Packaging equipment and packaging method for instant scallops

A technology of packaging equipment and packaging methods, applied in packaging, transportation packaging, packaging sterilization and other directions, can solve problems such as uneven feeding, improve work efficiency, avoid uneven feeding, and avoid food spoilage and meat discoloration. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

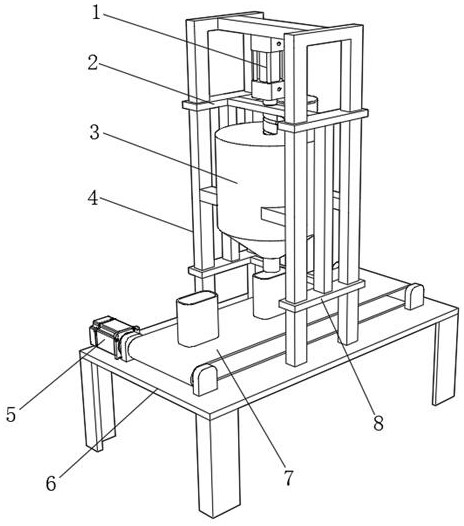

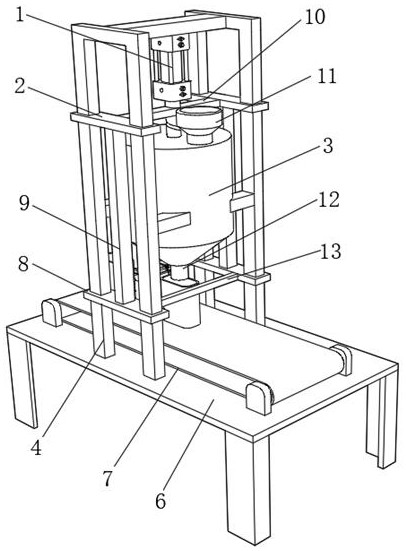

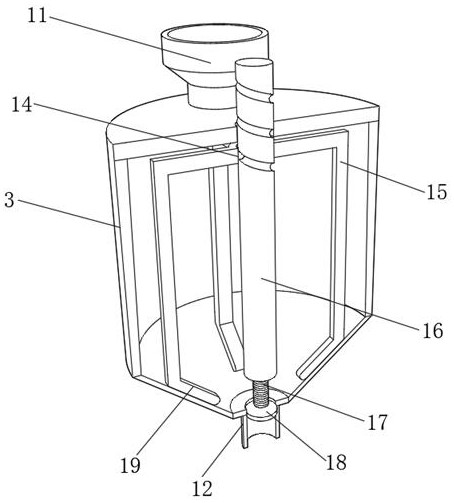

[0034] refer to Figure 1-Figure 4 , a kind of packaging equipment for instant scallops, comprising an operating table 6, the upper surface of the operating table 6 is fixed with a mounting frame 4 by bolts, one side of the mounting frame 4 is fixed with a plurality of fixing plates by bolts, and one end of the fixing plate is fixed by bolts There is a storage tank 3, the bottom of the storage tank 3 is provided with a discharge port, and a discharge pipe 12 is fixed in the discharge port by bolts, and a hydraulic cylinder 1 is fixed on the top and bottom of the installation frame 4 by bolts, and the hydraulic pressure of the hydraulic cylinder 1 One end of the rod is fixed with a connecting shaft 16 by a bolt, and the connecting shaft 16 is slidably connected with the storage tank 3, and one end of the connecting shaft 16 is threadedly connected with a threaded rod 17, and one end of the threaded rod 17 is fixed with a piston 18 by a bolt, and the piston 18 and the The discha...

Embodiment 2

[0047] refer to Figure 1-Figure 4 , a kind of packaging equipment for instant scallops, comprising an operating table 6, the upper surface of the operating table 6 is fixed with a mounting frame 4 by bolts, one side of the mounting frame 4 is fixed with a plurality of fixing plates by bolts, and one end of the fixing plate is fixed by bolts There is a storage tank 3, the bottom of the storage tank 3 is provided with a discharge port, and a discharge pipe 12 is fixed in the discharge port by bolts, and a hydraulic cylinder 1 is fixed on the top and bottom of the installation frame 4 by bolts, and the hydraulic pressure of the hydraulic cylinder 1 One end of the rod is fixed with a connecting shaft 16 by a bolt, and the connecting shaft 16 is slidably connected with the storage tank 3, and one end of the connecting shaft 16 is threadedly connected with a threaded rod 17, and one end of the threaded rod 17 is fixed with a piston 18 by a bolt, and the piston 18 and the The discha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com