounted on one side outside the machine body, the inlet of the circulating pump is communicated with the inside of the liquid collecting tank through a pipette, the outlet of the circulating pump is connected to a small filter through a pipeline, and a steam port of the dryer is connected to a condenser through an air duct. The solid-liquid separation device for chemical production provided by the invention can filter solids of different particle sizes by adjusting the diameter of filter casing meshes, at the same time can dry the solids obtained by solid-liquid separation, thus improving the solid quality.

Owner:HANDAN COLLEGE

Operating room waste treatment device

ActiveCN109647845AEfficient separationAchieving separation of workSolid waste disposalLandfill technologiesEngineeringWaste treatment

The invention discloses an operating room waste treatment device. A box, a seal cover, a switch mechanism, a first partition plate, a second partition plate, a third partition plate, a telescopic rodand a conical sleeve are included. The upper end of the box is opened. One side of the opening horizontally extends along the inner wall of the box so that a cover plate can be formed. A gap is formedbetween the other corresponding side of the opening and one end of the cover plate, and a first through hole is horizontally formed in one side face of the cover plate. By means of the operating roomwaste treatment device, effective separation of waste in an operating room can be achieved.

Owner:史明

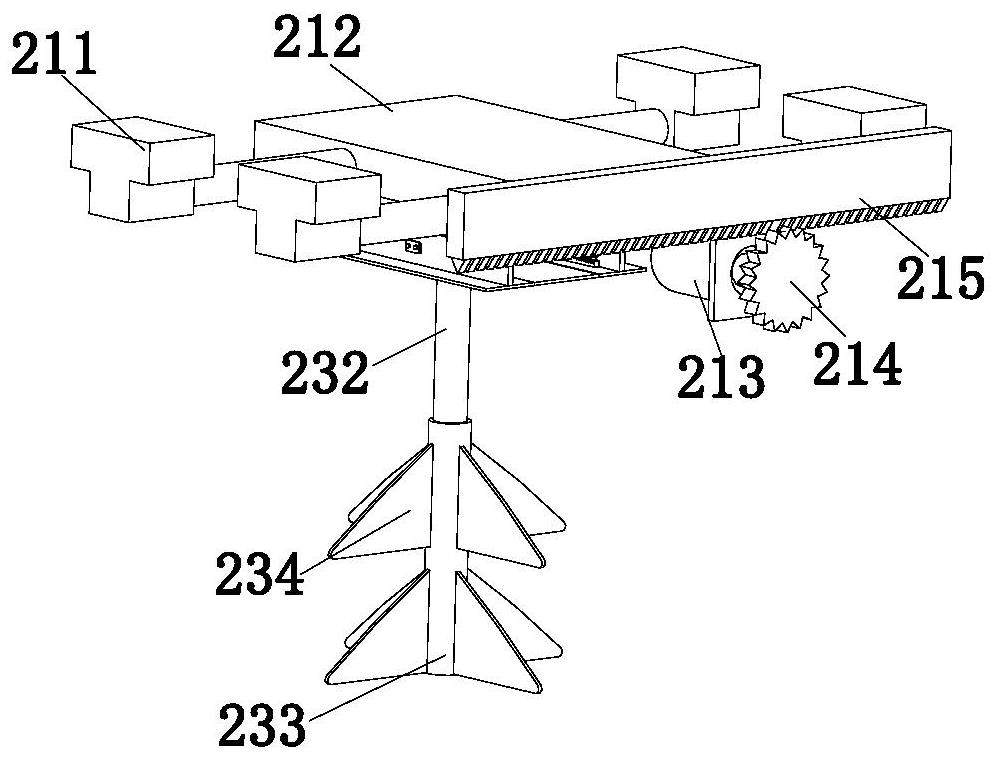

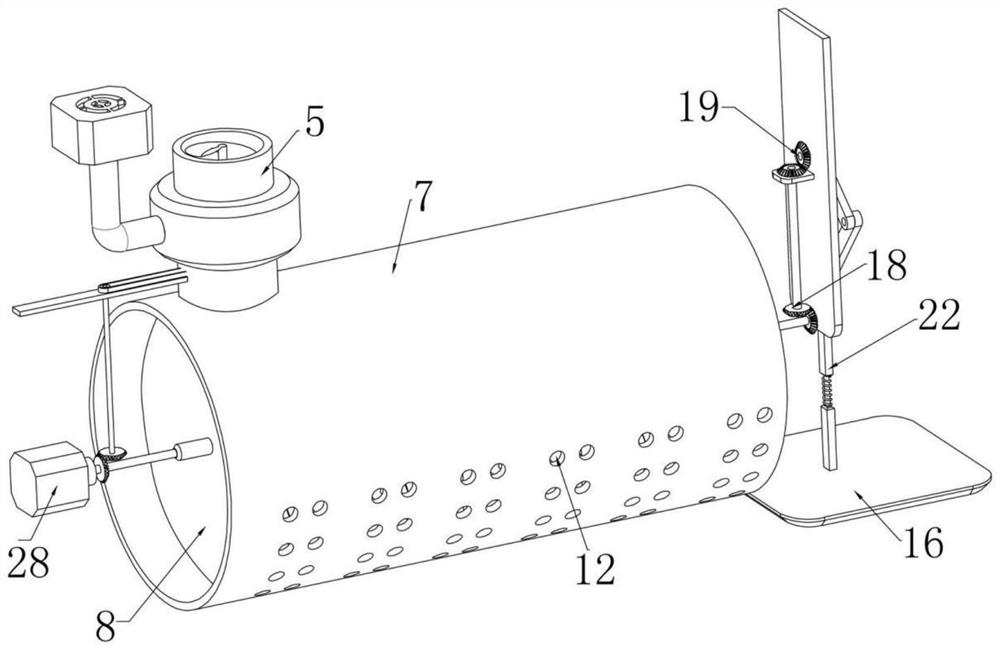

Non-block tea-leaf dust sieving device

The invention relates to a non-block tea-leaf dust sieving device. The non-block tea-leaf dust sieving device comprises a main frame body, wherein a material feeding port, a material discharge port, and a dust sieving device which can rotate around a shaft are arranged on the main frame body. The dust sieving device comprises a supporting frame which is connected on the main frame body and a dust sieving cylinder which is assembled on the supporting frame. At least one strip-shaped sieving hole which is communicated end to end is formed along the circumferential direction in the side wall of the material feeding port. The strip-shaped sieving hole penetrates through the side wall of the dust sieving cylinder. The material feeding port is formed in the inclined upper portion of the dust sieving cylinder, the material discharge port is formed in the inclined lower portion of the dust sieving cylinder, the material discharge port is provided with a first tooth plate which is matched with the dust sieving cylinder, and first convex teeth which can be inserted into the strip-shaped sieving hole are arranged on the first tooth plate. The tea-leaf dust sieving device can effectively achieve separation work of tea leaves and tea dust, and through dredge effect assisted by a first tooth plate and a second tooth plate, the fact the blocking phenomenon of sieving holes cannot occur when the dust sieving device is in work is guaranteed. In addition, the size of the non-block tea-leaf dust sieving device is small, noise when the dust sieving device is in work is small, use is simple and convenient, and work efficiency is high.

Owner:福建省状元茗茶有限公司

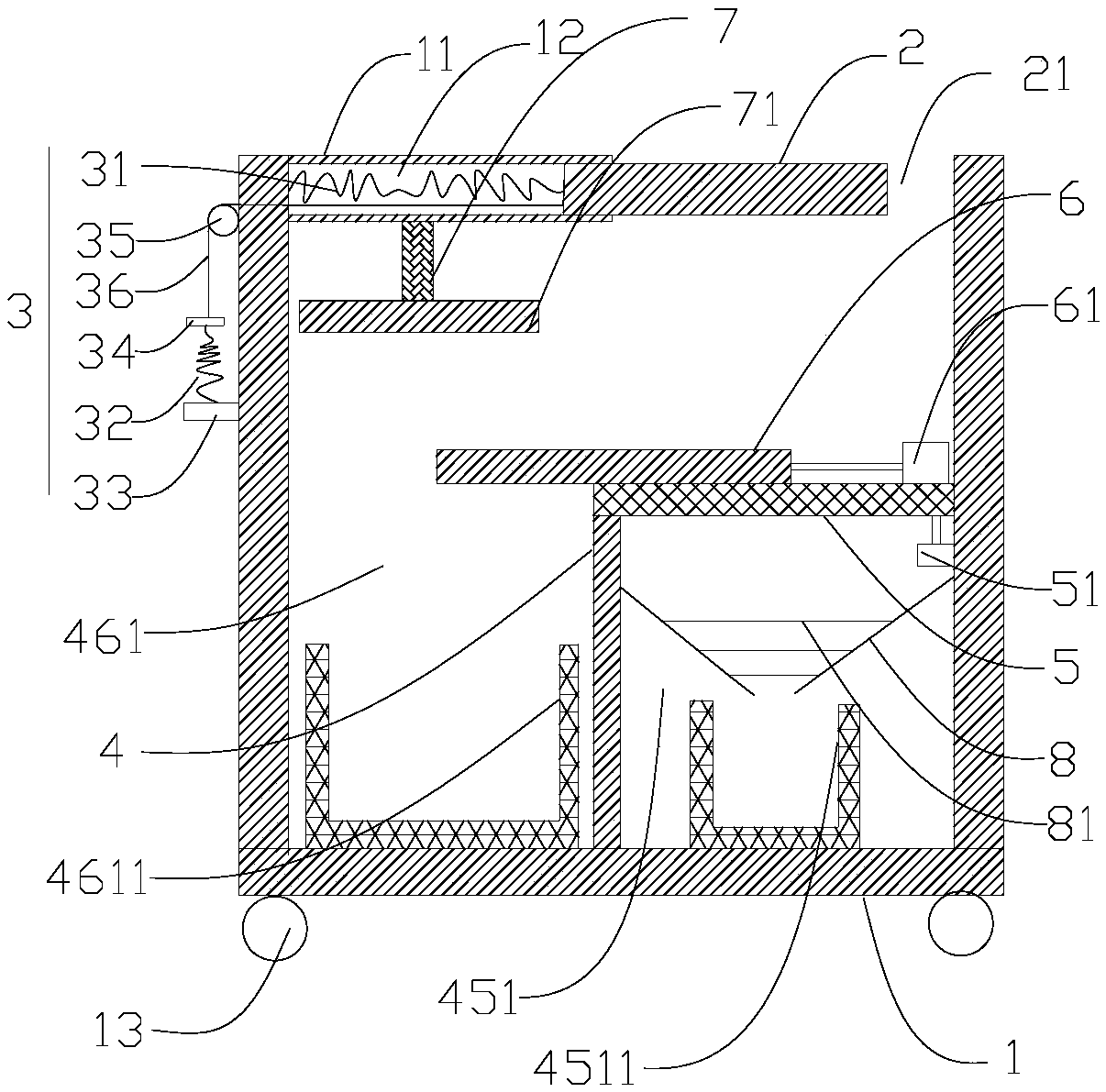

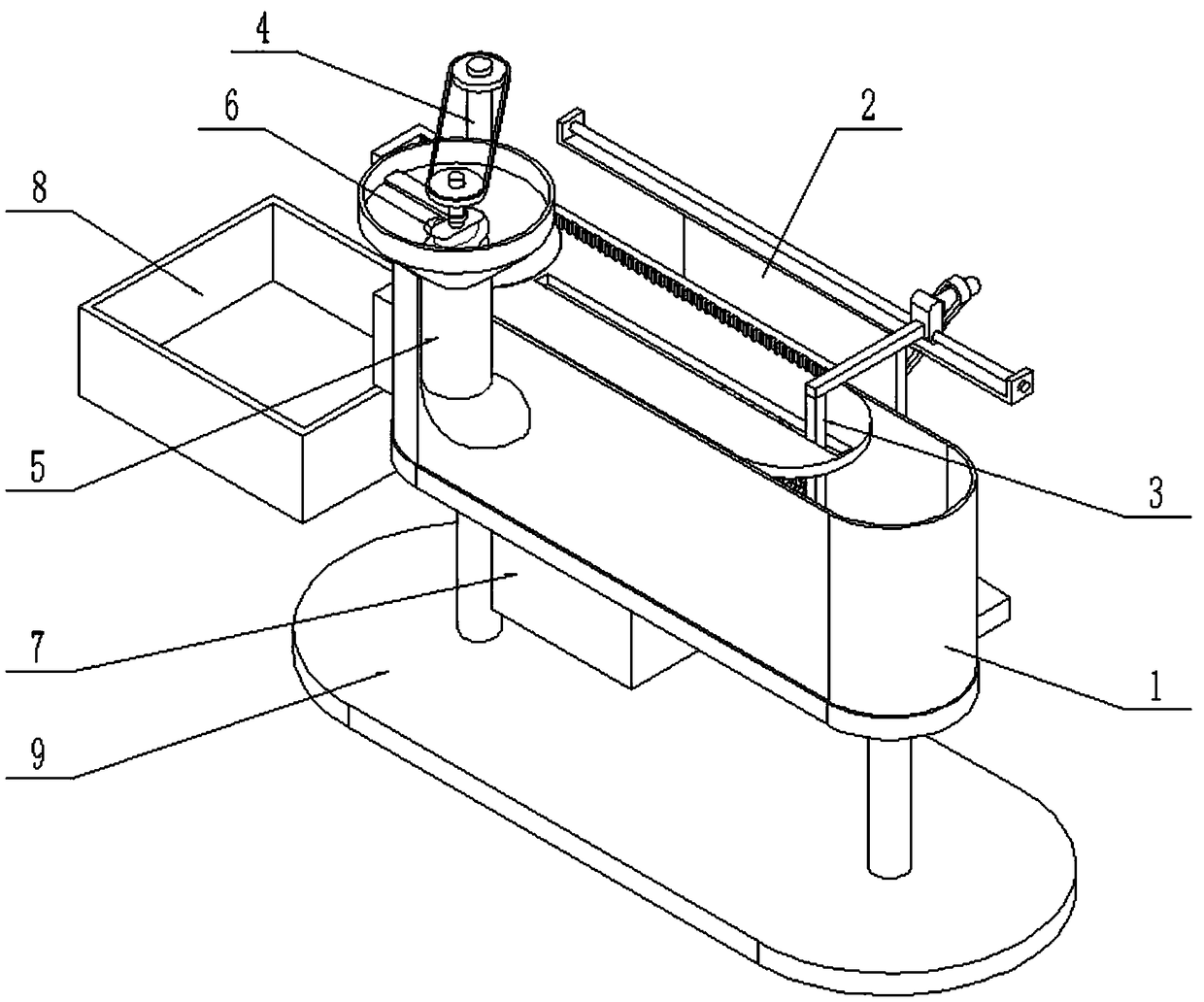

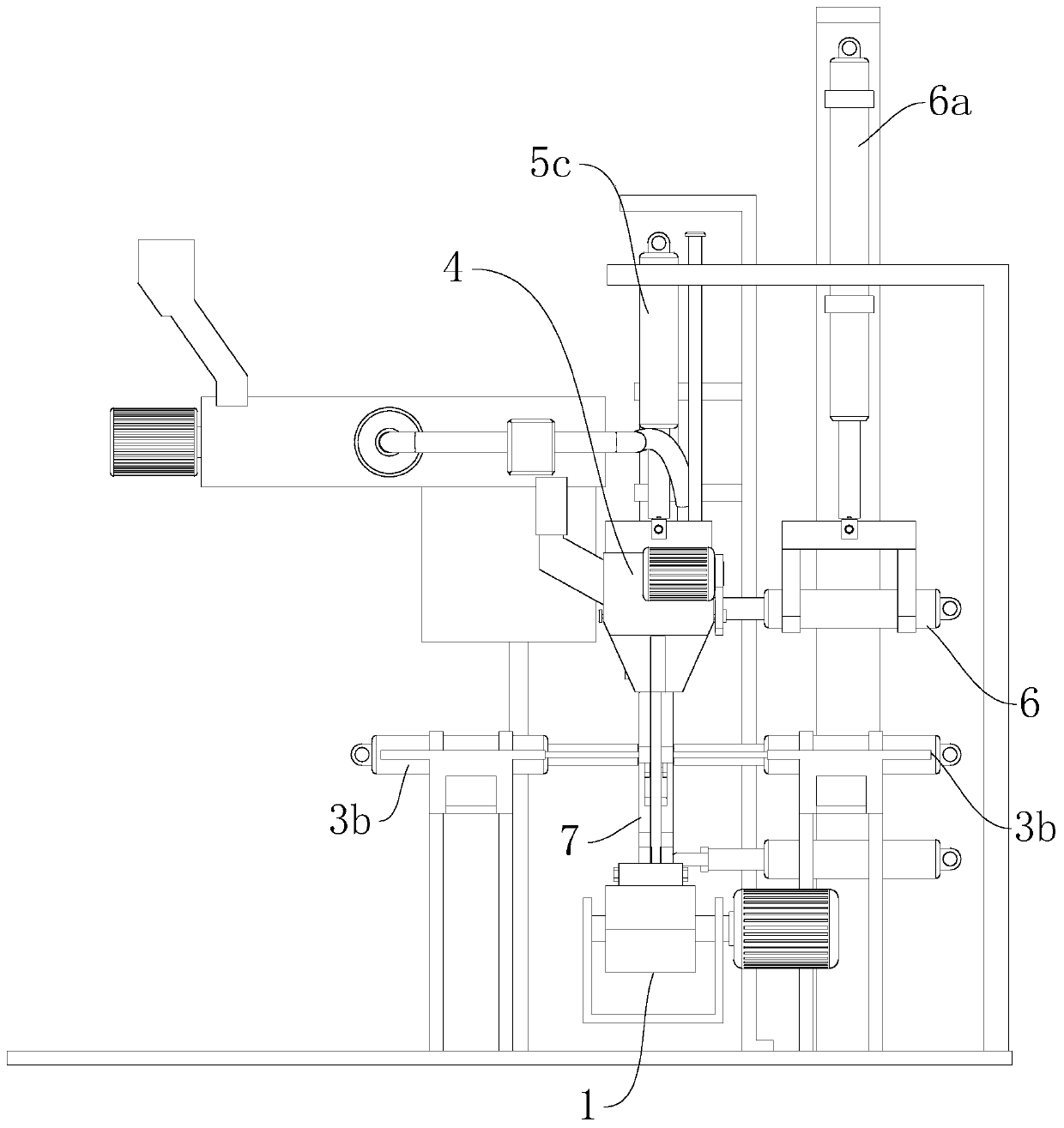

Hawthorn kernel separation equipment for food processing

PendingCN112602937AAchieving separation of workAchieve normal workFruit stoningBiotechnologyEngineering

The invention relates to separation equipment, in particular to hawthorn kernel separation equipment for food processing. According to the hawthorn kernel separation equipment for food processing, hawthorn kernels can be separated, pitted hawthorns can be shaken evenly at intervals, material blocking and quantity controlling of the hawthorns can be controlled at intervals, meanwhile, the kernels can be ejected out, and automatic discharging of the hawthorns can be completed. The hawthorn kernel separation equipment for food processing comprises a bottom plate and a kernel ejecting mechanism, and the kernel ejecting mechanism is arranged at the top of the bottom plate. Through arrangement of the kernel ejecting mechanism, the kernel ejecting mechanism is matched with a first discharging mechanism, and hawthorn kernel separation work can be achieved; the material blocking mechanism is matched with the first discharging mechanism, so that material blocking and controlling work of the hawthorns can be realized; the material shaking mechanism is matched with the first discharging mechanism, the hawthorn fruits in a material containing box can be shaken to be flat, and therefore the situation that the hawthorn fruits fall out of the material containing box due to unevenness can be effectively avoided.

Owner:赖新华

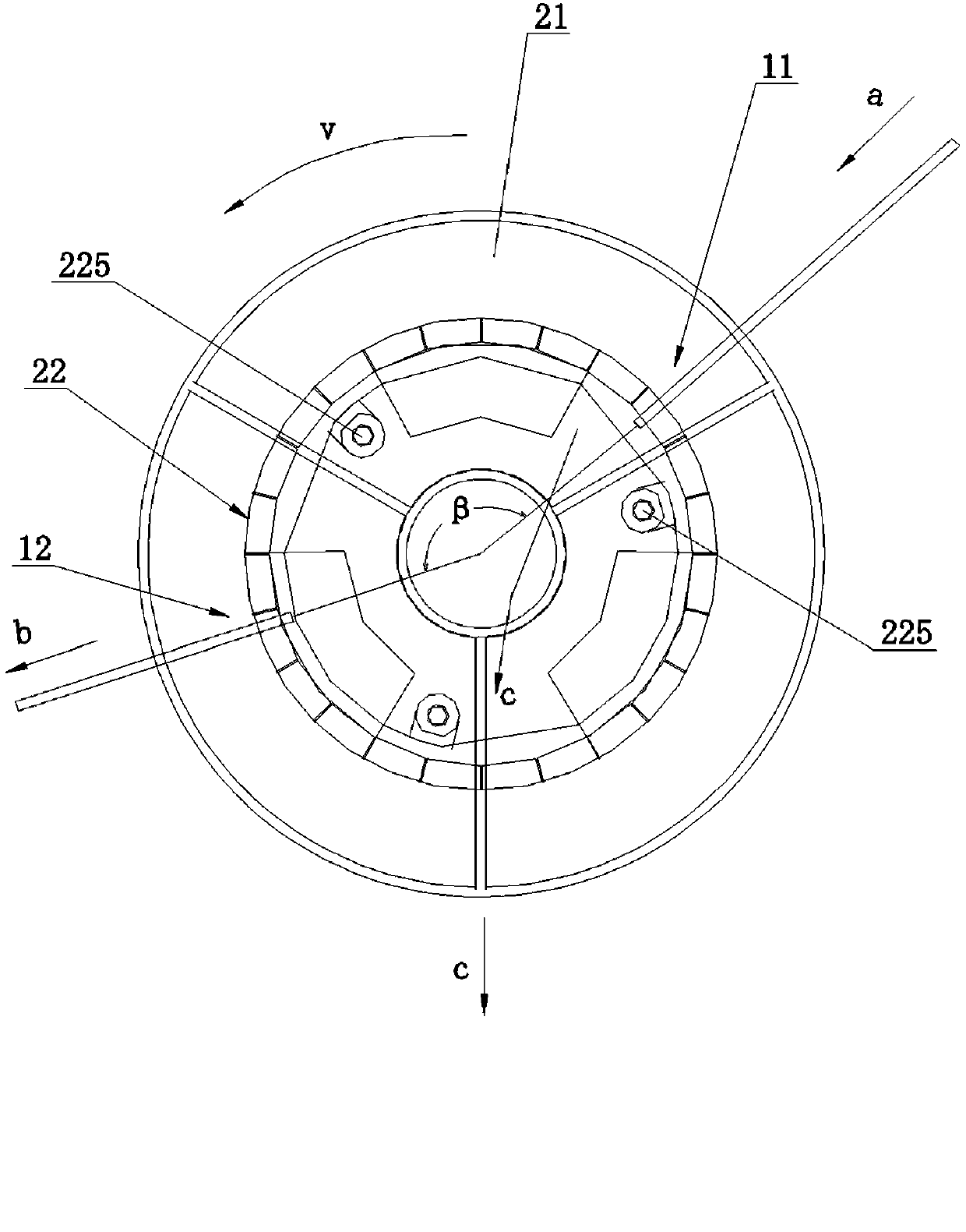

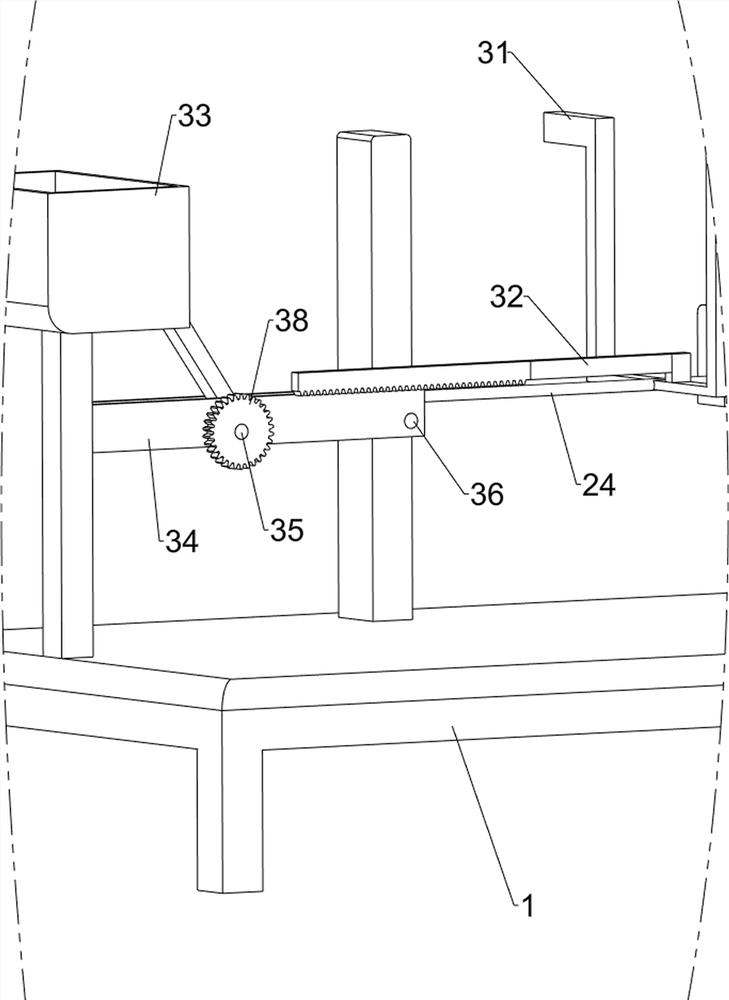

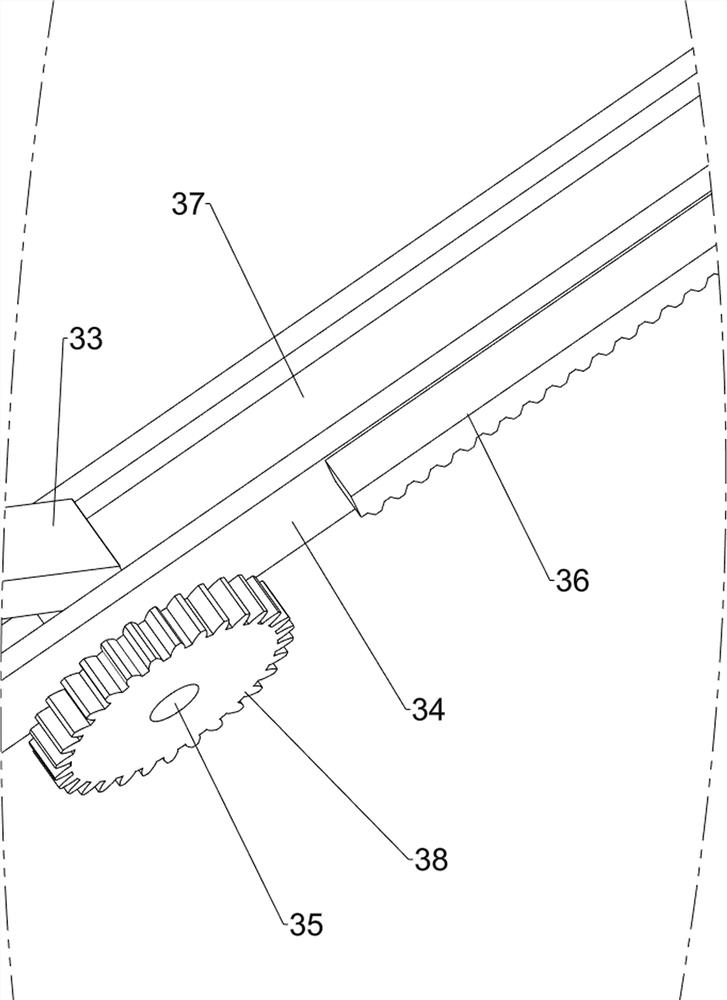

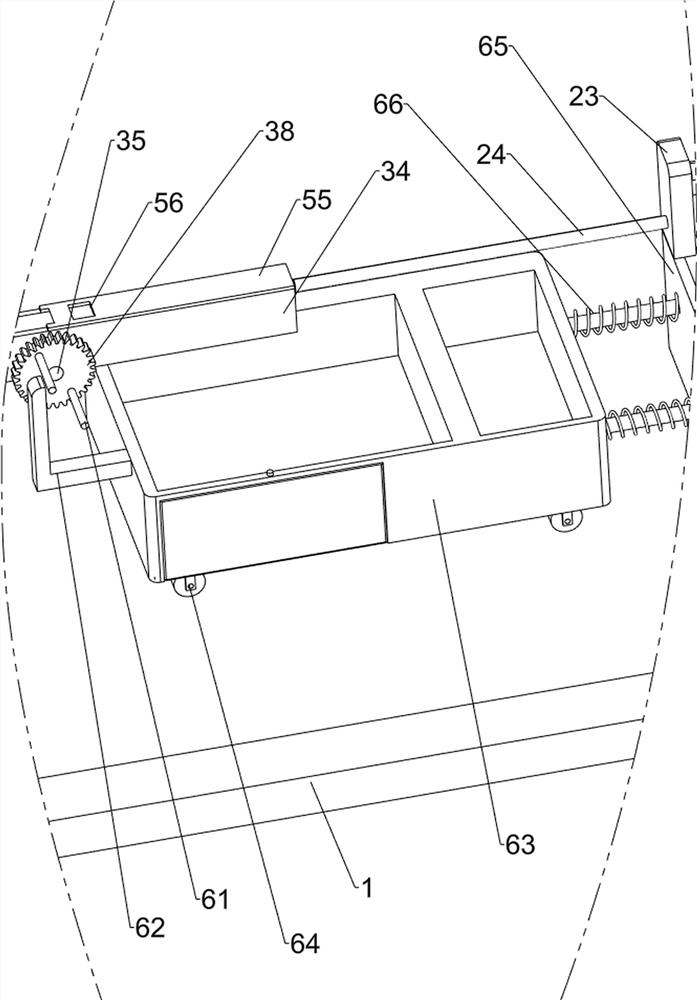

Bamboo green and yellow separation equipment and separation method thereof

PendingCN114311192AImprove separation efficiencyReduce the difficulty of separationCane mechanical workingProfiling/shaping machinesKnife bladesStructural engineering

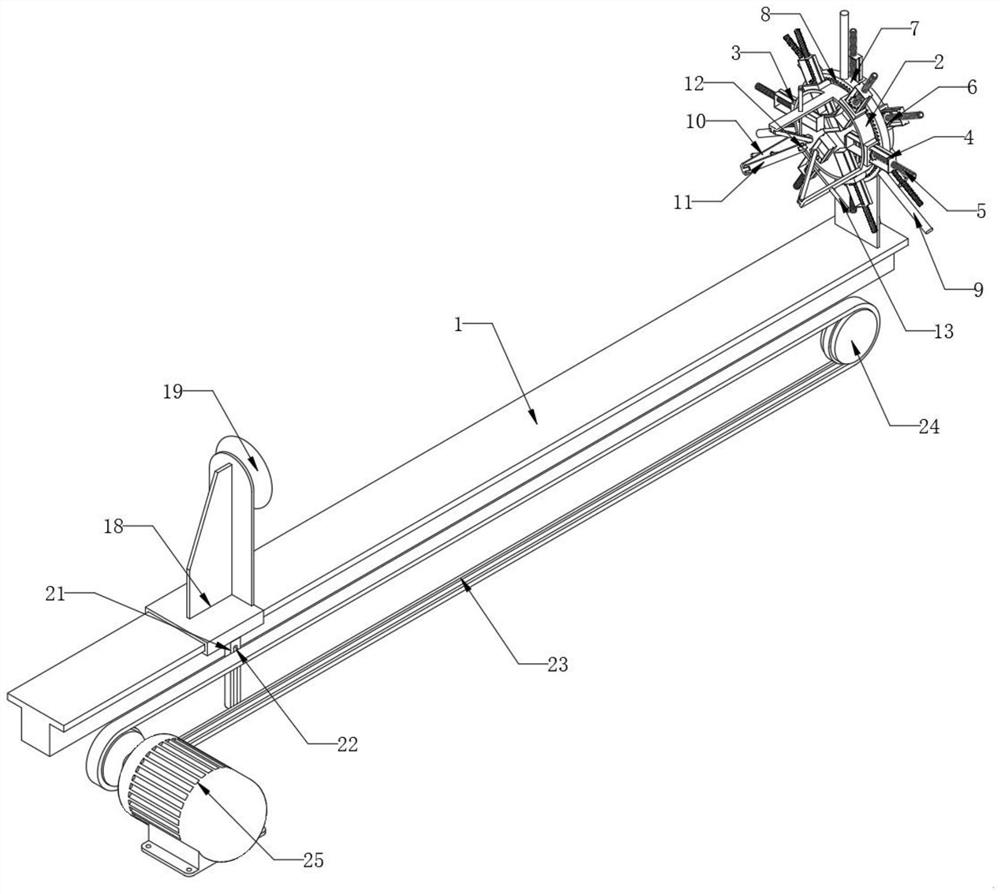

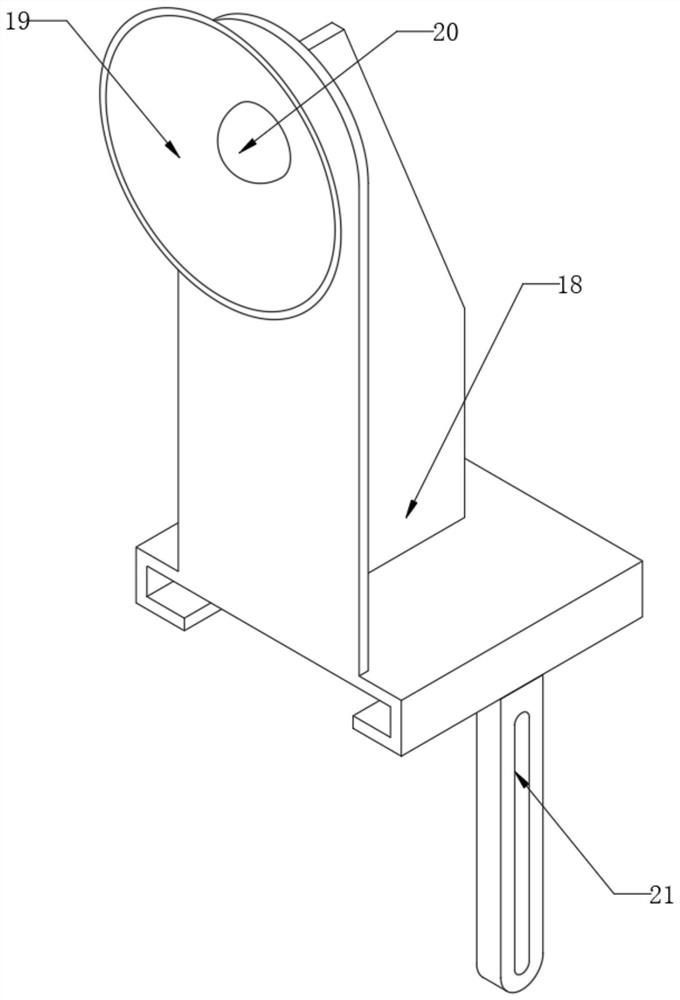

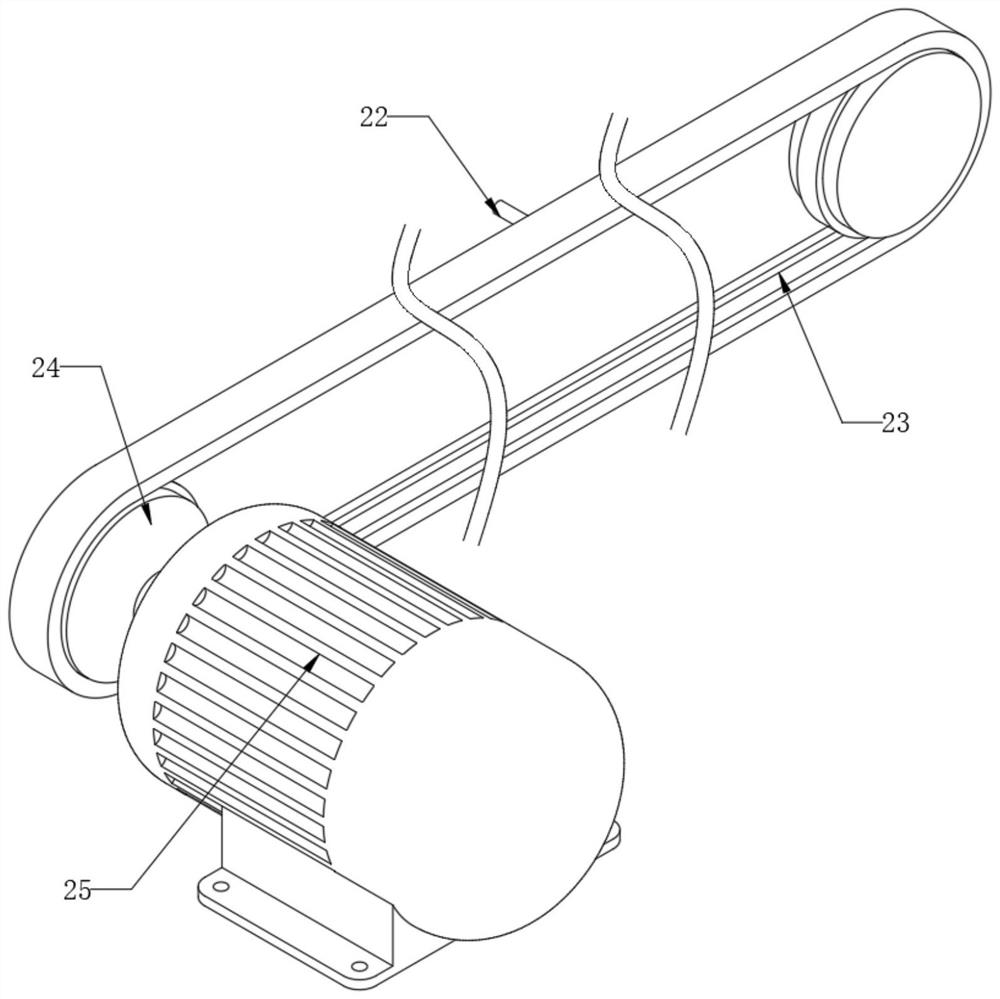

The invention discloses bamboo green and yellow separation equipment and a separation method thereof, and belongs to the field of bamboo green and yellow separation. The bamboo green and yellow separation equipment comprises a guide rail, an annular fixing frame is fixedly connected to the edge of the upper side of the guide rail, a plurality of cutting blades are arranged on the annular fixing frame, and a cutting edge is arranged on one side of each cutting blade; the annular fixing frame is further provided with a cutter adjusting mechanism used for adjusting the positions of the multiple cutting blades, the annular fixing frame is further provided with a bamboo body guiding mechanism used for positioning bamboos in the middle of the annular fixing frame, the guiding rail is further provided with a bamboo body transmission mechanism and a power assembly, and the bamboo body transmission mechanism is slidably connected to the upper side of the guiding rail. According to the bamboo green and tabasheer separating device, the bamboo green and tabasheer separating work can be simply and rapidly completed, a user can utilize the bamboo green and tabasheer according to different material characteristics of the bamboo green and tabasheer, the utilization rate of bamboo wood is improved, the separating efficiency is high, the separating difficulty is low, and the separating accuracy is high.

Owner:FUJIAN SHUANGYI BAMBOO DEV CO LTD

Rice dust removal and screening device

The invention discloses a rice dust removal and screening device. The device comprises a box body, wherein a feeding funnel is fixed on the top surface of the box body, the feeding funnel is communicated with the box body, and a fixing rod is transversely fixed in the feeding funnel. According to the rice dust removal and screening device, through the arrangement of a material distributor, the rice discharged from the feeding funnel can evenly fall onto the screen through the distributor, so that the situation that the rice is accumulated on the screen below the feeding funnel is effectively avoided, the screening effect of the screen is effectively improved, the rice on the screen mesh cannot be gathered together due to vibration through the arrangement of the partition plates, and the situation that the rice on the screen is shaken off from the screen due to vibration is effectively prevented, due to the arrangement of a magnet plate, scrap irons and the small-grain rice fall down from the screen together, the scrap irons can be sucked by the magnet plate, the small-grain rice can be packaged without scrap irons, so that the separation work of the scrap irons and the small-grainrice are effectively realized, and unnecessary waste is effectively avoided.

Owner:宿迁市君来米业有限公司

Screening device used before sowing of garden and forestry seeds

InactiveCN112808577AAchieving separation of workImprove processing efficiencySievingScreeningAgricultural engineeringMechanical engineering

The invention relates to the technical field of garden planting, and more specifically relates to a screening device used before sowing of garden and forestry seeds. The screening device comprises a screening machine body and a screening bin, the screening bin is slidably mounted in the screening machine body, threaded rods which penetrate through two ends of the screening bin and are in threaded connection with the screening bin are symmetrically and rotatably mounted in the screening machine body, a stepping motor used for driving the threaded rods is arranged on the screening machine body, a mounting frame is fixedly mounted on the screening machine body, the stepping motor is fixedly mounted on the mounting frame, a plurality of screens are slidably inserted into the screening bin, springs are fixedly connected between two sides of the screens and the screening bin, and a screening driving mechanism is arranged in the screening machine body. According to the device, screening is conducted according to the size of seed particles, wizened seeds and saturated seeds are effectively separated through the buoyancy effect of water, and the whole screening effect is improved.

Owner:黄召

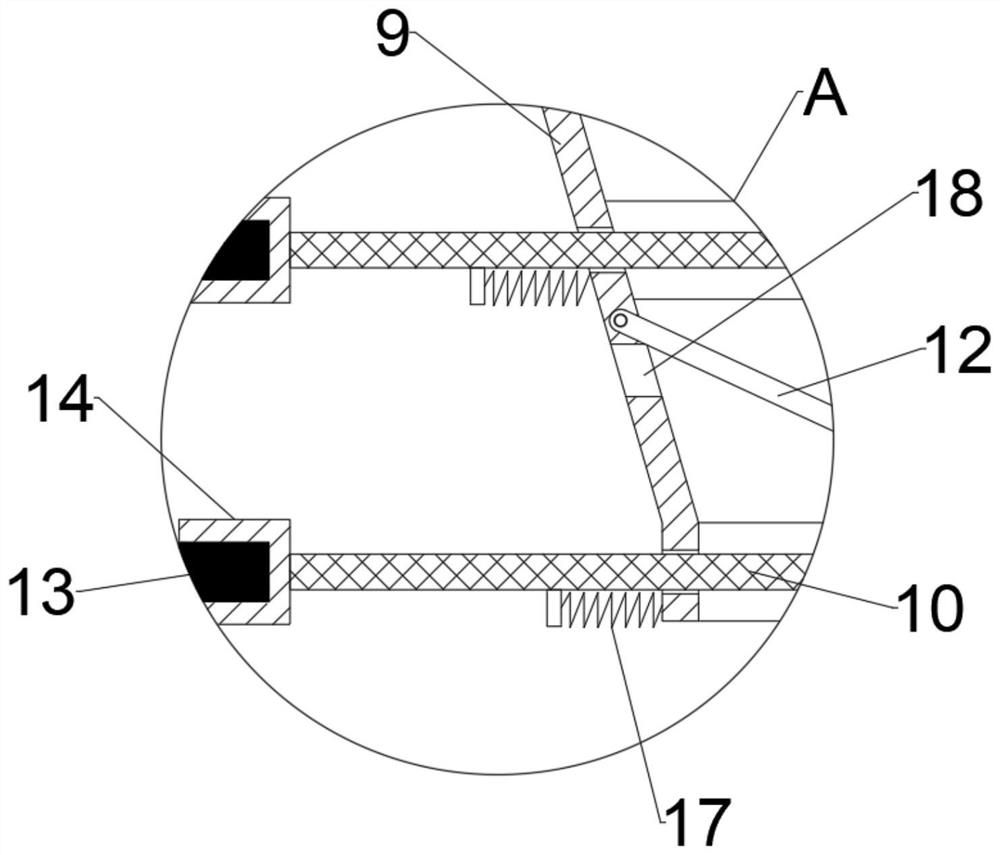

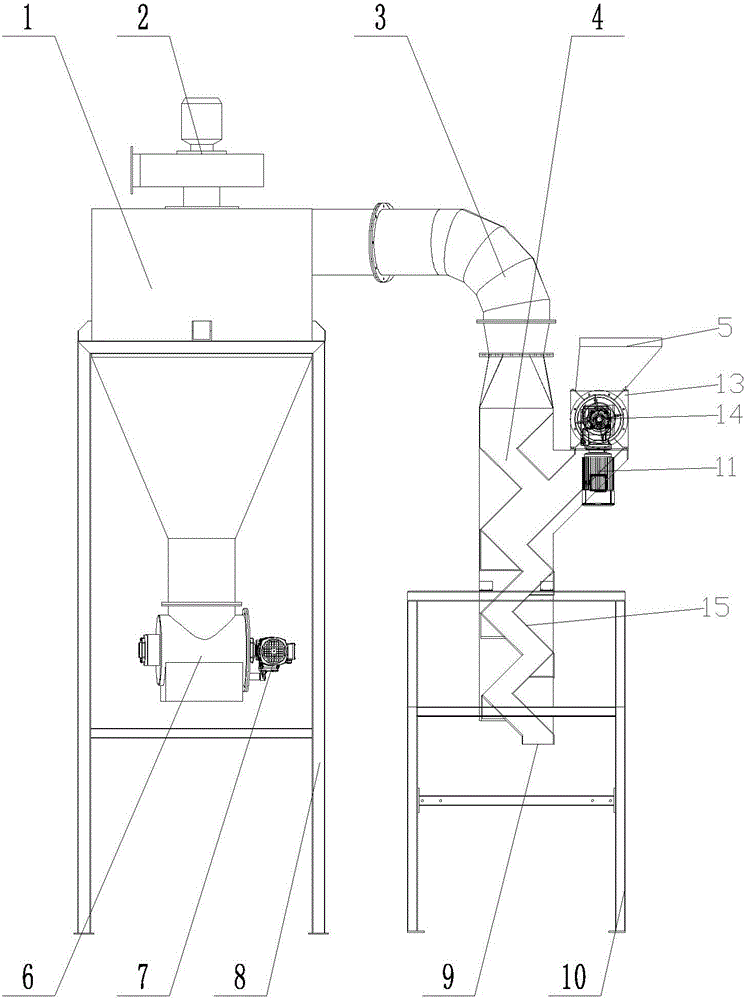

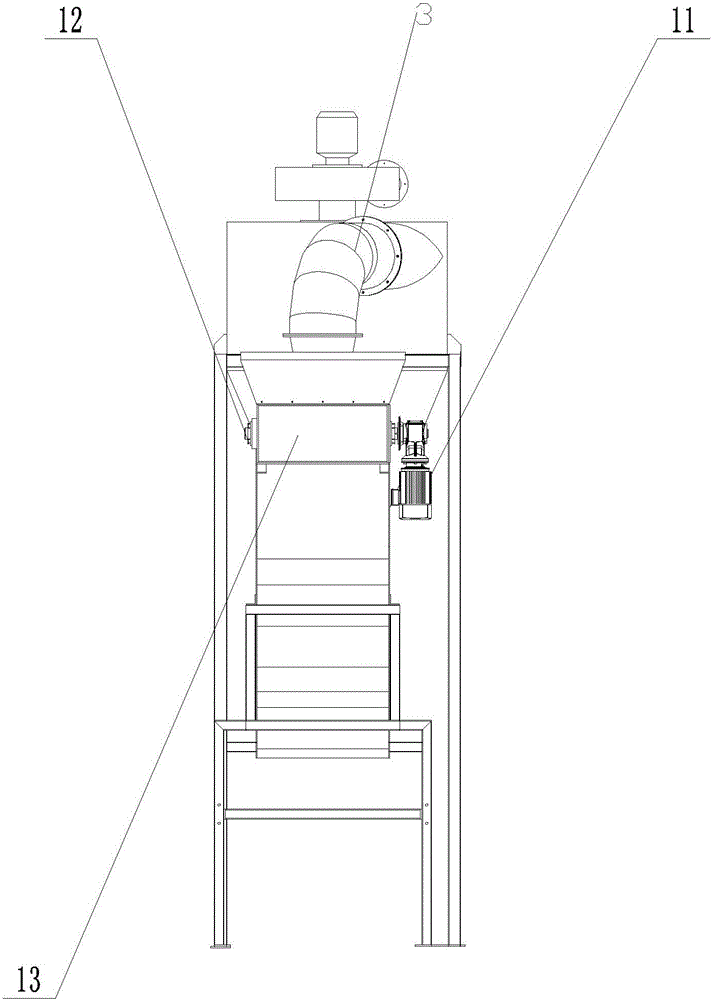

Glass plastic airflow separator

InactiveCN105817418AAchieving separation of workEasy to separateGas current separationMechanical engineeringPhysics

The invention relates to a separator, in particular to a glass plastic airflow separator, and belongs to the technical field of separation equipment. The glass plastic airflow separator comprises a plastic collecting barrel, a draught fan, a bend, a separator body, an unloader, a bearing fixing base, a material scattering box, a material scattering rotor and separation pipes. A separation channel is arranged in the separator body and comprises the multiple separation pipes of a Z-shaped structure, and the multiple separation pipes are connected into a whole in sequence from top to bottom. A feeding port is formed in the side face of the separator body, the material scattering box is arranged in the feeding port, and the interior of the material scattering box is rotationally connected with the material scattering rotor through the bearing fixing base. A discharging port is formed in the lower end of the separator body, and the upper end of the separator body is connected with the plastic collecting barrel through the bend. The draught fan is arranged on the plastic collecting barrel. According to the glass plastic airflow separator, the separation work of glass and plastic can be achieved, the work efficiency is improved, and the separation effect is good. The glass and the plastic can be sufficiently separated through the separation pipes of the Z-shaped structure.

Owner:江苏绿凯思科环保科技有限公司

Kiwi fruit processing device and method

ActiveCN109222114AImprove crushing efficiencyGood crushing effectJuice extractionKiwi fruitEngineering

The invention relates to the field of processing of fruits and vegetables, in particular to a kiwi fruit processing device and method. The kiwi fruit processing device includes a crushing and separating box, a driving device, a reciprocating extrusion plate, a crushing cutter wheel, a feeding box, a primary crushing feeder, a juice collecting box, a fruit residue collecting box and a support; thecrushing and separating box is fixedly connected to the support; the driving device is fixedly connected to the rear end of the crushing and separating box and is in transmission connection with the reciprocating extrusion plate, and the reciprocating extrusion plate is slidably and cooperatively connected to the right end of the inner side of the crushing and separating box; the crushing cutter wheel is rotatably and cooperatively connected to the left end of the inner side of the crushing and separating box; the reciprocating extrusion plate is in transmission connection with the crushing cutter wheel. The kiwi fruit processing device can achieve putting of kiwi fruit raw materials, crushing of kiwi fruits and separation of kiwi fruit juice from pulp and peels synchronously, the efficiency of crushing the kiwi fruits is high, and the crushing effect is great.

Owner:徐州丰姚农业发展有限公司

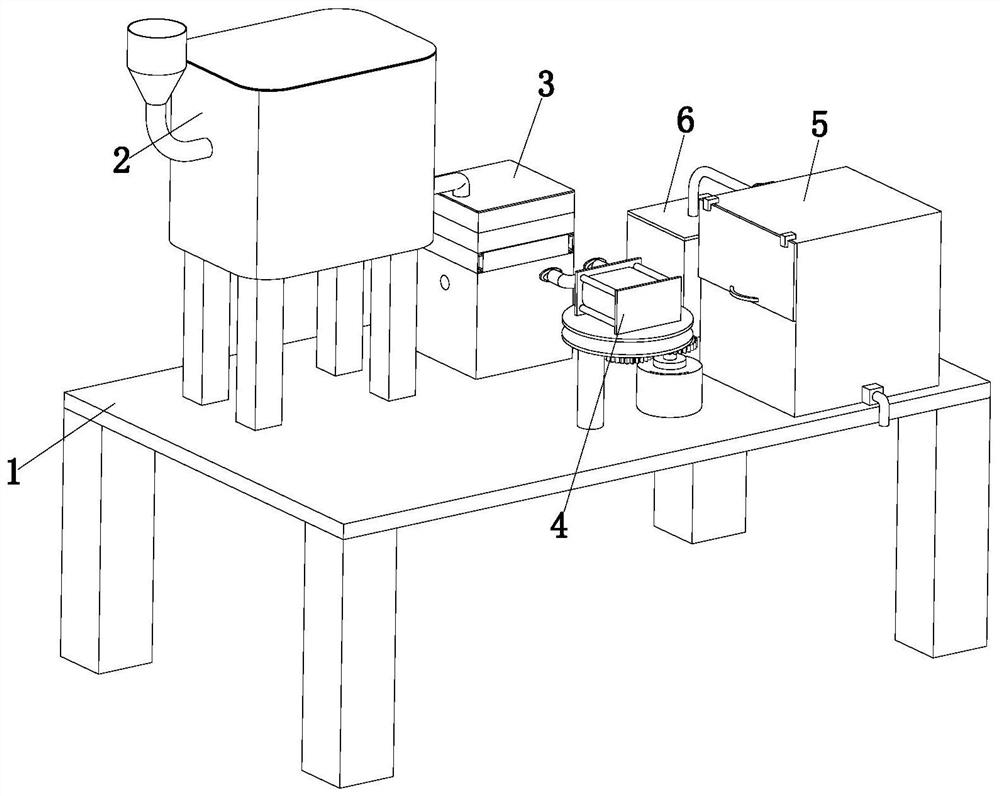

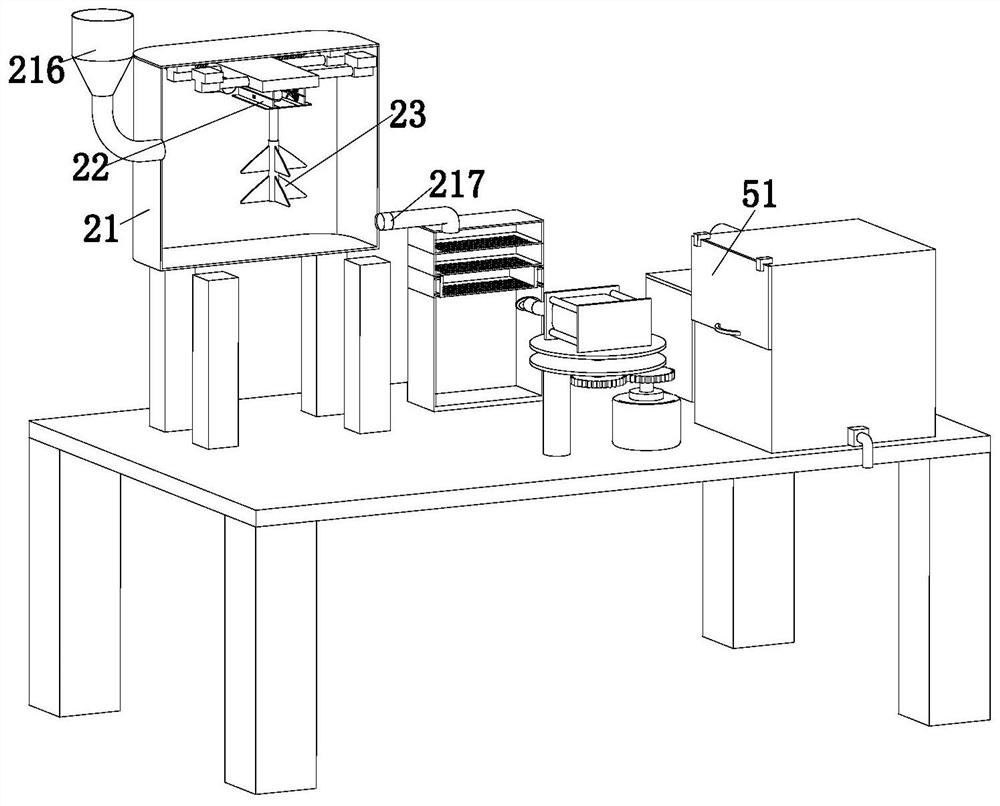

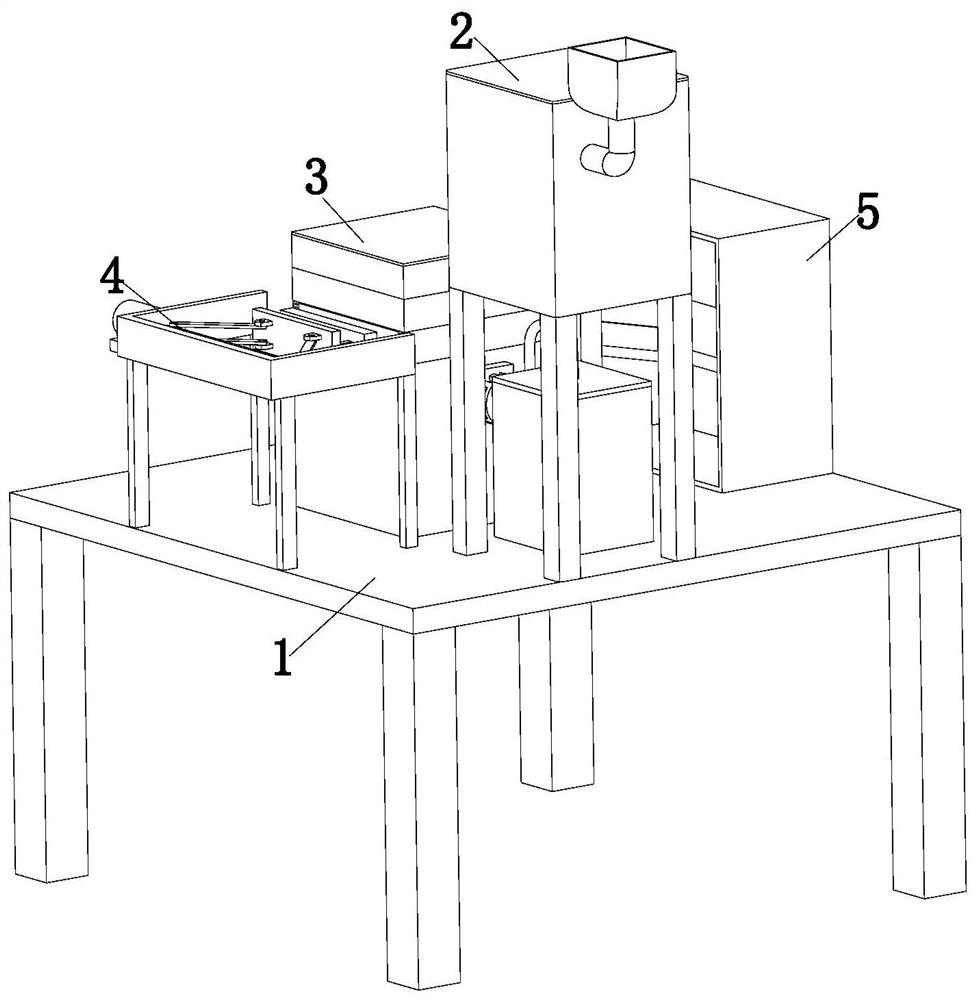

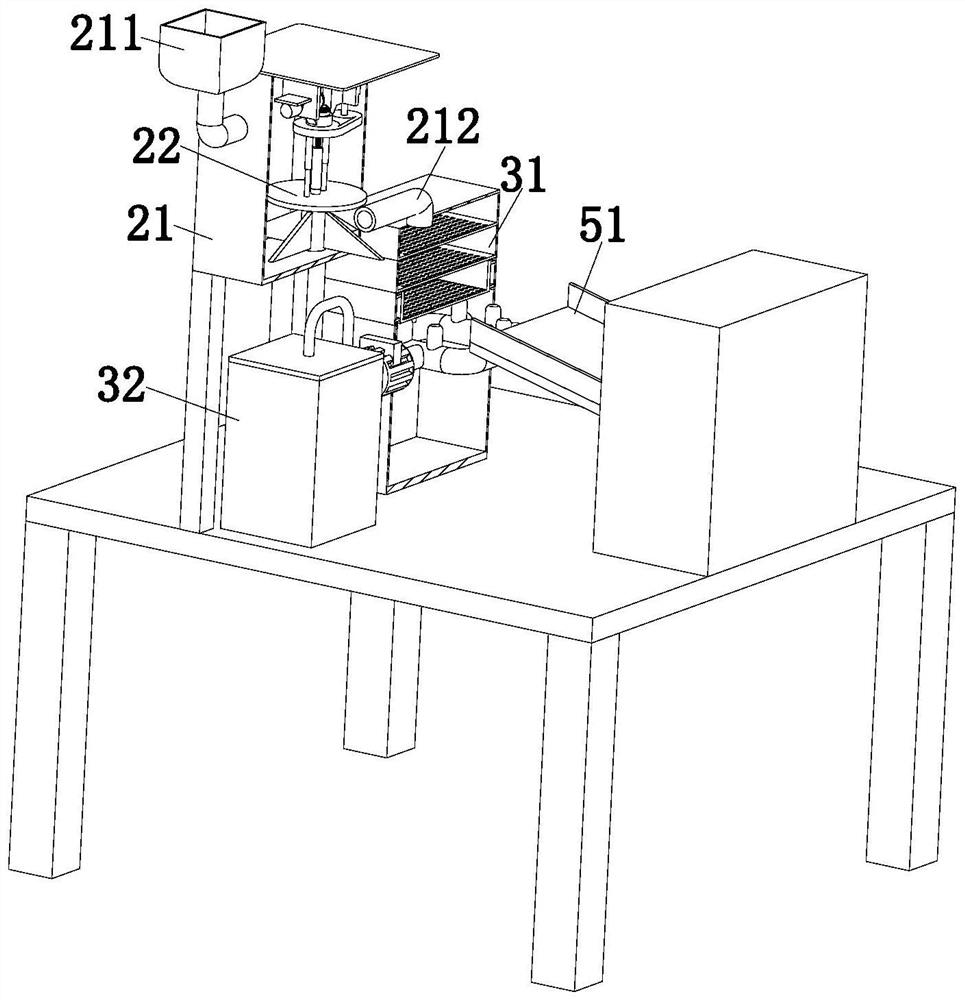

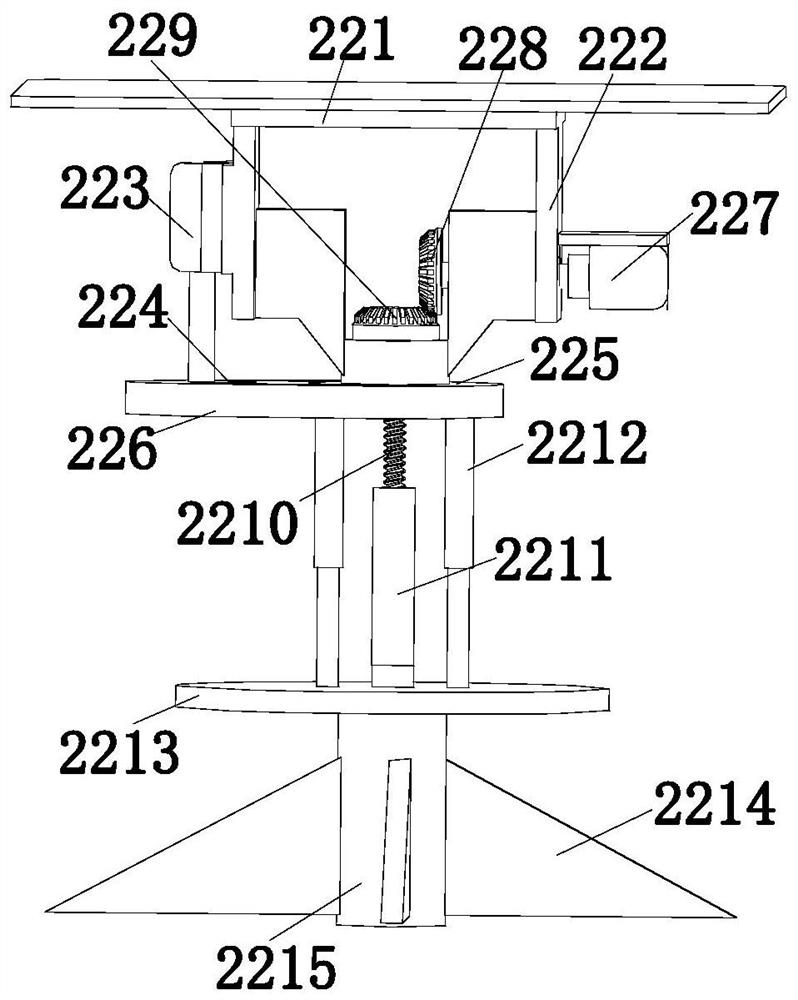

Stem cell amplification device

InactiveCN112553050AImprove practicalityPromote amplificationBioreactor/fermenter combinationsBiological substance pretreatmentsBiotechnologyPetri dish

The invention relates to the technical field of stem cell amplification, in particular to a stem cell amplification device. The device comprises a workbench, a separation device, an extraction box, atransfer device, a culture dish and a culture solution spraying device. The workbench is arranged on a horizontal plane, the separation device is arranged on the workbench, the extraction box is arranged on the surface of the workbench and located beside the separation device, the transfer device is arranged on the workbench and located on the opposite side of the extraction box, and the culture dish is arranged on the workbench and located beside the transfer device. The culture solution spraying device is arranged on the workbench, and the spraying end of the culture solution spraying deviceextends into the culture dish. The separation device separates stem cells in blood, the extraction box extracts the stem cells, and the transfer device transfers the extracted stem cells into the culture dish. The culture solution spraying device sprays a culture solution on the surfaces of the stem cells uniformly, so that stem cell amplification is facilitated.

Owner:杨慧慧

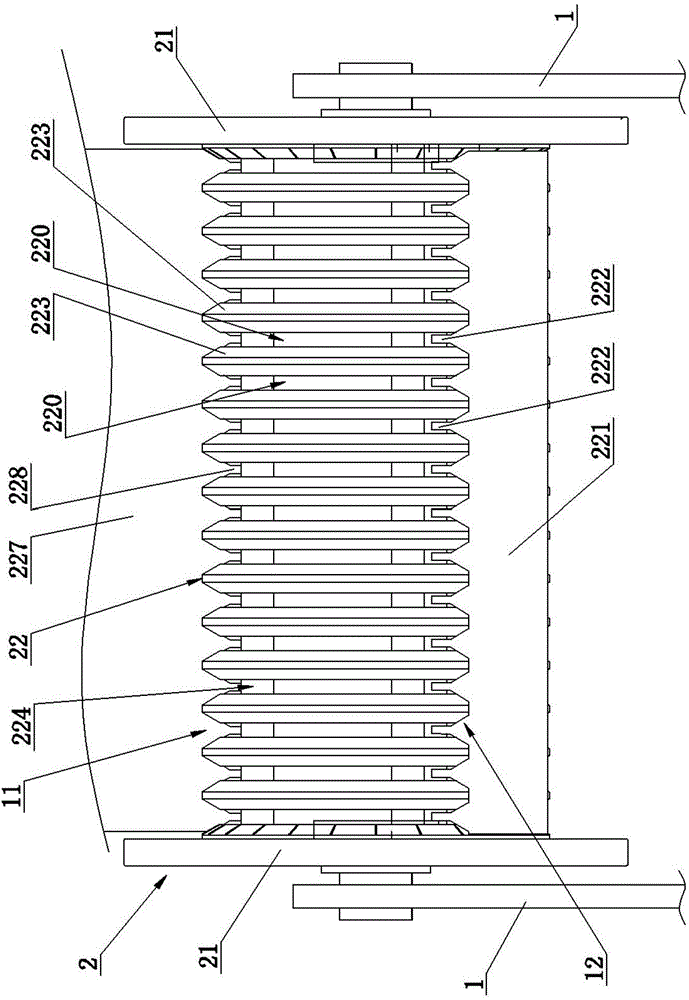

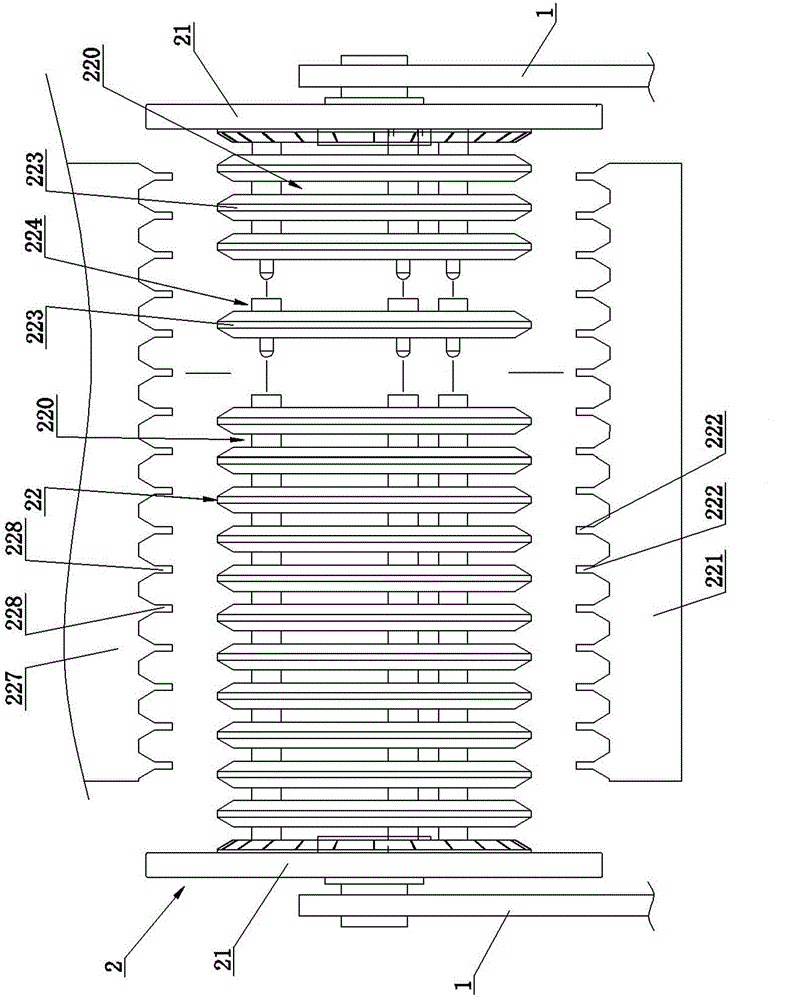

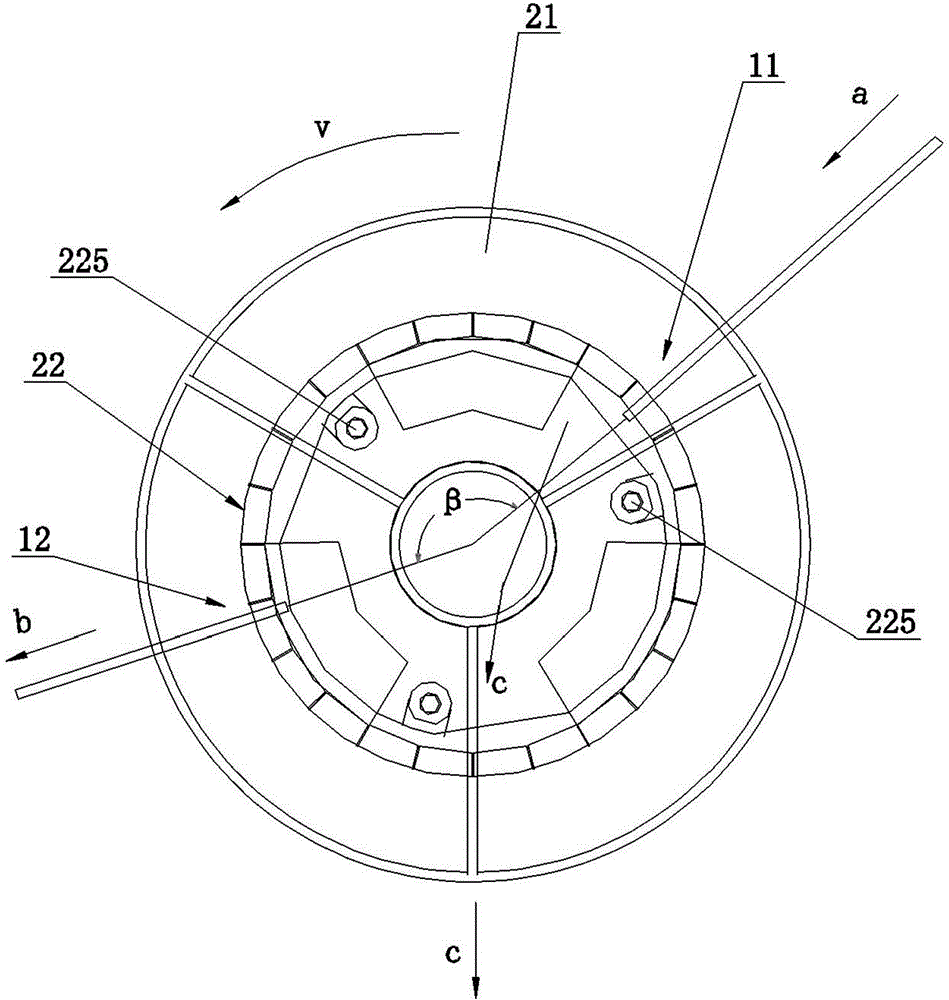

Energy-saving fractionation device for xylene production

ActiveCN113842659AImprove the completeness of adsorptionReduce usageDistillation regulation/controlSolid sorbent liquid separationXylyleneEngineering

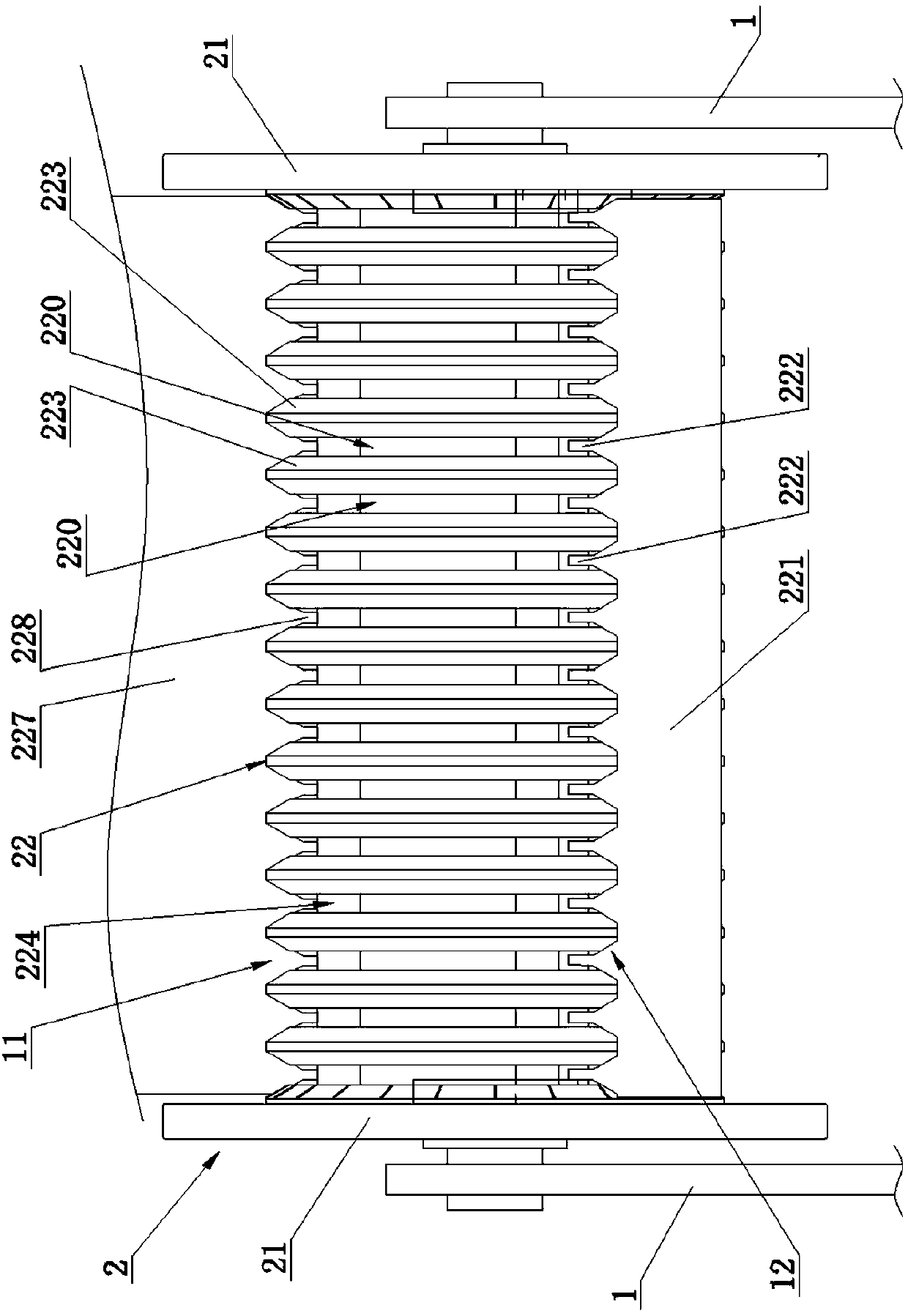

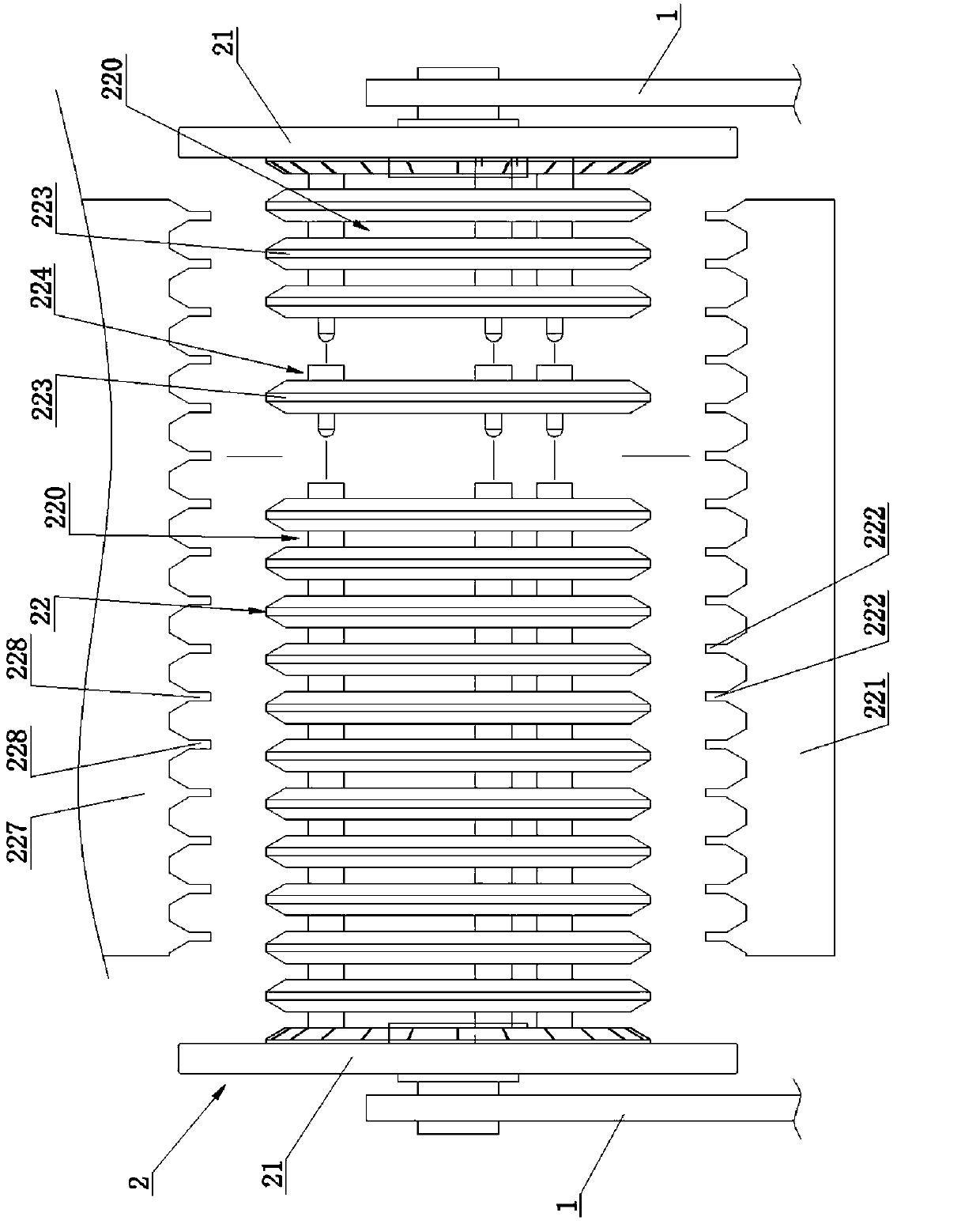

The present invention discloses an energy-saving fractionation device for xylene production, and relates to the technical field of xylene fractionation. The energy-saving fractionation device for xylene production comprises a first box body and a second box body installed at the bottom of the first box body, wherein the bottom of the second box body is rotatably provided with a vertical screw, a driving mechanism in transmission connection with the top end of the screw is fixed to the top of the first box body, the top of the screw is sleeved with a sleeve in a threaded mode, a first circular plate and a second circular plate are fixed to the two ends of the sleeve correspondingly, the circumferential outer walls of the first circular plate and the second circular plate are close to and do not make contact with the inner walls of the first box body and the second box body, a vertical pipe is fixed between the first circular plate and the second circular plate, and a plurality of sets of annularly-distributed adsorption plates are fixed to the circumferential outer wall of the vertical pipe. The adsorption plates can fully adsorb stock solutions at different heights in the first box body and the second box body in the lifting process, and the usage amount of a desorption solution is reduced.

Owner:东营威联化学有限公司

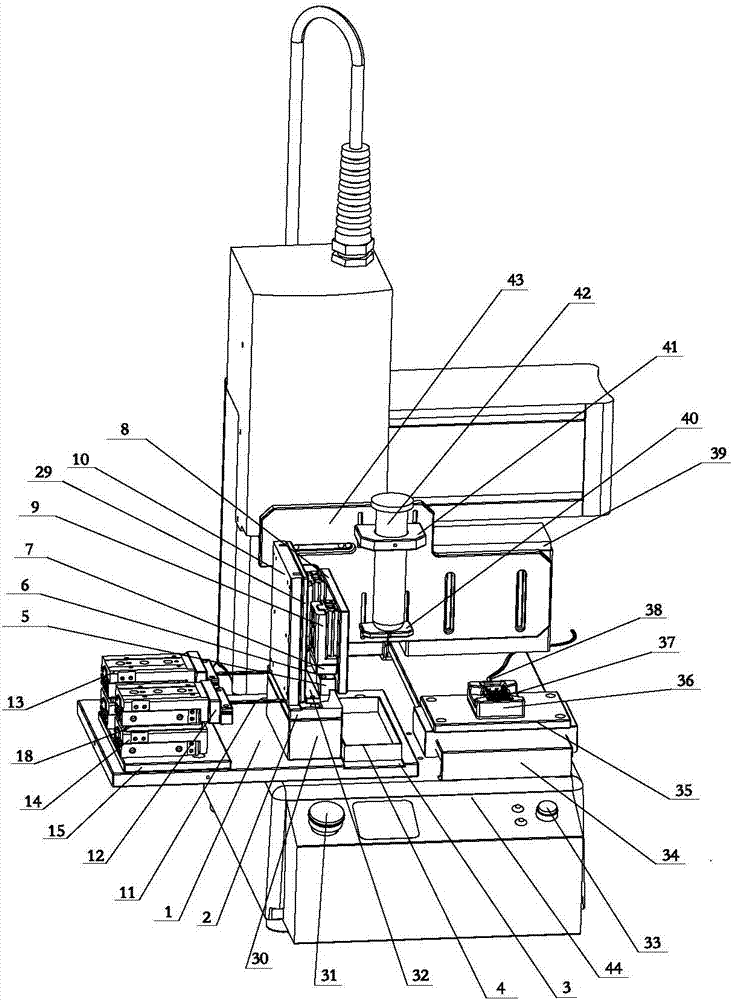

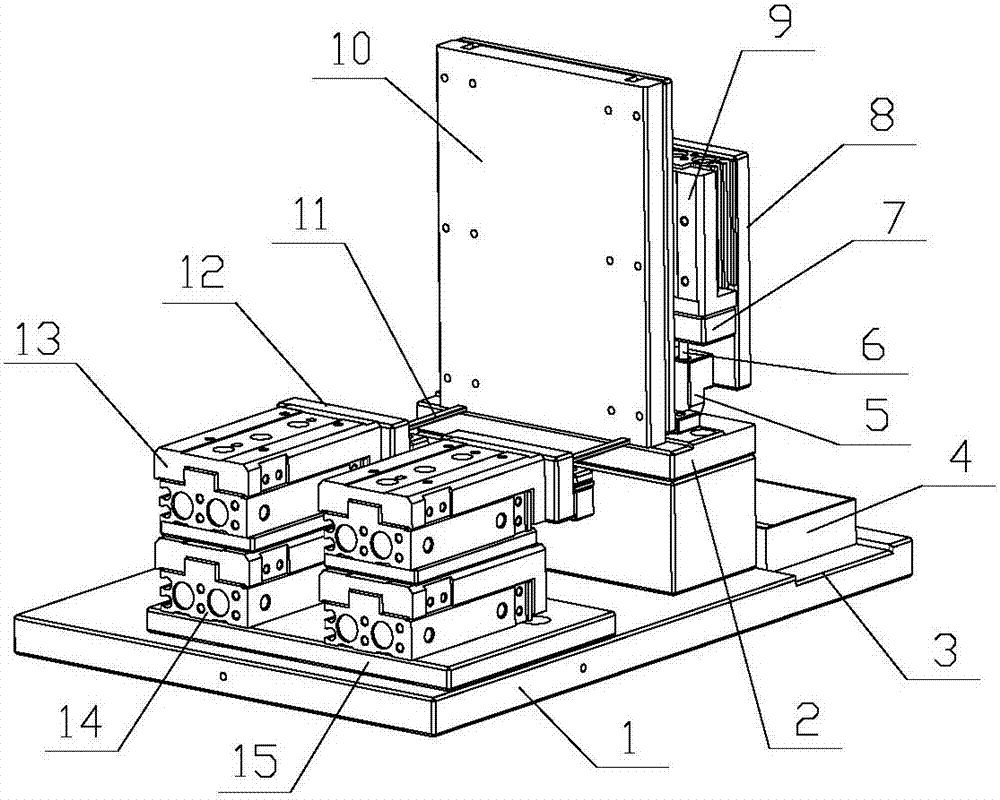

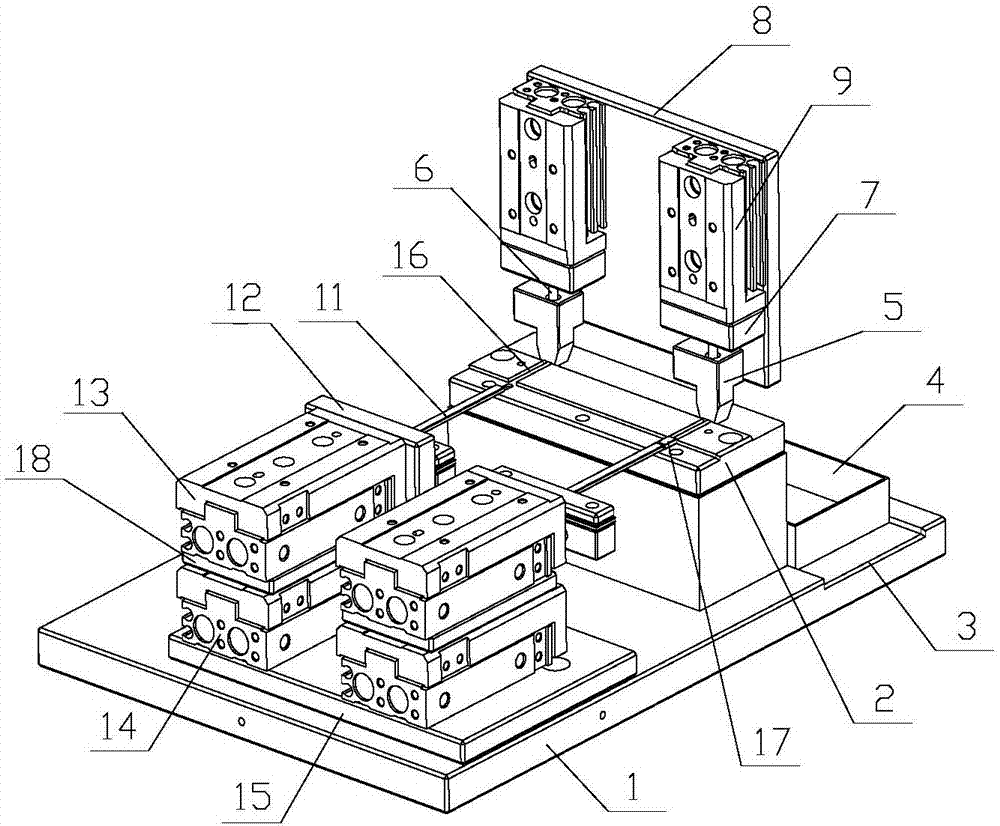

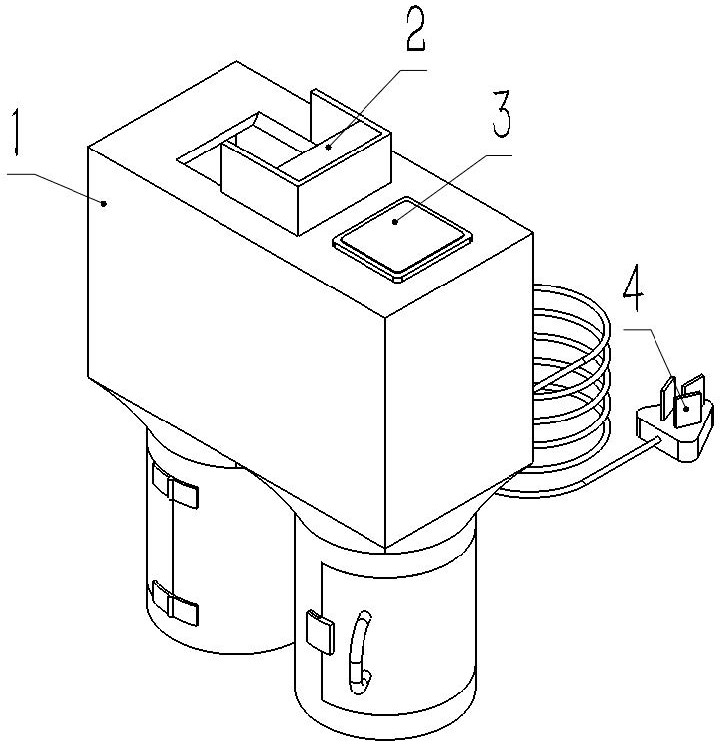

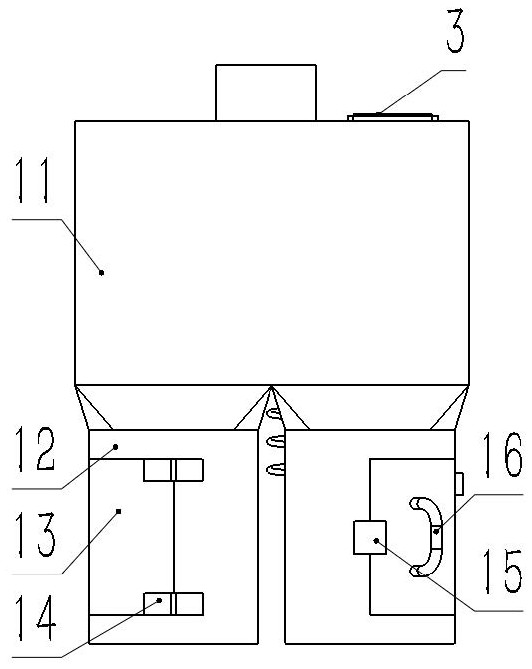

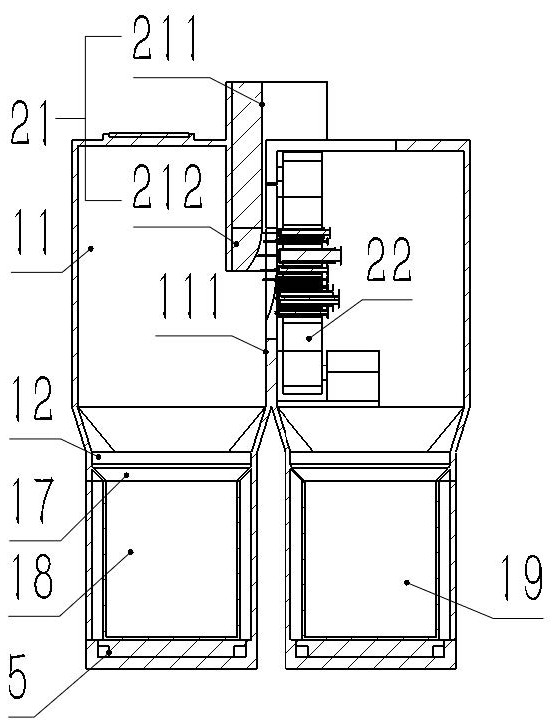

Magnetic material assembling device

ActiveCN107257619AAchieving separation of workRealize the delivery workElectrical componentsEngineeringMechanical engineering

A magnetic material assembling device provided by the present invention comprises a product fixing base, a separating mechanism and a dispensing mechanism. The product fixing base is installed on a Y-axis motion mechanism, the dispensing mechanism is installed on a Z-axis motion mechanism, and the separating mechanism comprises a separation fixing base. A feed bin is arranged above the separation fixing base, a discharging port is arranged at the bottom of the feed bin, and a discharging gap is formed between the discharging port and the separation fixing base. A separation ejecting block is arranged at one side of the feed bin, and a horizontal push mechanism is arranged at the other side of the feed bin. The horizontal push mechanism and the separation ejecting block are located at the relative two sides of the feed bin respectively, and the horizontal push mechanism and the Z-axis motion mechanism are arranged on an X-axis motion mechanism separately. The magnetic material assembling device of the present invention separates the magnetic materials, the horizontal push mechanism transports the magnetic materials to a product on the product fixing base to assemble, and the dispensing mechanism fixes the assembled materials, thereby separating, transporting and assembling the magnetic materials, being convenient to operate and easy to separate, being high in assembly efficiency and strong in reliability.

Owner:GEER TECH CO LTD

Iron removal device for mineral processing

PendingCN113019696AGuaranteed continuityGuaranteed validityMagnetic separationGrain treatmentsMineral collectingDrive motor

The invention discloses an iron removal device for mineral processing, and relates to the technical field of mineral processing. The iron removal device comprises a main body, a separation mechanism and a feeding mechanism, the separation mechanism is arranged on the upper side of the interior of the main body, and the upper end of the main body is connected with the feeding mechanism; and the feeding mechanism comprises a feeding bin, and the feeding bin is of a calabash-shaped hollow structure. A conveying belt is integrally formed by the insulating connecting pieces and the electromagnetic rod which are connected at intervals, the conveying belt is driven to rotate by matching a driving wheel with a driving motor, and the electromagnetic rod is electrified by matching conductive pieces arranged at the two ends of the electromagnetic rod, so that the electromagnetic rod adsorbs iron in minerals in the mineral conveying process. When the mineral is conveyed to the left end, the mineral falls into a mineral collecting bin due to the gravity of the mineral, iron continues to be conveyed through adsorption of the electromagnetic rod, when the mineral is conveyed to the notches of the conductive pieces, the electromagnetic rod is powered off, the iron falls into the iron collecting bin due to the gravity of the iron, and the work of separating the iron in the mineral is achieved.

Owner:KUNMING UNIV OF SCI & TECH

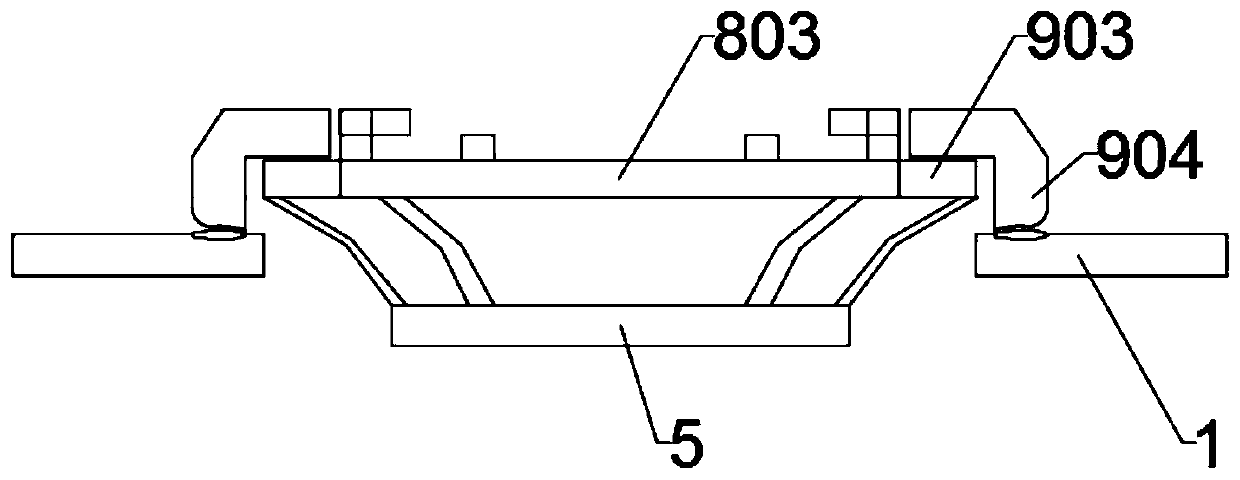

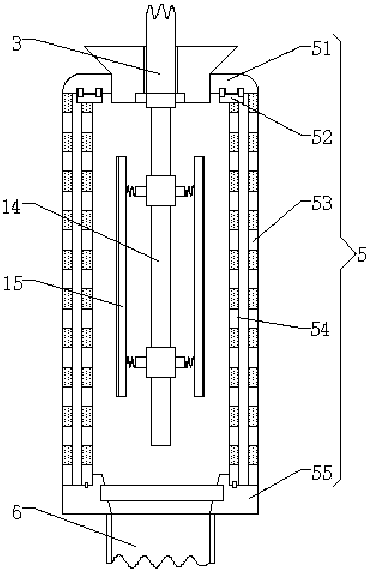

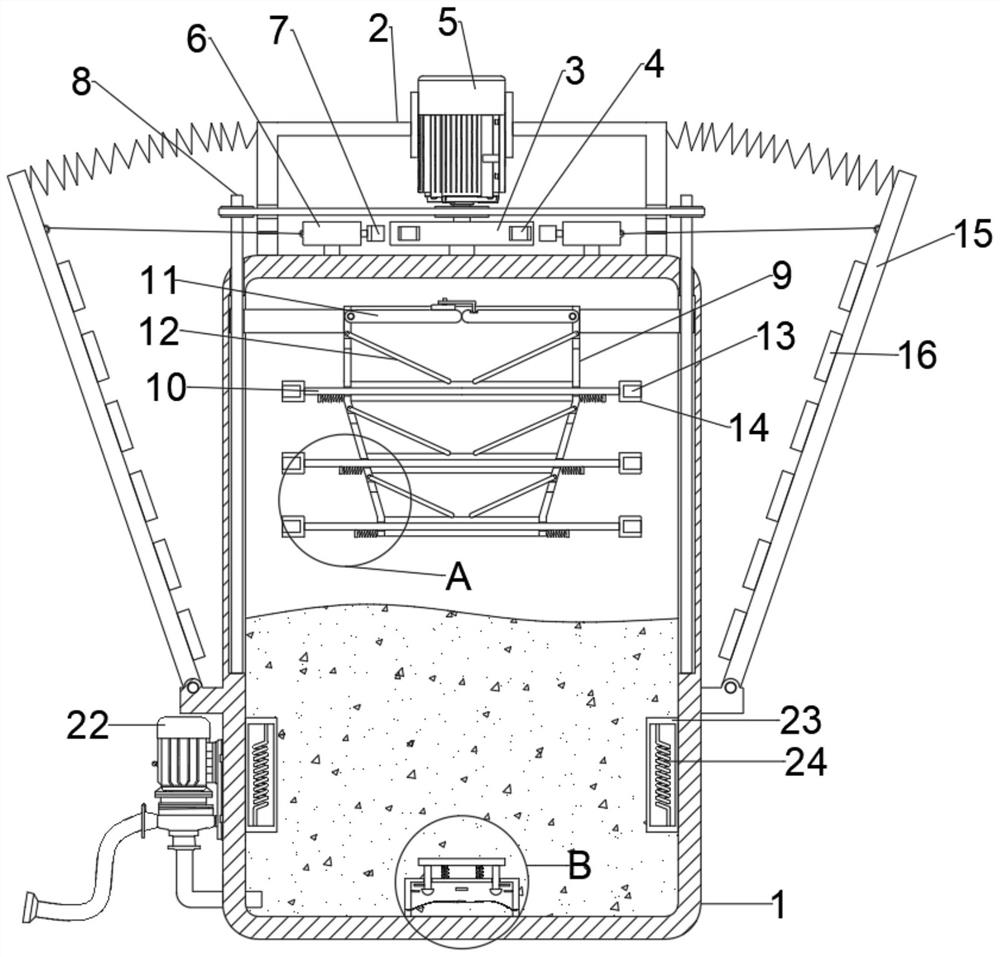

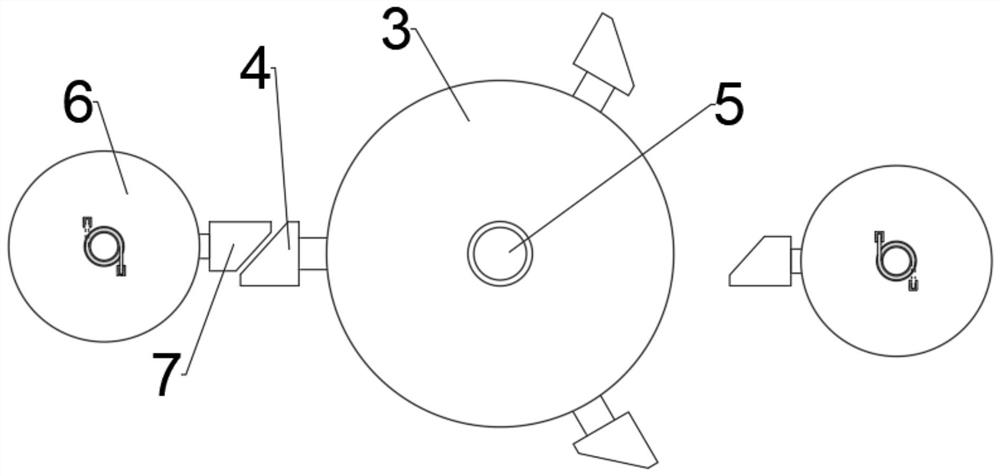

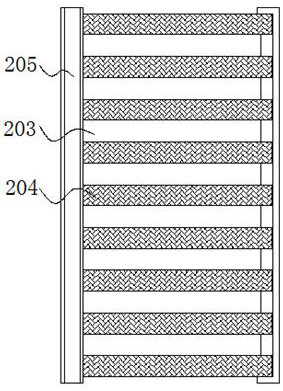

Underwater mud-water separation device for test pools

ActiveCN108609824AGuaranteed to passAvoid cloggingSludge treatment by de-watering/drying/thickeningStationary filtering element filtersWater poolChemical engineering

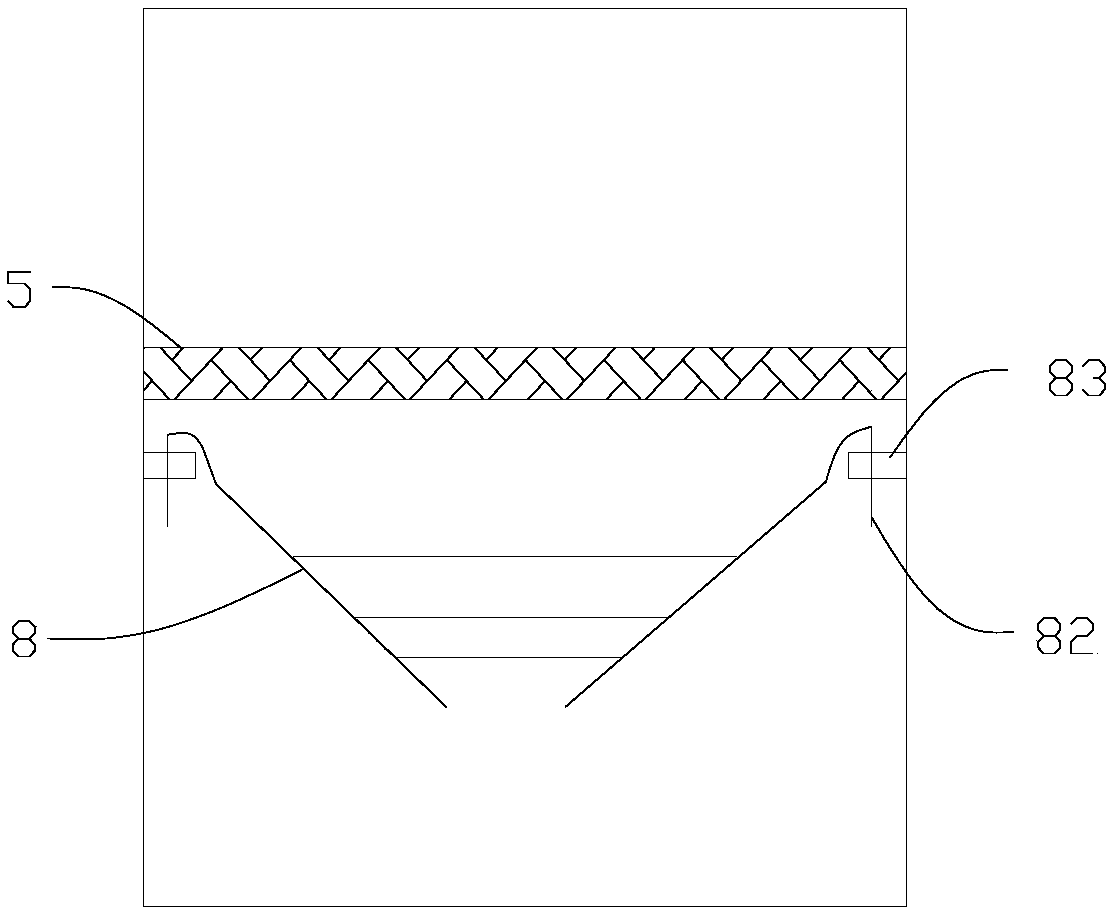

The invention discloses an underwater mud-water separation device for test pools. The device includes a filter cylinder, the top of the filter cylinder is equipped with an upper cover plate, the bottom is equipped with a lower fixed plate, and the undersurface of the filter cylinder is supported by a support seat; a mud guard, a coarse filter plate and a fine filter plate are installed parallellyat interval inside the filter cylinder from top to bottom in order, a lead screw is installed at the middle part of the filter cylinder, guide rods are installed at two ends of the lead screw respectively, the lead screw and guide rods pass through the mud guard, the coarse filter plate and the fine filter plate in order, and lead screw nuts are installed to the lead screw above the mud guard, atthe same time two ends of the lead screw support the upper cover plate and the lower fixed plate respectively through bearings, and both ends of the guide rods are locked to the upper cover plate andthe lower fixed plate through nuts respectively, positioning sleeves are installed at the bottom of the lower fixed plate, and encircle the nuts at the bottoms of the guide rods. The device provided by the invention improves the mud-water separation work efficiency.

Owner:CHINA SHIP SCIENTIFIC RESEARCH CENTER (THE 702 INSTITUTE OF CHINA SHIPBUILDING INDUSTRY CORPORATION)

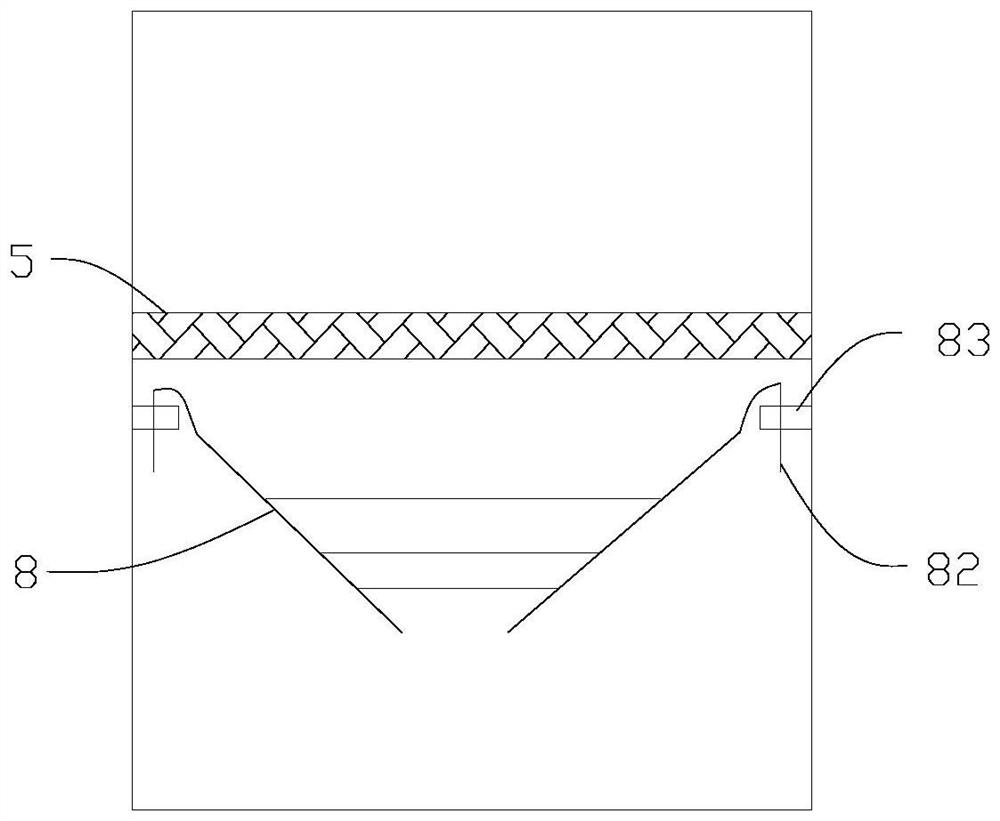

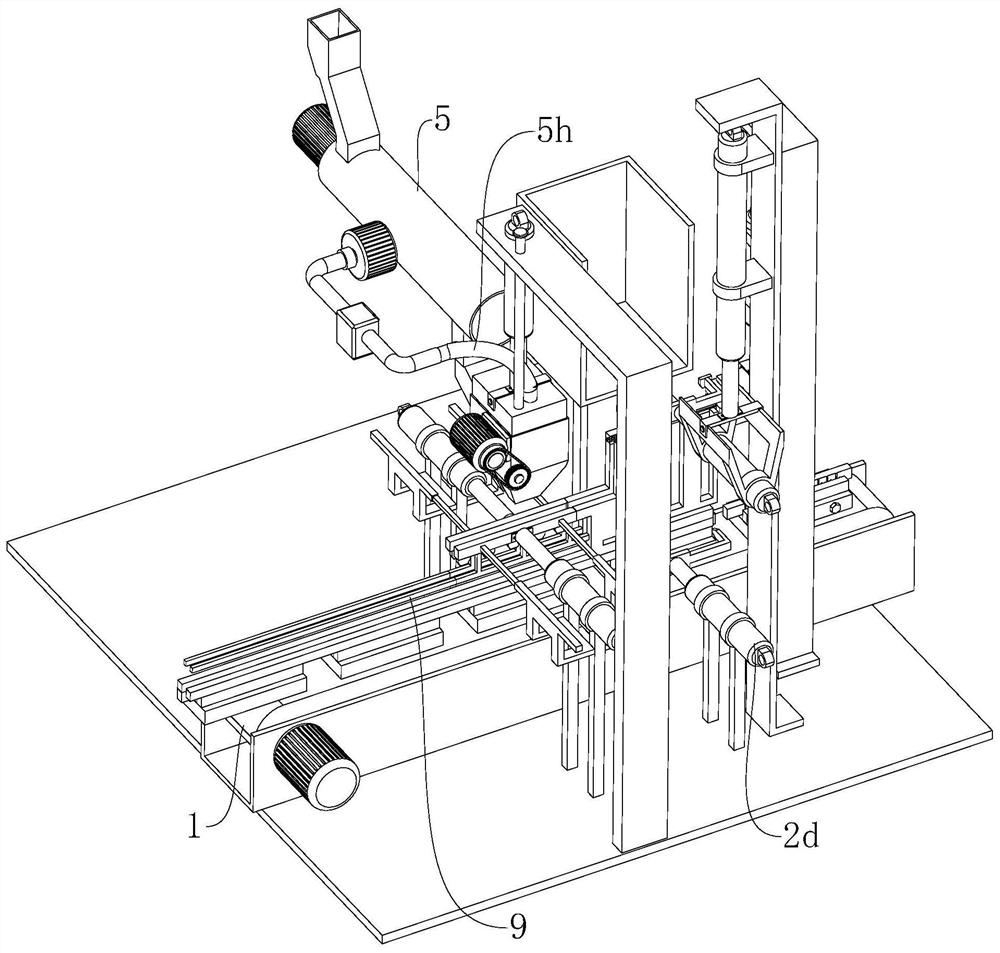

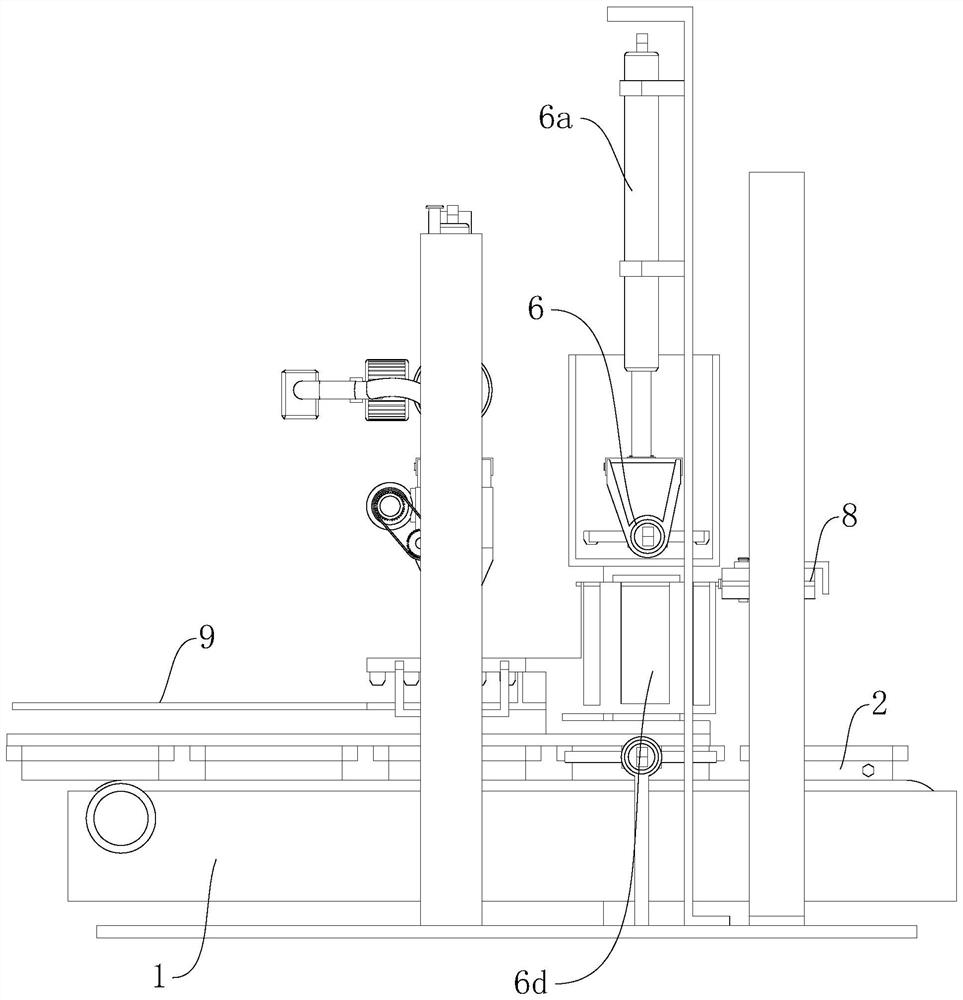

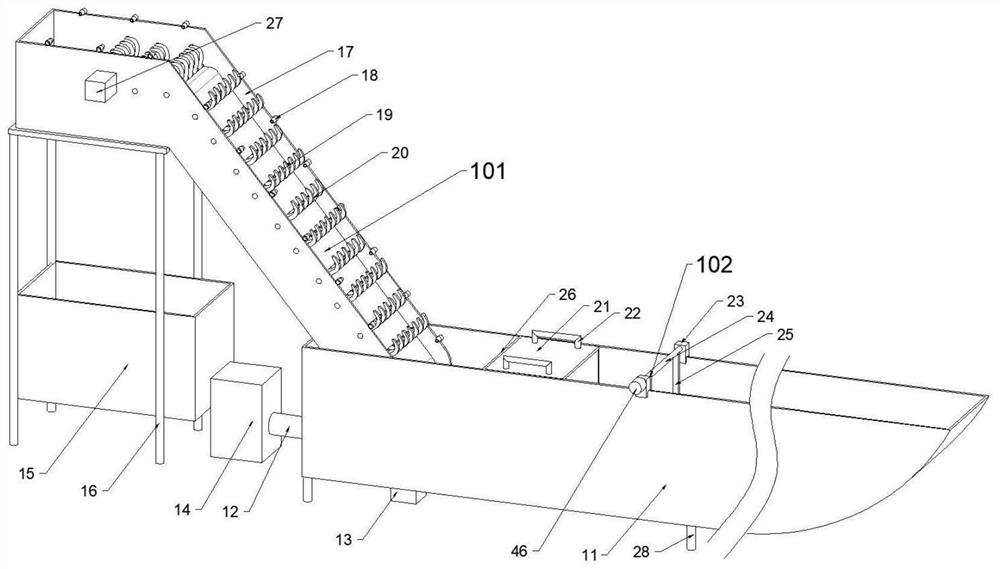

Automatic filling equipment and filling method for abalone soft can

ActiveCN111470099AAchieving separation of workEliminate the effects of sputteringLiquid materialAnimal scienceEngineering

The invention relates to the field of abalone processing equipment, in particular to automatic filling equipment and filling method for an abalone soft can. The automatic filling equipment comprises aretort pouch bracket, and the filling equipment comprises a filling conveyor belt, a bag opening mechanism, a filling mechanism, a feeding mechanism and a bag feeding mechanism; and a plurality of jigs arranged at intervals in the conveying direction are arranged on the conveying plane of the filling conveyor belt, the filling mechanism is inverted and capable of being vertically and movably arranged above the middle section of the filling conveyor belt through a micro motion mechanism, the bag opening mechanism is arranged on the middle section of the filling conveyor belt and located underthe filling mechanism, the feeding mechanism is arranged beside the filling mechanism, the feeding mechanism communicates with the filling mechanism, the bag feeding mechanism and the retort pouch bracket are symmetrically arranged at the upstream end of the filling conveyor belt, two limiting baffles are symmetrically arranged between the bag feeding mechanism and the retort pouch bracket, a limiting narrow channel is formed between the two limiting baffles, and all the jigs are capable of moving directly below the limiting narrow channel one by one. The automatic filling equipment can automatically fill abalone into the soft can quantitatively so as to improve the production efficiency of the enterprise.

Owner:PUTIAN HUILONG SEAFOOD

Operating room waste disposal unit

ActiveCN109647845BEfficient separationAchieving separation of workSolid waste disposalLandfill technologiesOperating theatresStructural engineering

Owner:史明

A kind of automatic filling equipment and filling method of abalone soft can

ActiveCN111470099BAchieving separation of workEliminate the effects of sputteringLiquid materialAnimal scienceRetort pouch

The invention relates to the field of abalone processing equipment, in particular to an automatic filling equipment for soft canned abalone and a filling method thereof, including a retort bag bracket, and the filling equipment includes a filling conveyor belt, a bag opening mechanism, a filling mechanism, and a feeding mechanism And the bag feeding mechanism, the conveying plane of the filling conveyor belt is provided with a plurality of jigs arranged at intervals along the conveying direction, the filling mechanism is inverted and can be vertically moved by the micro-motion mechanism and is set above the middle section of the filling conveyor belt , the bag opening mechanism is set up in the middle of the filling conveyor belt and below the filling mechanism, the feeding mechanism is set up beside the filling mechanism, and the two are connected, and the bag feeding mechanism and the retort bag bracket are symmetrically arranged on the filling conveyor belt The upstream end of the two limit baffles is symmetrically arranged in the middle of the two limit baffles. A limit narrow passage is formed between the two limit baffles. The invention can automatically fill abalone quantitatively into soft cans, so as to improve the production efficiency of enterprises.

Owner:PUTIAN HUILONG SEAFOOD

Semi-automatic and accurate segmentation algorithm of dentures and jaws based on sag-aware harmonic scalar field

ActiveCN109993751BAccurate extractionReduce interactionImage enhancementImage analysisAlgorithmEngineering

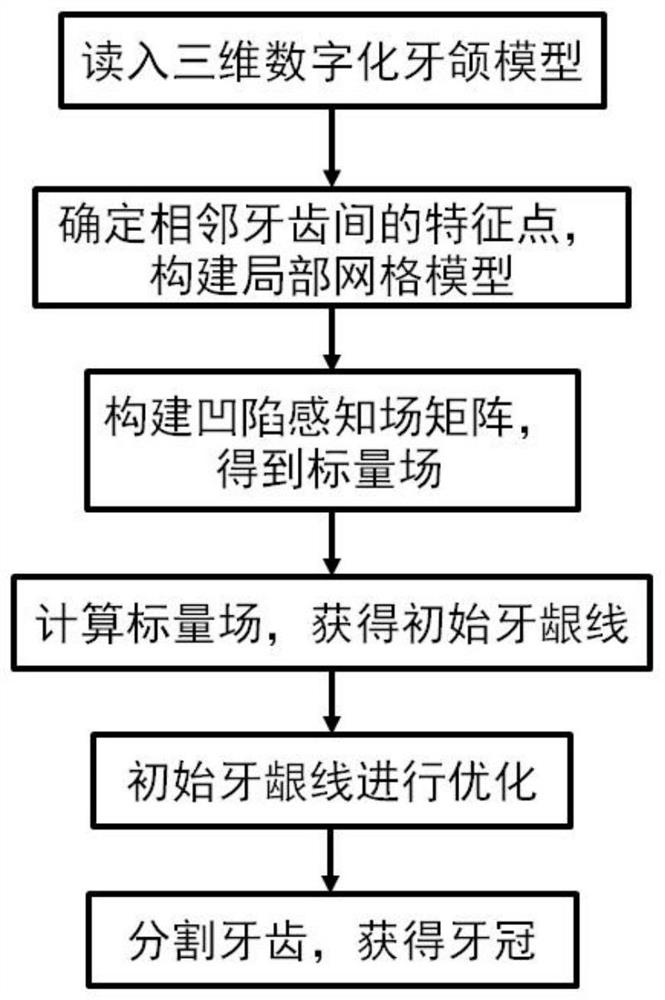

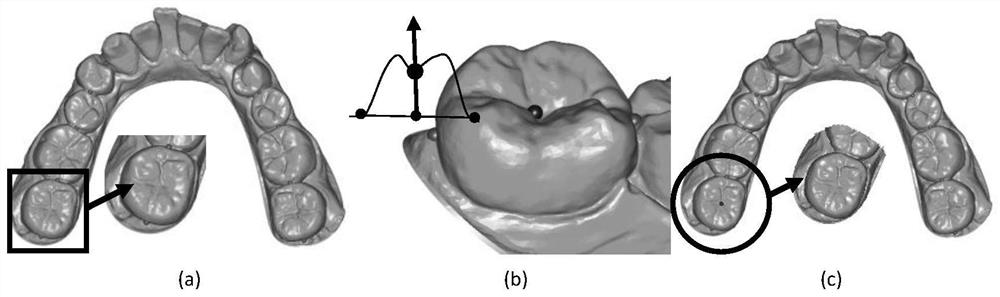

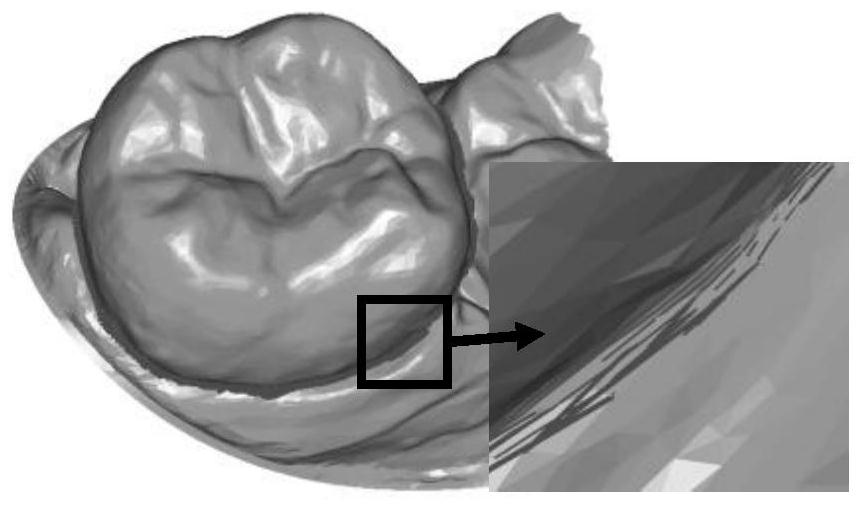

The invention discloses a semi-automatic precise segmentation algorithm for dentures and jaws based on the sag-sensing harmonic scalar field, which mainly includes the following steps: first, manually pick up a point on the gap between two adjacent teeth, and use the points picked up on both sides of each tooth The points of the local depression perception harmonic field matrix are constructed, and the harmonic scalar field of the local area of the model is calculated; secondly, a series of isolines are obtained on the local grid, and a voting mechanism is used to select the best isoline as the tooth dividing line; finally, the A heuristic feature line extraction algorithm optimizes the segmentation line to obtain precise gum lines and achieve precise tooth segmentation. Using this algorithm can achieve accurate segmentation of teeth, does not require too much subsequent manual interaction, has a high degree of automation, and takes less time for comprehensive extraction, which can meet actual needs.

Owner:CHANGSHU INSTITUTE OF TECHNOLOGY

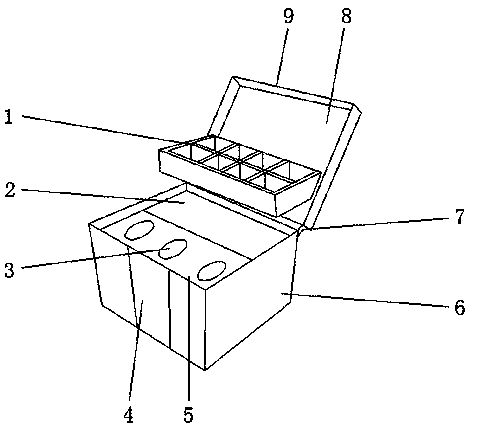

Magnetic type edge tool storage device

ActiveCN114588411AAchieving separation of workPrevent dumpingWaste collection and transferInfusion needlesComputer hardwareStress sensors

The invention discloses a magnetic type edge tool storage device. The magnetic type edge tool storage device comprises a supporting structure, an execution device, a control structure and a power source structure. The execution device is arranged in the supporting structure and fixedly connected with the supporting structure. The control structure is arranged on the top of the supporting structure and fixedly connected with the supporting structure. The power supply structure is arranged on the outer side wall of the supporting structure, and the power supply structure is fixedly connected with the supporting structure; a pressure sensor for measuring the weight is arranged in the supporting structure; the execution device, the control structure, the pressure sensor and the power source structure are connected through wires. During use, the sharps box is placed at the top of the pressure sensor, the execution device separates the needle from the injector, the needle falls into the sharps box, and when the pressure sensor detects that the sharps box is full of two thirds, a signal is sent out, so that the execution device stops moving and a user is reminded to replace the sharps box.

Owner:BEIJING YOUAN HOSPITAL CAPITAL MEDICAL UNIV

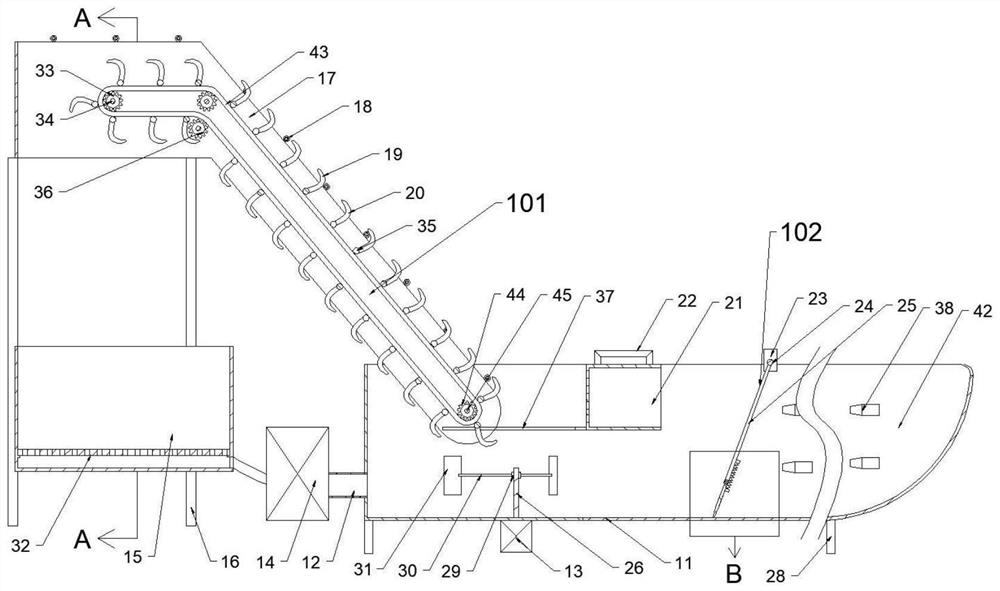

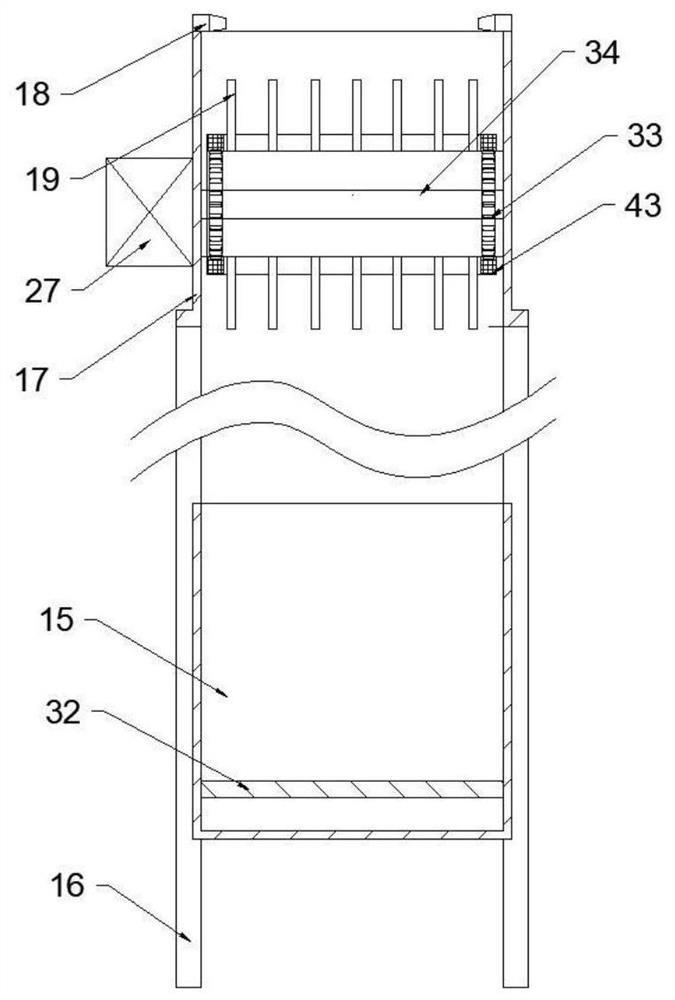

Fish scale recycling and cleaning device

PendingCN113680793ARealize the cleaning workAchieving separation of workSolid waste disposalFiltrationWater flow

The invention discloses a fish scale recycling and cleaning device. The fish scale recycling and cleaning device comprises a fishing mechanism, wherein a fishing portion of the fishing mechanism is obliquely placed in a box body; the fishing mechanism comprises a secondary fishing hook and a primary fishing hook which are fixedly arranged on a fishing connecting rod. According to the fish scale recycling and cleaning device, waste is separated by utilizing water flow scouring, primary filtration is carried out on grids, large garbage is hooked by the fishing hooks, the garbage is brought out through chain transmission, small fish scales and the garbage are stirred through stirring fan blades, the fish scales and floating garbage are thrown out to the front of a scraping plate, the floating garbage is driven by water flow to be collected by a filtering and recycling box, the fish scales are scraped by the scraping plate in a scraping plate mechanism, and the scraping plate slides along the bottom of the space of the box body to take out the cleaned fish scales. According to the fish scale recycling and cleaning device, the fish scales can be recycled and separated from the waste of fish treatment, the primary cleaning work is completed, raw materials are provided for subsequent fish scale recycling and processing, and the working efficiency is improved.

Owner:邵宇

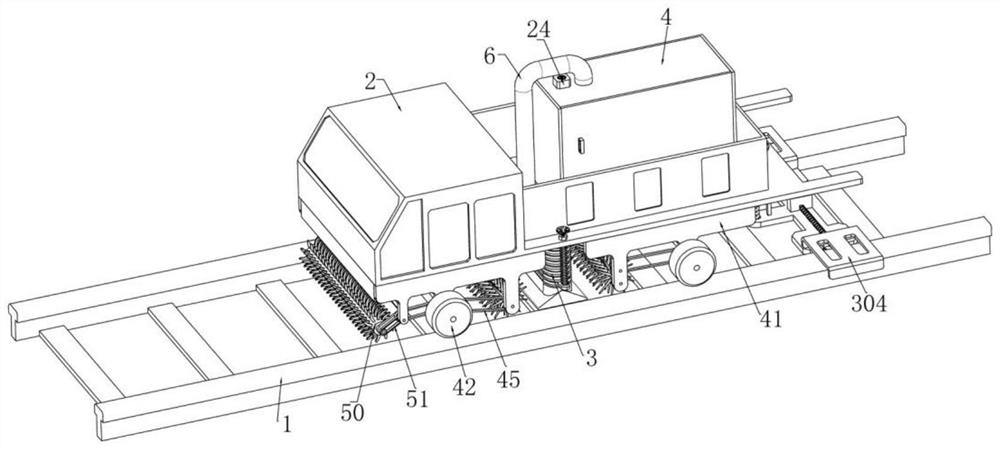

Track cleaning and correcting device

InactiveCN114438951AAchieving separation of workReduce security risksRailway cleaningPressesAugerTrackway

The invention provides a track cleaning and correcting device which effectively solves the problem that weeds and garbage grow between two tracks and the problem that normal use is affected due to the fact that the tracks deform, a cleaning vehicle is installed on the tracks in a left-right sliding mode, and a dust collection cylinder is fixedly installed at the bottom of the cleaning vehicle. A sorting box is fixedly installed at the upper end of the cleaning vehicle, an upper auger barrel is fixedly installed at the upper end of the sorting box, a guide pipe is fixedly connected between the upper auger barrel and the dust collection barrel, and a separation barrel located in the sorting box is fixedly installed at the lower end of an upper auger; through cooperative use of a dust collection barrel, a guide pipe, an upper auger barrel, a separation barrel, a stirring rod and a poke rod, separation work of soil and garbage is achieved, the situation that the soil and the garbage are mixed together, consequently, treatment is difficult in the later period, and the burden of later work is caused is avoided, meanwhile, the garbage on the rail 1 can be cleaned, and the working efficiency is improved. And the manual cleaning efficiency is higher, and the potential safety hazard of train running is reduced.

Owner:ZHENGZHOU RAILWAY VOCATIONAL & TECH COLLEGE

Non-block tea-leaf dust sieving device

The invention relates to a non-block tea-leaf dust sieving device. The non-block tea-leaf dust sieving device comprises a main frame body, wherein a material feeding port, a material discharge port, and a dust sieving device which can rotate around a shaft are arranged on the main frame body. The dust sieving device comprises a supporting frame which is connected on the main frame body and a dust sieving cylinder which is assembled on the supporting frame. At least one strip-shaped sieving hole which is communicated end to end is formed along the circumferential direction in the side wall of the material feeding port. The strip-shaped sieving hole penetrates through the side wall of the dust sieving cylinder. The material feeding port is formed in the inclined upper portion of the dust sieving cylinder, the material discharge port is formed in the inclined lower portion of the dust sieving cylinder, the material discharge port is provided with a first tooth plate which is matched with the dust sieving cylinder, and first convex teeth which can be inserted into the strip-shaped sieving hole are arranged on the first tooth plate. The tea-leaf dust sieving device can effectively achieve separation work of tea leaves and tea dust, and through dredge effect assisted by a first tooth plate and a second tooth plate, the fact the blocking phenomenon of sieving holes cannot occur when the dust sieving device is in work is guaranteed. In addition, the size of the non-block tea-leaf dust sieving device is small, noise when the dust sieving device is in work is small, use is simple and convenient, and work efficiency is high.

Owner:福建省状元茗茶有限公司

Stem cell storage extractor

InactiveCN112410191AEfficient separationImprove separation efficiencyBioreactor/fermenter combinationsBiological substance pretreatmentsPetri dishComputer science

The invention relates to the technical field of stem cell extraction, and in particular relates to a stem cell storage extractor. The stem cell storage extractor comprises a workbench, a separation device, an extraction device, a pushing device and a second culture dish; the workbench is arranged on the horizontal plane; the separation device is fixedly arranged on one side of the workbench; the extraction device is arranged on the workbench and located beside the separation device; the pushing device is arranged on the horizontal plane and located beside the separation device; the second culture dish is arranged on the workbench; a conveying channel is formed in the second culture dish; one end of the conveying channel is connected with the extraction device; the other end of the extraction device is connected to the second culture dish; in the working state, stem cells are separated through the separation device and extracted through the extraction device; the extracted stem cells are transferred into the second culture dish from the conveying channel through the pushing device; and the extracted stem cells are stored through the second culture dish.

Owner:杨慧慧

Drawable cosmetics case

InactiveCN107836798ARealize the scaling functionImprove efficiencyOther accessoriesPackaging toiletriesEngineeringCard holder

The invention discloses a drawable cosmetic case, which comprises a support base, a cover shell and a cosmetic case main body. The support base is installed at the bottom end of the cosmetic case main body. A first card frame is installed on one side of the buckle inner cavity, and one end of the first card frame is connected to a second card frame, and one end of the second card frame is elastically connected to a spring, and the bottom end of the second card frame is clipped with a The connecting buckle, the second card frame is fixed to the connecting bottom plate by a spring, and a groove is provided on one side of the connecting bottom plate, a connecting frame is fixed on one side of the inner end of the supporting base, and the center of the connecting frame is telescopically connected with a push frame, A socket pipe is installed at the bottom end of the inner cavity of the moving frame, and a connection seat is connected to one side of the socket pipe, and a turret is connected to the top of the socket pipe in rotation. The present invention is a drawable cosmetic case, and the purpose of increasing the area of the inner end is realized through the setting of the push frame.

Owner:沈晓杰

Material separation structure inside a municipal road cleaning and maintenance device

ActiveCN110694899BPlay a supporting roleAchieving separation of workGas current separationRoad cleaningElectric machineStructural engineering

The invention discloses a material separation structure inside a municipal road cleaning and maintenance device. The structure comprises a mounting frame, a protective box and a conveying frame, wherein a fixing box is arranged at one end of the top of the mounting frame, a feeding plate is arranged on one side of the fixing box, a first motor is arranged below the feeding plate, two bearing seatsare arranged on the position, on one side of the first motor, of mounting frame, a discharging shaft is arranged between the two bearing seats, a screw rod is driven to rotate through the output endof a third motor, when the screw rod is rotated, due to the fact that a nut seat is arranged on the screw rod and is in threaded connection with the screw rod, a screening fan moves up and down alongtwo sliding rods, the wind direction can be adjusted, so that the cross airflow between a side fan and the screening fan is consistent with the discharging direction of the conveying frame, when a material passes through the cross airflow, a material with the large mass falls onto a conveying belt, a material with the small mass is blown to a buffer ring through the airflow, and then fall on a discharging belt, so that the material separation work is realized, and the material is convenient to process.

Owner:苏州科腾软件开发有限公司

Device and method for separating branches, leaves and flowers of honeysuckle

PendingCN113019903AEasy to operateAchieving separation of workSievingScreeningEngineeringStructural engineering

The invention discloses a device and method for separating branches, leaves and flowers of honeysuckle. The device comprises a honeysuckle drying box, wherein a conveying crawler belt is rotatably connected between supporting frames, the honeysuckle drying box is arranged above the conveying crawler belt, and the conveying crawler belt is driven by a motor fixedly connected with the supporting frames; an upper filter screen and a lower filter screen are further connected between frame bodies, the lower filter screen is arranged below the upper filter screen, the left end of the upper filter screen communicates with the conveying crawler belt, rubber rods are evenly arranged above the upper filter screen at intervals, the rubber rods are fixedly connected with the frame bodies, and the right end of the upper filter screen further communicates with a branch collecting box; one end of the lower filter screen communicates with a leaf collecting box, and a honeysuckle collecting box is further arranged below the lower filter screen; and a plurality of upper cams and a plurality of lower cams are further rotatably connected between the frame bodies, the upper cams are in contact with the bottom end of the upper filter screen, and the lower cams are in contact with the lower filter screen. The device is easy to operate, the work of separating the branches, the leaves and the flowers of the honeysuckle is effectively achieved, and the honeysuckle separating efficiency and quality are effectively improved.

Owner:SHANDONG UNIV OF TRADITIONAL CHINESE MEDICINE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com