Full automatic high efficiency splitting smashing stirring machine

A kind of pulverizer, fully automatic technology, applied in the direction of mixer with rotating stirring device, mixer, dissolving, etc., can solve the problems of high hopper, crowded chamber space, low output, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

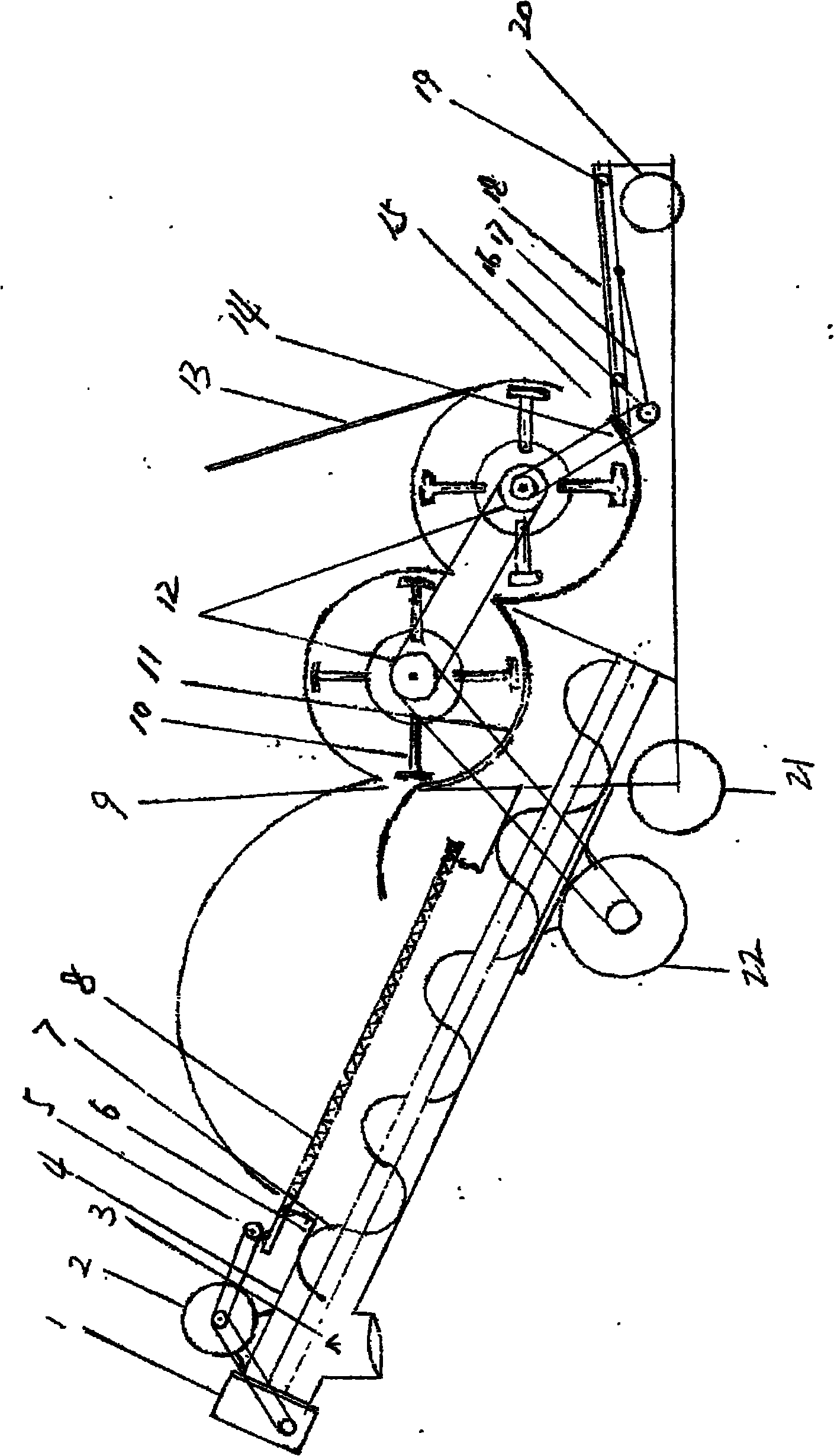

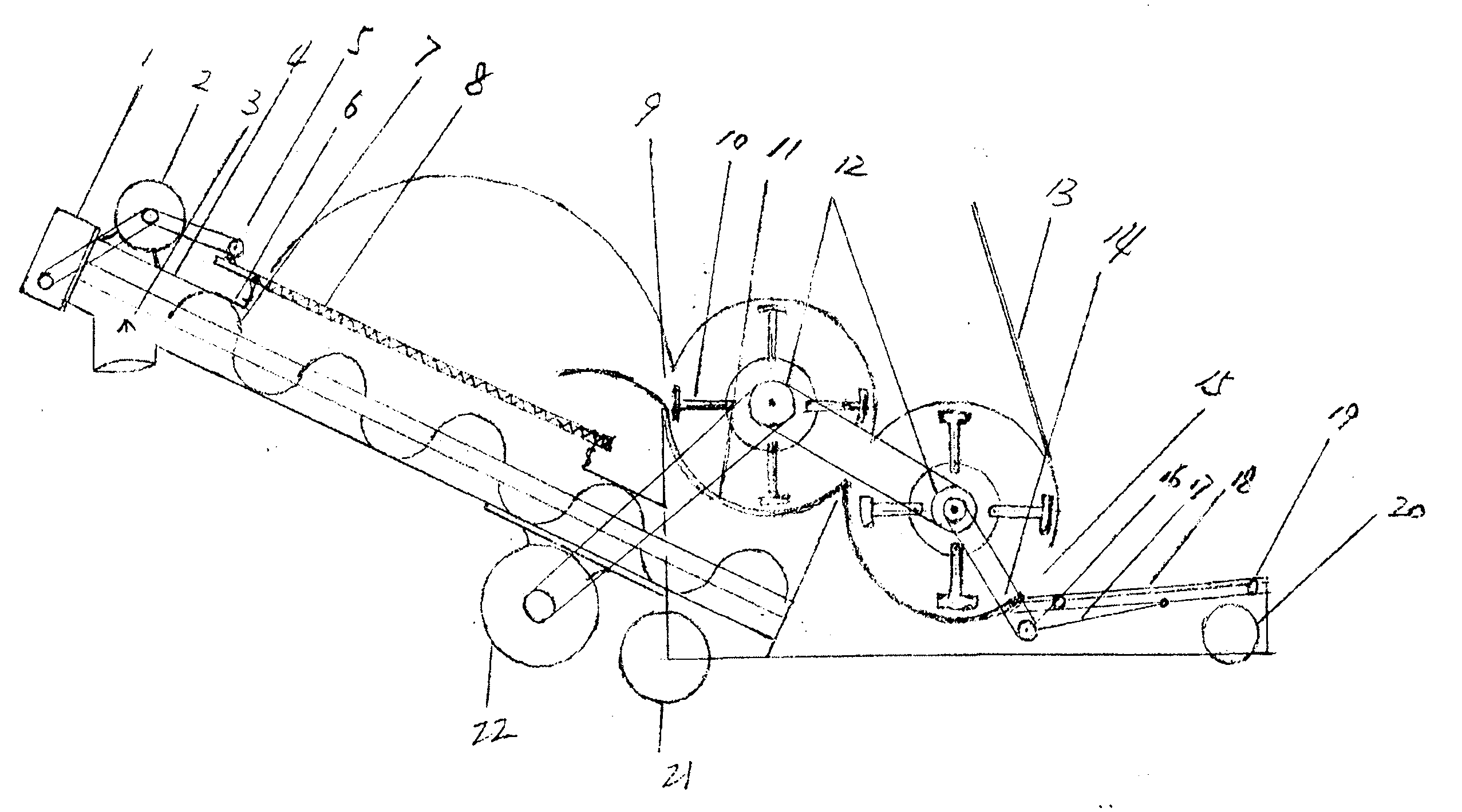

[0018] Accompanying drawing is a kind of specific embodiment of the present invention. This embodiment includes a feeding device and a pulverizing device, the rear end of the pulverizing device is provided with a feeding device, and the feeding device is located at the rear and lower part of the pulverizer; the front end of the pulverizer is provided with a stirring device connected at a certain angle to the bottom plane, The device includes a mixing drum 6 with a stirring shaft 4 and a spiral piece 7 inside. The stirring shaft 4 and the spiral piece 7 are welded together. The gearbox 1, the vibrating screen 8 and the gearbox 1 are communicated with the motor 2 respectively, and the discharge port is provided with a water spray head 3; the feeding device includes a transmission shaft 16, The movable pushing plate 18 that is connected with transmission shaft 16 by connecting rod 17, the sliding bearing 19 that is used to reduce friction and the sliding bearing track that is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com