Automatic filling equipment and filling method for abalone soft can

A technology of automatic filling and soft canning, which is applied in the directions of packaging, transportation and packaging, and the type of packaged items. It can solve the problems of inconvenient storage, high cost of use, and increased travel weight.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] Below in conjunction with accompanying drawing and embodiment of description, specific embodiment of the present invention is described in further detail:

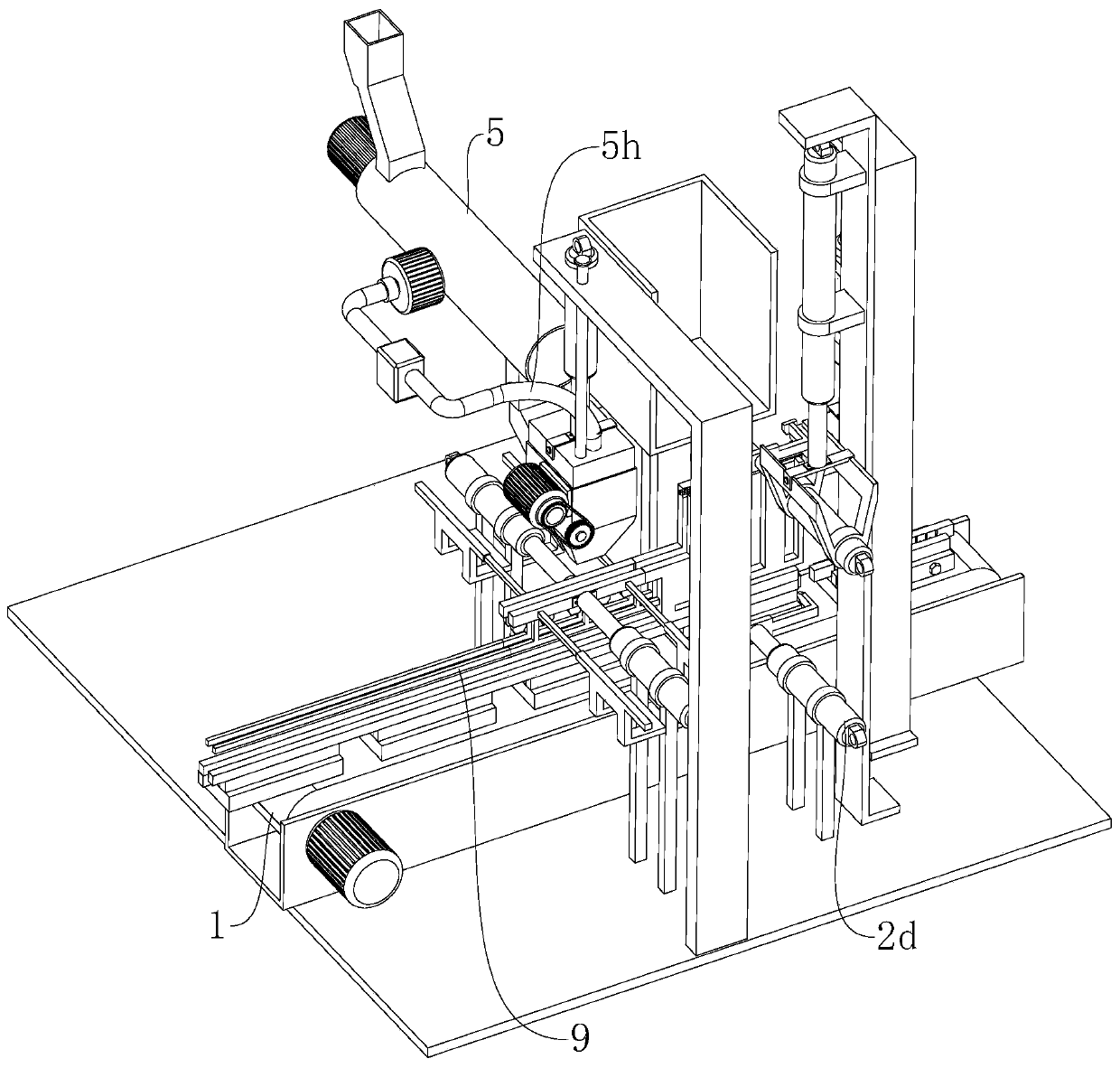

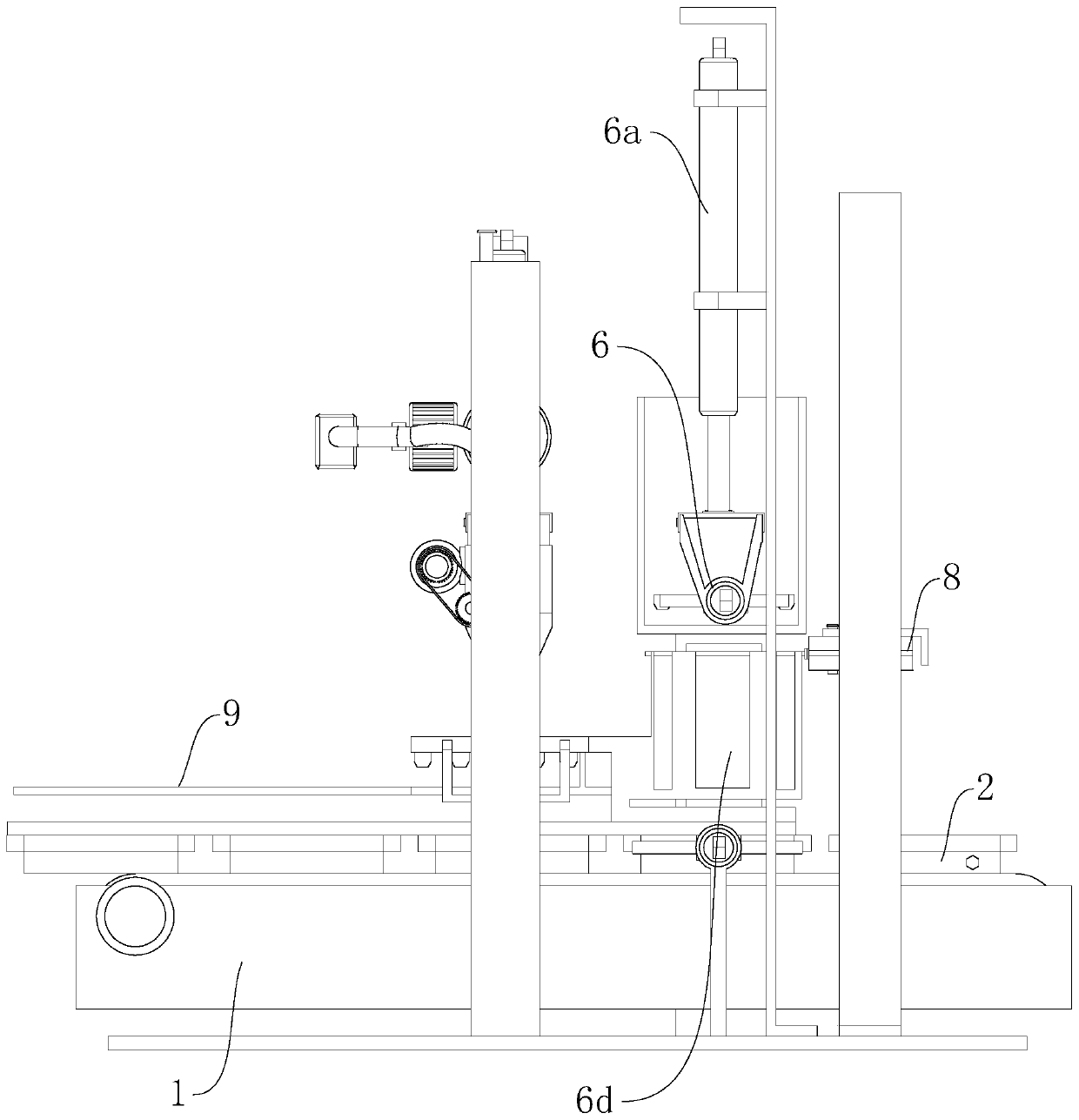

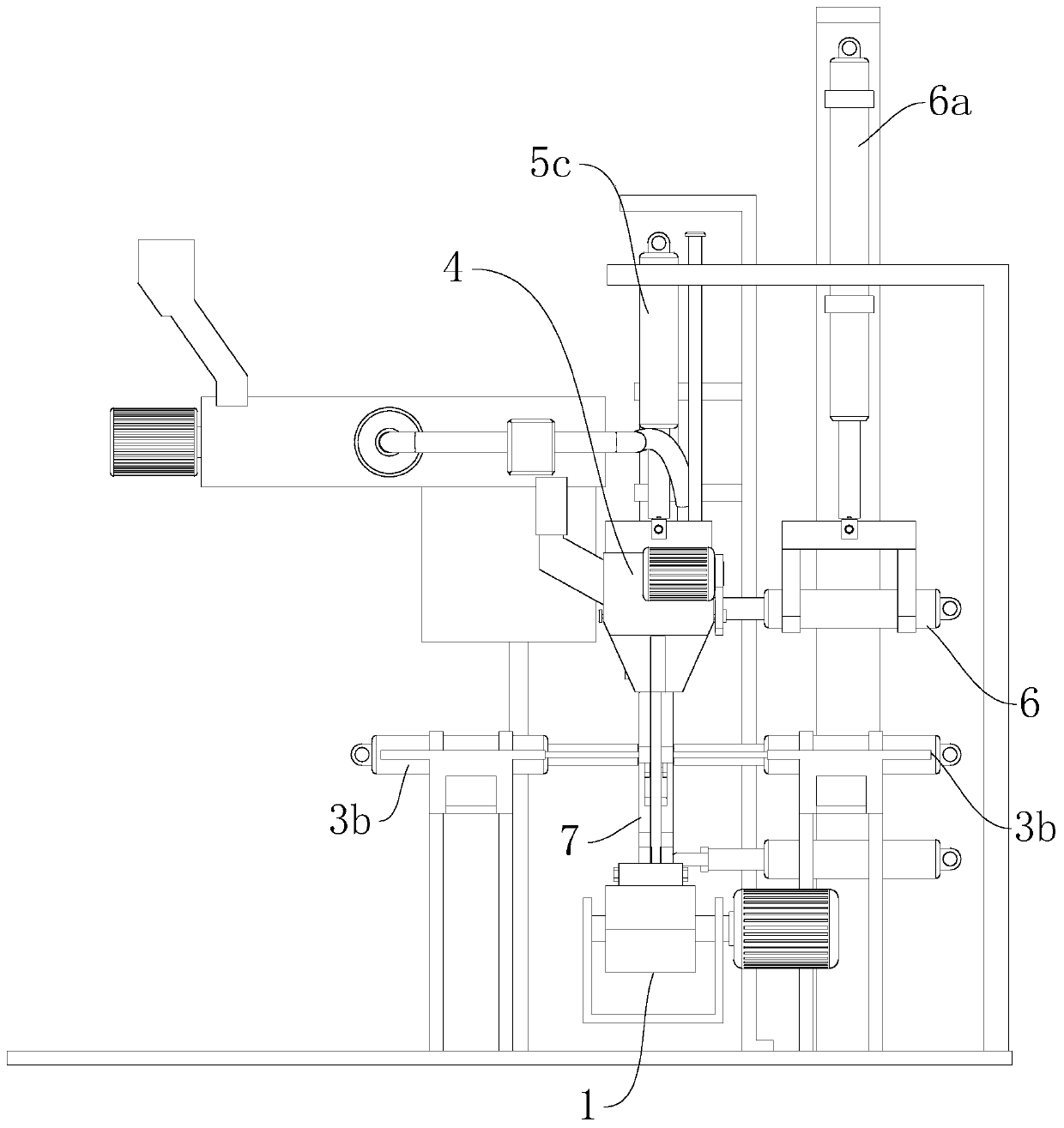

[0042] refer to Figure 1 to Figure 11 The shown automatic filling equipment for abalone soft cans includes a retort bag bracket. The filling equipment includes a filling conveyor belt 1, a bag opening mechanism, a filling mechanism, a material feeding mechanism, and a bag feeding mechanism. The filling conveyor belt 1 is horizontal The conveying plane is equipped with a plurality of jigs arranged at equal intervals along the conveying direction. The filling mechanism is inverted and can be vertically moved in a small range through the micro-motion mechanism. The bag opening mechanism is set up in the middle section of the filling conveyor belt 1, and is located below the filling mechanism. The feeding mechanism is set up beside the filling mechanism, and the two are connected. The upstream end of the conveyor belt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com