Patents

Literature

32results about How to "Avoid uneven feeding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

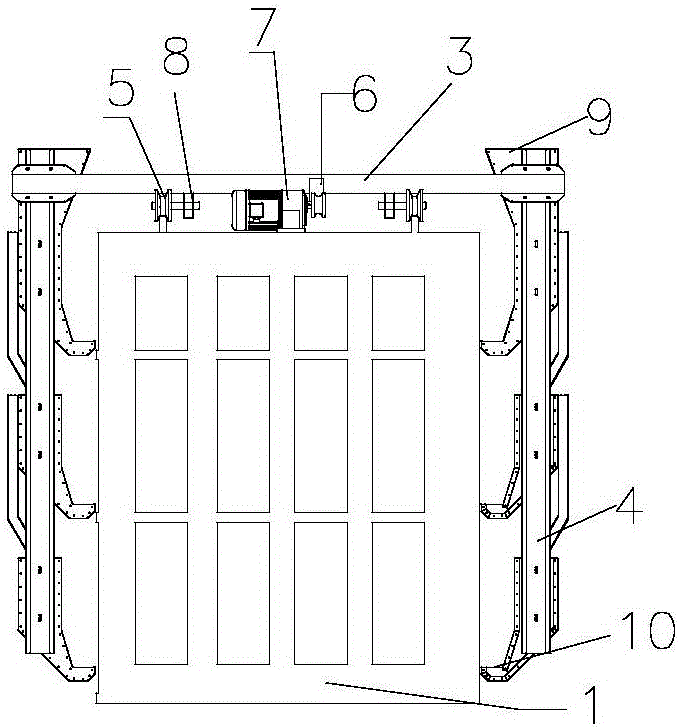

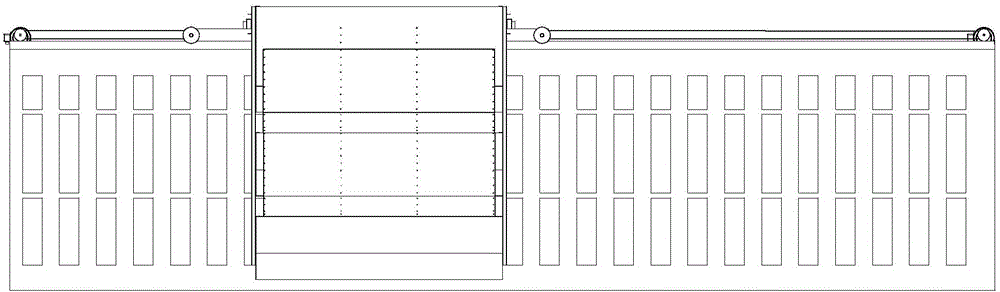

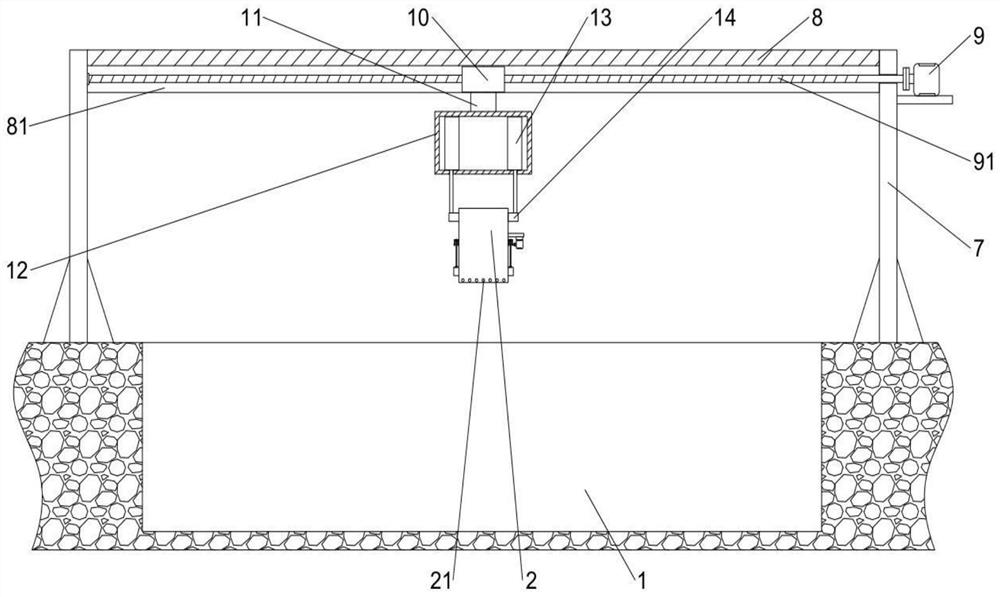

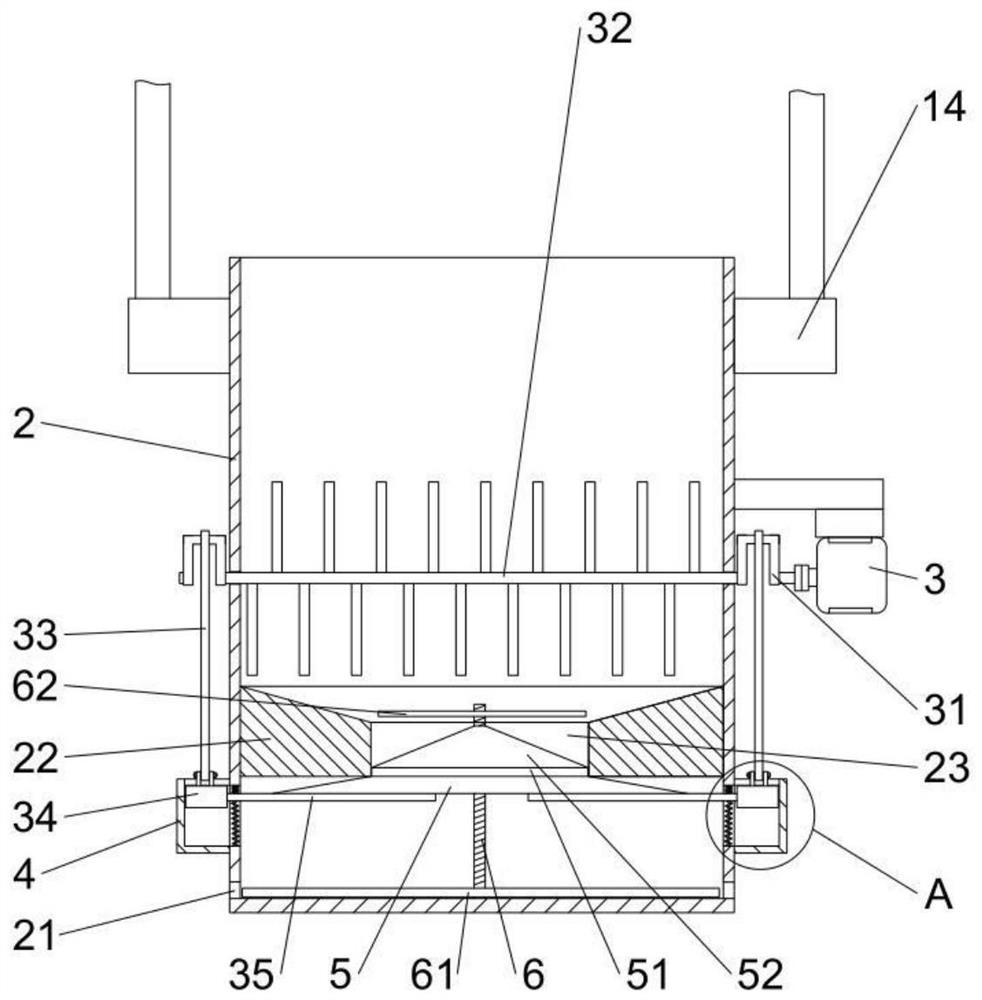

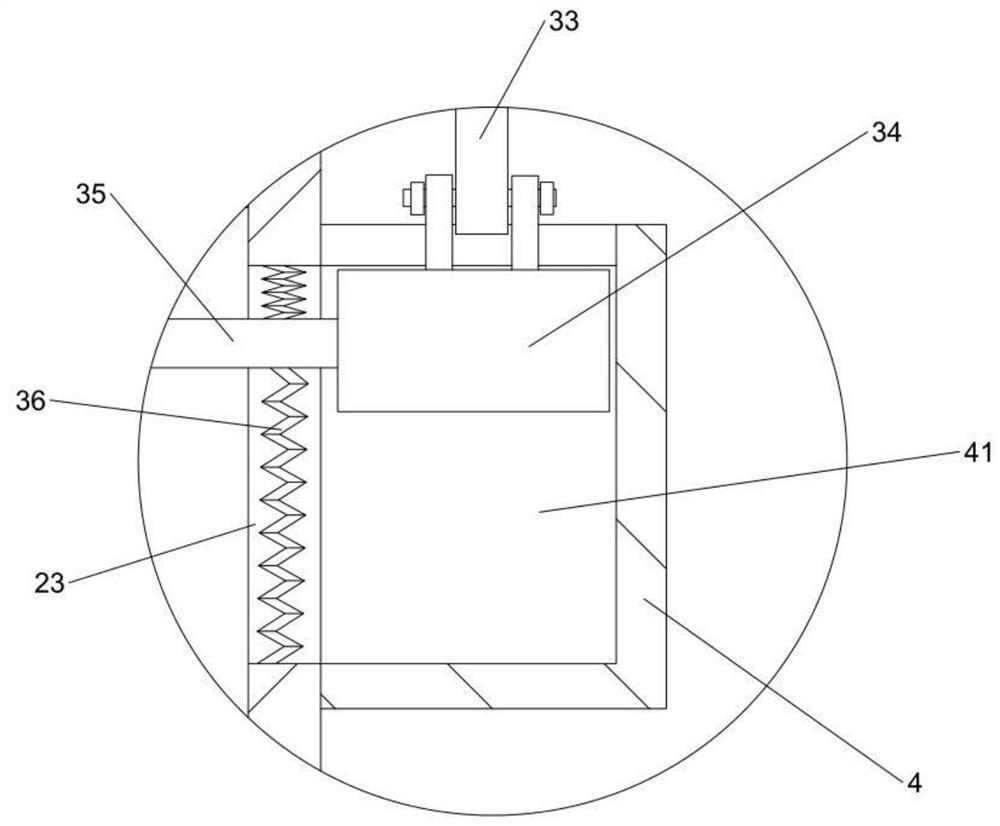

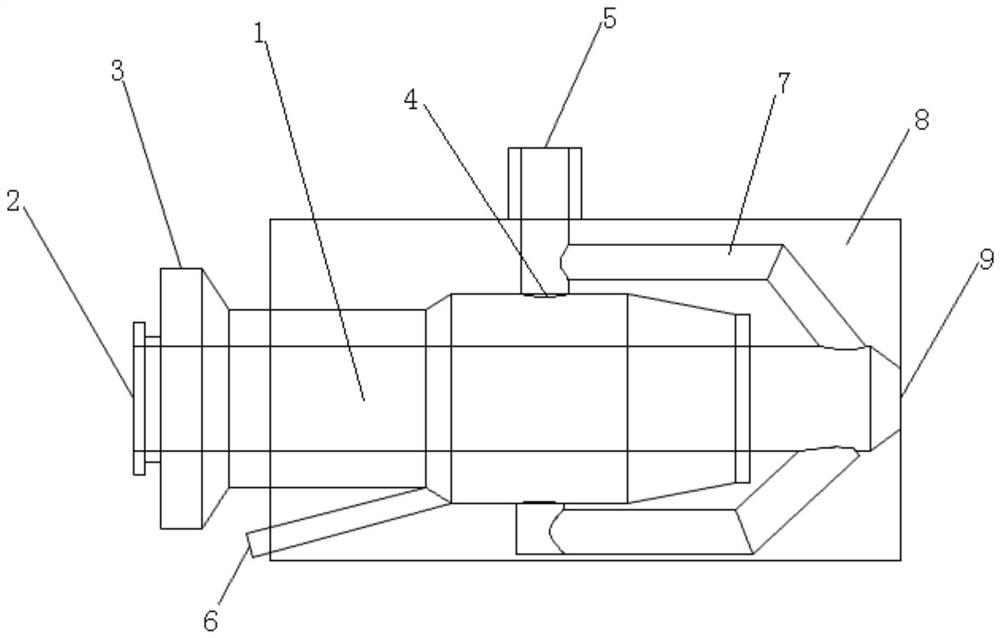

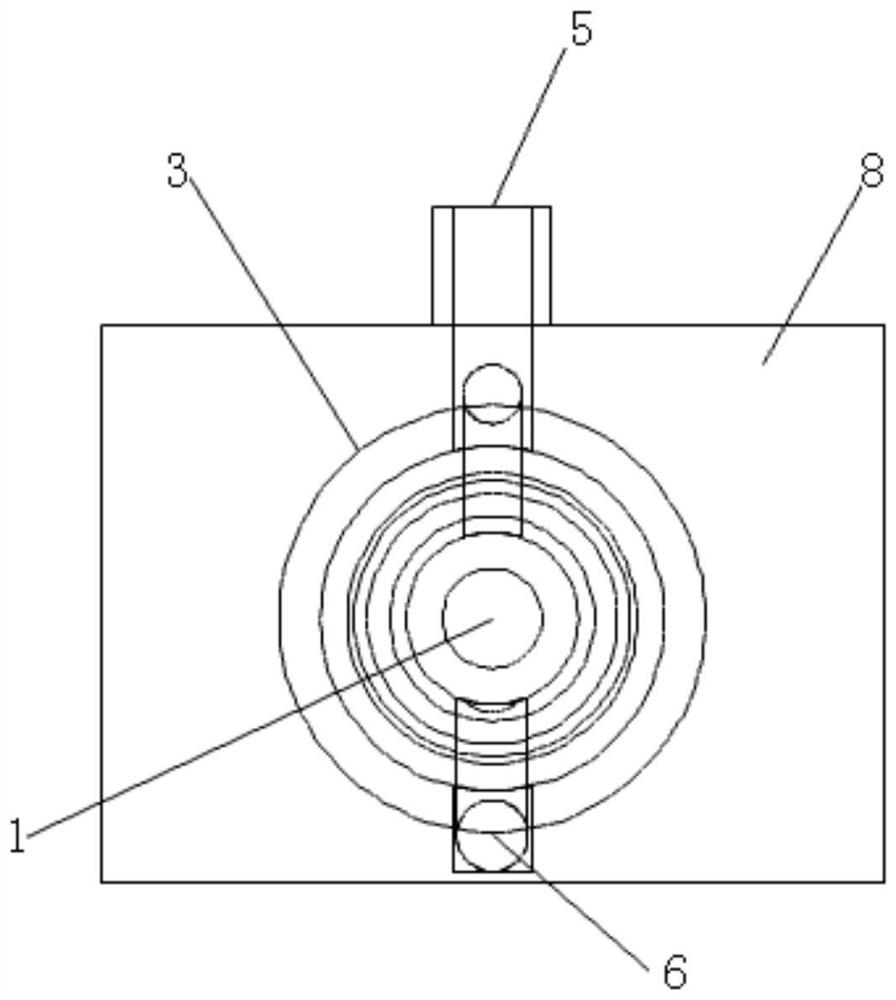

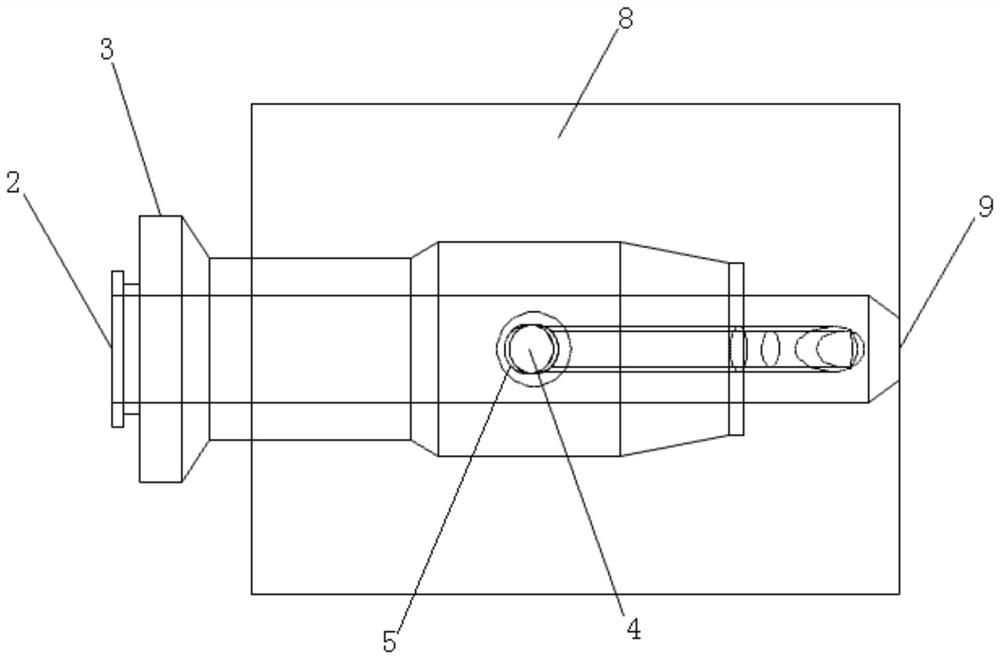

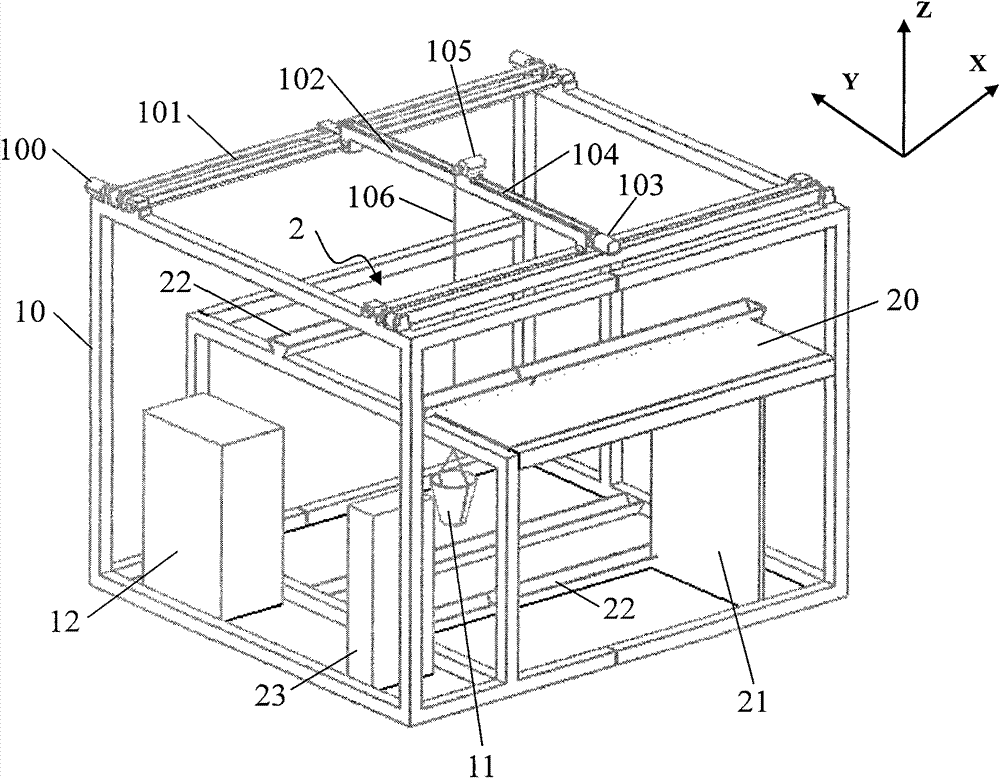

Pig house automatic feeding device and method and matched pig house

ActiveCN101785436AAvoid uneven feedingReduce labor intensityAnimal feeding devicesAnimal housingElectric machineryEngineering

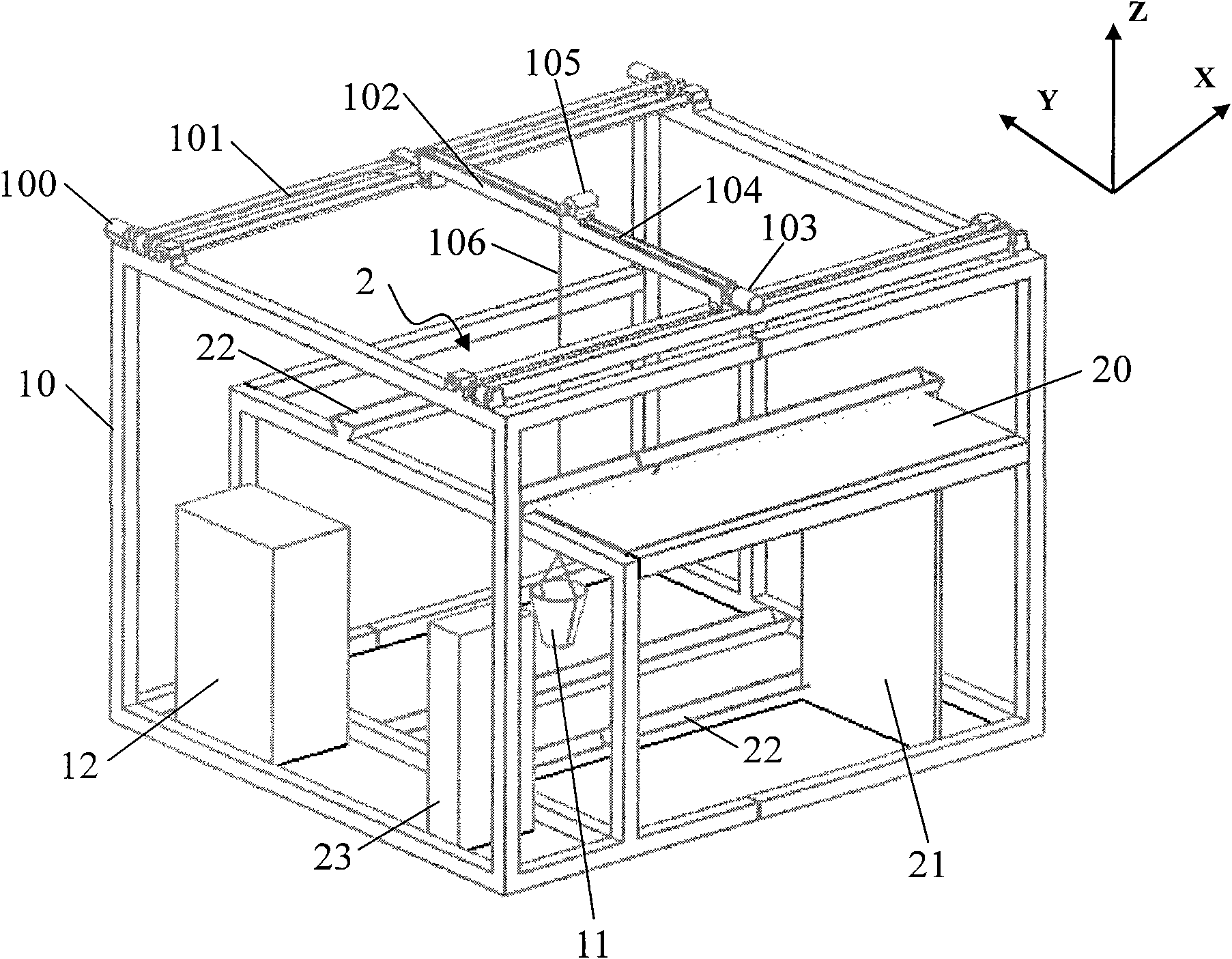

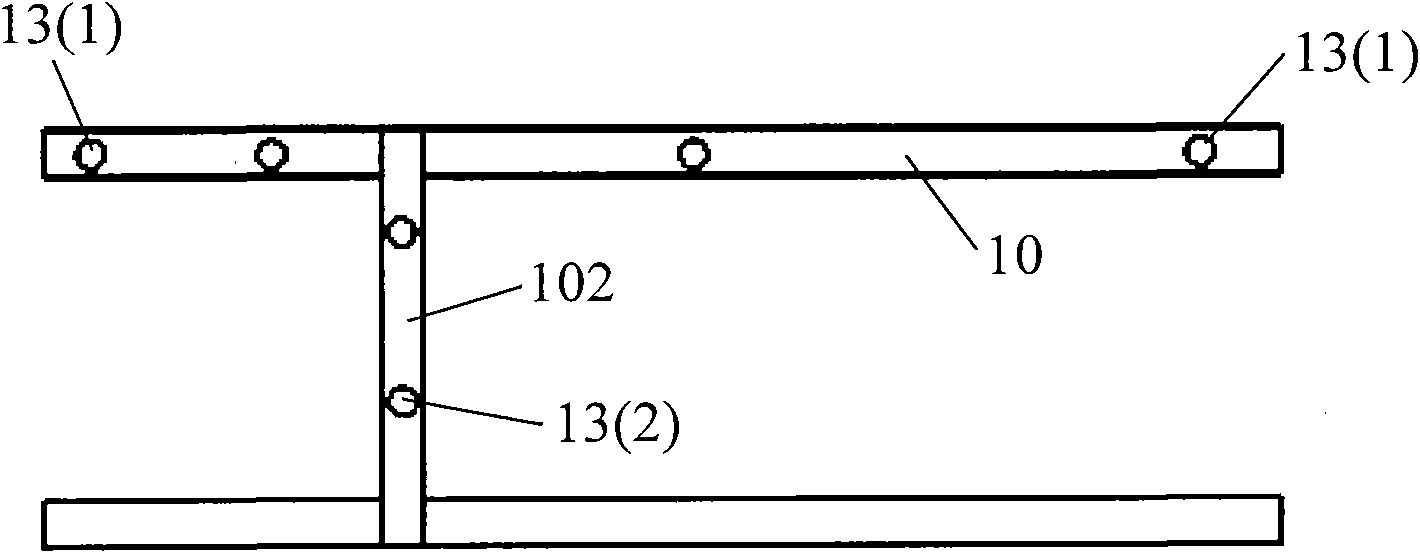

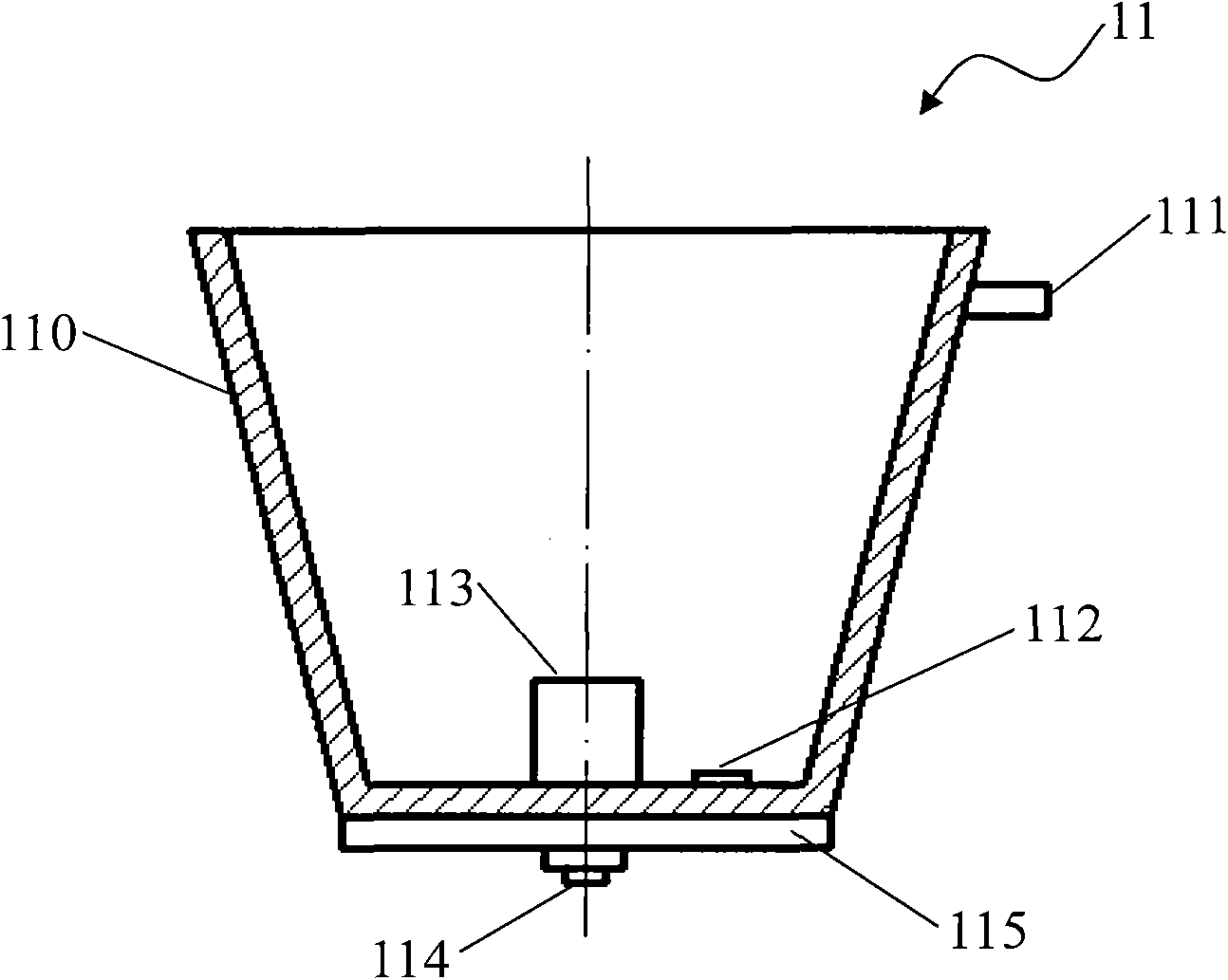

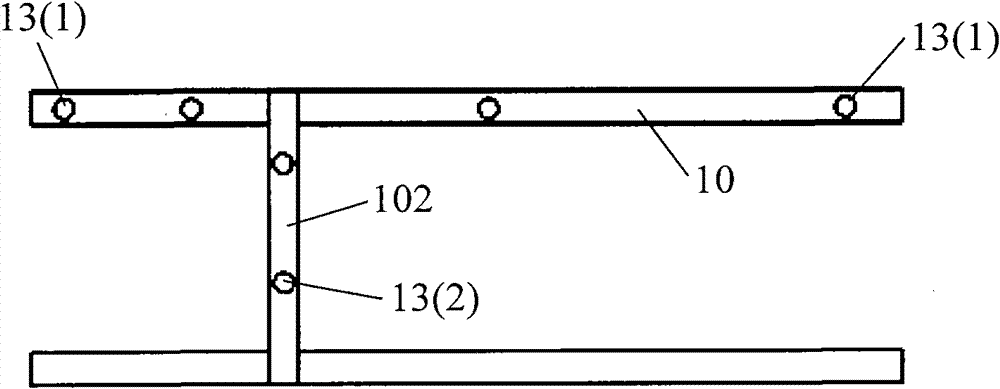

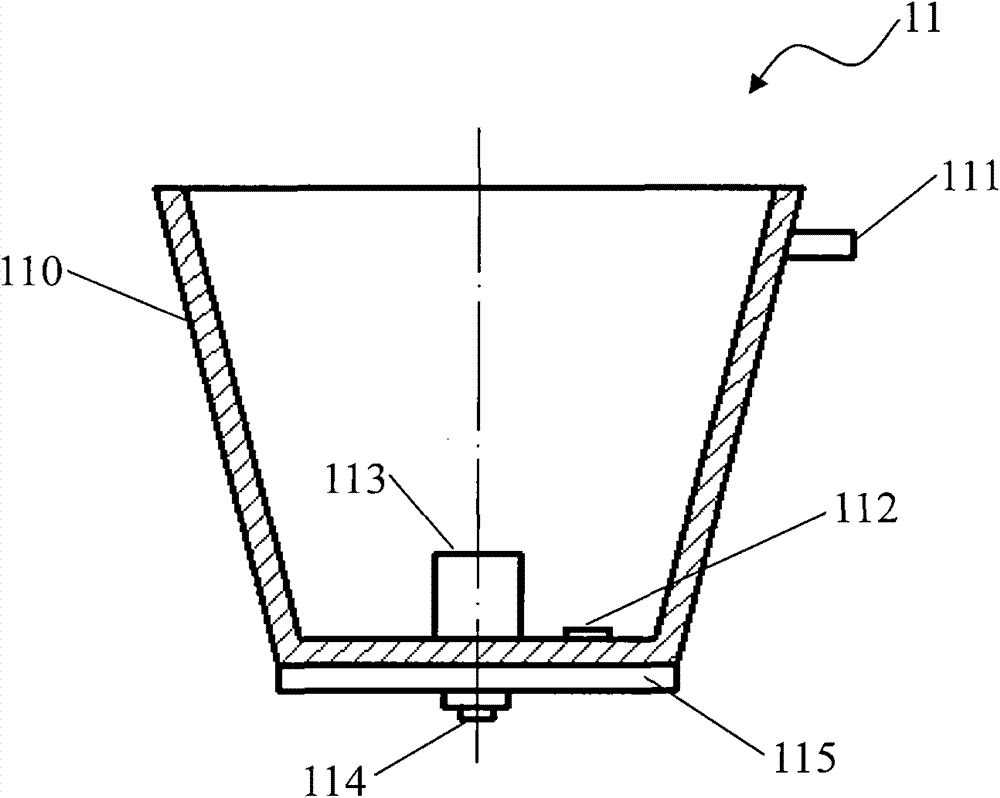

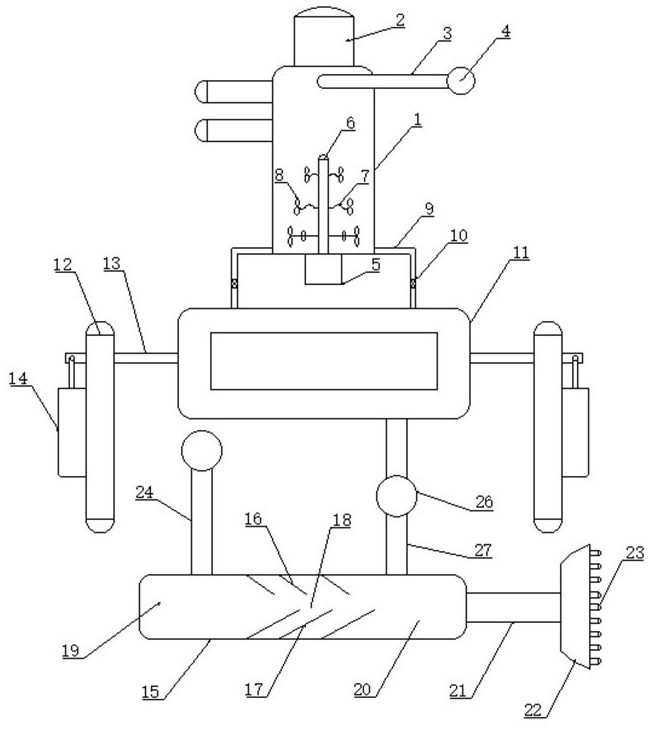

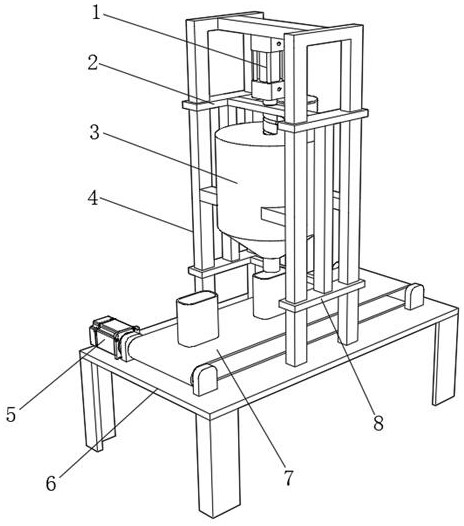

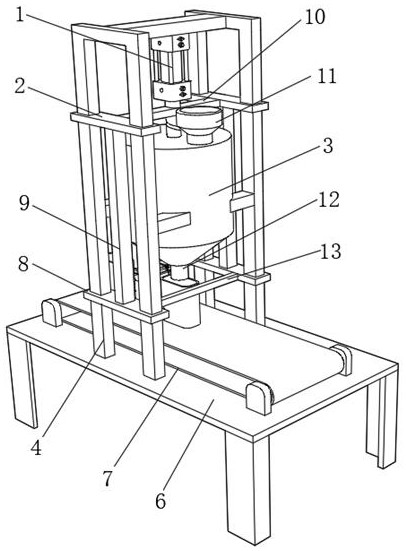

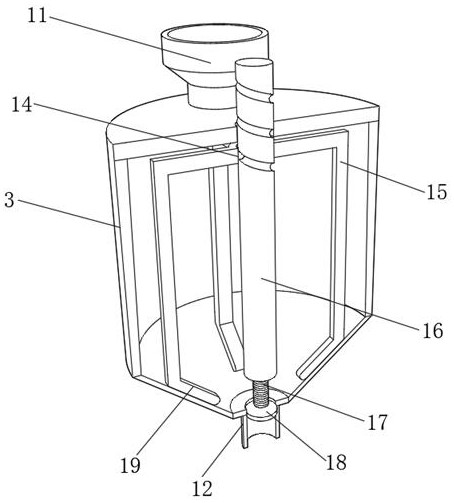

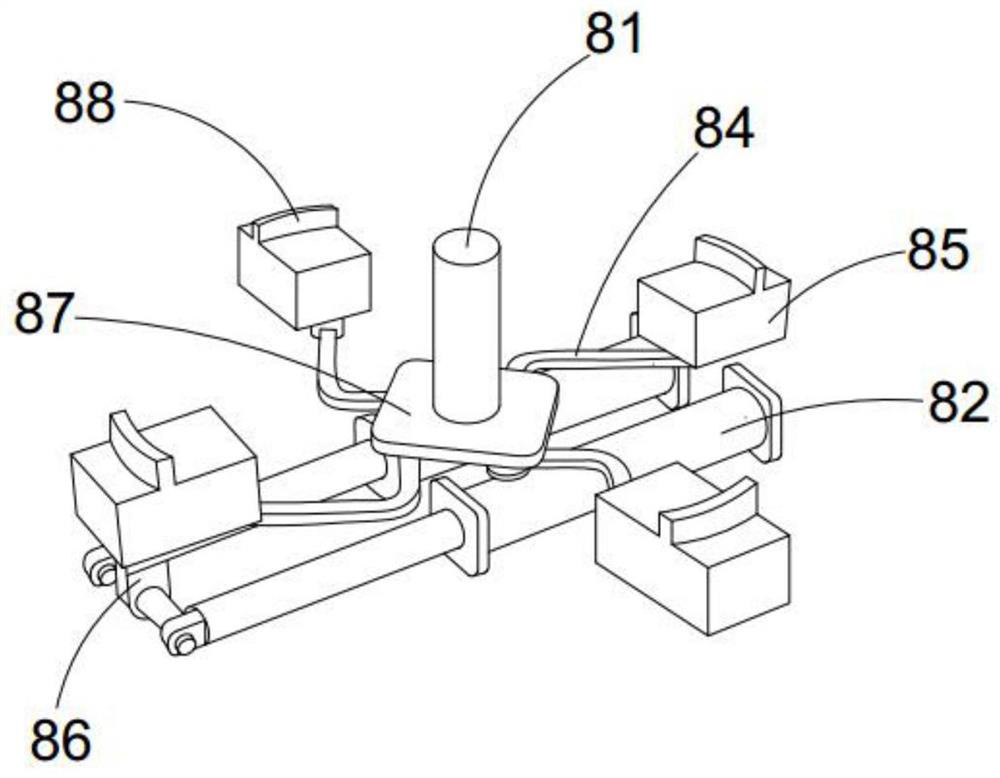

The invention provides a pig house automatic feeding device and a method and a matched pig house. An X-direction driving motor, an X-direction transmission mechanism and a movable cross beam are arranged at the top part of a bracket of the pig house automatic feeding device; the movable cross beam is provided with a Y-direction driving motor, a Y-direction transmission mechanism and a Z-directiondriving motor; a feed thrower is connected with the Z-direction driving motor by a Z-direction transmission mechanism in a transmission manner; a first sensor is arranged at the top part of the feed thrower; a second sensor, a feed throwing driving motor and a feed throwing valve are arranged at the bottom part of the feed thrower; and the feed throwing driving motor controls the opening and closing of the feed throwing valve so as to throw feed into a feed groove. A controller receives sensing signals output by the first sensor and the second sensor, and controls the X / Y / Z-direction driving motors and the feed throwing driving motor to finish the automatic feeding process. The invention effectively increases the pig raising efficiency and lowers the labor intensity of raising personnel. The pig house quantitatively throws the feed to the pig at fixed time, which avoids non-uniform feeding of the pig and reduces injuries of the pig due to fighting.

Feeding mechanism with culturing cage and feeding through in separated mode and feeding method

InactiveCN106804462AReduce demandReduce installation volumeBird housingsReciprocating motionEngineering

Owner:山东益圆农牧机械科技有限公司

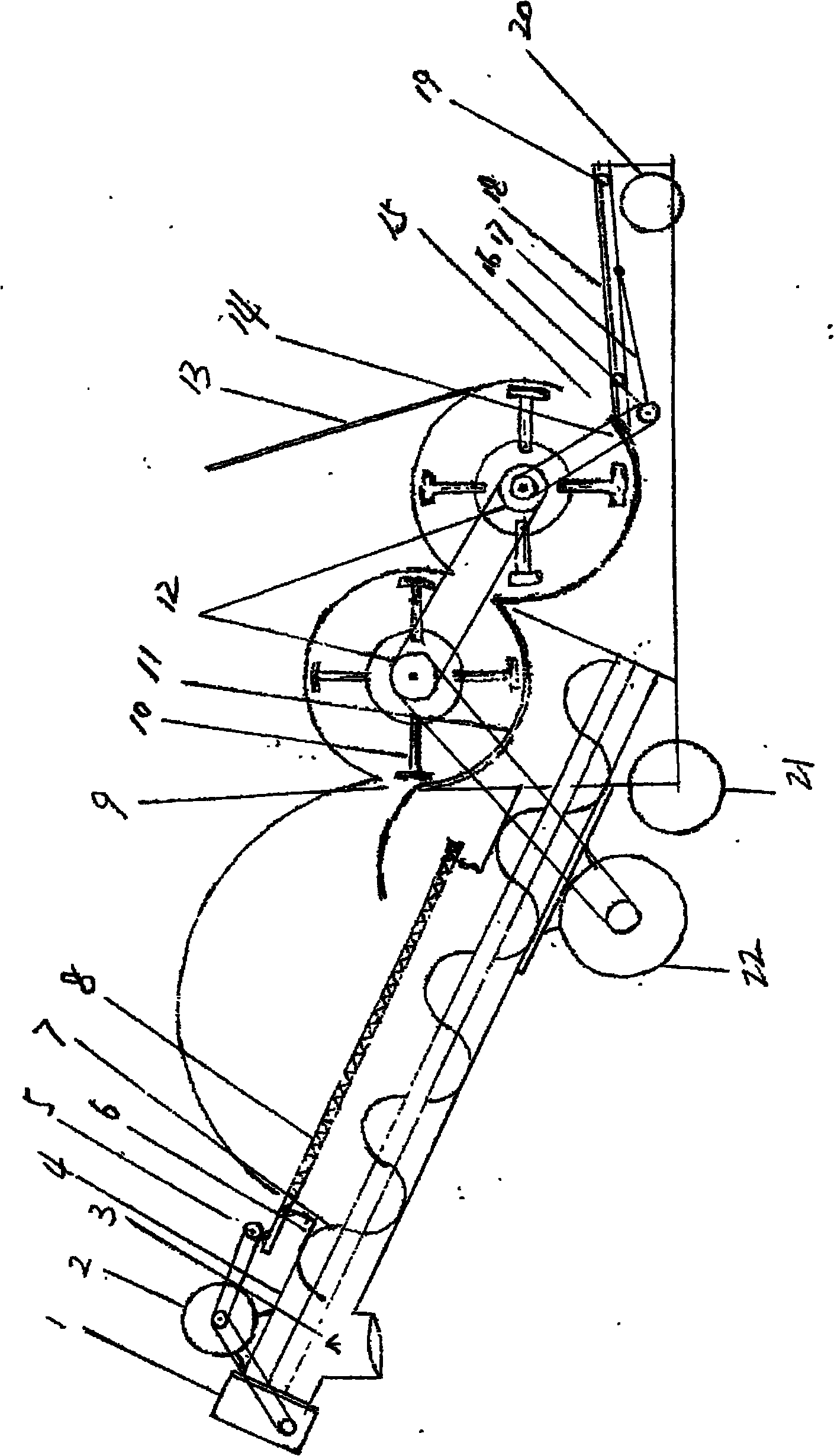

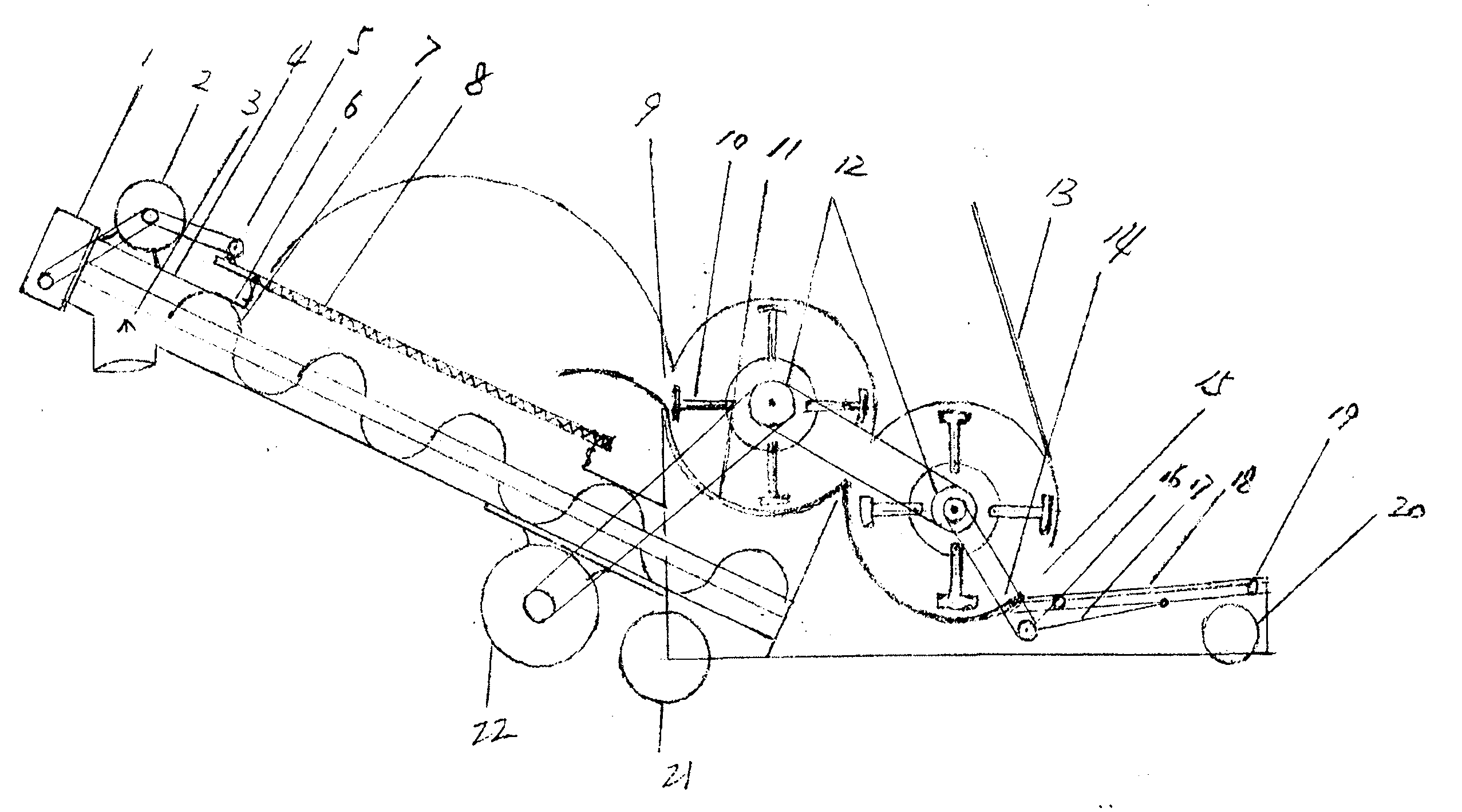

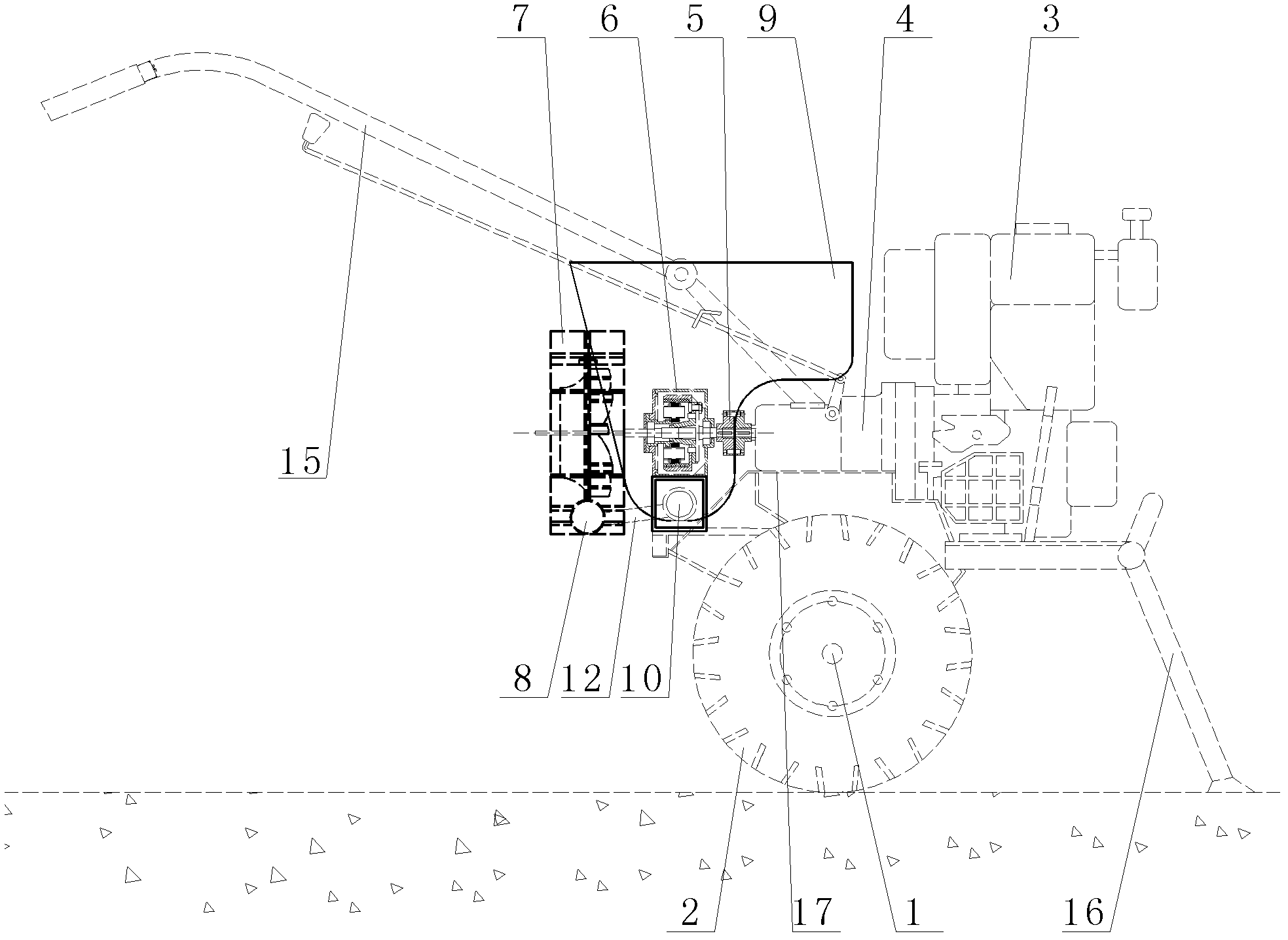

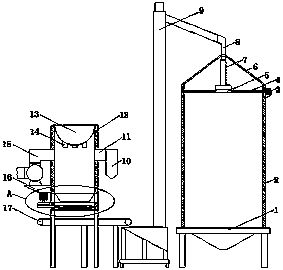

Full automatic high efficiency splitting smashing stirring machine

InactiveCN101816972AAvoid pollutionAvoid accumulationRotary stirring mixersGrain treatmentsEngineeringDust pollution

The invention relates to an automatic smashing stirring integrational operation device for multiple industrial mixing lump materials, in particular to a full automatic high efficiency splitting smashing stirring machine. The full automatic high efficiency splitting smashing stirring machine comprises a feeding device and a smashing device, wherein the rear end of the smashing device is provided with the feeding device, the feeding device is arranged behind the lower part of the smashing machine, the front end of the smashing machine is provided with a stirring device or a conveyor device connected with the bottom surface at certain angle. The invention saves time and effort, avoids dust pollution in operation, is environmentally friendly and sanitary, and the invention can be moved randomly as the structure thereof is compact.

Owner:郝中山

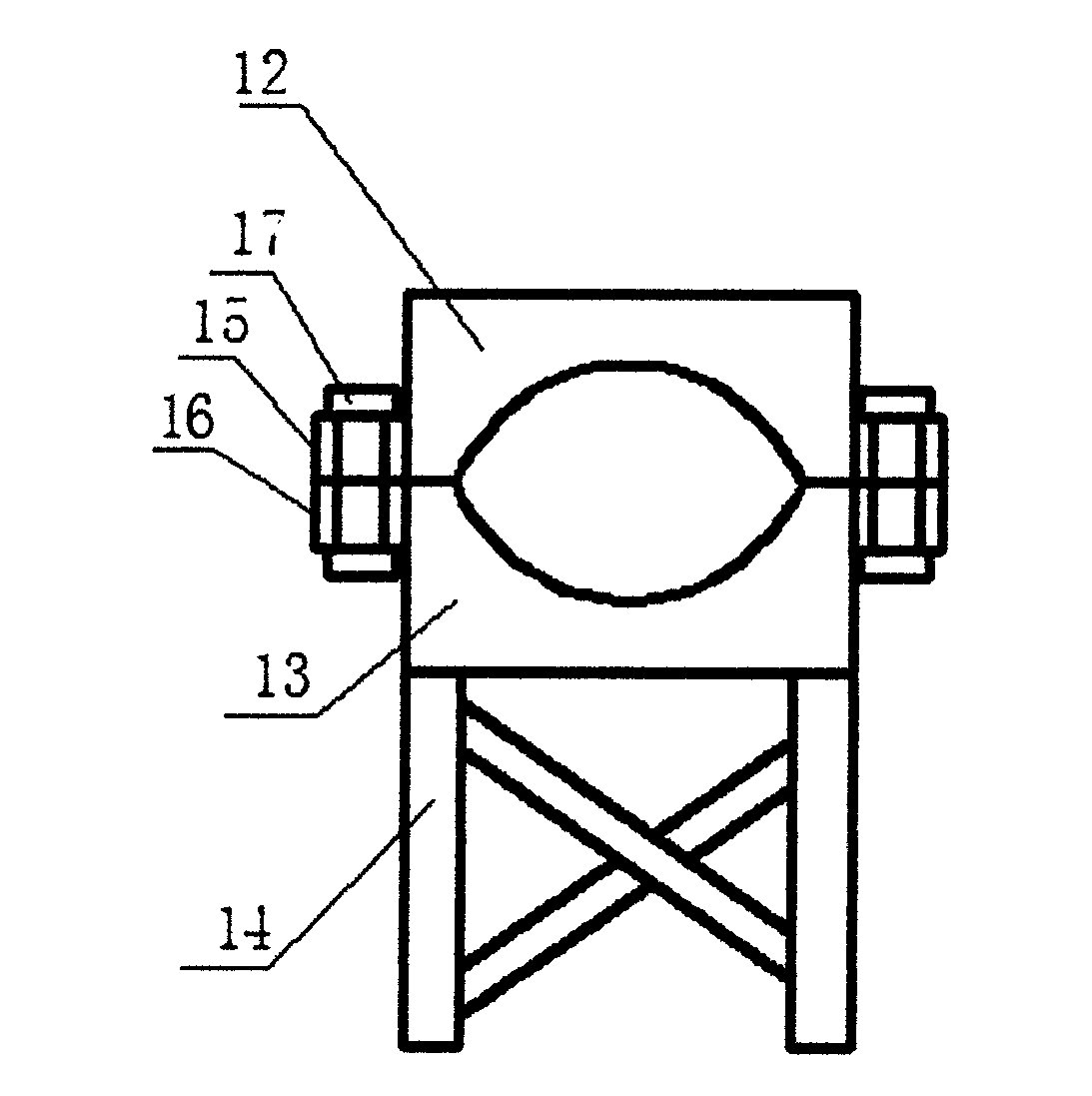

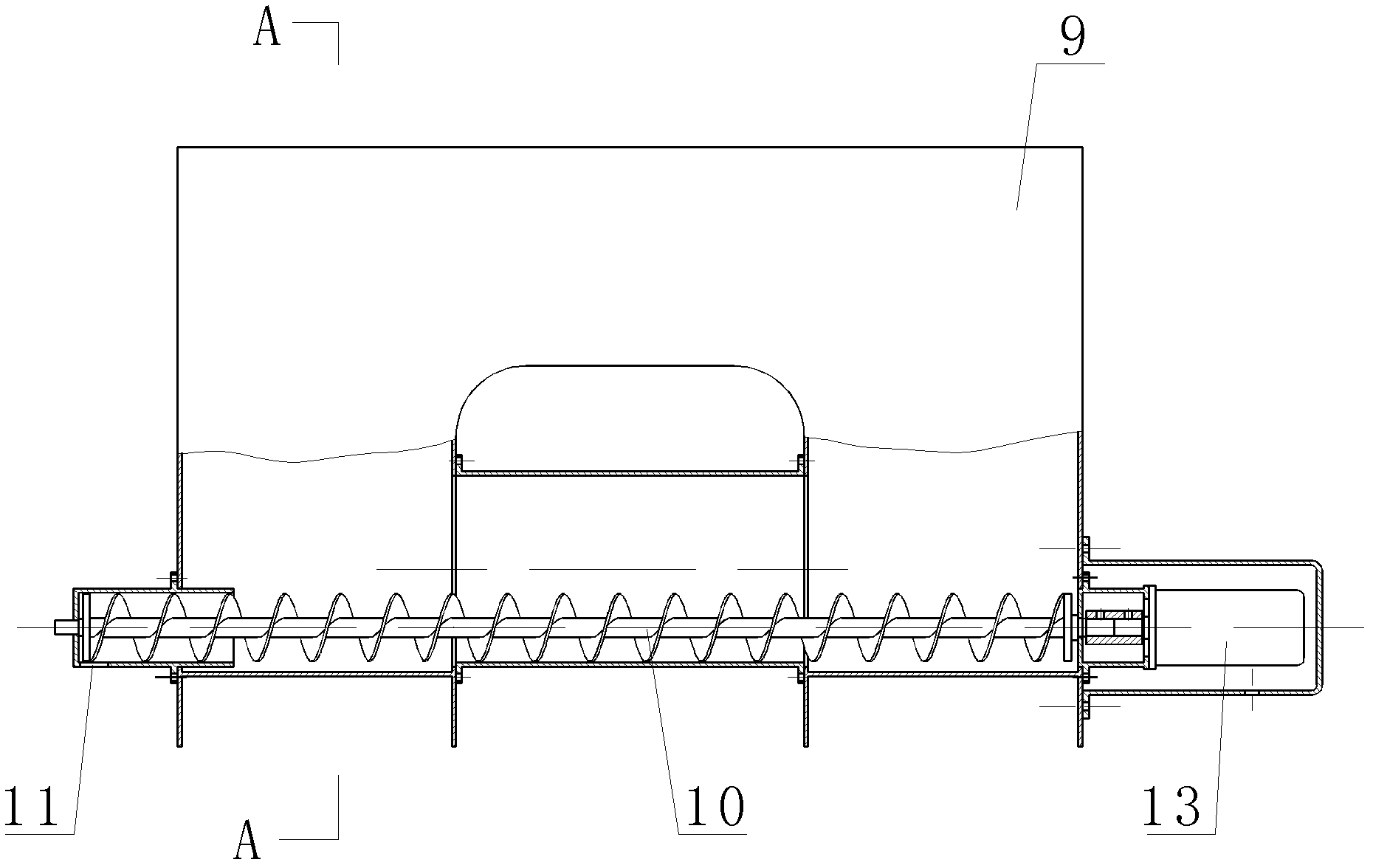

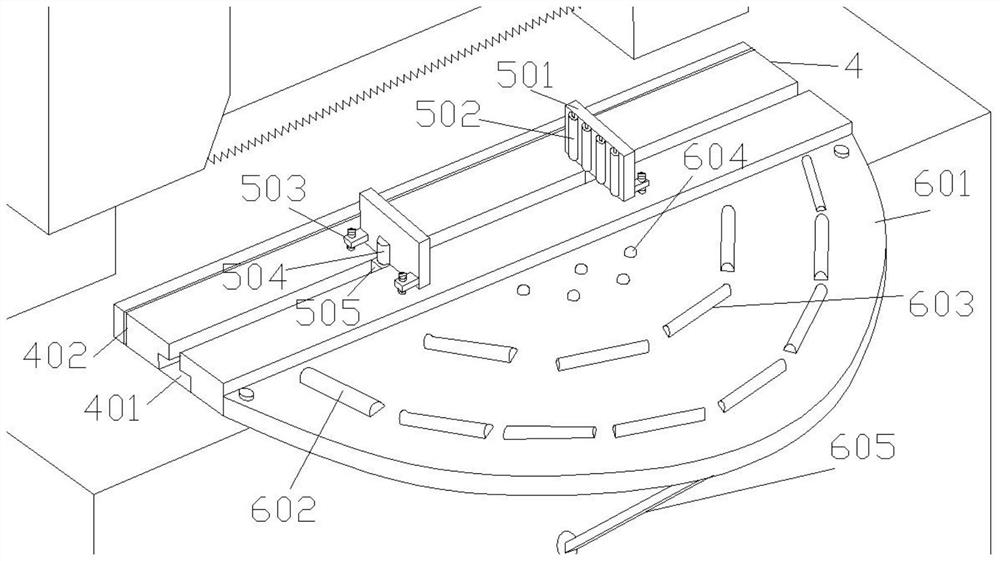

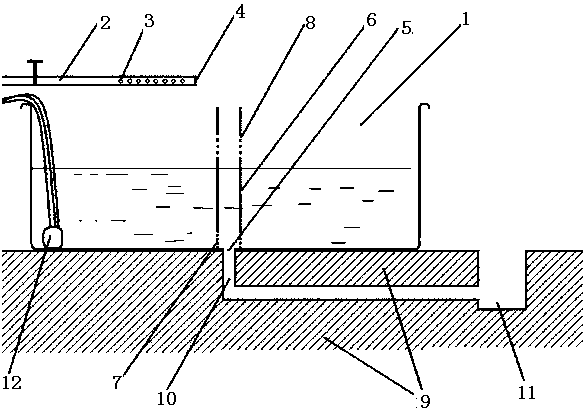

Track underwater feed device for aquaculture

InactiveCN110235839AReduce labor intensityImprove feeding efficiencyClimate change adaptationPisciculture and aquariaUnderwaterFodder

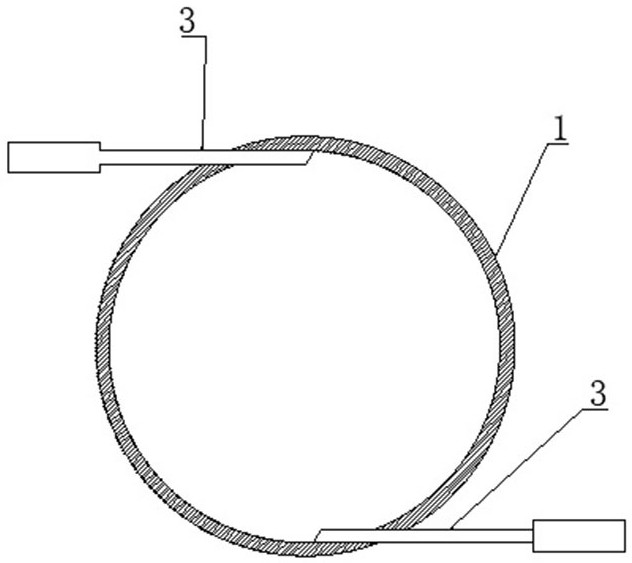

The invention discloses a track underwater feed device for aquaculture. The device comprises an annular supporting plate and an aquaculture tank body, wherein the annular supporting plate is erected above the water surface of the aquaculture tank body, the lower end of the annular supporting plate is fixedly connected with a moving part, the moving part is fixedly connected with a feed tank, the inner wall of the left side of the feed tank is provided with a feeding part, and the bottom of the feed tank is provided with a discharging mechanism. The track underwater feed device for the aquaculture has the advantages that an electric pulley and the feed tank are driven through an annular electric track, and cooperate with the discharging mechanism to perform regular feeding on the aquaculture tank body, which replaces manual feeding, reduces the labor intensity, and effectively improves the feeding efficiency; a miniature hydraulic cylinder is regularly started and controlled through a set cycle timing switch, so that the miniature hydraulic cylinder drives a baffle plate to close a discharging port regularly so as to regularly and quantitatively perform feeding on the aquaculture tank body to avoid the situation of uneven feeding.

Owner:蚌埠市建金智能科技有限公司

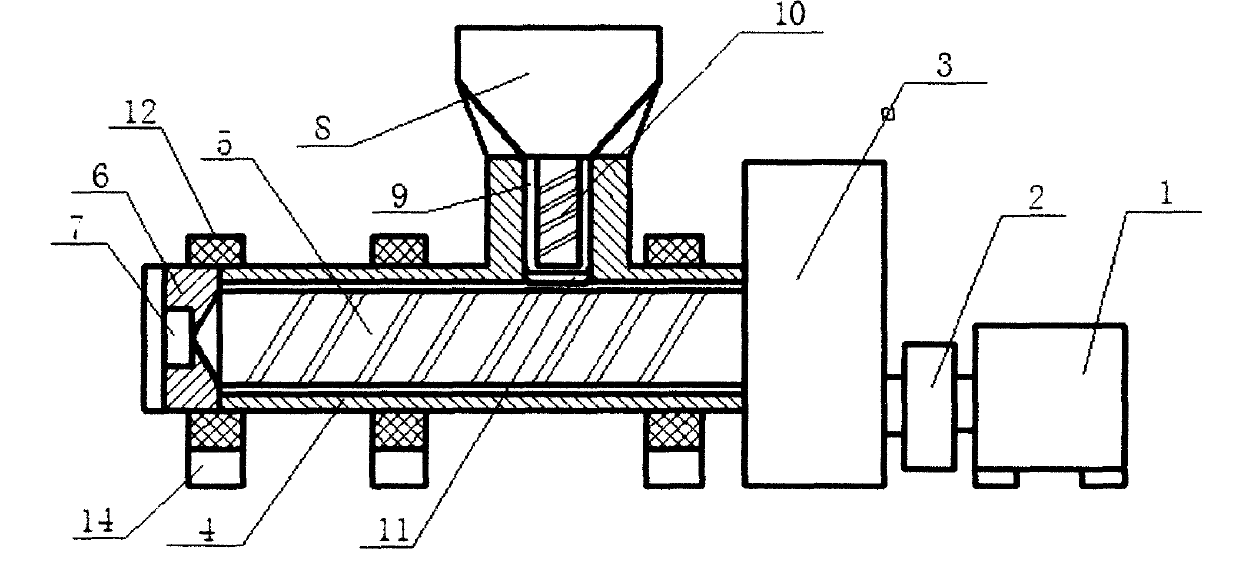

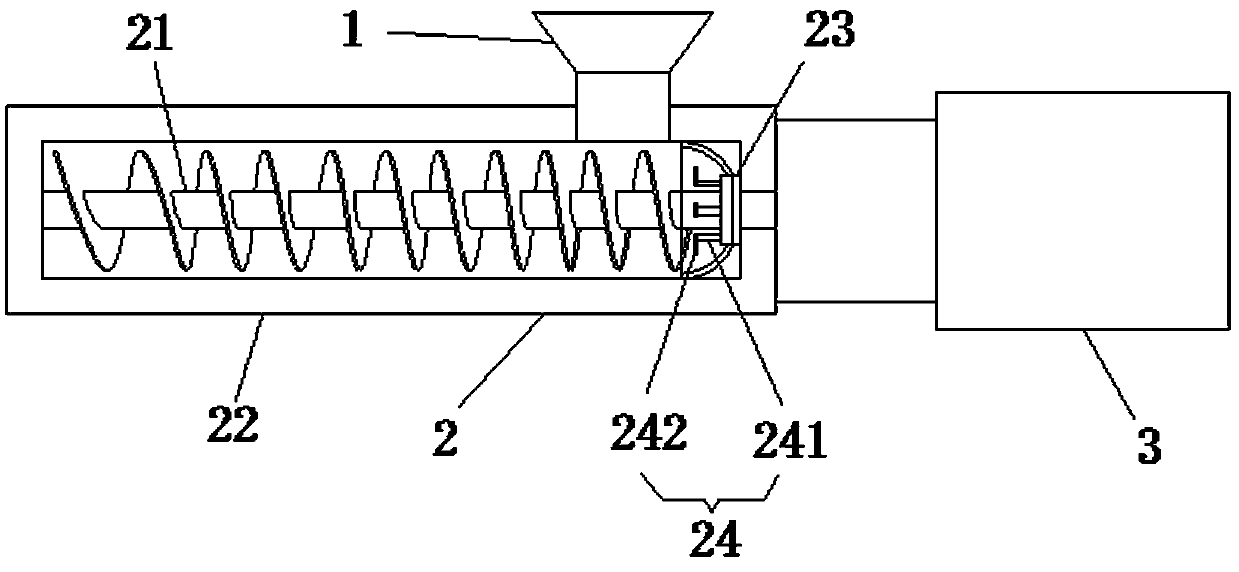

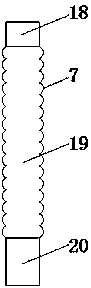

Novel double-screw extruder

The invention discloses a novel double-screw extruder which comprises a power device, a speed reducer connected with the power device, a transmission mechanism connected with the speed reducer, a sleeve connected with the transmission mechanism, lead screws arranged in the sleeve, a machine head arranged at the top end of the sleeve, a hopper arranged on the sleeve, support frames arranged on the sleeve at equal intervals, and a material barrel arranged on the ground, wherein a runner for communicating the hopper with the sleeve is arranged in the hopper and is internally provided with a feeding lead screw, and the lead screws are in transmission connection with the transmission mechanism. Materials are transmitted to the hopper through a conveying device, compacted through the feeding lead screw in the runner, discharged into the lead screws through a filter net, and extruded by a forming mould in the machine head through the first lead screw and the second lead screw. The novel double-screw extruder has the advantages of simple structure and high working efficiency, and avoids phenomena of nonuniform material conveying and sleeve shaking.

Owner:胡君

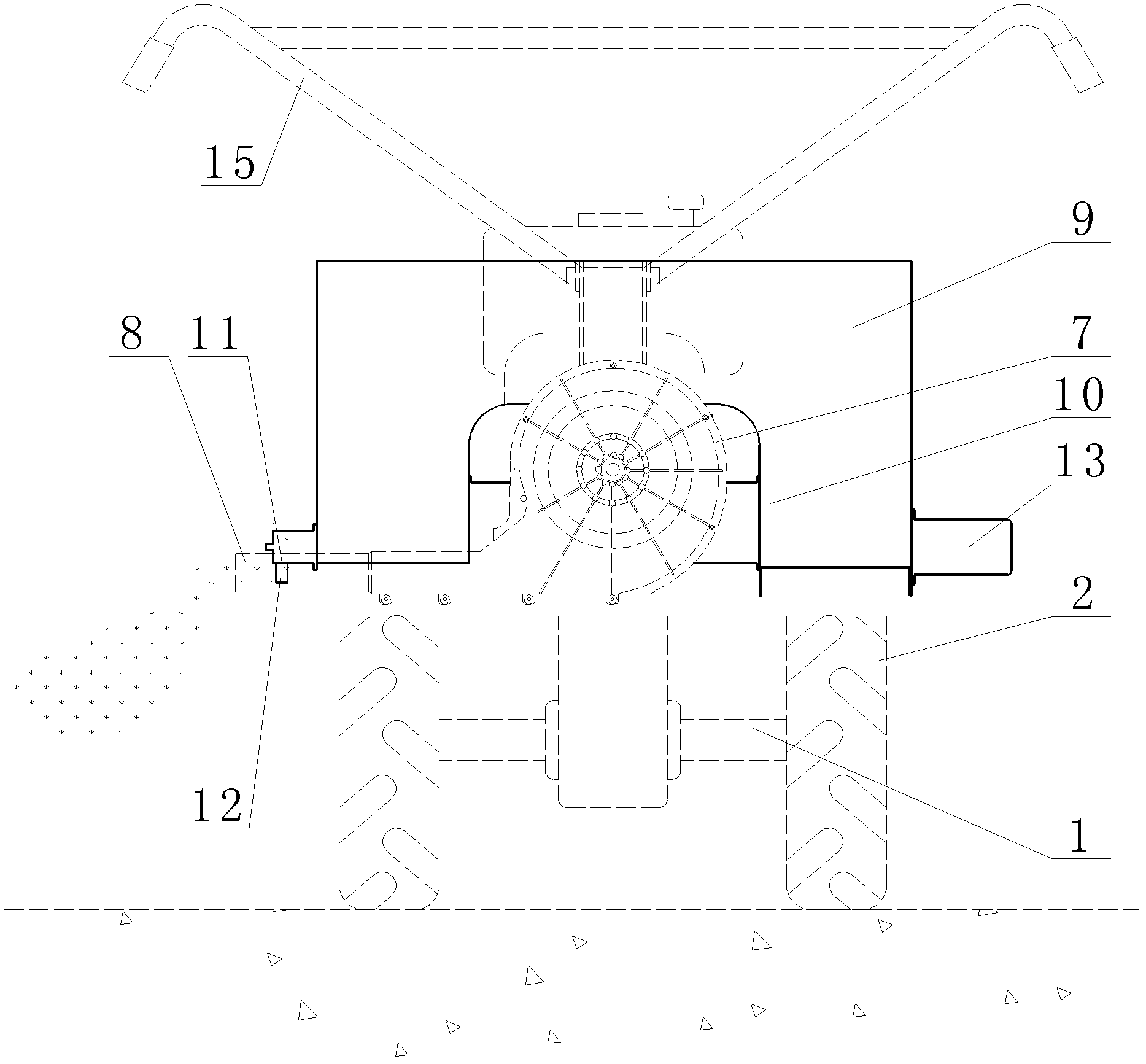

Device for feeding shrimps and crabs

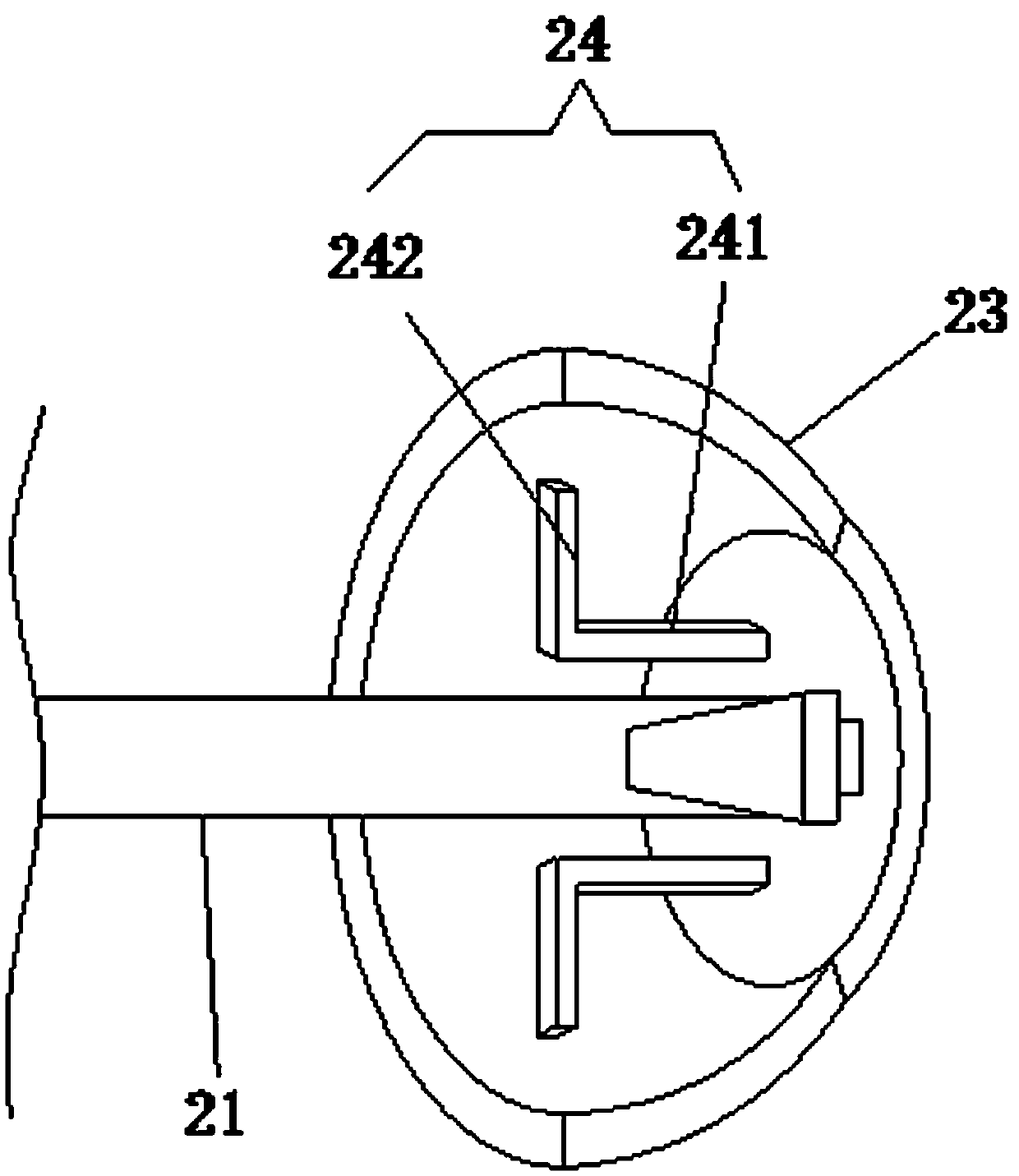

The invention provides a device for feeding shrimps and crabs. Both sides of a horizontal axle have a roller respectively; a machine frame is fixed above the axle, and the center of the machine frame is fixedly provided with a generator; the generator is connected with a transmission box; the axle is connected with a main shaft of the transmission box, and an auxiliary shaft of the transmission box is sequentially connected with a rotor of the generator and an impeller middle shaft of a centrifugal fan by couplings; a saddle-shaped hopper is arranged above the generator, two lower ends of the saddle of the hopper are connected with each other by a spiral feeder, and the bottom part of the output end of the spiral feeder is provided with a discharge hole which is communicated with an opening of an air discharge tube by a downwards inclined material-conveying tube; and the other end of the hopper is provided with a motor. The device has multiple functions; the device can realize movable feeding, plowing and the like; and the device has high flexibility and adjustable traveling speed and feeding quantity.

Owner:FISHERY MACHINERY & INSTR RES INST CHINESE ACADEMY OF FISHERY SCI

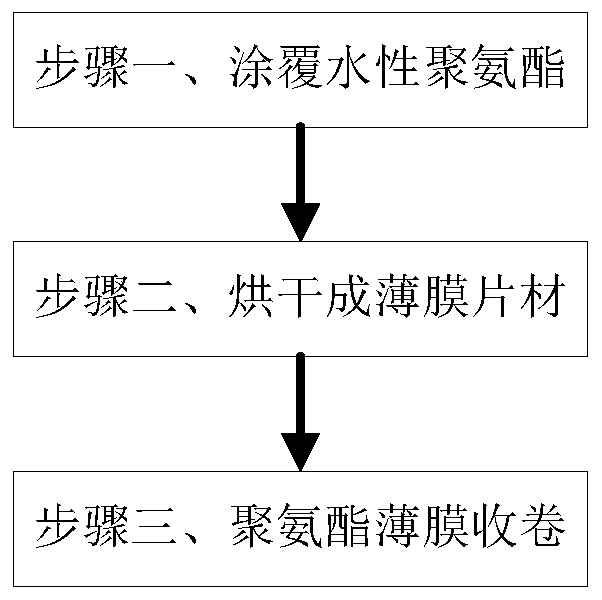

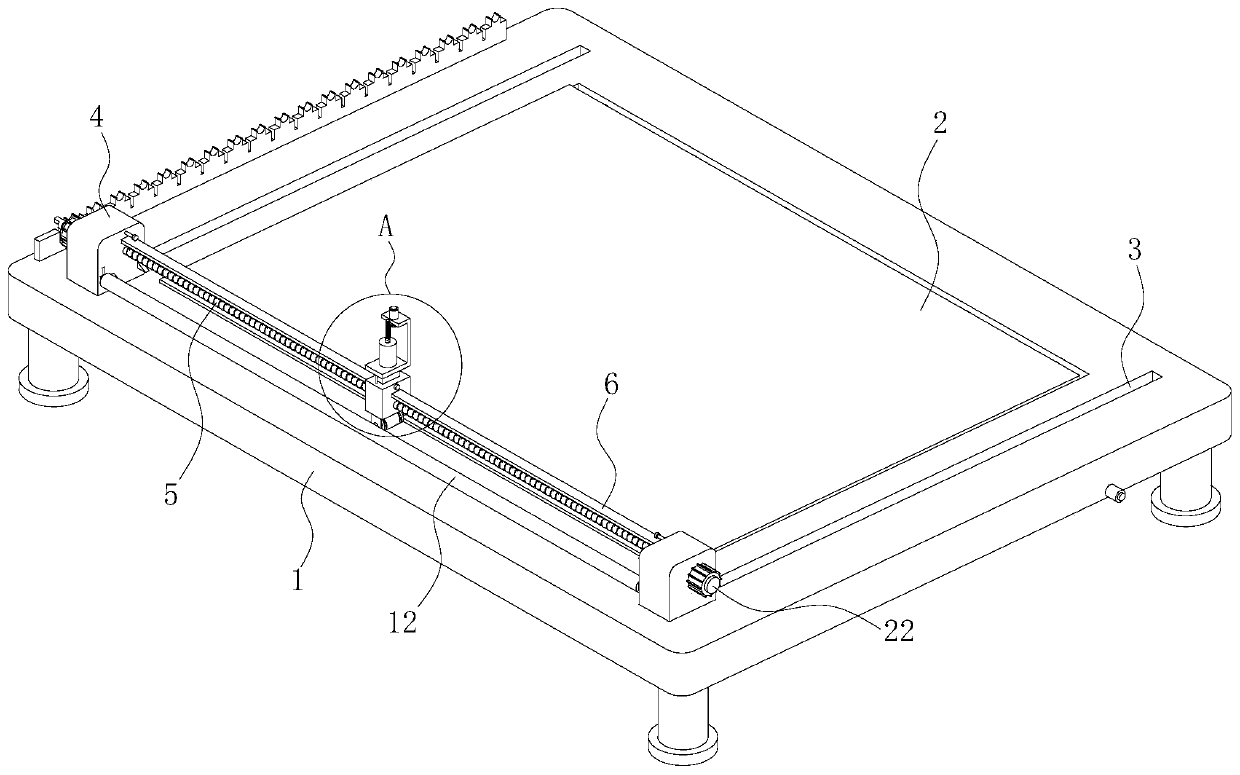

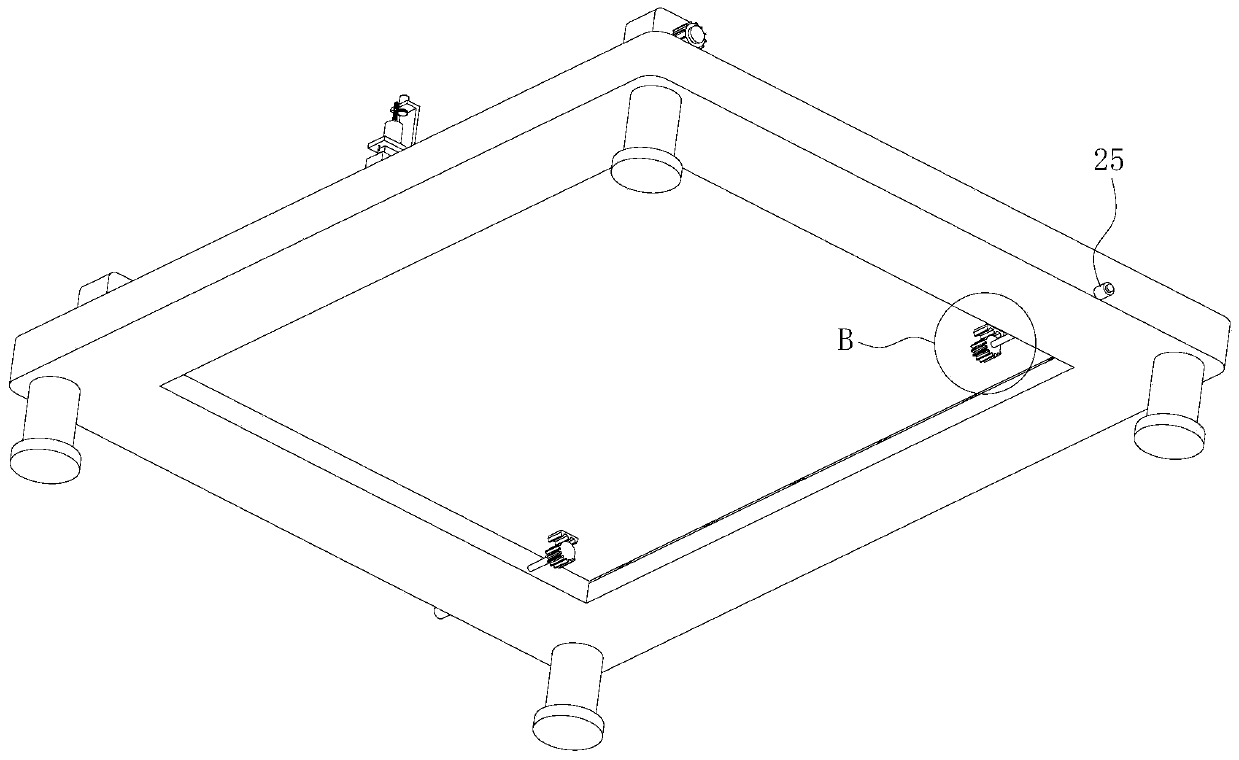

Preparation and processing technology of waterborne polyurethane film

InactiveCN111423606AImprove uniformityAvoid poolingLiquid surface applicatorsCoatingsPolymer sciencePolyurethane coating

The invention belongs to the technical field of new materials, and particularly relates to a preparation and processing technology of a waterborne polyurethane film. The preparation and processing technology comprises the following steps: step 1, coating of waterborne polyurethane: uniformly coating a flat base material with the waterborne polyurethane; step 2, drying to form a thin film sheet: heating and drying the waterborne polyurethane on the base material to form the thin film sheet with uniform thickness; step 3, polyurethane film rolling: rolling the dried waterborne polyurethane filmsheet, wherein the process of coating of the waterborne polyurethane in the step 1 is completed by adopting a waterborne polyurethane film preparation and processing device. According to the invention, when the surface of a substrate is coated with the waterborne polyurethane, a conveying mechanism supplies materials at a constant speed, the waterborne polyurethane coating the surface of the substrate is in a continuous and non-overlapped state, so the waterborne polyurethane is prevented from being gathered on the surface of the base material; and transverse trowelling can be conducted on thewaterborne polyurethane, so the uniformity of the thickness of the dried film is improved.

Owner:谢富玉

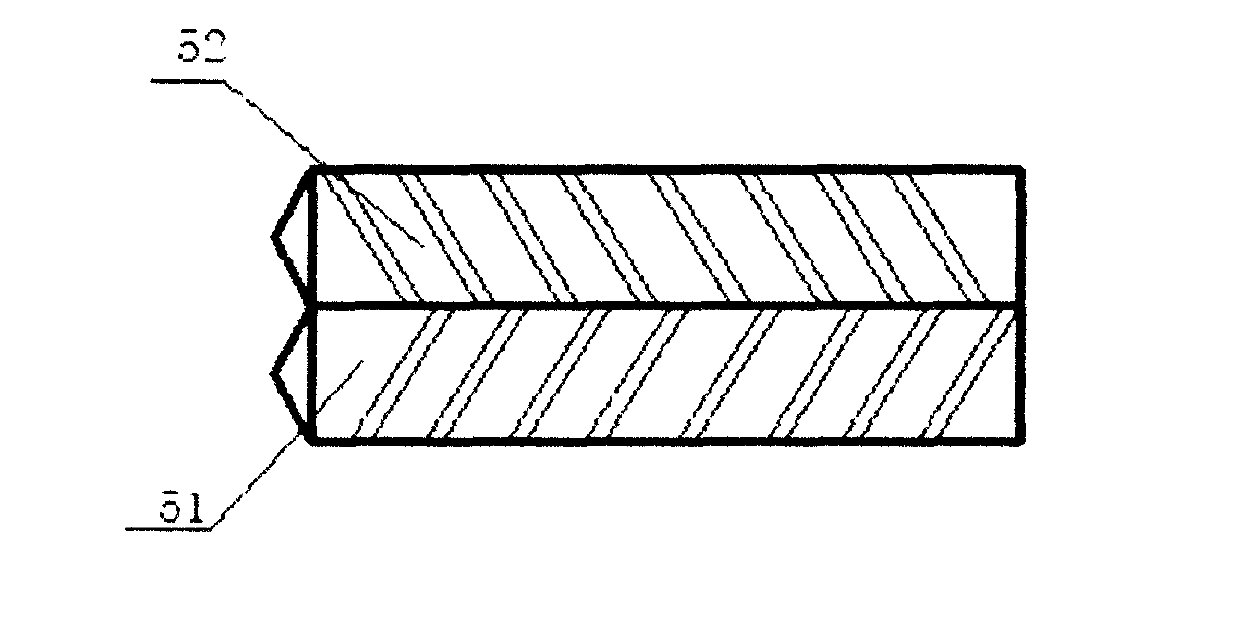

Fiber plastic profile outdoor floor and preparation method thereof

The invention discloses a fiber plastic profile outdoor floor and a preparation method thereof, and belongs to the technical field of composite materials. According to the fiber-plastic profile outdoor floor, the fiber-plastic composite material made of the waste textile fabric and the waste plastic serves as the raw material, the cost is low, the floor is green and environmentally friendly, meanwhile, recycling of the waste textile fabric and the waste plastic is achieved, and in addition, the environment-friendly effect is achieved. The fiber-plastic composite material used by the fiber-plastic profile outdoor floor provided by the invention has more excellent mechanical properties than a single component in the fiber-plastic composite material.

Owner:上海纤苏新材料科技有限公司

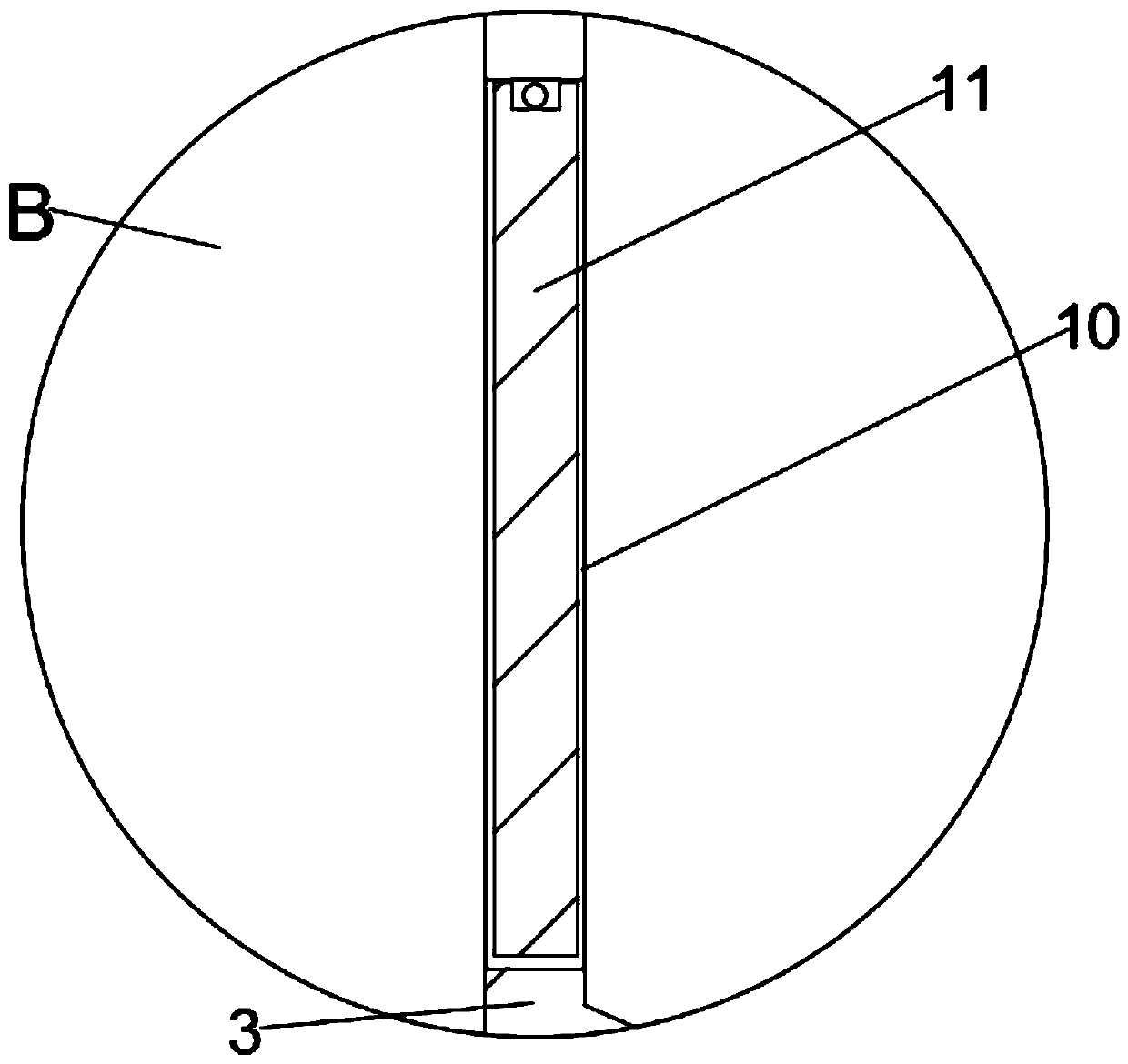

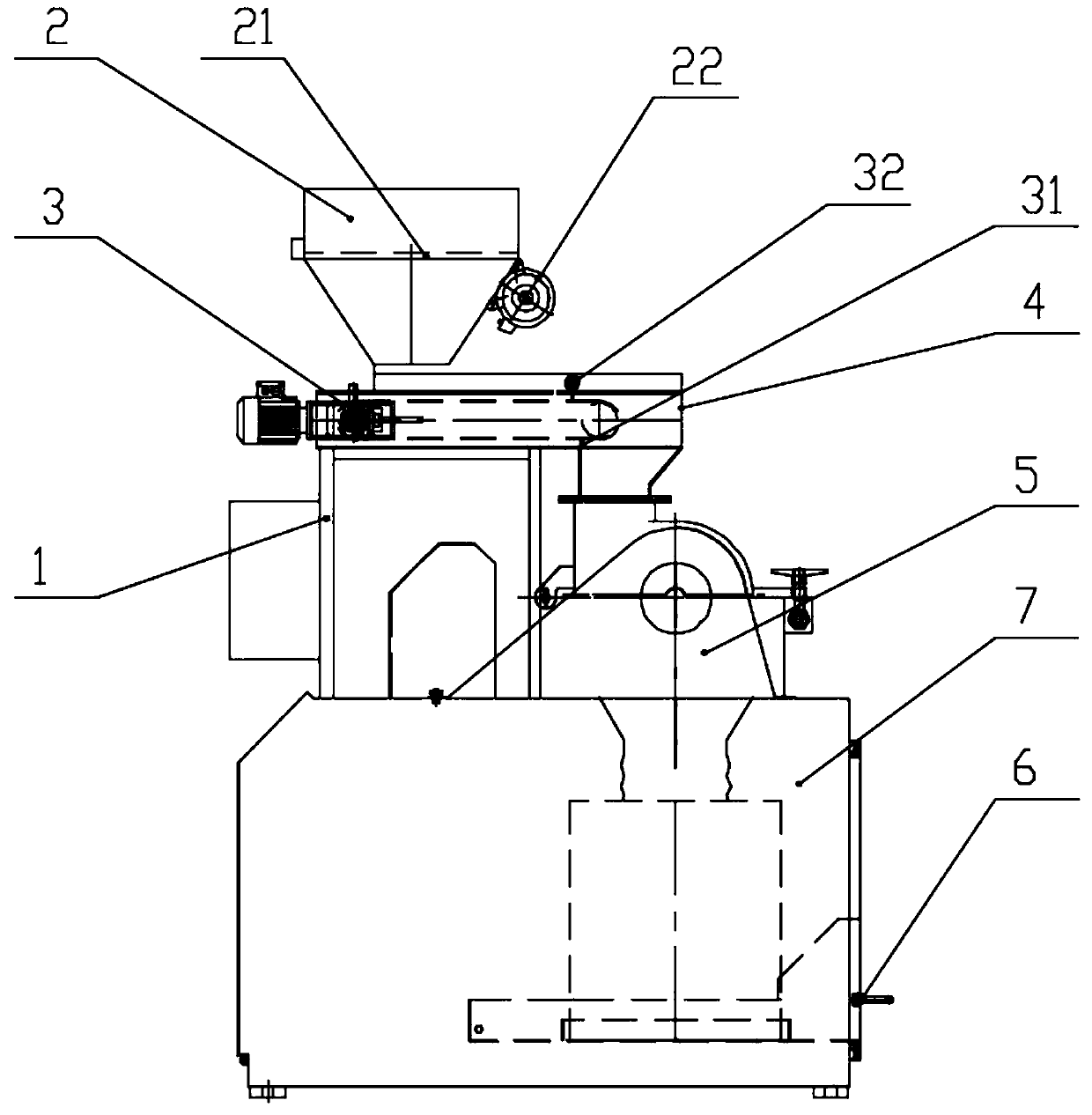

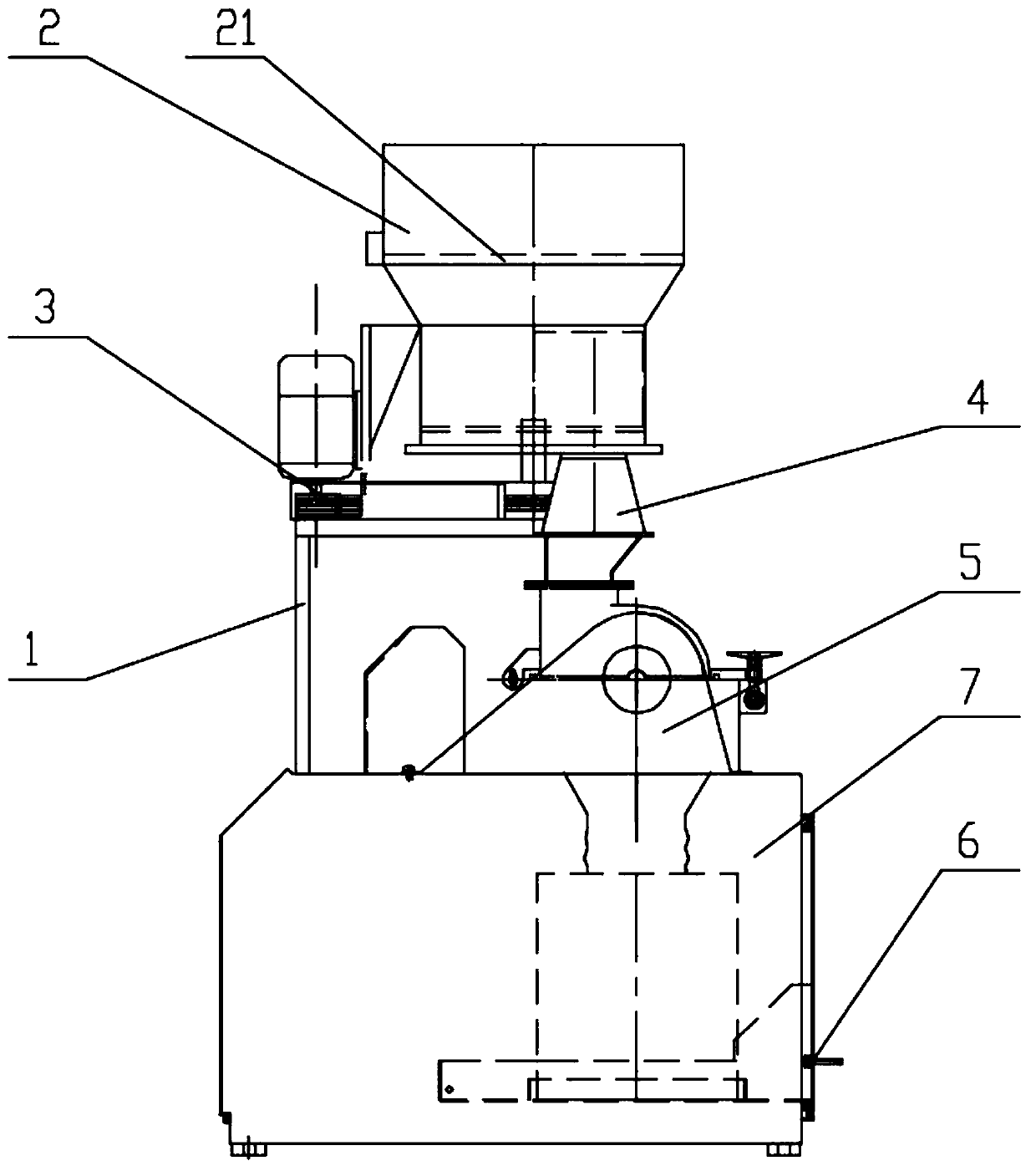

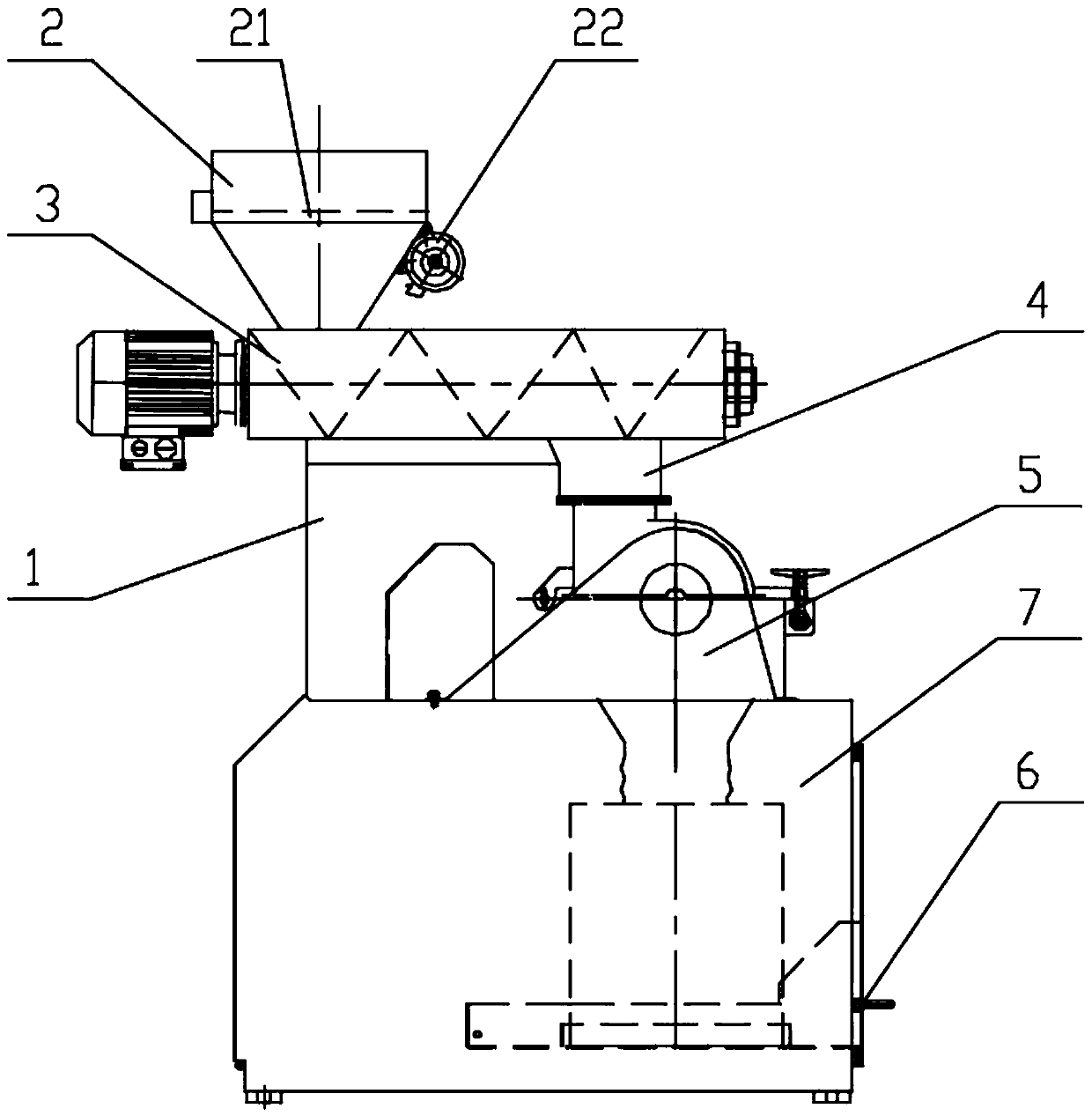

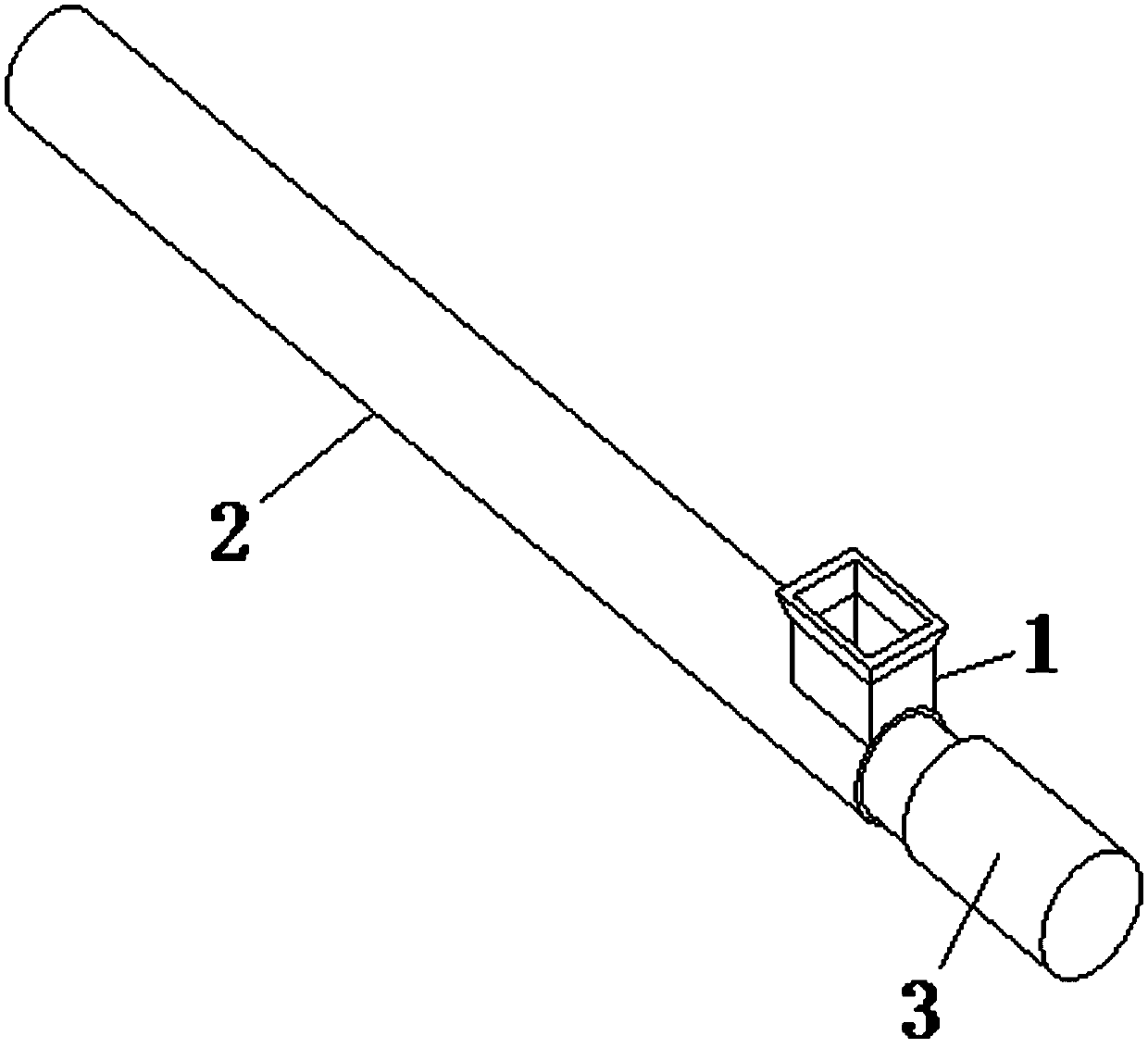

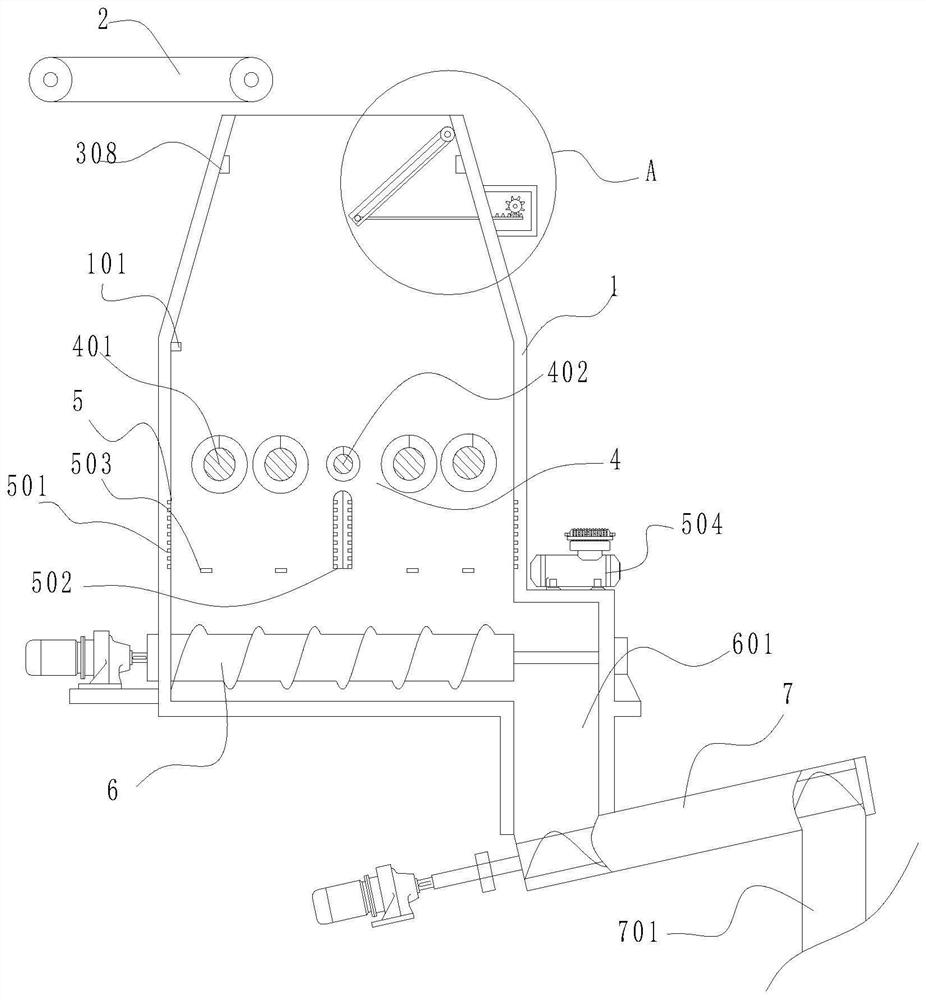

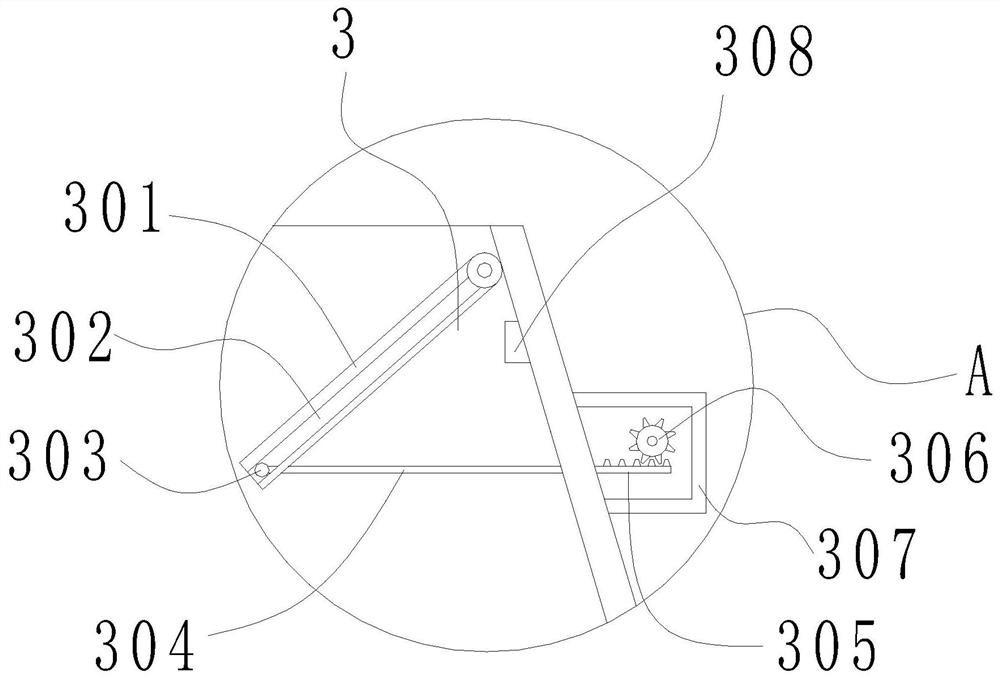

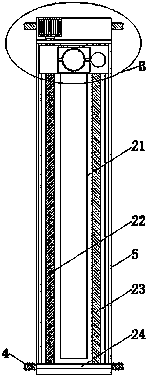

Sample preparation crusher capable of automatically feeding

InactiveCN110575898AIncrease the level of automationImprove work efficiencyGrain treatmentsElectric controlCrusher

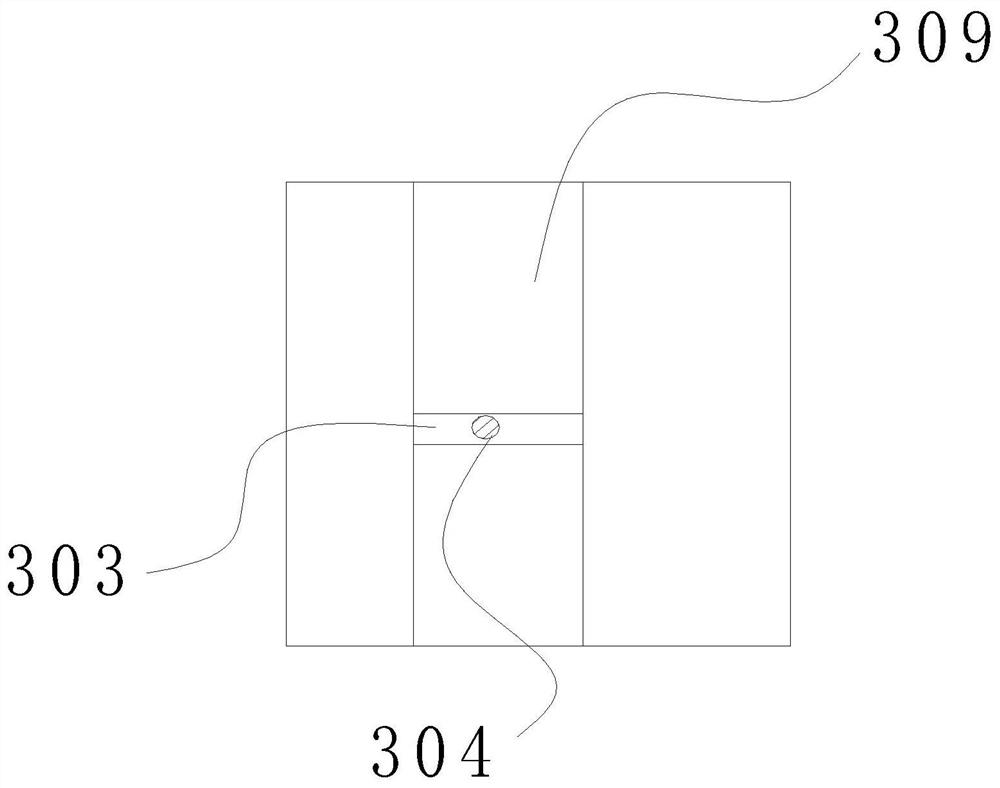

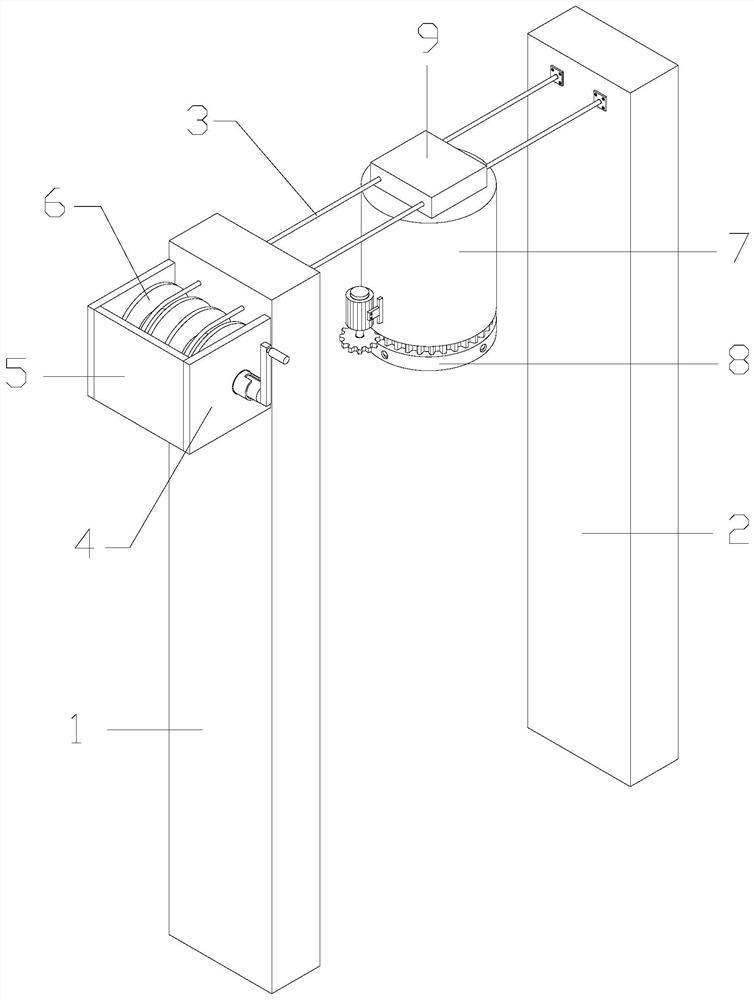

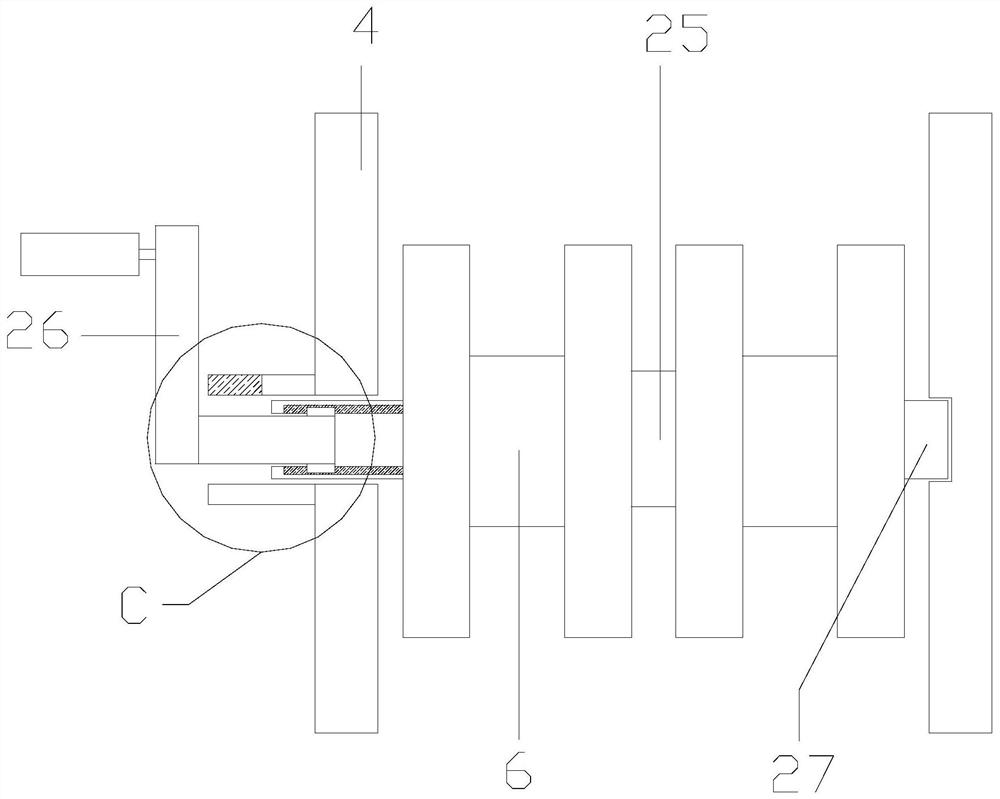

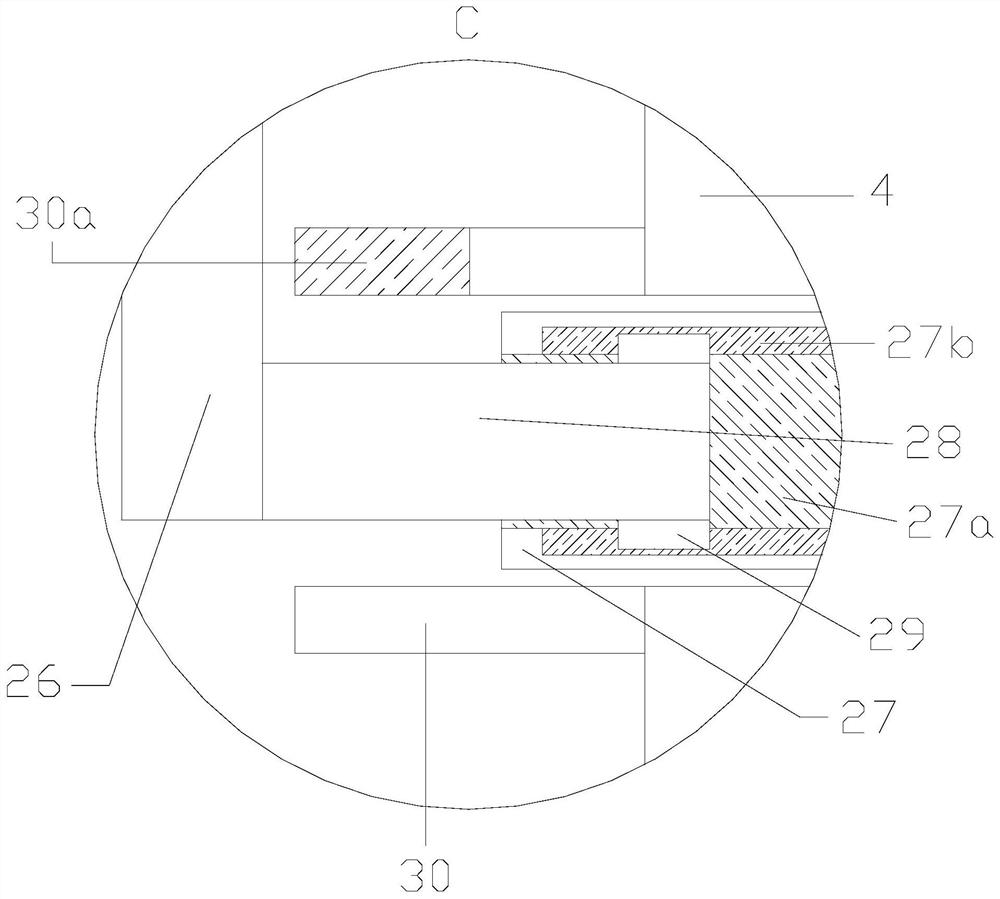

The invention discloses a sample preparation crusher capable of automatically feeding. The sample preparation crusher capable of automatically feeding comprises a feeding base (1), a feeding bin (2),a material conveying device (3), a feeding shield (4), a crushing cavity (5), a material receiving drawer (6), a machine body (7) and an electric control device, wherein the position, corresponding tothe crushing cavity, of the feeding base is fixedly arranged on the machine body; the feeding bin, the material conveying device and the feeding shield are all fixedly mounted on the feeding base; the feeding shield is hermetically arranged outside the feeding bin, the material conveying device and the crushing cavity; the material conveying device comprises a speed-adjustable driving mechanism,a conveying mechanism, a sweeper (31) and a material sensor (32); and the electric control device comprises a PLC controller, a material conveying loop and a material crushing loop. The sample preparation crusher capable of automatically feeding is capable of avoiding the problem of locking of a crushing moving part, and realizing stable and continuous sample crushing, and is particularly suitablefor solid material sample preparation crushing operation in industrial analysis.

Owner:XUZHOU HUAFENG MEASUREMENT & CONTROL TECH

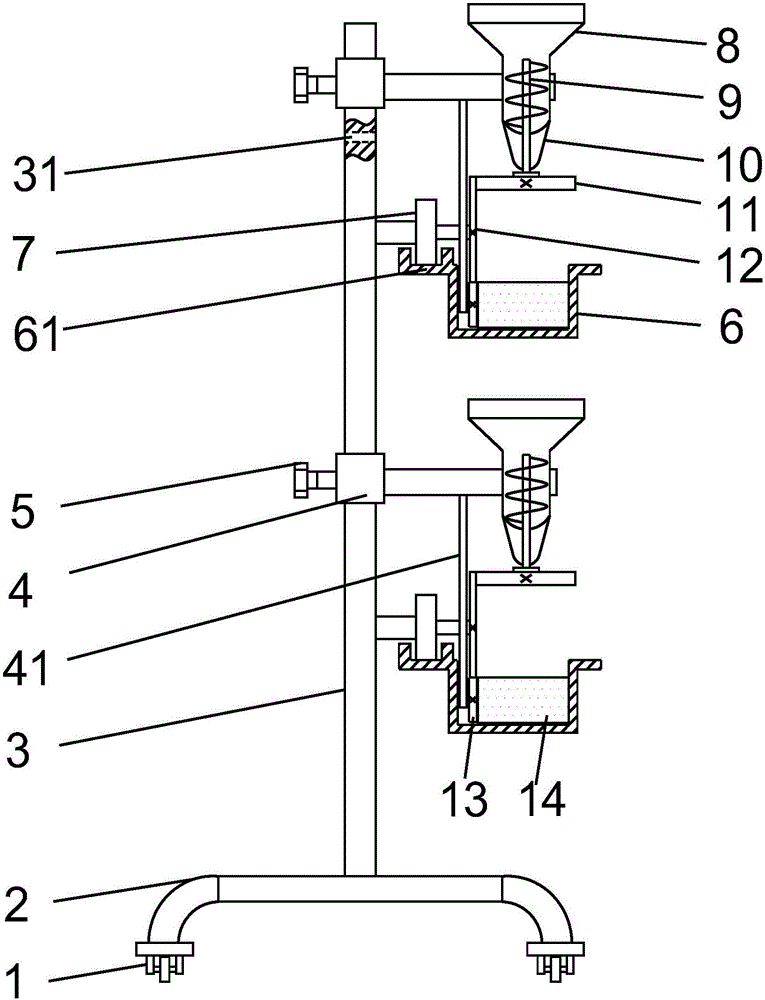

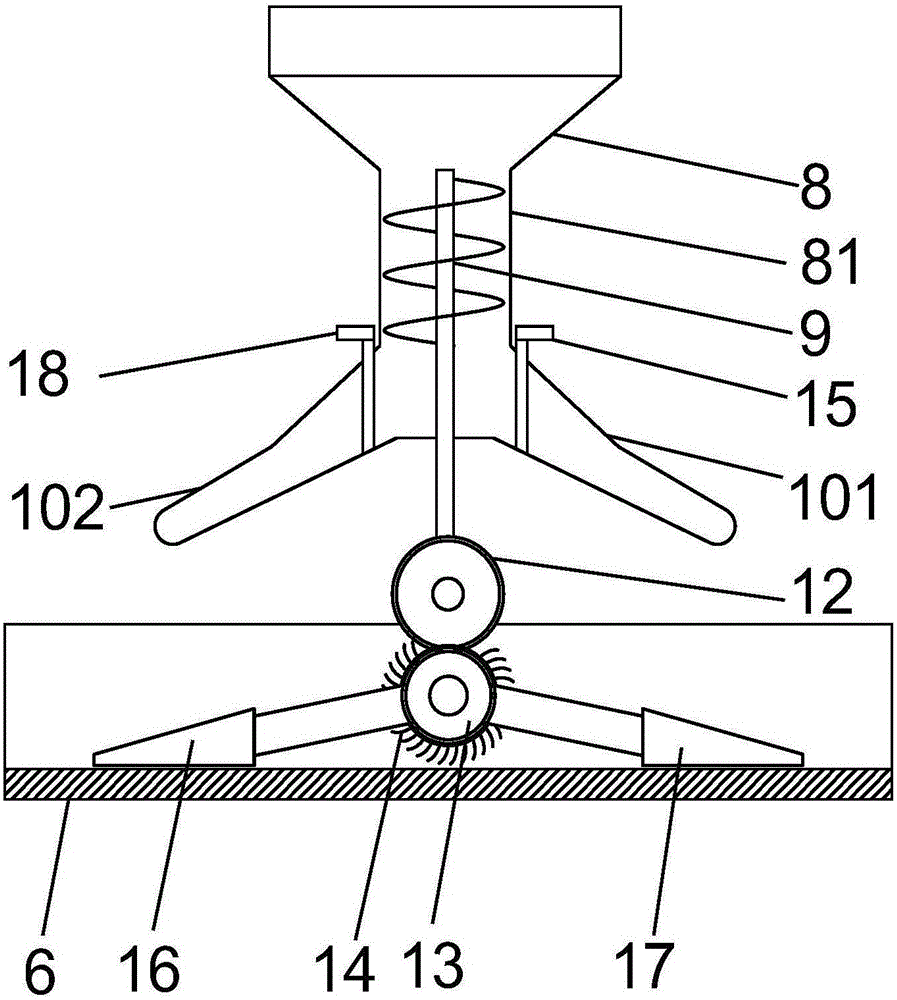

Manual feeding device for poultry breeding farm

The invention discloses a manual feeding device for a poultry breeding farm. The manual feeding device comprises a stand frame, cribs, a feeding assembly and a cleaning assembly. The stand frame is located on one side of the cribs, a plurality of rollers are installed on the stand frame, and each roller is located in a sliding groove formed in one side of the corresponding crib. The feeding assembly comprises a charging hopper, a discharging cavity, a packing auger and a discharging groove, the discharging cavity is connected to the bottom of the charging hopper, the packing auger is located in the discharging cavity, and the discharging groove is obliquely connected to the bottom of the discharging cavity. The cleaning assembly comprises a cylinder, buckets and a gear structure and is rotationally arranged on an installation rack, the cylinder is located in the corresponding crib and makes contact with the bottom face of the corresponding crib, the cylinder is provided with hard brush bristles, the buckets comprise the left bucket and the right bucket, and the left bucket and the right bucket are fixedly arranged on the installation rack respectively and located on the left side and the right side of the cylinder respectively. The feeding efficiency and the cleaning efficiency are greatly improved, and the problems of uneven feeding, waste due to excess fodder and the like in manual feeding are avoided.

Owner:ZHENGZHOU SOUQU INFORMATION TECH CO LTD

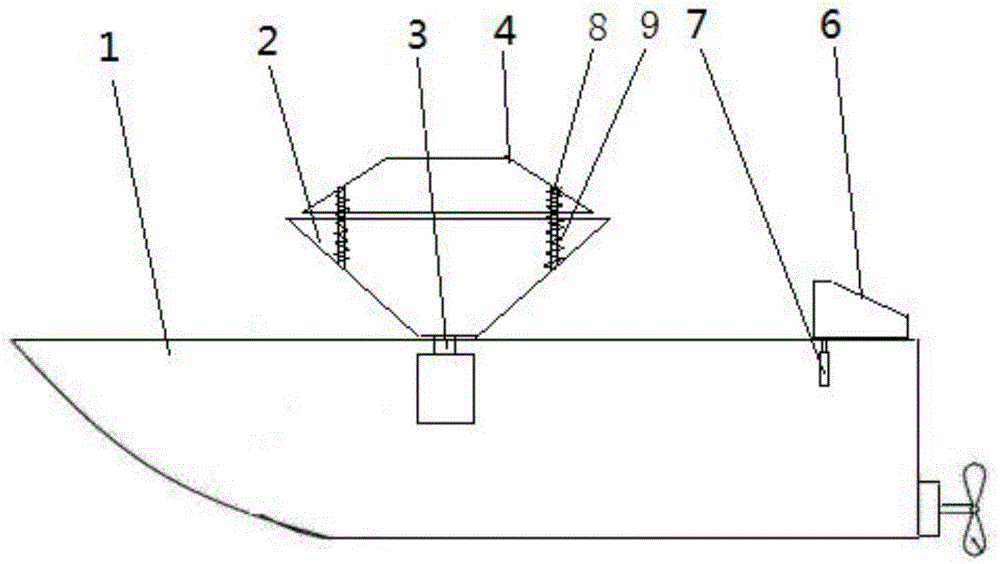

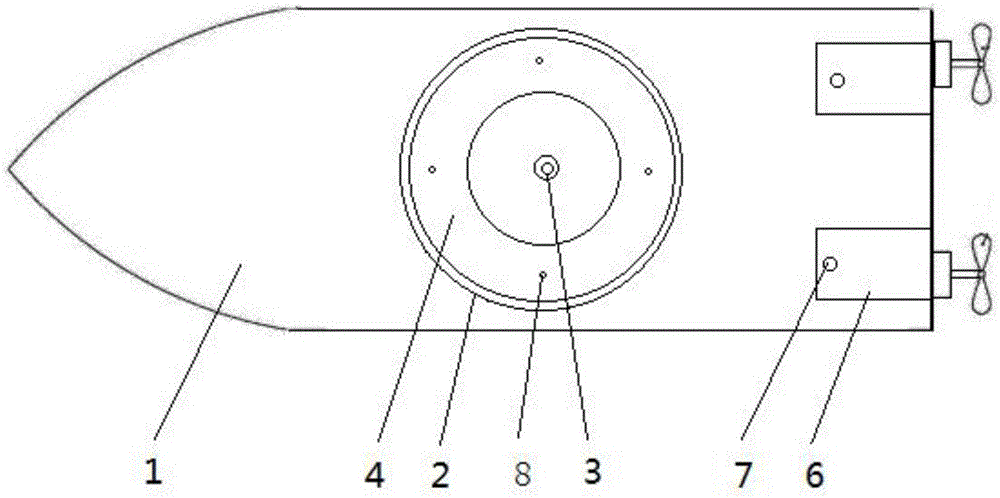

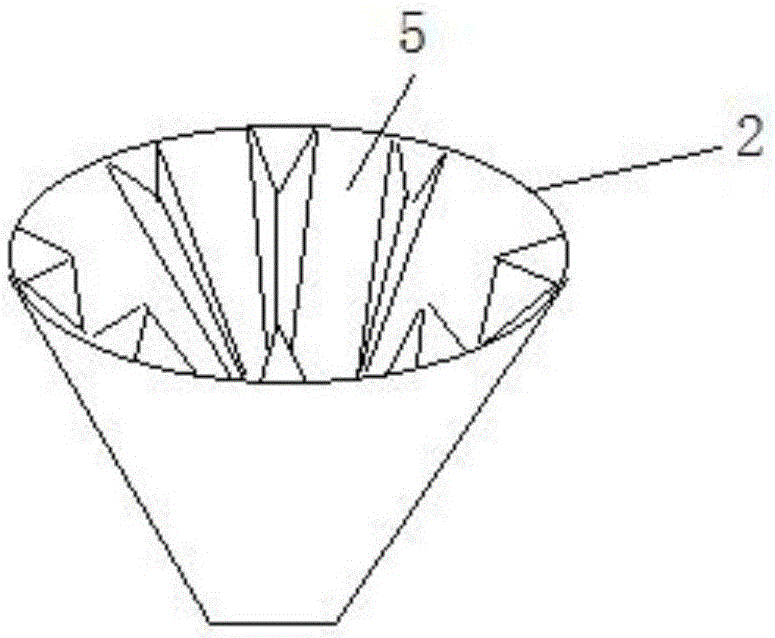

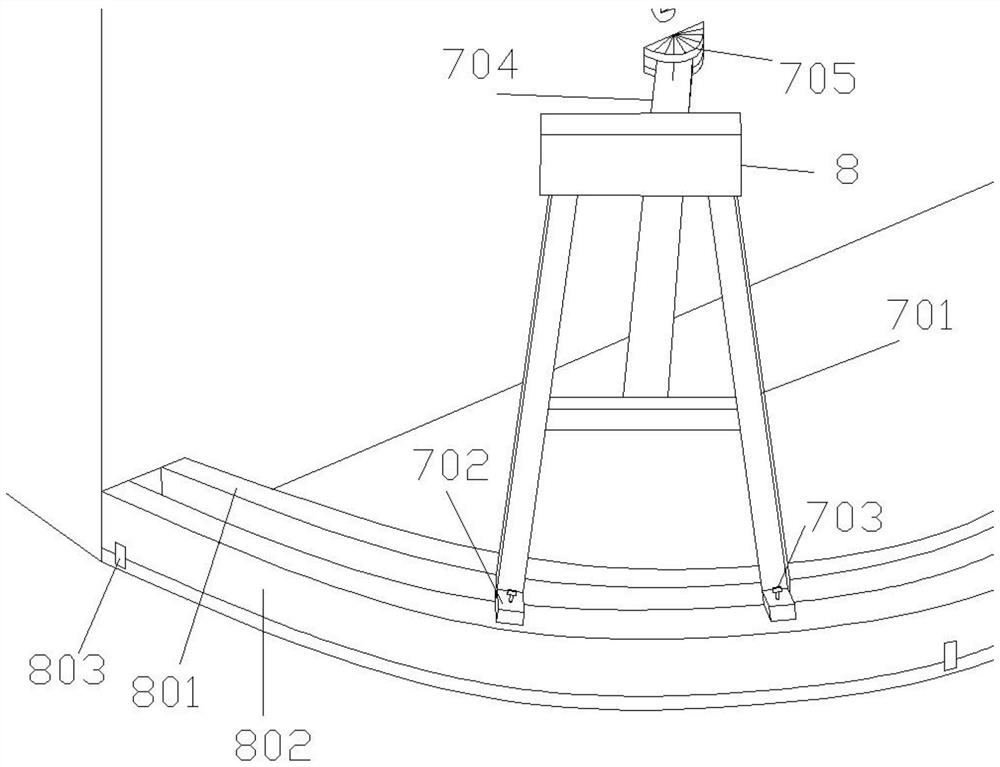

Fishing bait feeding ship

PendingCN107517939AFeed quicklySmooth feedingWaterborne vesselsOther angling devicesRotational axisFishery

The invention relates to a fishing bait feeding ship which comprises a ship hull. A hopper-shaped feeding bin is further arranged on the ship hull, a rotary shaft is arranged on the lower side of the feeding bin, a material cover is arranged on the upper side of the feeding bin and is in the shape of an inverted hopper with an upper opening and a lower opening, the diameter of the lower opening of the material cover is smaller than that of an upper opening of the feeding bin, and gaps are reserved between the material cover and the feeding bin. The fishing bait feeding ship has the advantages that concave guide grooves are longitudinally formed in the feeding bin, so that bait can be rotationally centrifuged; the fishing bait feeding ship is optimized in such a manner that the rotational speeds of rotary motors can be controlled, and accordingly the feeding ranges can be accurately controlled; fed bait can be uniformly, regularly and quickly scattered on water surfaces, the feeding ranges can be accurately controlled, and accordingly excellent fish luring effects can be realized.

Owner:张光华

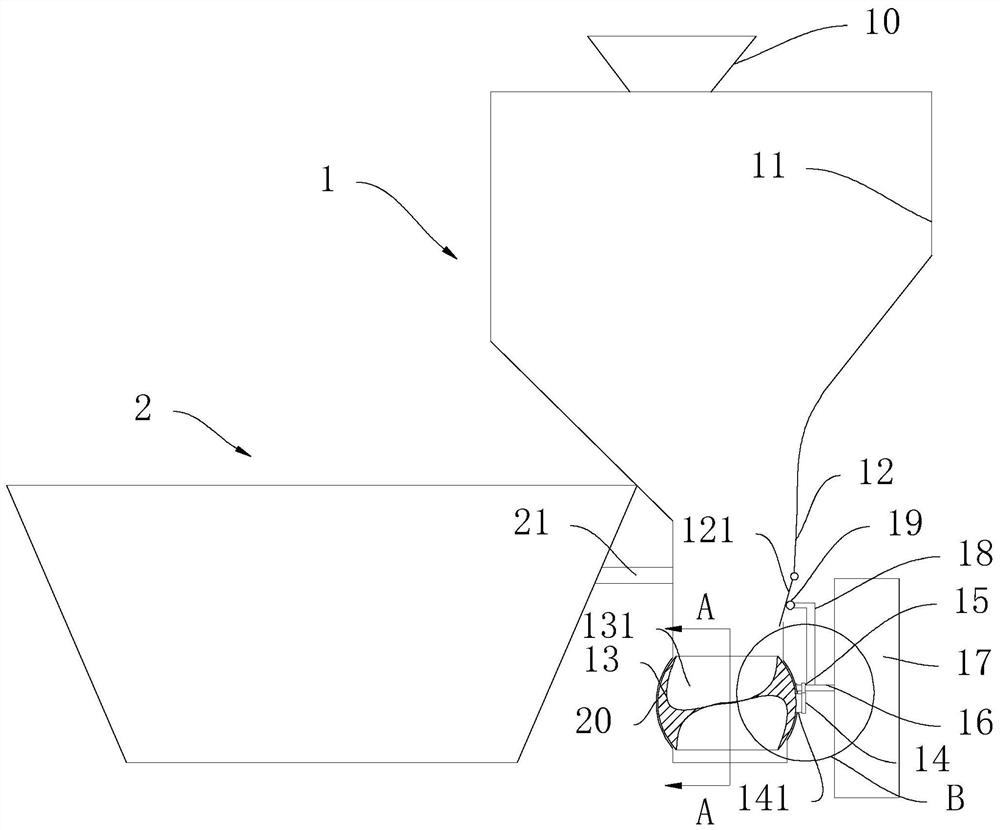

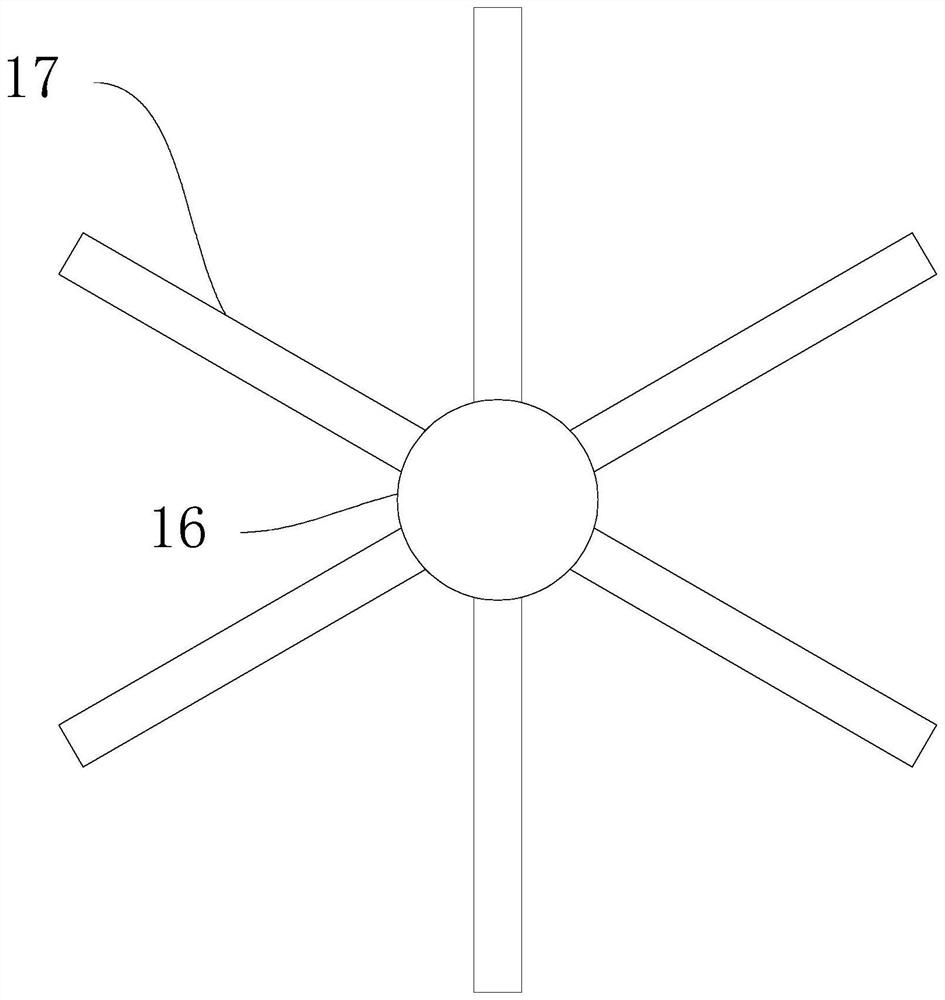

Electrically-controlled mechanical feeding equipment

PendingCN113273532AReduce labor intensityAvoid uneven feedingClimate change adaptationPisciculture and aquariaElectrical controlScrew thread

The invention provides electrically-controlled mechanical feeding equipment. The electrically-controlled mechanical feeding equipment comprises a feeding barrel, a first flow guide block, a screw rod, a first shifting rod, a plurality of feeding holes, a shielding plate, a first lifting mechanism, a timer and a controller, wherein the feeding barrel is arranged above a pond; the first flow guide block is sleeved with the feeding barrel, and a discharging port is formed in the center of the first flow guide block; the screw rod is vertically arranged in the feeding barrel, one end of the screw rod is rotationally connected with the center of the inner bottom surface of the feeding barrel, and the other end of the screw rod extends into the discharging port; the first shifting rod is horizontally fixed at the lower end of the screw rod in a sleeving manner; the plurality of feeding holes are formed in the side wall of the bottom of the feeding barrel in the circumferential direction of the feeding barrel; the shielding plate is arranged under the discharging port, and the shielding plate is arranged on the screw rod in a sleeving mode and is in threaded connection with the screw rod; the first lifting mechanism is arranged on the feeding barrel, and the output end is connected with the shielding plate; the timer is electrically connected with a power supply module; the controller is electrically connected with the timer, the first lifting mechanism and the power module. The electrically-controlled mechanical feeding equipment can realize timed automatic feeding and is uniform in feeding.

Owner:西安交通工程学院

A garment cutting device

ActiveCN111926554BConstant crop lengthIncrease profitSevering textilesEngineeringStructural engineering

The invention discloses a garment cutting device, which comprises a fixed frame, a cutting device for cutting cloth according to a required length is installed inside the fixed frame, and a placing platform for placing the cut cloth is installed at the bottom of the fixed frame, In clothing processing and production, the cloth is introduced into the device through the feeding trough, and the cloth is introduced by using electric telescopic rods and electric suction cups to avoid uneven feeding due to the softness of the cloth, and the cloth is stretched by using the stretching device. After reaching the required length, push the limit lever to control the cutting guillotine to fall to complete the cutting. The stretching device separates the fabric synchronously during cutting, so that the cutting length of the fabric is constant. The placing platform is used instead of the ordinary placing table, so that the stacked fabrics are stacked on the top layer of fabrics. The height is always constant, and it is convenient to use the smoothing device to smooth the fabric, which further improves the internal flatness of the stacked fabric, avoids wrinkles in the internal fabric, and improves the fabric utilization rate.

Owner:MEISHENG CULTURE INNOVATION HLDG

Hopper type screw feeder for collagen casing production

PendingCN110422643AControl amountAvoid using influenceConveyorsCleaningEngineeringMechanical engineering

The invention relates to the technical field of feeders and discloses a hopper type screw feeder for collagen casing production. The hopper type screw feeder for collagen casing production comprises afeeding hopper, a conveying device and a conveying motor. The feeding hopper is fixedly installed on the upper side of the conveying device. The side wall of the end, close to the feeding hopper, ofthe conveying device is fixedly connected with the conveying motor. A rotating shaft is movably installed in the feeding hopper. The rotating shaft is connected and sleeved with a roller. The left side wall and the right side wall of the roller are both fixedly provided with damping blocks. The damping blocks are connected to the rotating shaft in a sleeving manner. The portions, at the two ends of the roller, of the rotating shaft are both provided with springs. According to the micelle raw material dedicated hopper type screw feeder for collagen casing production, the rotating shaft, the roller and devices on the roller are arranged in the feeding hopper for use, during feeding, a straight plate pair and an arc plate pair can decelerate feeding and also can control the material quantityduring feeding, the situation that excessive materials are fed at a time, so that a device fault is caused and equipment use is influenced is avoided, and the practicability of the device is improved.

Owner:河南景珍生物科技有限公司

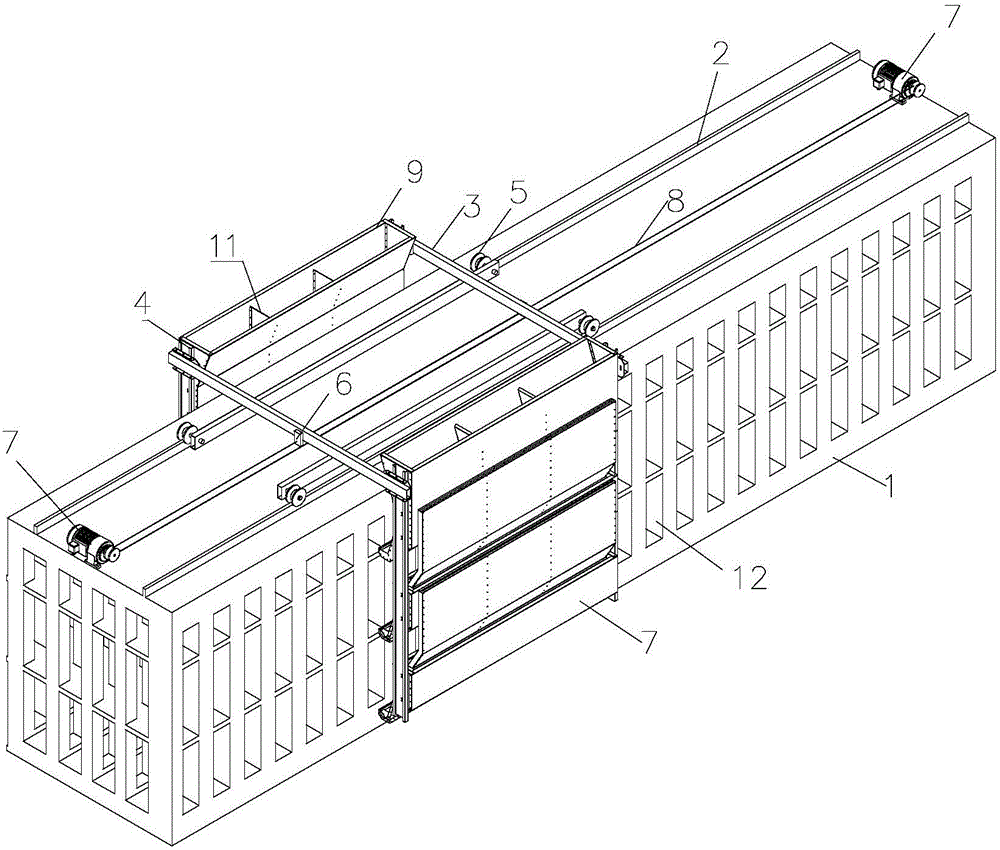

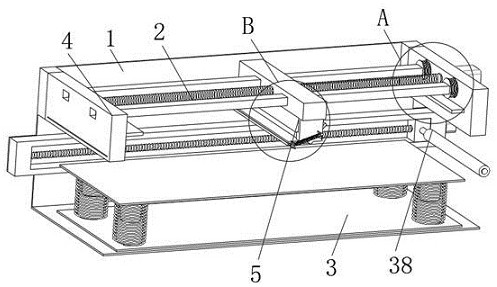

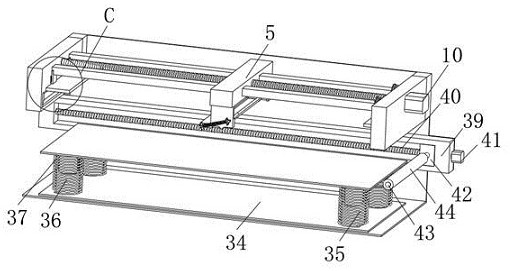

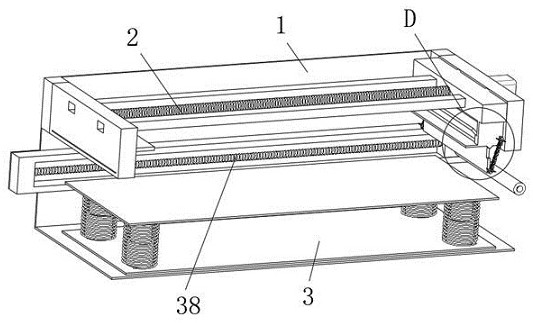

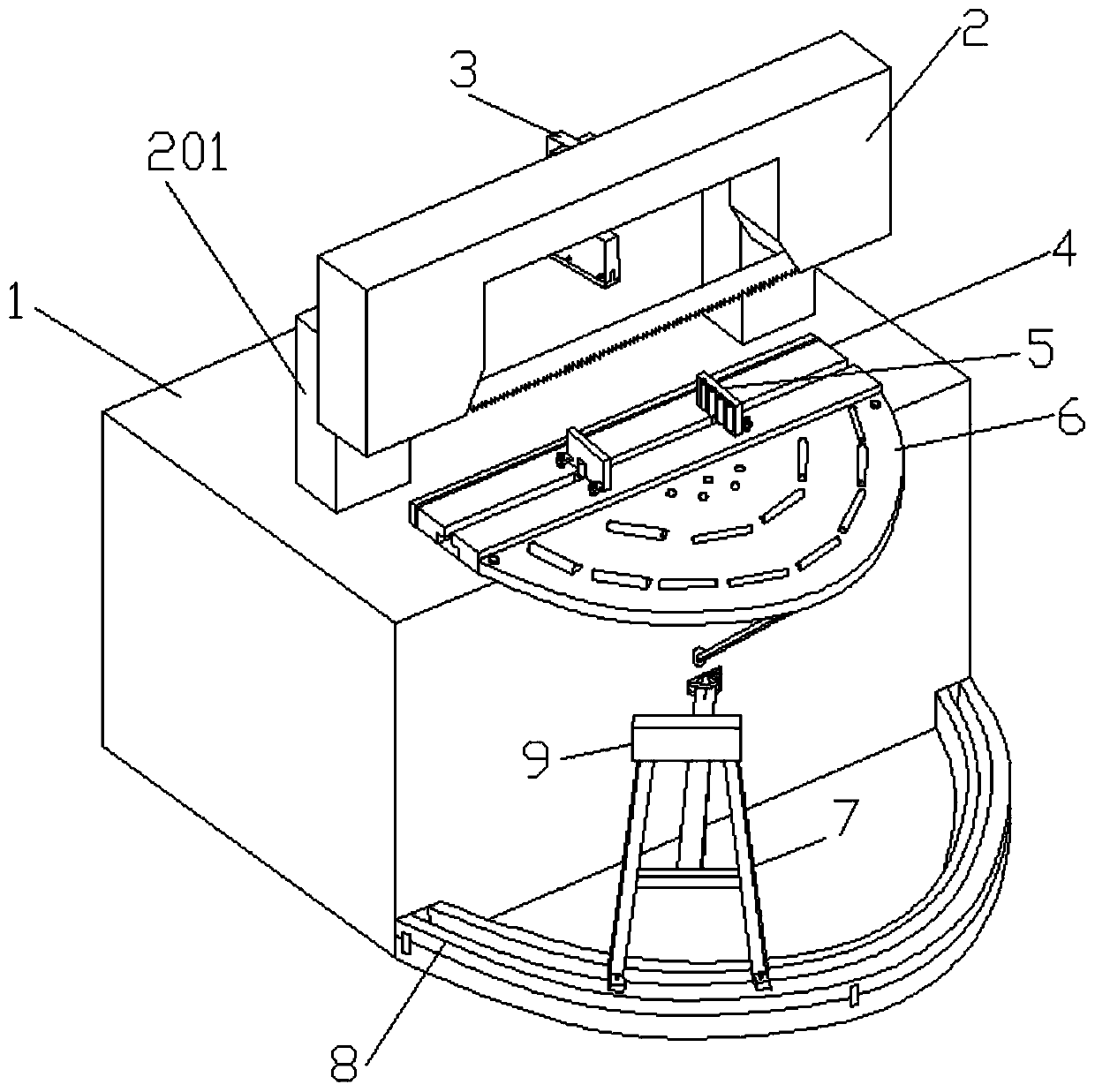

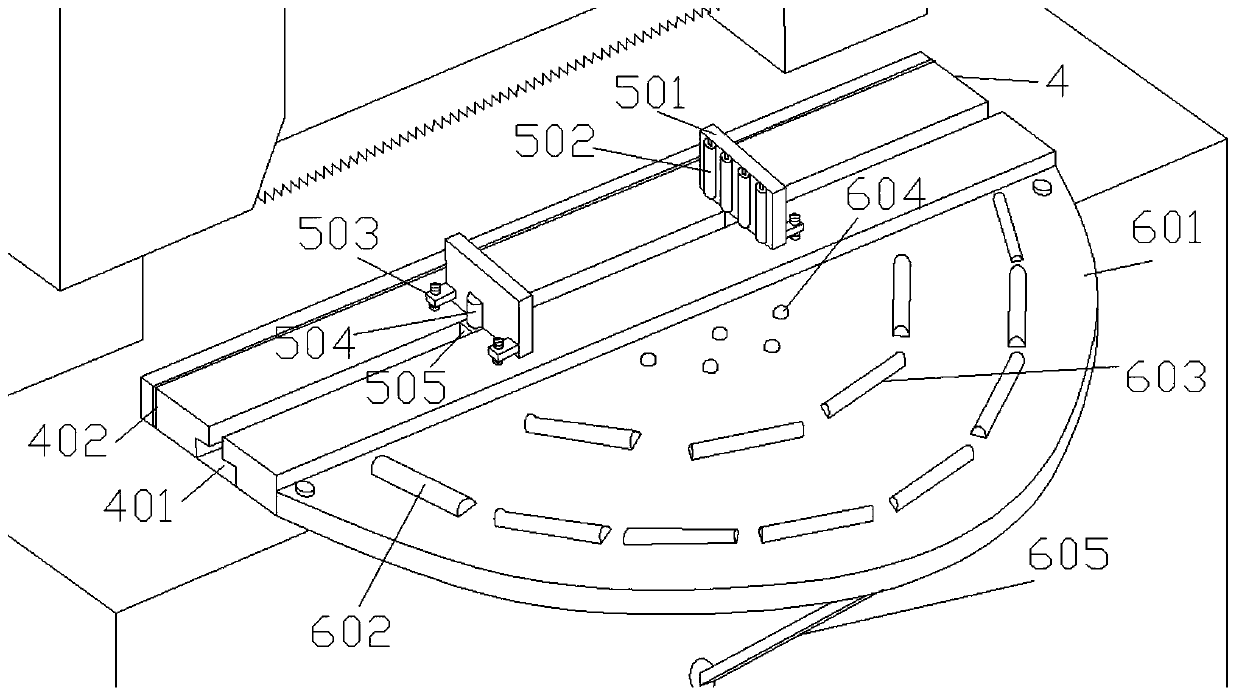

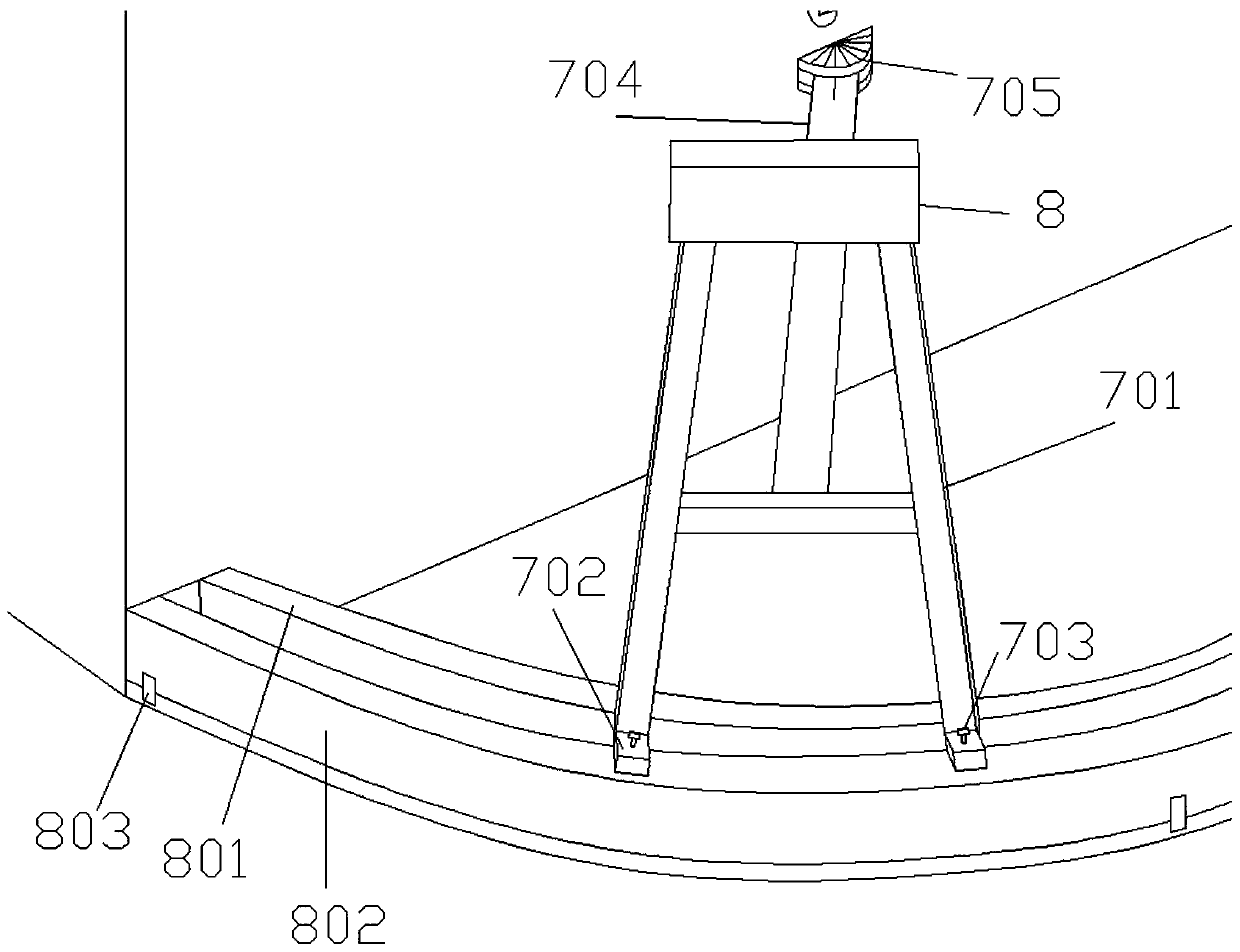

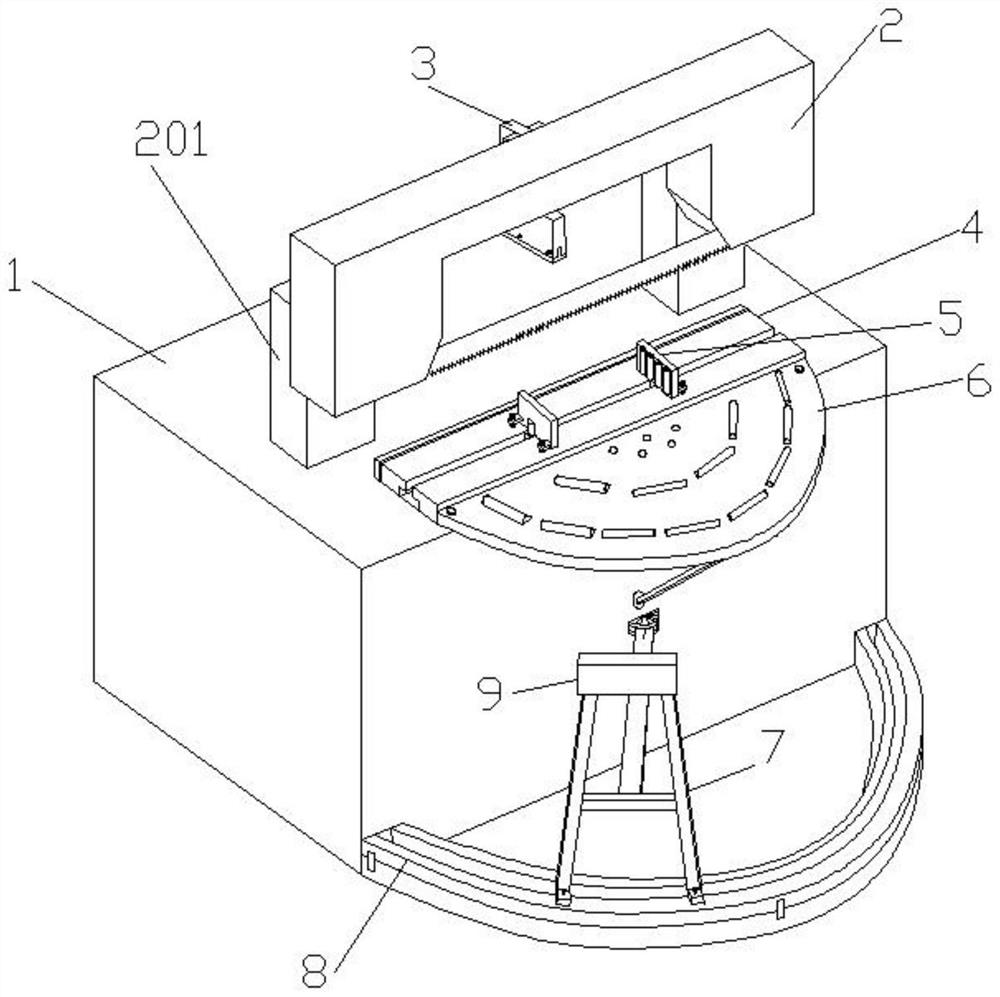

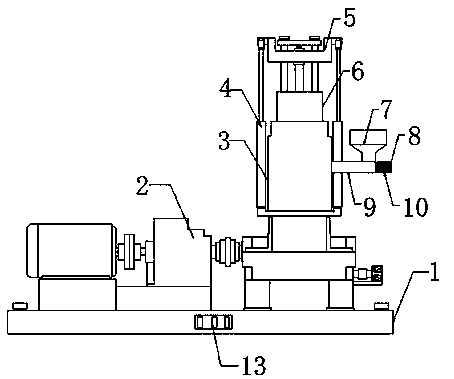

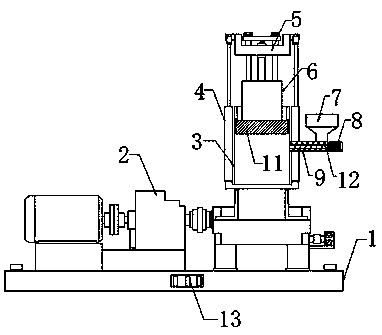

Horizontal band sawing machine with automatic feeding device

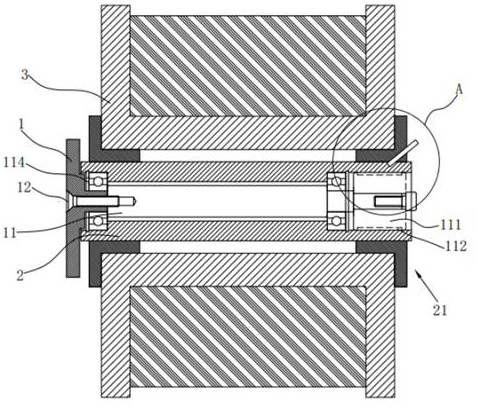

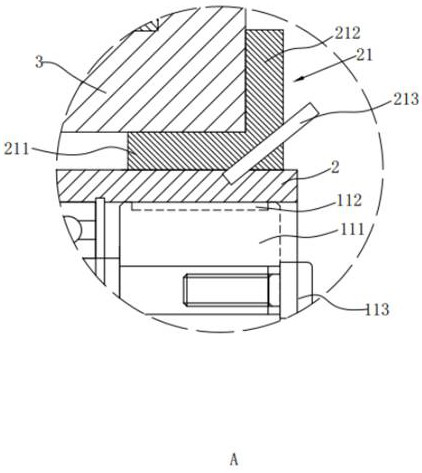

ActiveCN111496318AUniform and stable feedingImprove feeding effectMetal sawing devicesElectric machineryEngineering

The invention discloses a horizontal band sawing machine with an automatic feeding device. The horizontal band sawing machine with the automatic feeding device comprises a band sawing machine base, wherein a saw frame lifting device is arranged on the band sawing machine base, a saw frame is installed at the top of the saw frame lifting device, a workbench is arranged in front of the saw frame, asaw kerf is formed at a position corresponding to a saw blade on the saw frame, on the workbench, a conveying plate is arranged in front of the workbench, a conveying element and a motor are arrangedon the conveying plate, the motor is capable of driving the conveying element to rotate, and a workpiece placed on the conveying element is conveyed to the workbench; and a movable support is arrangedin front of the conveying plate, a conveying plate is also arranged on the movable support, a conveying element and a motor are also arranged on the conveying plate, and a workpiece placed on the conveying element is conveyed to the workbench. According to the horizontal band sawing machine with the automatic feeding device, through improvement for clamping components and conveying components, the horizontal band sawing machine with the automatic feeding device is capable of meeting higher location accuracy and conveying efficiency, and meeting a machining need on strip-shaped workpieces withdifferent angles and different shapes.

Owner:中电建成都铁塔有限公司

A kind of 3d printer feeding assembly

ActiveCN111300825BAchieve rotationRealize the function of dischargingAdditive manufacturing apparatus3D object support structuresComputer printingEngineering

The present invention relates to the technical field of 3D printing, in particular to a 3D printer feeding assembly, aiming to solve the problem that the retraction of the wire feeder in the printing process in the prior art can cause the material tray to reverse at a certain angle, and even cause the The technical point of the problem of the material coming out of the material tray is that it includes a material hanging bracket and a rotating shaft that rotates synchronously with the material hanging bracket. The outer periphery of the material hanging shaft is provided with a support sleeve that abuts against the side wall of the central axis hole of the material tray, and the material hanging shaft is relatively rotatable with the rotating shaft. Through the setting of the support sleeve, there is friction between the material hanging shaft and the material tray. When the material hanging shaft rotates, the friction force provided by the support sleeve enables the material tray to rotate, thereby realizing the material discharging. Function.

Owner:JIANGSU OURING THREE DIMENSIONAL SCI & TECH CO LTD

A feed bin in front of a biomass boiler

ActiveCN109956210BImprove stabilityAvoid cloggingFuel feeding arrangementsLarge containersBoiler furnaceProcess engineering

The invention discloses a feed bin in front of a biomass boiler furnace. A material equalizing mechanism is provided, and a screw feeding device is arranged under the material uniforming mechanism. The plate and the second equalizing plate evenly spray the material falling from the screw carrier, so that the material is evenly distributed on the screw feeding device. This ensures the uniformity of feeding materials from the silo to the boiler, and improves the stability of boiler combustion.

Owner:国祯美洁 (安徽)生物质热电有限公司

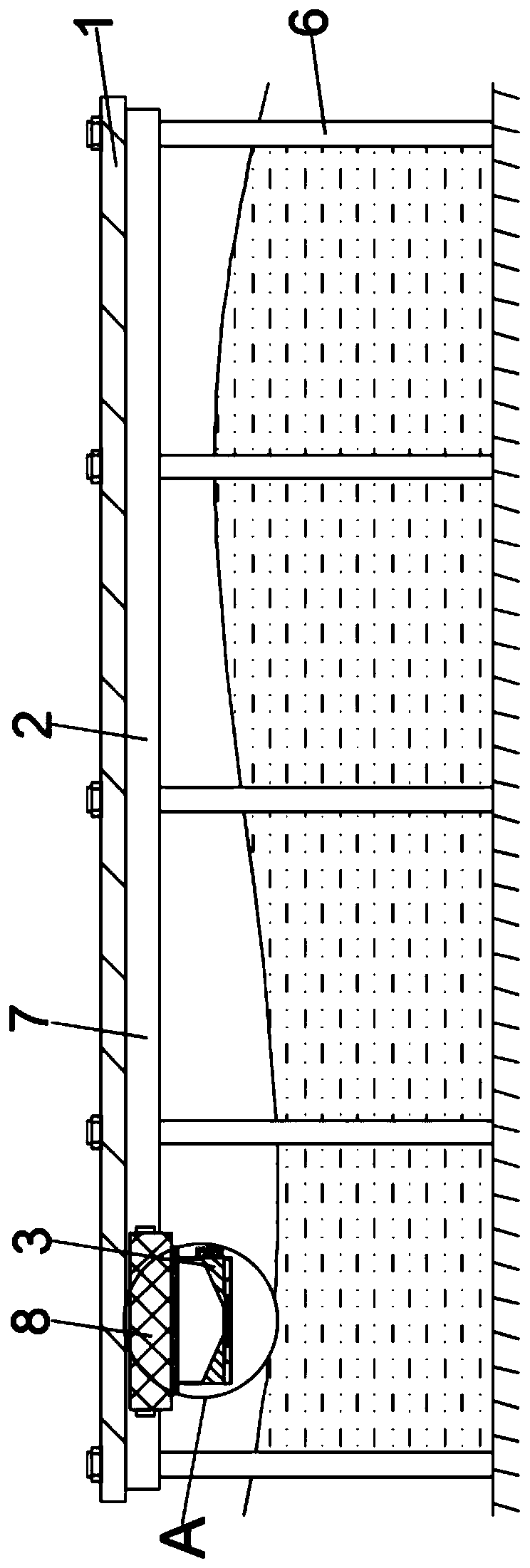

Feeding device for aquaculture

InactiveCN113841651AAdjustable spacingSprinkle evenlyClimate change adaptationPisciculture and aquariaEngineeringAquaculture

The invention discloses a feeding device for aquaculture. The feeding device comprises a first supporting column and a second supporting column which are vertically arranged in parallel, a distance adjusting assembly is arranged on the side, away from the second supporting column, of the first supporting column, the distance adjusting assembly comprises steel wire ropes, the ends, away from the second supporting column, of the steel wire ropes are connected with length adjusting pieces used for adjusting the lengths of the steel wire ropes, a moving assembly is arranged on the two steel wire ropes in a sliding mode, a material storage assembly is arranged below the moving assembly and comprises a material storage box, a material throwing assembly is arranged on the side, away from the moving assembly, of the material storage assembly, the material throwing assembly comprises a material throwing disc of a hollow structure, the material throwing disc is located on the lower side of the material storage box, the material storage box and the material throwing disc communicate through a vertically-arranged discharging pipe, and the material throwing disc is further connected with the material storage box through a rotating assembly, so that materials are evenly sprayed into a water pool, and uneven feeding caused by a manual feeding mode is avoided.

Owner:湖南金秋禾农业开发有限公司

Powdered activated carbon incineration feeding device

PendingCN114811611AImprove disposal efficiencyImprove securityIncinerator apparatusNon-combustible gases/liquids supplyActivated carbonCombustion

The invention relates to a powdered activated carbon incineration feeding device which comprises a combustion pipe, a primary air inlet, a secondary air inlet and an electronic igniter. One end of the combustion pipe is an activated carbon inlet, the other end of the combustion pipe is a fire spraying port, the primary air inlet, the electronic igniter and the secondary air inlet are all arranged on the combustion pipe, the primary air inlet is connected with a primary air inlet pipe, the secondary air inlet is connected with a secondary air inlet pipe, and an air spraying pipe is arranged between each secondary air inlet pipe and the combustion pipe close to the fire spraying port. The included angle between the axial center line of the joint of the gas ejector pipe and the combustion pipe and the axial center line of the combustion pipe is an acute angle. According to the technical scheme, the direct spraying combustion technology is utilized, the situations of uneven feeding, low burning removal rate and deflagration caused by a traditional feeding mode are avoided, the treatment efficiency and safety of waste activated carbon are greatly improved, and a new direction is guided for activated carbon burning.

Owner:山东清博生态材料综合利用有限公司

Pig house automatic feeding device and method and matched pig house

ActiveCN101785436BEasy feedingAvoid uneven feedingAnimal feeding devicesAnimal housingAnimal sciencePig breeding

Owner:靖江市城中村投资建设有限公司

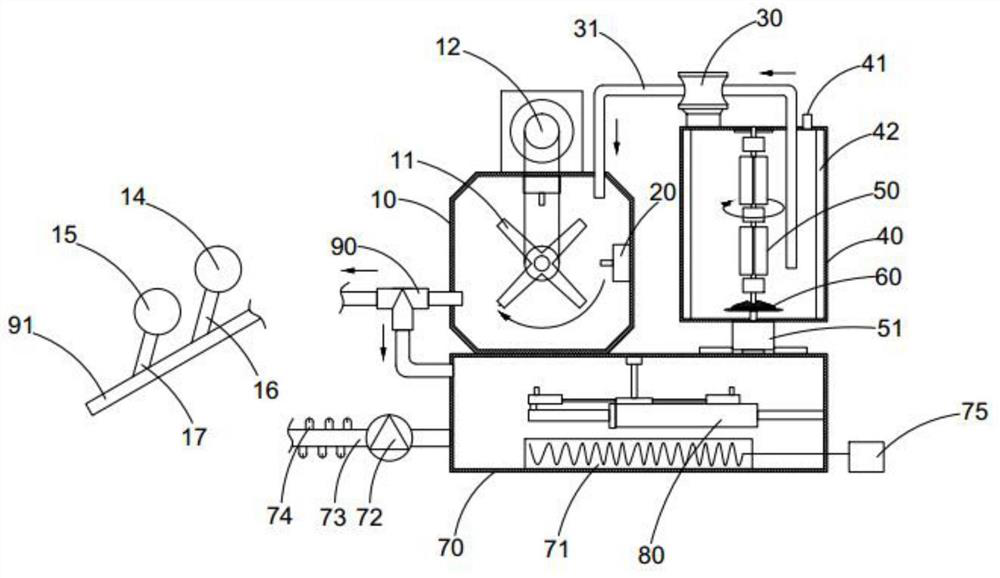

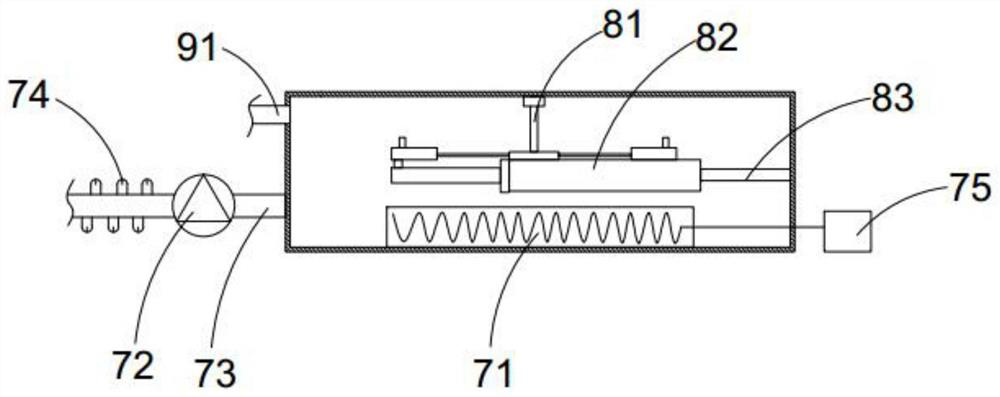

Bait multi-stage mixing device and technology thereof

The invention relates to a bait multi-stage mixing device and a technology thereof. The bait multi-stage mixing device comprises a longitudinal barrel, a transverse barrel and a mixing barrel, a feed box is installed on the upper portion of the longitudinal barrel, a water inlet mechanism is arranged on the side portion, close to the feed box, of the longitudinal barrel, water entering from the water inlet mechanism enters the longitudinal barrel in the horizontal direction, a bait entering from the feed box enters the longitudinal barrel in the vertical direction, and water and the bait are mixed in the longitudinal barrel to form a primary mixture; and a material mixing mechanism is mounted at the bottom in the longitudinal barrel, and the longitudinal barrel communicates with the transverse barrel through a feeding pipe. The device has the advantages that primary mixing is carried out on the bait in the longitudinal cylinder, secondary mixing is carried out in the transverse cylinder, and secondary pressurization is carried out in the mixing cylinder and a reducing sleeve, so that the bait is fully sprayed out, pond water is stirred while bait casting is carried out, the oxygenation effect is achieved, the pond bottom oxygenation effect is good, the pond bottom environment can be improved, and the bait effect is more uniform.

Owner:烟台市海洋经济研究院(烟台市渔业技术推广站、烟台市海洋捕捞增殖管理站)

Packaging equipment and packaging method for instant scallops

PendingCN114348367AAvoid blockageImprove work efficiencyPackage sterilisationPackaging by pressurising/gasifyingProcess engineeringFood packaging

The invention relates to the technical field of scallop processing, in particular to instant scallop packaging equipment which comprises an operation table, a mounting frame is fixedly connected to the upper surface of the operation table, a plurality of fixing plates are fixedly connected to one side of the mounting frame, a storage tank is fixedly connected to one end of each fixing plate, and a discharge port is formed in the bottom of each storage tank; the invention further provides a packaging method of the instant scallops, which comprises the following steps: S1, cooling and sterilizing: freezing and cooling the instant scallops needing to be packaged; and S2, food filling: putting the instant scallops into a storage barrel, and carrying out food filling operation on the food packaging bags on the assembly line through the storage barrel. The filling device can be effectively prevented from being blocked, the working efficiency of the filling device is improved, scallop meat can be prevented from adhering to the interior of a discharging pipe, the situation of uneven feeding is avoided, the situations of food deterioration and meat color change of scallops are avoided, and the fresh-keeping effect of products is improved.

A horizontal band sawing machine with an automatic feeding device

ActiveCN111496318BUniform and stable feedingImprove feeding effectMetal sawing devicesElectric machineryWorkbench

The invention discloses a horizontal band sawing machine with an automatic feeding device, which comprises a band sawing machine base, a saw frame lifting device is arranged on the band sawing machine base, a saw frame is installed on the top of the saw frame, and a working table is arranged in front of the saw frame , the position of the workbench corresponding to the saw blade on the saw frame is provided with a saw kerf, and a conveying plate is provided in front of the workbench. The conveying plate is provided with a conveying element and a motor. The motor can drive the conveying original to rotate, and the workpiece placed on the conveying element Conveying to the workbench; there is a movable support in front of the conveying plate, and a conveying plate is also set on the movable support. The conveying plate is also equipped with a conveying original and a motor, and the workpiece placed on the conveying element is conveyed to the workbench. The invention improves the clamping part and the conveying part so that it can meet better positioning accuracy and conveying efficiency, and at the same time meet the processing requirements of bar-shaped workpieces with different angles and shapes.

Owner:中电建成都铁塔有限公司

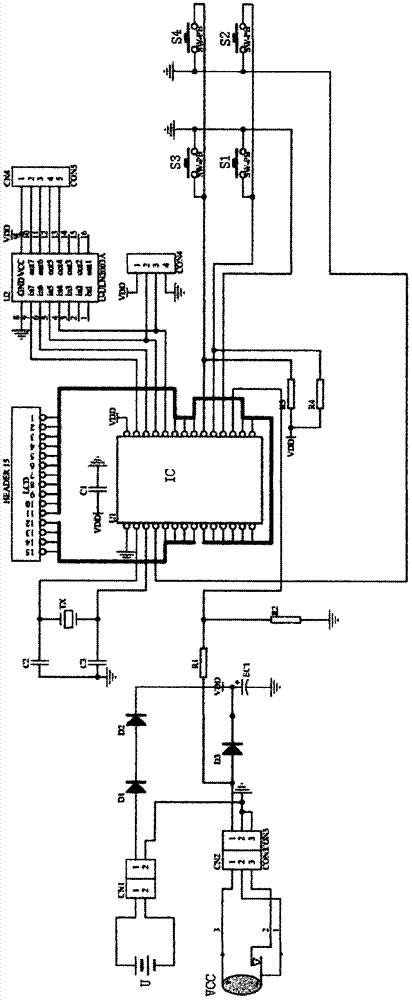

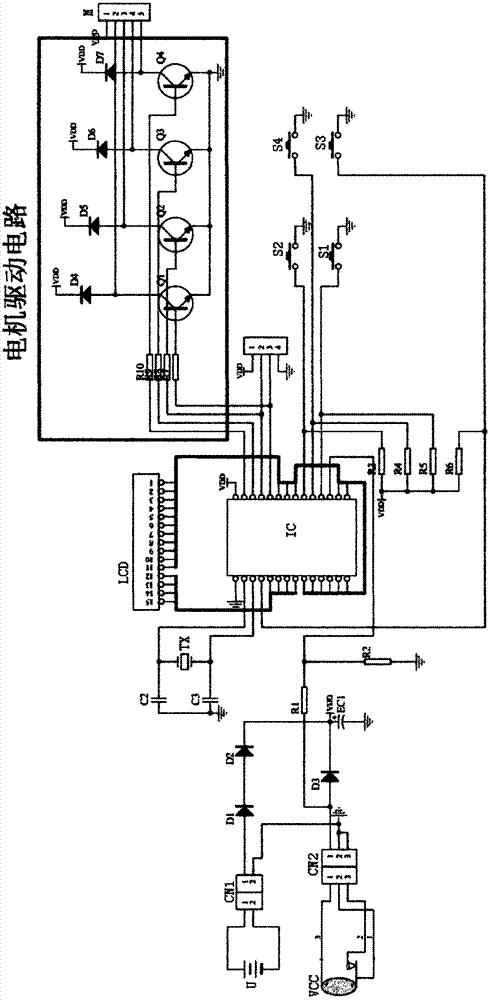

Self-timing push-pull-type anti-blocking moisture-proof feeding circuit

InactiveCN107950452ASolve the problem of blockingPrevent overstuffingProgramme controlComputer controlMotor driveAdhesive

The invention discloses a self-timing push-pull-type anti-blocking moisture-proof feeding circuit. The feeding circuit comprises a power adaptation circuit, a control chip, a DC power socket, a DC battery box, an LCD display interface, a touch-key input circuit, a stepping motor driving circuit and an electric quantity detection circuit. According to the invention, the problem that blocking of large particles and medium granular feed is solved, so that the feeding is more guaranteed, the food feeding is faster, and uneven food feeding is prevented; through replacement of a plurality of fixed standard boxes of various sizes, the food feeding is more accurate, so that the fed animals are prevented from being overfed to death due to excessive feeding; through the push-pull-type food feeding,side leakage of fish food is prevented; through the design of sealing and moisture prevention by an EVA adhesive, the storage time of fish materials can be longer; and through the use of a replaceablehopper, the capacity can be expanded at any time.

Owner:珠海市华尔安科技有限公司

A kind of breeding method of sturgeon

ActiveCN107018929BImprove balanceAvoid uneven feedingClimate change adaptationAnimal feeding stuffIlluminanceHabit

Owner:彭水县碧水清泉渔业有限公司

Feeding device for aquaculture

InactiveCN111357698BAvoid uneven feedingSmooth feedingWaterborne vesselsClimate change adaptationAnimal scienceZoology

Owner:佛山市嘉沃农业科技合伙企业(有限合伙)

Environmental-friendly feeding device of tire internal mixer

The invention discloses an environmental-friendly feeding device of a tire internal mixer. The environmental-friendly feeding device of the tire internal mixer comprises a base, wherein an internal mixer body is fixedly arranged at the top end of the base; a feed inlet is formed in the top end of the internal mixer body; a charging barrel is fixedly arranged at the top end of the feed inlet; electric hydraulic cylinders are fixedly arranged on two side outer walls of the charging barrel; the telescopic ends of the two electric hydraulic cylinders are fixedly connected with two sides of the bottom end of a cross plate; a push rod is fixedly arranged in the middle of the bottom end of the cross plate; and a push plate is fixedly arranged at the bottom end of the push rod. According to the environmental-friendly feeding device of the tire internal mixer provided by the invention, a drive motor drives a packing auger rod to rotate, so that uniform loading is conveniently realized, and theoccurrence of the phenomenon that the nonuniformity of loading influences a mixing effect of the internal mixer is avoided; and the arranged electric hydraulic cylinders stretch out and draw back to drive the push rod to move up and down, and the push rod moves up and down so as to conveniently press a material entering the charging barrel into the internal mixer so as to mix the material, so thatthe occurrence of the phenomenon that tire rubber blocks the feed inlet so as to influence mixing is avoided.

Owner:DOUBLE COIN GRP JIANGSU TIRE

Cage culture liquid feed cleaning and feeding system

InactiveCN112189608AImprove liquidityAvoid cloggingClimate change adaptationSpraying apparatusBiotechnologyAnimal science

The invention discloses a cage culture liquid feed cleaning and feeding system, and belongs to the field of culture equipment. The cage culture liquid feed cleaning and feeding system comprises a feeding box body, a discharging box body is arranged at the side of the feeding box body, a storage box body is arranged below the discharging box body, and a stirring assembly used for stirring materialsis arranged in the storage box body; the stirring assembly comprises a supporting rotating rod connected with the inner top wall of the storage box body, a stirring rotating plate is connected to thebottom of the supporting rotating rod, a stirring connecting rod is hinged to the bottom of the stirring rotating plate, and a stirring block is fixedly connected to the upper end of the stirring connecting rod; a stirring auxiliary plate is arranged at the upper end of the stirring block, and a hydraulic rod is arranged at the bottom of the stirring rotating plate; and the telescopic end of thehydraulic rod is connected with the stirring connecting block, and the side face of the hydraulic rod is fixedly connected with the inner wall of the storage box body through an auxiliary connecting rod. According to the cage culture liquid feed cleaning and feeding system, the blockage probability in a pipe is low in the liquid feed feeding process, the pipe can be automatically cleaned after feeding is completed, material residues in the pipe and bacterium breeding are avoided, the palatability of feed is improved, the smell of the feed is reduced, and it is guaranteed that feeding is free of waste.

Owner:MARINE FISHERIES RES INST OF ZHEJIANG

Warehouse for improving storage integration for grain storage

InactiveCN110946008AQuality improvementImprove filtering effectAgriculture tools and machinesGas current separationElectric machineGrain storage

The invention discloses a warehouse for improving storage integration for grain storage. The warehouse comprises a base and a lifting apparatus, wherein the base is provided with a storage bin, a material inlet bin is fixedly installed on the top of the storage bin, a material inlet pipe is fixedly installed on the top of the material inlet bin, one side of the material inlet pipe is fixedly connected with a material outlet end of the lifting apparatus, the storage bin is fixedly equipped with a first rotating motor through a support plate installed at one side of the storage bin, and a firstthreaded rod is fixedly connected with an output end of the first rotating motor. According to the warehouse for improving storage integration for grain storage, through the cooperative use of an impurity storage bin, an impurity inlet pipe, a screening box, a buffer bin, material discharge pipes, a fan apparatus and an equipment base, grains can be screened and filtered, shriveled grains and somerelatively light impurities are removed, and thereby the quality of the grains is improved. In addition, the arrangement of the buffer bin and the material discharge pipes helps to improve the feeding uniformity, and thereby helps to improve screening and filtering effects on the grains.

Owner:安徽都灵精密机械有限公司

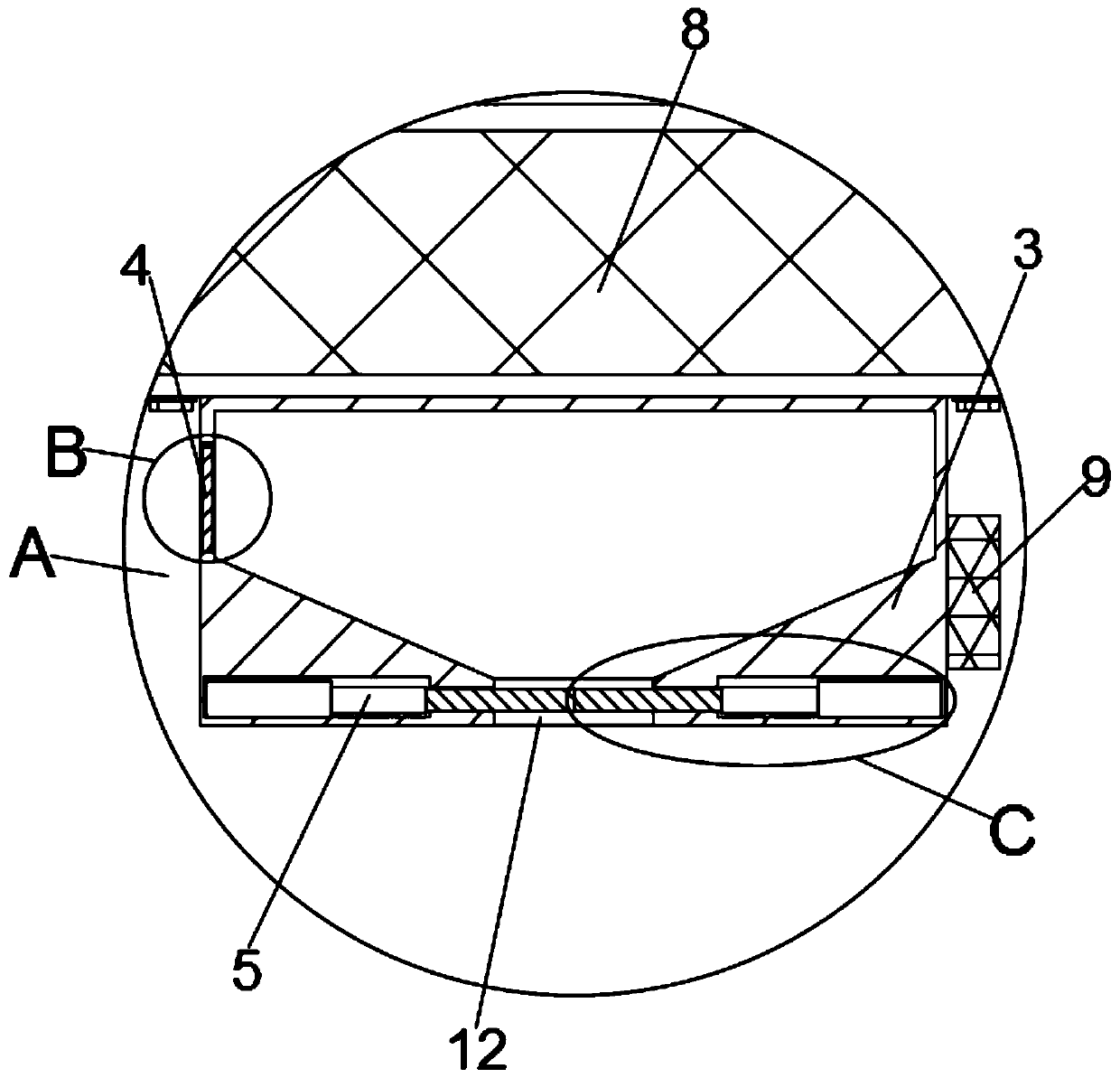

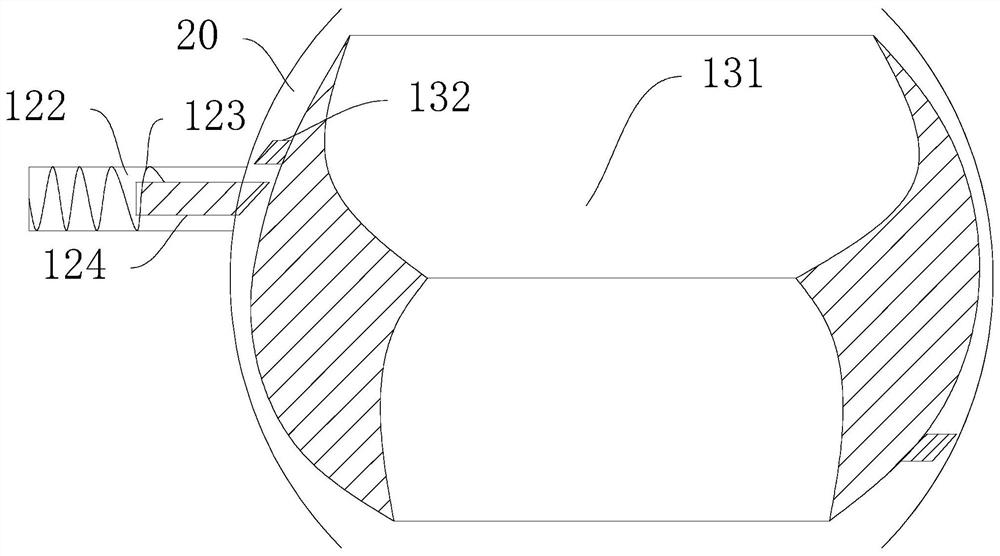

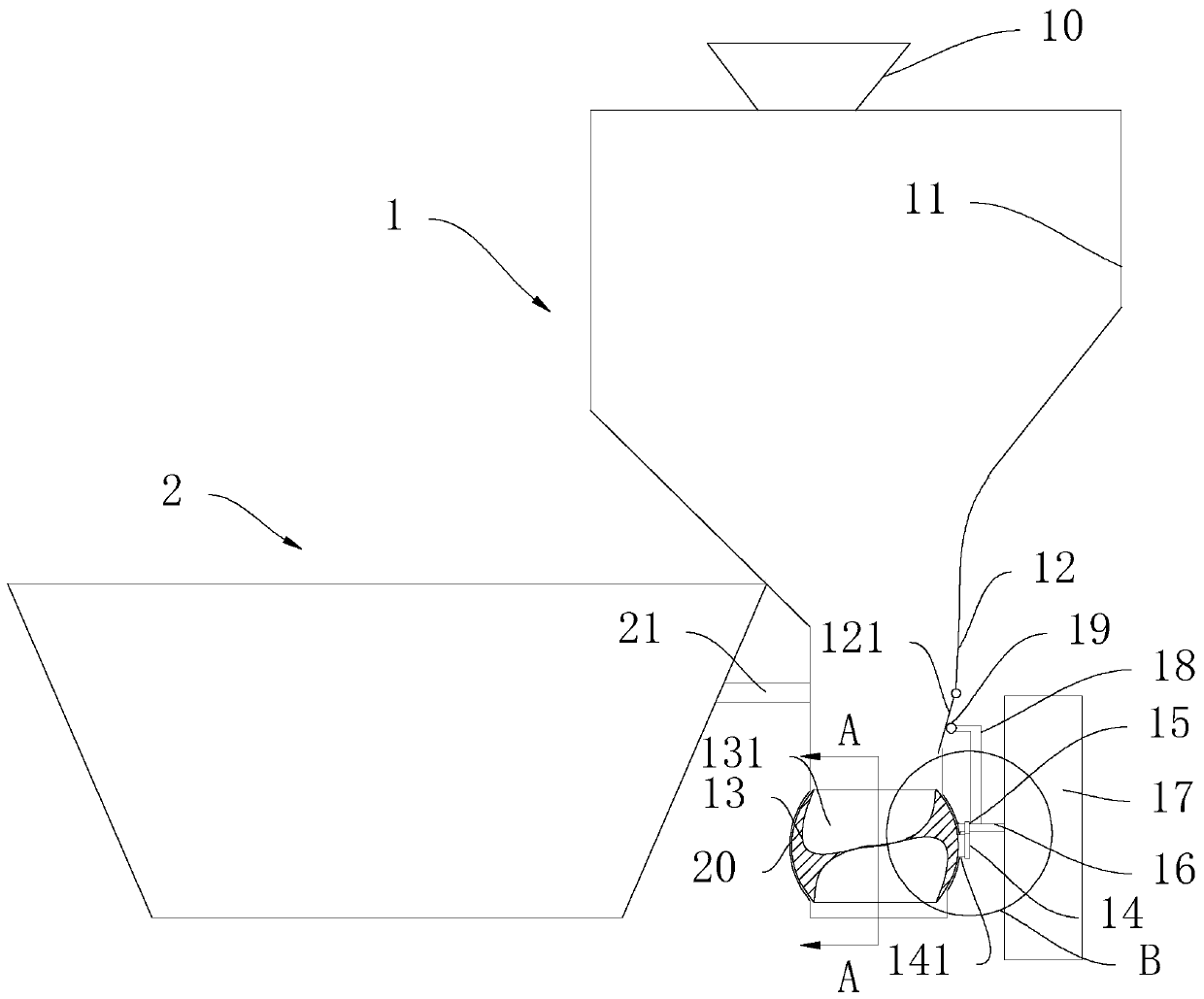

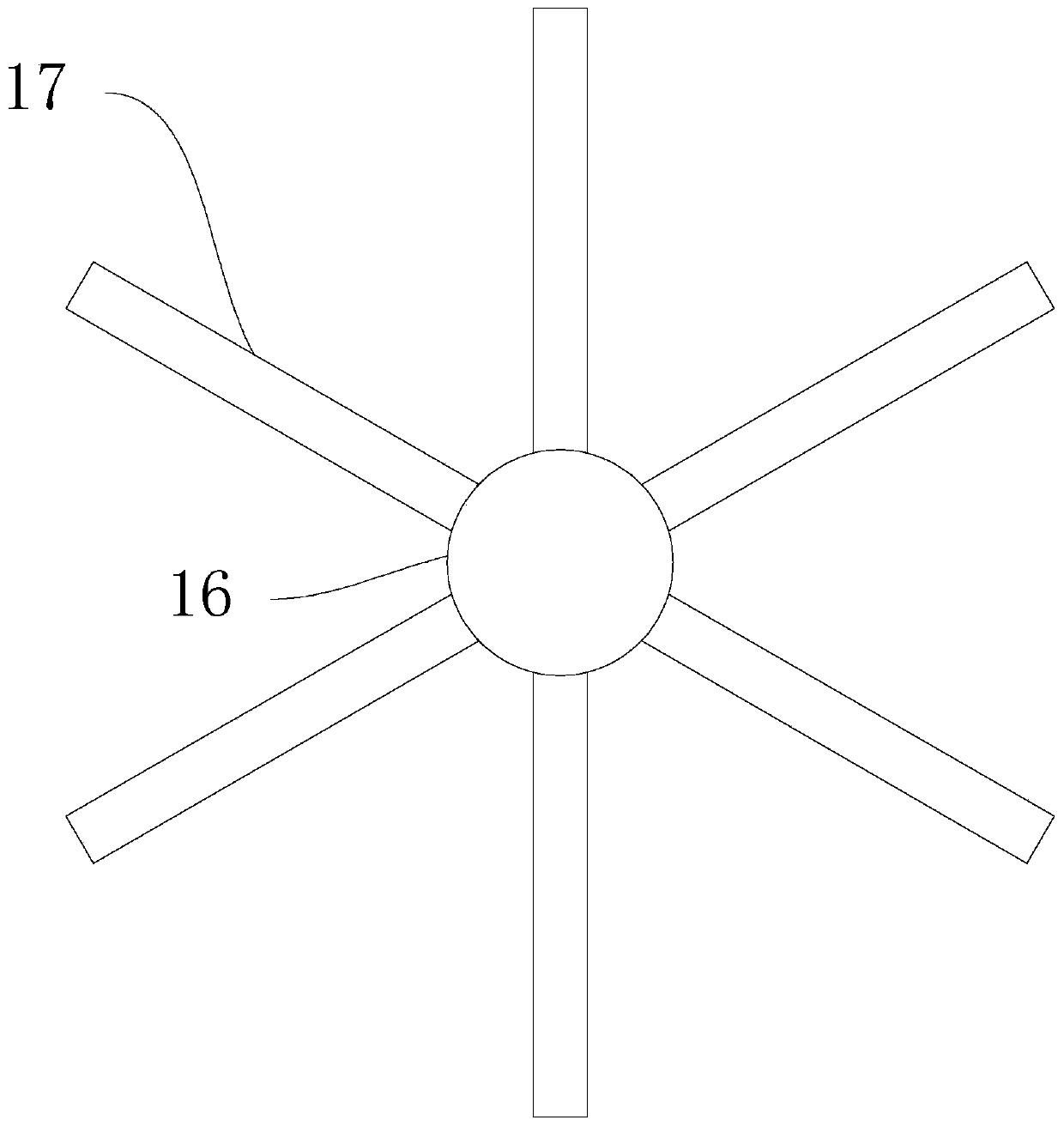

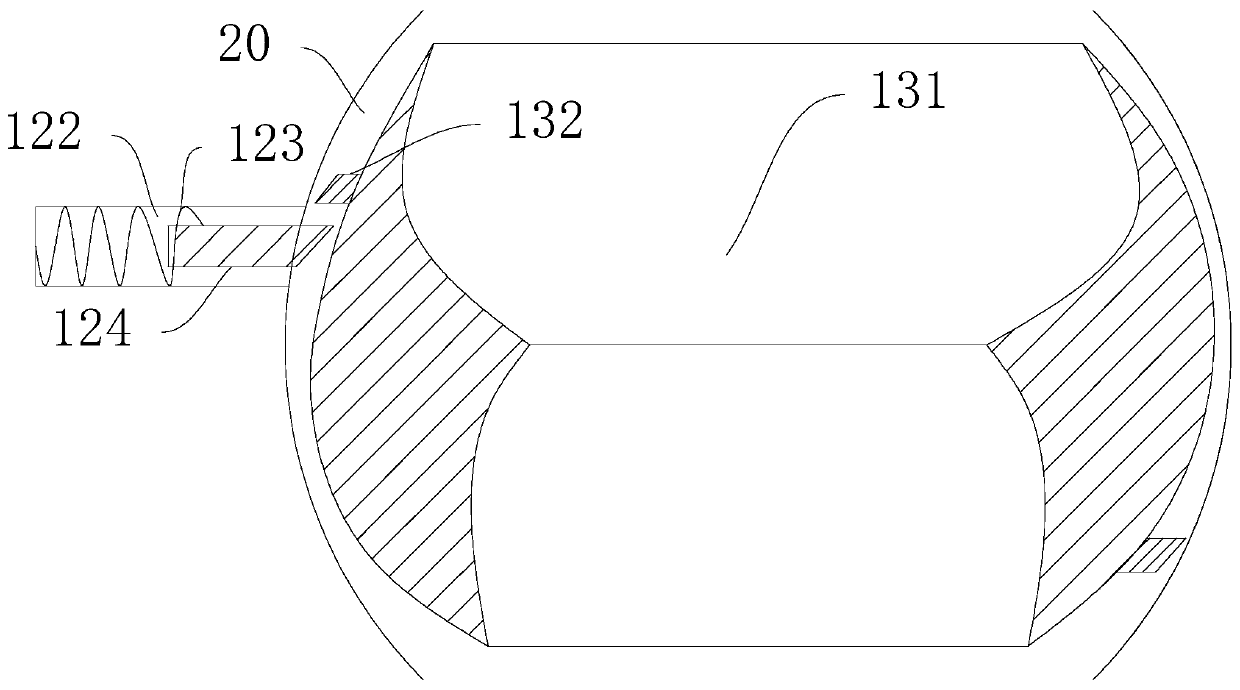

Feeding device for aquaculture

InactiveCN111357698AAvoid uneven feedingSmooth feedingWaterborne vesselsClimate change adaptationEngineeringZoology

The invention discloses a feeding device for aquaculture, and belongs to the technical field of aquaculture. The feeding device comprises a feeding barrel and a feeding vessel, wherein the feeding barrel is fixedly and integrally connected with the feeding vessel through a connecting arm; the feeding barrel comprises a barrel body, a feeding pipe and a feeding device; a material feeding opening isformed in the top end of the feeding barrel, and penetrates through the inner part of the feeding barrel; a feeding pipe is fixedly arranged at the lower end of the barrel body, and penetrates through the inner part of the barrel body; and a spherical cavity is formed in the lower end of the feeding pipe, and is used for allowing the feeding device to be placed. The feeding device for aquaculturedisclosed by the invention has the beneficial effects that feeds are placed in the feeding barrel, and through a method for changing the structure of the discharging opening in the lower end, so thatintermittent and uniform feeding is realized.

Owner:佛山市嘉沃农业科技合伙企业(有限合伙)

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com