Hopper type screw feeder for collagen casing production

A technology of collagen casings and bucket snails, applied in the direction of conveyors, sausage casings, conveyor objects, etc., to increase practicability, reduce hazards, and improve practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

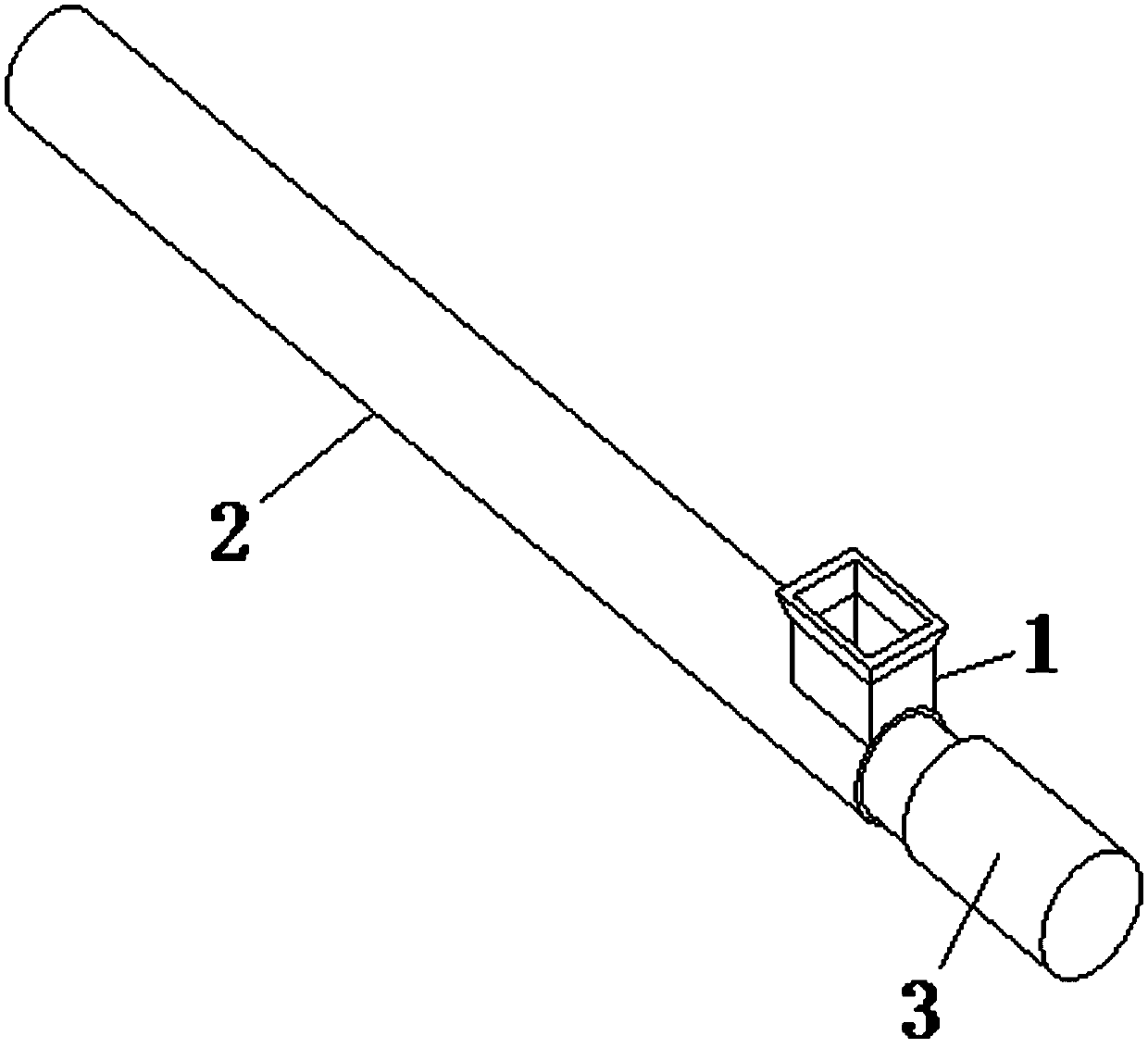

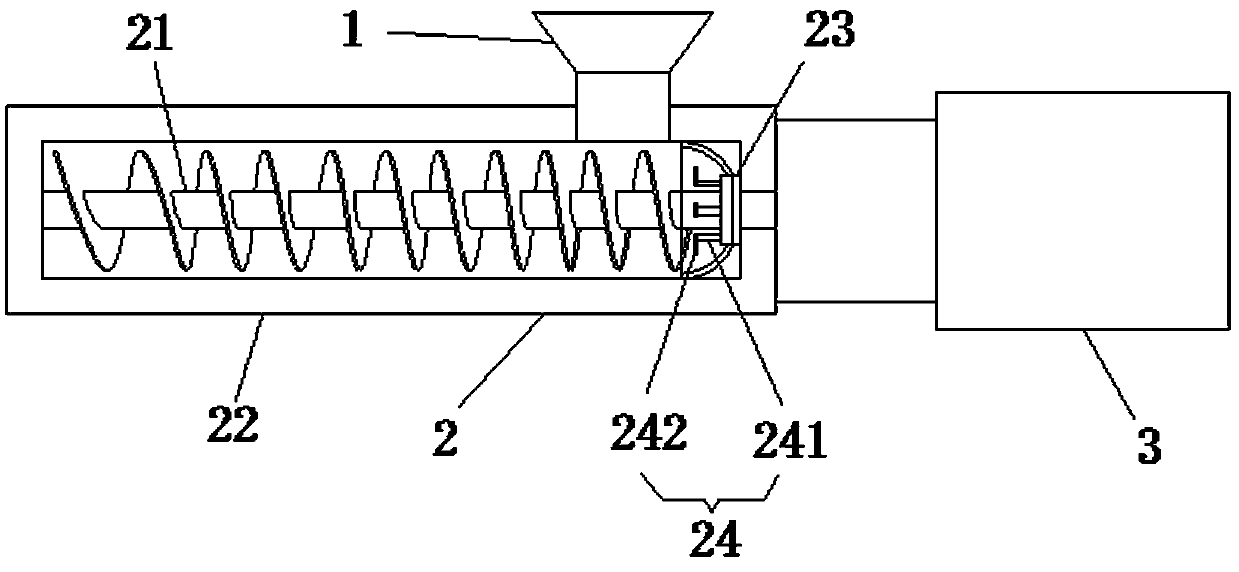

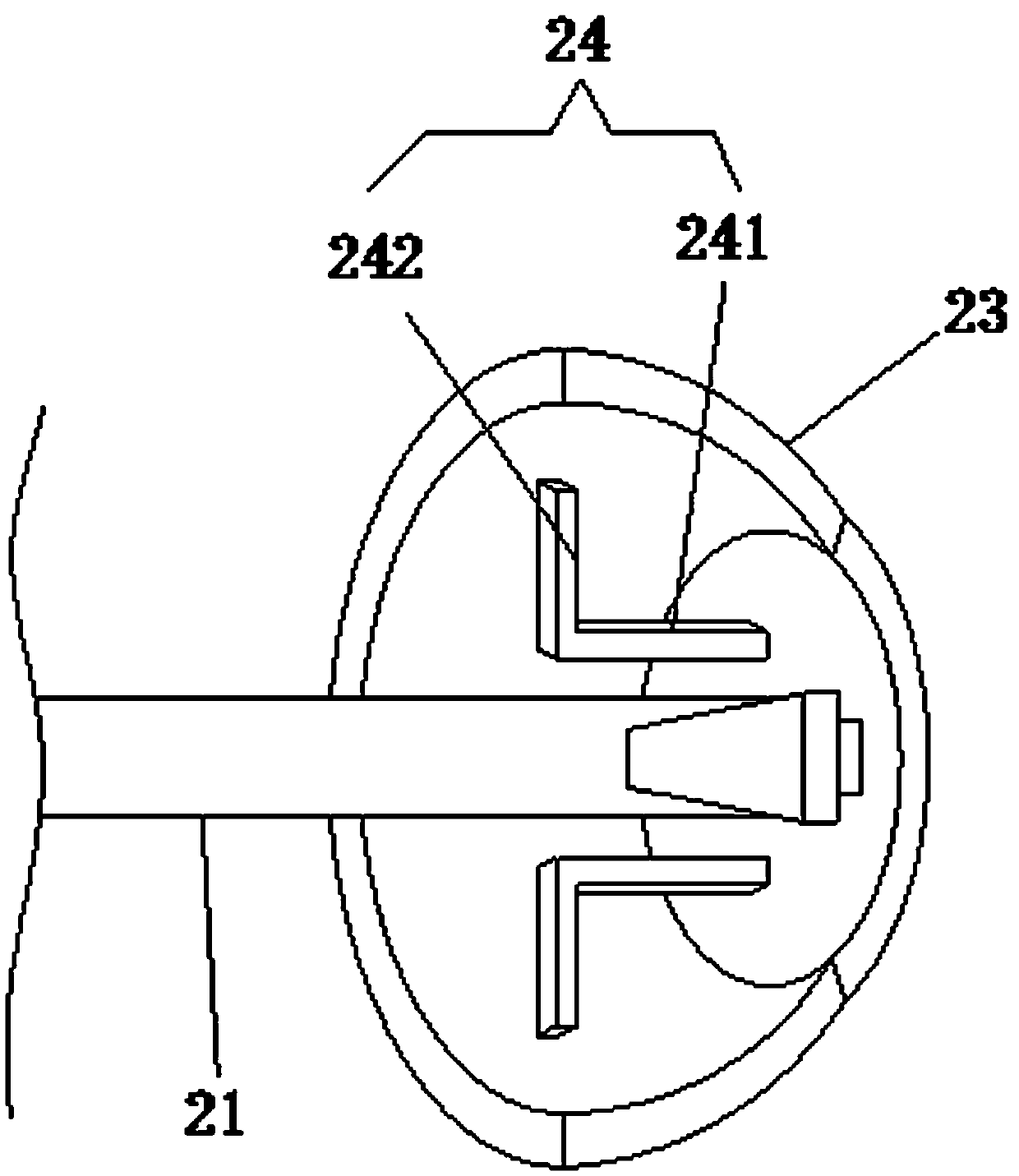

[0031] see Figure 1-5 , a bucket screw feeder for the production of collagen casings, comprising a feed hopper 1, a conveying device 2 and a conveying motor 3, the specific shape of the feed hopper 1 is as follows figure 1 As shown, the feeding hopper 1 is fixedly installed above the conveying device 2, and the side wall of the conveying device 2 close to the end of the feeding hopper 1 is fixedly connected with the conveying motor 3, and the rotating shaft 11 is movable installed in the feeding hopper 1, and the rotating shaft 11 is cylindrical Shaft, the two ends of the rotating shaft 11 are connected with the left and right inner walls of the feed hopper 1, the rotating shaft 11 is sleeved with a drum 12, and the rotating shaft 11 is sleeved with two shock absorbing blocks 13, and the side wall of the shock absorbing block 13 is connected to the drum 12 The left and right side walls are fixedly connected, and the rotating shaft 11 is provided with a spring 14 at both ends ...

Embodiment 2

[0034] see Figure 1-3 And 6-7, a kind of bucket screw feeder that is used for the production of collagen sausage casing, comprises feeding hopper 1, conveying device 2 and conveying motor 3, and the specific shape of feeding hopper 1 is as figure 1 As shown, the feeding hopper 1 is fixedly installed above the conveying device 2, and the side wall of the conveying device 2 close to the end of the feeding hopper 1 is fixedly connected with the conveying motor 3, and the rotating shaft 11 is movable installed in the feeding hopper 1, and the rotating shaft 11 is cylindrical Shaft, both ends of the rotating shaft 11 are connected with the left and right inner walls of the feed hopper 1, the rotating shaft 11 is sleeved with a drum 12, and the left and right side walls of the drum 12 are fixed with shock absorbing blocks 13, and the shock absorbing blocks 13 are also sleeved on the rotating shaft 11, the rotating shaft 11 is provided with a spring 14 at both ends of the drum 12, a...

Embodiment 3

[0037] see Figure 1-3 And 8-9, a kind of bucket screw feeder that is used for collagen sausage casing production, comprises feeding hopper 1, conveying device 2 and conveying motor 3, and the specific shape of feeding hopper 1 is as follows figure 1 As shown, the feeding hopper 1 is fixedly installed above the conveying device 2, and the side wall of the conveying device 2 close to the end of the feeding hopper 1 is fixedly connected with the conveying motor 3, and the rotating shaft 11 is movable installed in the feeding hopper 1, and the rotating shaft 11 is cylindrical Shaft, both ends of the rotating shaft 11 are connected with the left and right inner walls of the feed hopper 1, the rotating shaft 11 is sleeved with a drum 12, and the left and right side walls of the drum 12 are fixed with shock absorbing blocks 13, and the shock absorbing blocks 13 are also sleeved on the rotating shaft 11, the rotating shaft 11 is provided with a spring 14 at both ends of the drum 12, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com