Iron removal device for mineral processing

A technology of minerals and collection bins, applied in grain processing, magnetic separation, solid separation, etc., can solve the problems that iron cannot be separated, quantitative feeding cannot be carried out, and feeding is too much, so as to avoid uneven feeding and facilitate differentiation. Collect, ensure the effect of validity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

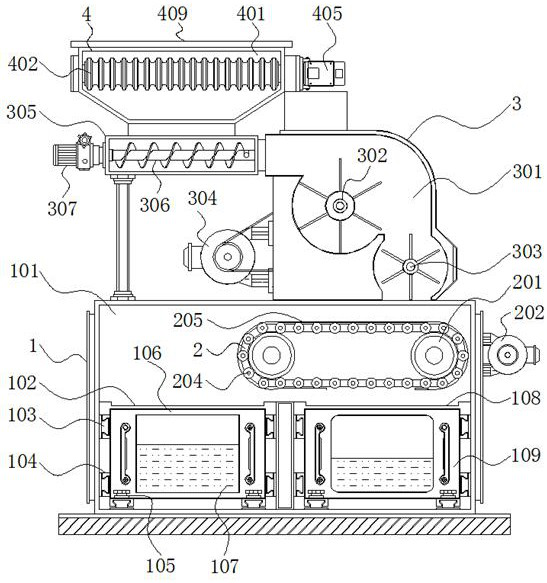

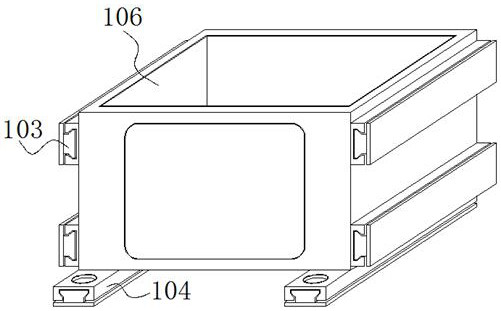

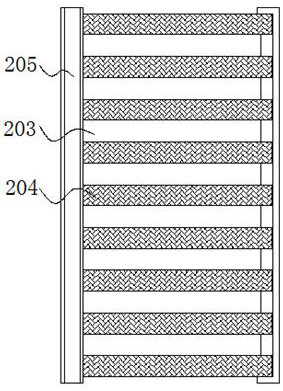

[0046] see Figure 1-2, an iron removal device for mineral processing, comprising: a main body 1; the main body 1 includes: a main bin 101, the main bin 101 has a rectangular hollow structure, and a mineral collection port 102 is arranged in the middle left side of the main bin 101; a limit slide Rail 103, which is arranged on the lower left side of the main compartment 101, and the limit slide rail 103 is vertically distributed with the main compartment 101, and the limit slide rail 103 is connected to the limit slide block 104 outside; the positioning knob 105, which wears Set on the inner side of the limit slider 104, and two positioning knobs 105 are provided, and the other side of the limit slider 104 is connected with a mineral collection bin 106; the limit slider 104 and the mineral collection bin 106 are fixedly connected , and the mineral collection bin 106 forms a sliding structure between the limit slider 104 and the limit slide rail 103 and the main bin 101. The l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com