Gas burner capable of multilevel controlled

A gas burner and burner technology, applied in the direction of liquid fuel burner, gas fuel burner, burner, etc., can solve the problems of high product cost, difficult to manufacture, difficult fuel gas and air mixing ratio, etc., to achieve reduction The amount, easy to manufacture the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

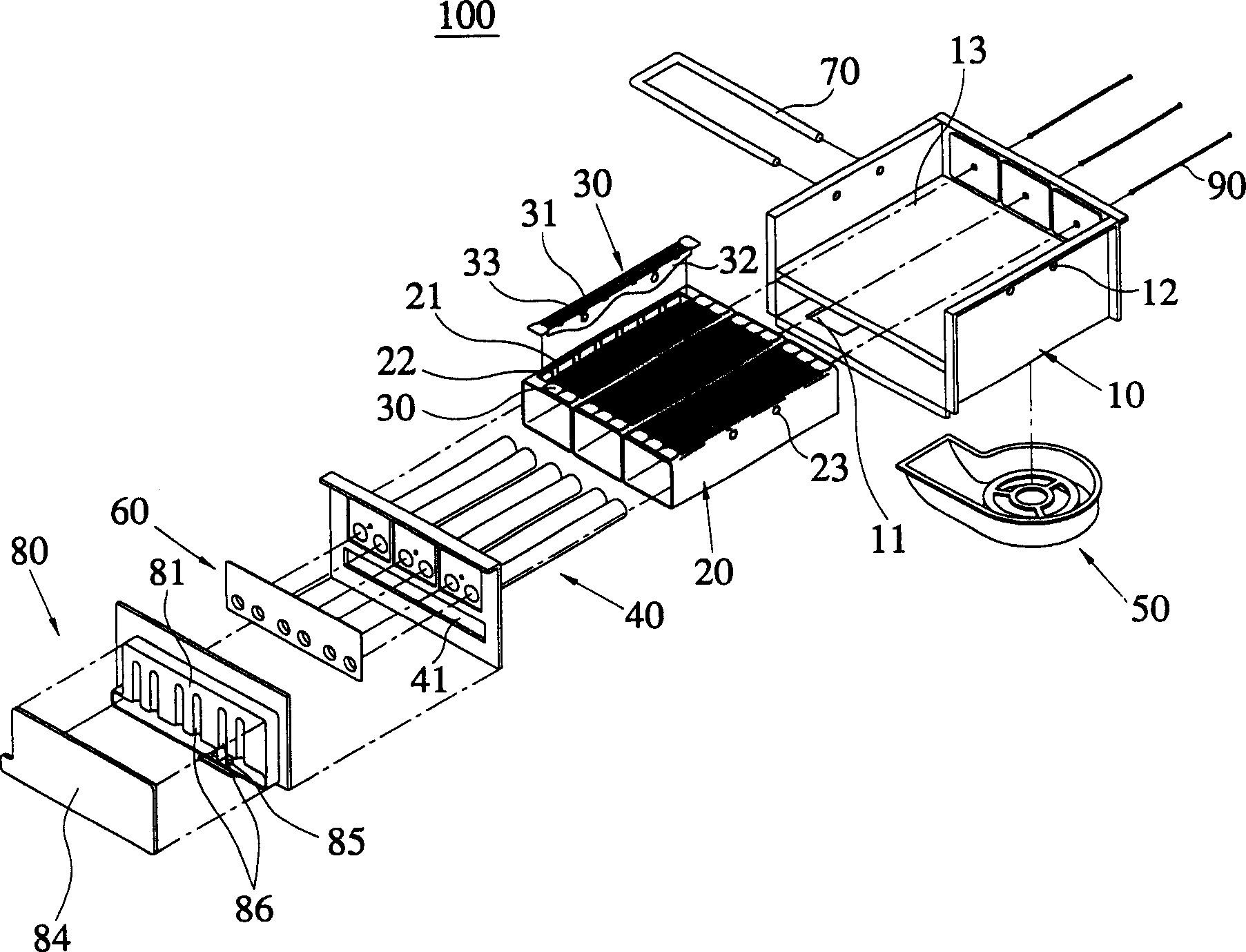

[0053] A gas burner capable of multi-stage control according to a preferred embodiment of the present invention will be described below with reference to the accompanying drawings.

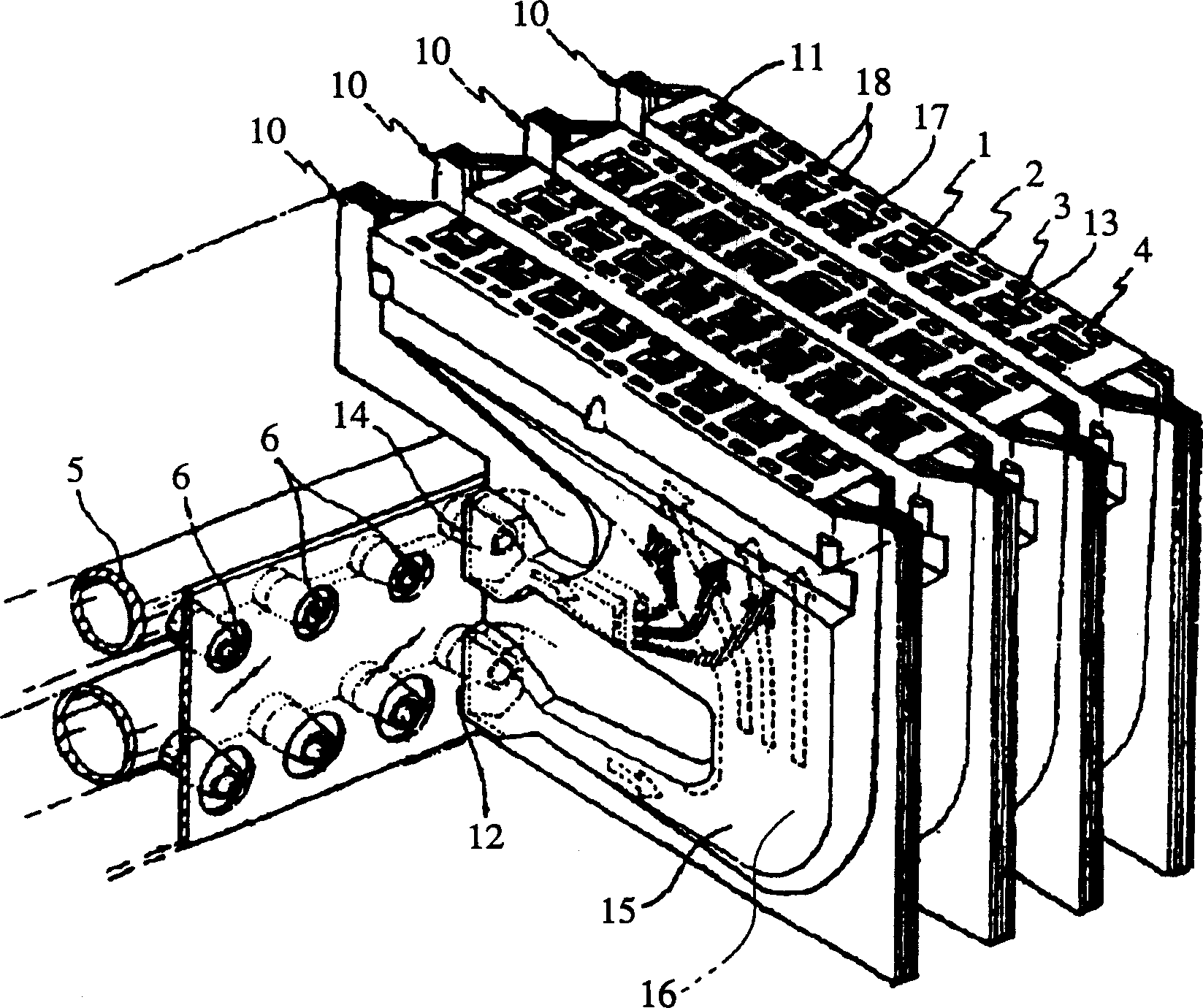

[0054] refer to Figures 3 to 10 , the gas burner capable of multi-stage control includes at least one tube burner 20 and at least one plate burner 30 each having the same burner output capacity, which are arranged in parallel to each other, wherein the number of working burners can be determined according to Desired number of calories varies.

[0055] Preferably, the multi-stage controllable gas burner 100 includes a main housing 10 , at least one tube burner 20 , at least one plate burner 30 , a plurality of mixture supply pipes 40 , a venturi 60 and a manifold 80 .

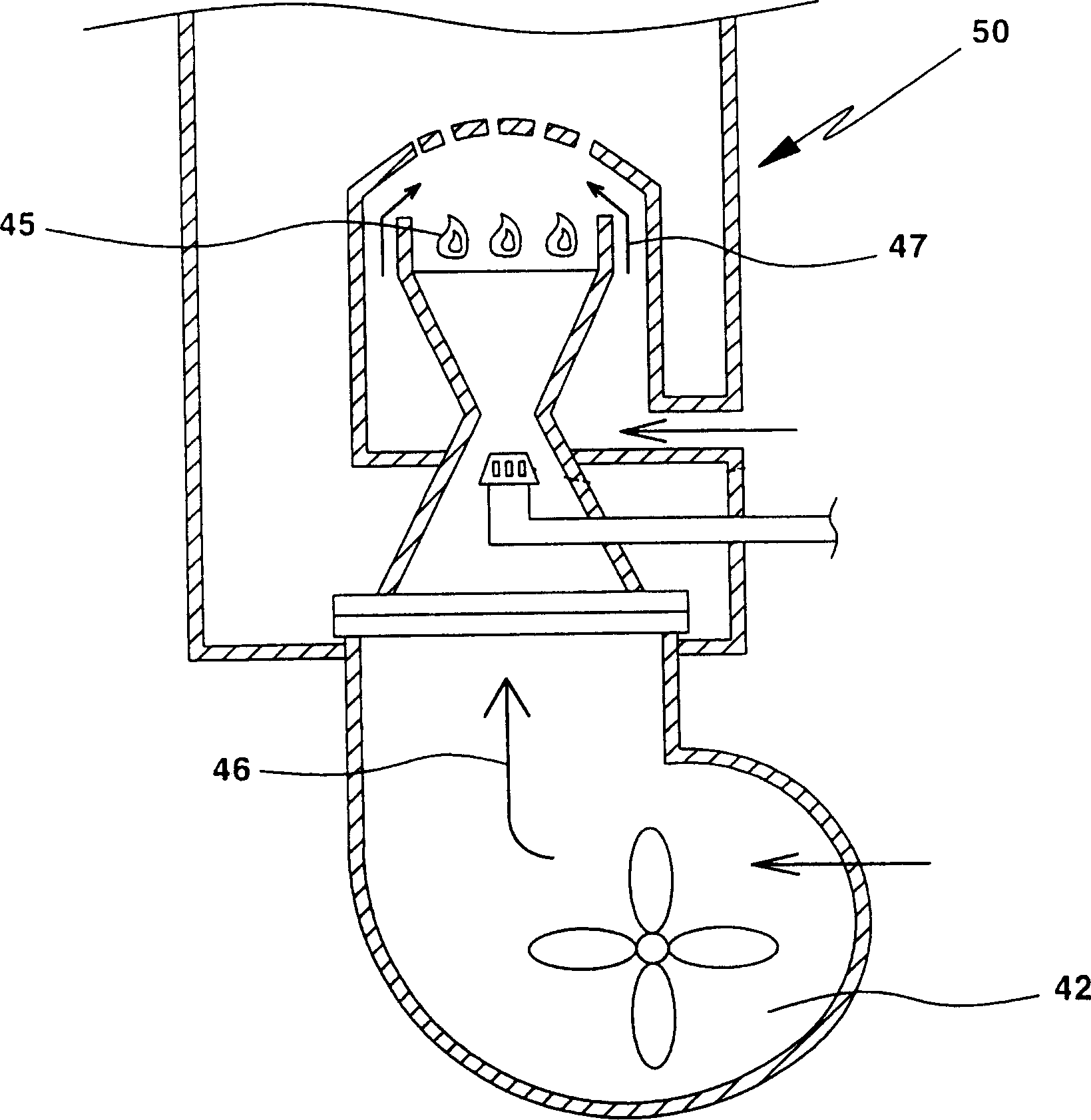

[0056] Here, the blower 50 is installed on the bottom surface of the main case 10 such that air can be supplied from the blower 50 through the air inlet 11 formed at the bottom of the main case 10 .

[0057] A tubular burner 20 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com