Cage culture liquid feed cleaning and feeding system

A liquid feed and cage culture technology, applied in the field of aquaculture equipment, can solve problems such as reducing labor intensity, and achieve the effects of improving support strength, ensuring high feeding efficiency and uniform distribution of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

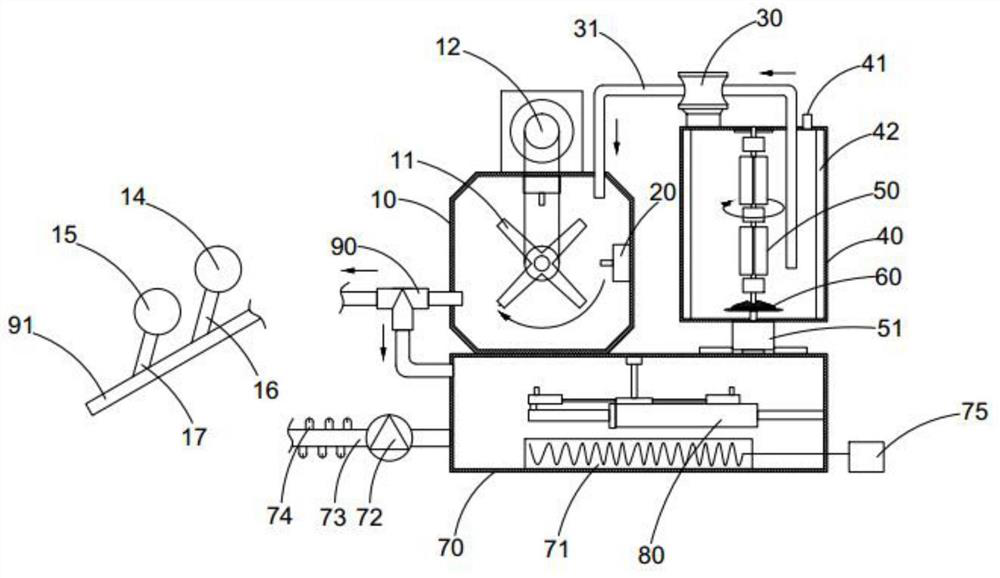

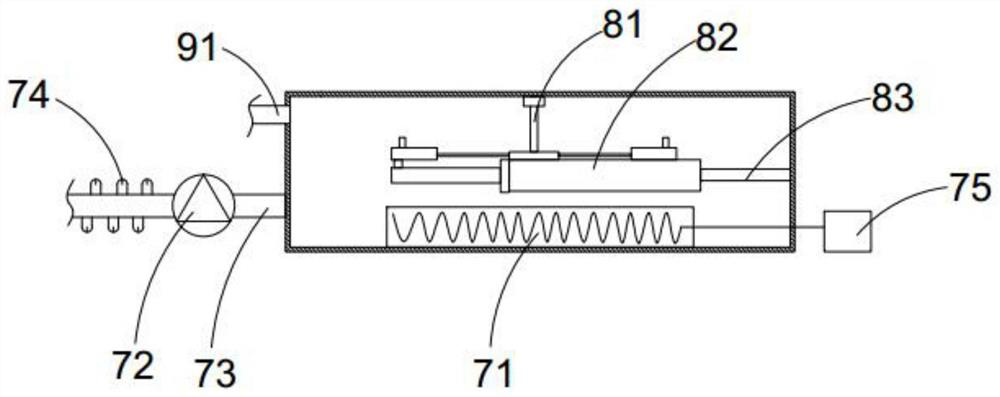

[0042] See attached Figure 1-11Shown, a kind of net cage culture liquid feed cleans throwing and feeding system, comprises: feeding box body 40, and feeding box body 40 top is provided with feeding port 41 and is provided with the first agitator 50 and the first agitator 50 for stirring material in it. The second agitator 60, the side of the feed box 40 is provided with a discharge box 10, the discharge box 10 and the feed box 40 are communicated through the first transmission pipe 31, and the transmission pipe 31 is provided with The first pump body 30, the discharge port of the discharge box body 10 is connected to the third transfer pipe body 91 and the third transfer pipe body 91 is connected with a three-way pipe 90, and the third transfer pipe body 91 is sequentially connected with the cleaning water pump 15 and the first The air pump 14, the inner wall of the third transmission pipe 91 is equipped with a liquid level sensor detection probe, and the bottom of the discha...

Embodiment 2

[0054] A method for feeding a cage culture liquid feed clean feeding system, the steps are as follows:

[0055] - Make surimi with different proportions of chilled miscellaneous fish and water to increase the permeability and flow effect of surimi during transmission. The amount of water added depends on the variety of chilled miscellaneous fish. Add additives in the casing 40, such as additives such as allicin, immune enhancer or probiotics, to improve the immunity of cultured fish;

[0056] - When feeding, the minced fish is sent from the feed box 40 to the discharge box 10 through the first pump body 30, and then the liquid minced fish feed formed by the third transmission pipe body 91 is fed, and each net cage is separated by 3 -5m layout is convenient for feeding, and at the same time, valves are set on each feeding pipe body to control feeding.

[0057] The power of the first pump body 30 is determined according to the cage area and the transmission distance of the cult...

Embodiment 3

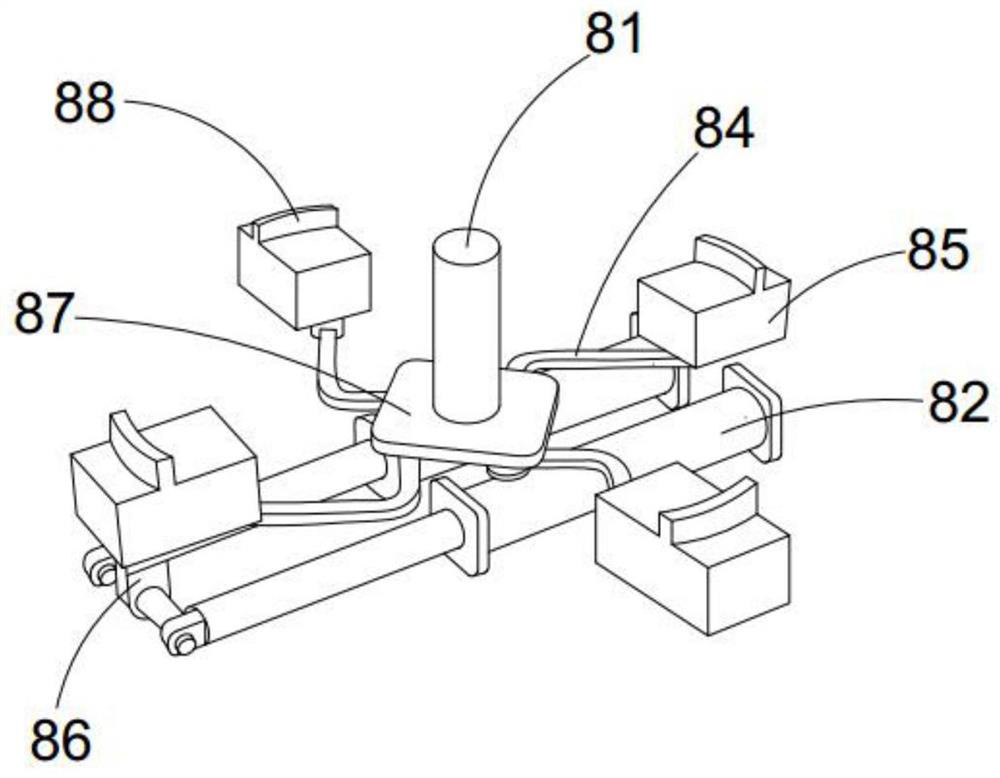

[0060] The further optimization scheme of present embodiment on the basis of embodiment 1 is: see appendix Figure 10-11 , the first air pump 14 is connected to the third transmission pipe body 91 through the air supply branch pipe 16, and the connection between the air supply branch pipe 16 and the third transmission pipe body 91 is oblique, and the cleaning water pump 15 is connected to the third transmission pipe body through the cleaning branch pipe 17. The pipe body 91 is connected, and the cleaning branch pipe 17 is obliquely connected with the third transmission pipe body 91. The inner wall of the air supply branch pipe 16 is spirally provided with a spiral groove body 18, which is blown in the third transmission pipe body 91 of the first air pump 14 box. In the process of high-temperature wind, the wind forms a spiral flow in the air supply branch pipe 16, and then forms a spiral flow after it enters the third transmission pipe body 91, prolonging the residence time of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com