Plate shearing machine

A technology of shearing machine and stepping motor, which is applied in the direction of shearing device, shearing machine equipment, shearing machine accessories, etc., can solve the problems of inconvenient operation, achieve the effect of convenient and fast separation, and reduce production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

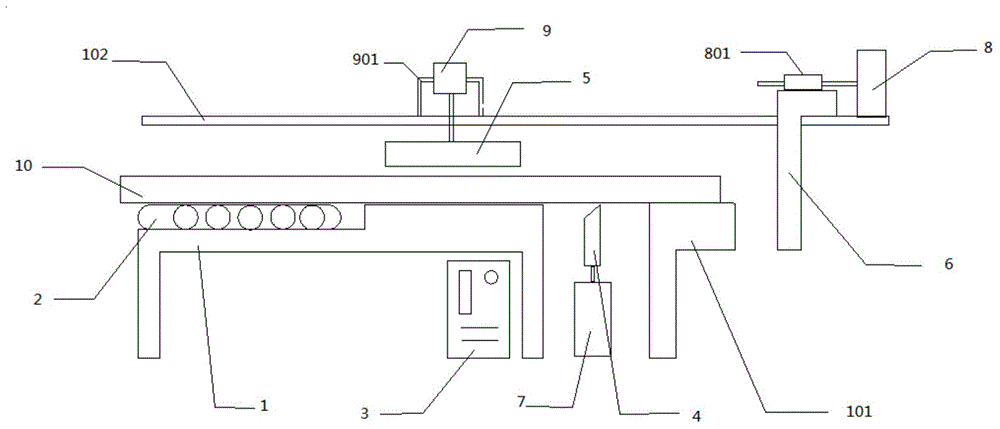

[0020] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

[0021] Such as figure 1 As shown, a shearing machine includes a first support 1, a conveyor belt 2, and a cutter section, as well as a fixed pressing system and a driving fixing system. The first support 1 is as the supporting part of the whole plate shearing machine, and its surface is divided into two parts, wherein a part is higher than the other part, and the lower part is equipped with the conveyor belt 2, and the height after the conveyor belt is installed is as high as the higher part, which is higher. The higher part plays the role of supporting the workpiece, and the higher part has a smooth surface, which is conducive to the advancement of the workpiece. The bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com