Electrically-controlled mechanical feeding equipment

An electrical control and mechanical technology, which is applied in the field of breeding and feeding, can solve the problems of insufficient feed for breeding animals, declining aquatic economy, uneven feed, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

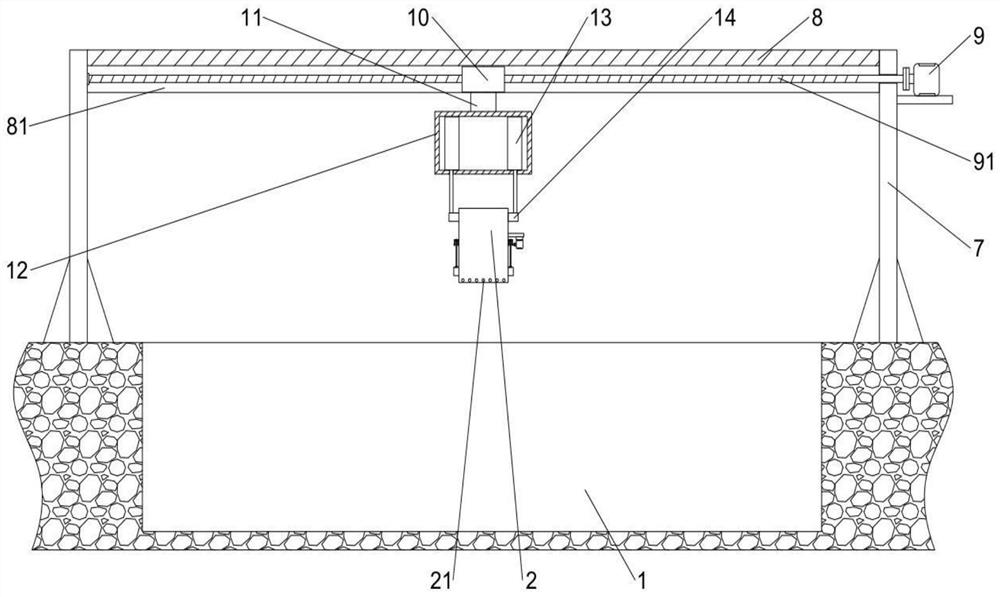

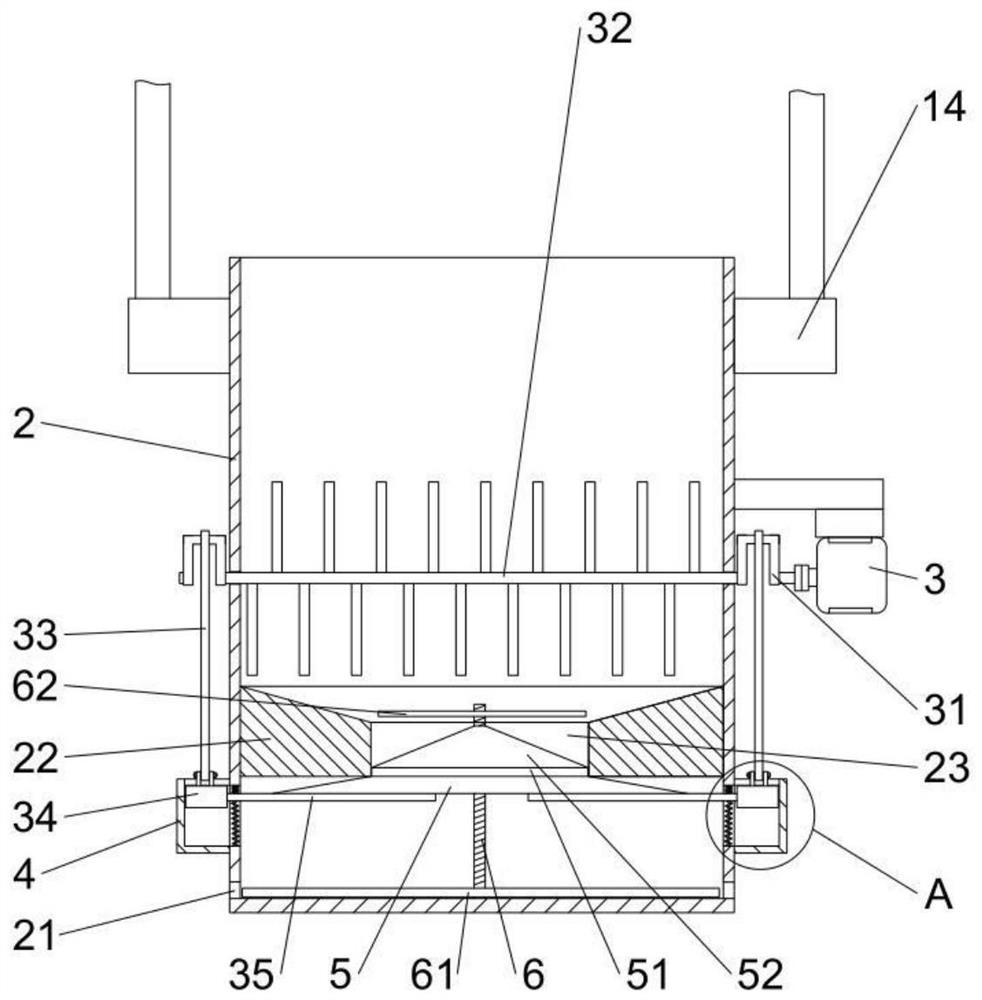

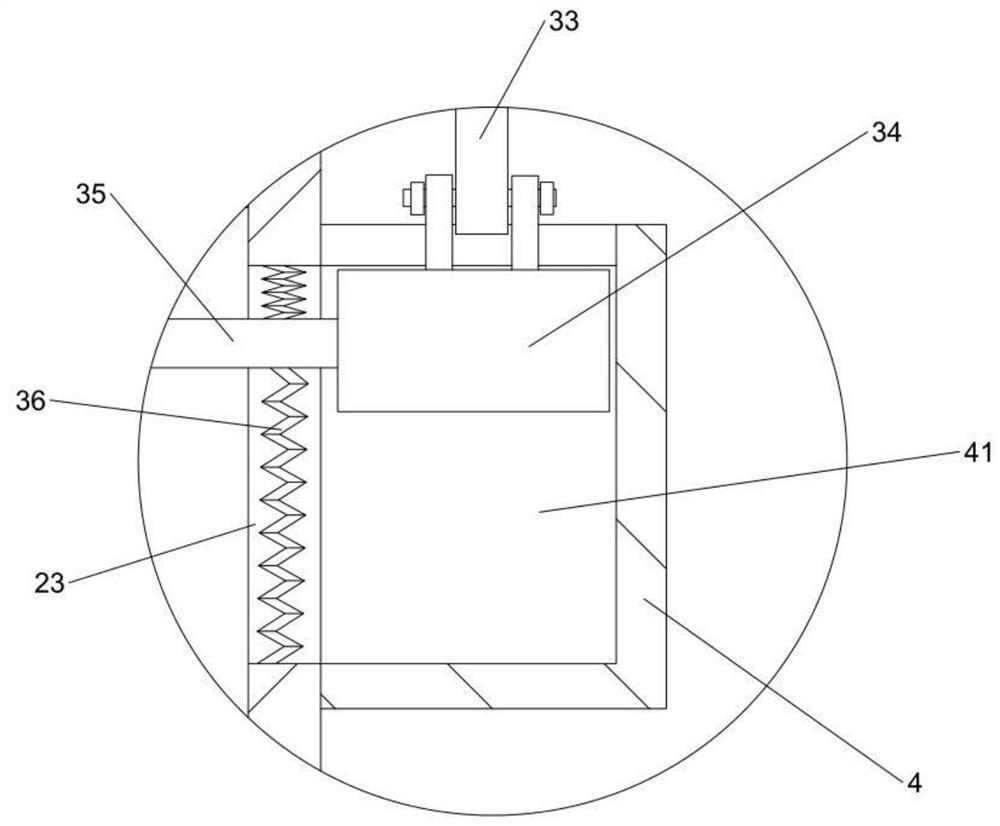

[0028] like Figure 1 to Figure 4 As shown, the present invention provides an electrically controlled mechanical feeding device, an electrically controlled mechanical feeding device, comprising a feeding barrel 2, a first guide block 22, a screw 6, a first driving rod 61, and a plurality of feeding holes 21 , shroud 5, first lifting mechanism, timer and controller; Feeding bucket 2 is arranged on the top of pond 1; A feeding port 23 is provided at the place; the screw rod 6 is vertically arranged in the feeding barrel 2, and one end of the screw rod 6 is rotationally connected with the center of the inner bottom surface of the feeding barrel 2, and the other end of the screw rod 6 extends into the feeding port 23; the first The lever 61 is horizontally set and fixed on the end of the screw rod 6 near the bottom of the feeding barrel 2; a plurality of feeding holes 21 are arranged on the bottom side wall of the feeding barrel 2 along the circumferential direction of the feeding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com