Non-block tea-leaf dust sieving device

A tea and sieve ring technology, applied in sieve, solid separation, grille, etc., can solve the problems of low work efficiency, easy blockage of sieve holes, troublesome use, etc., and achieve the effect of high work efficiency, low noise and easy use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Specific embodiments of the present invention will be described below with reference to the accompanying drawings.

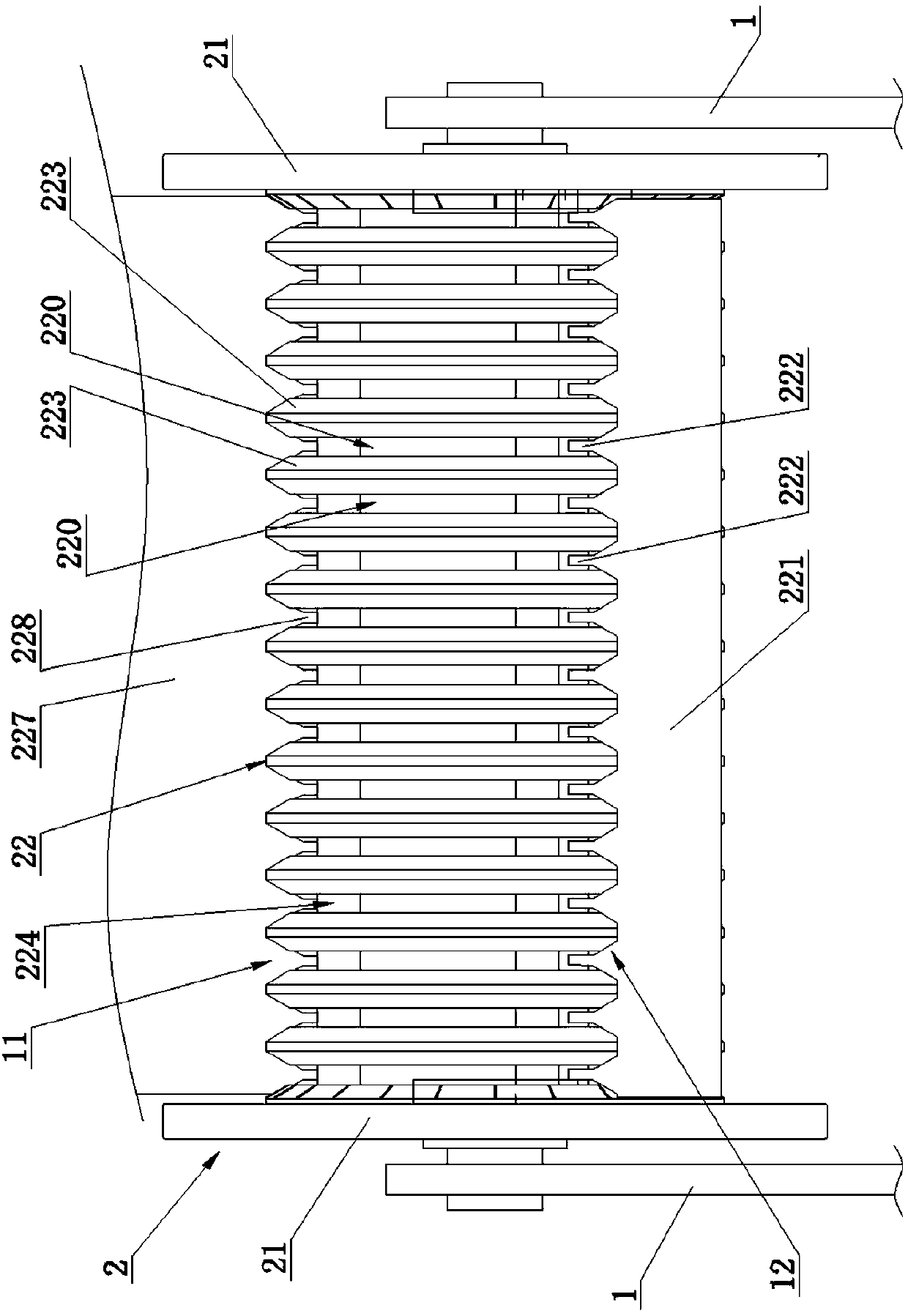

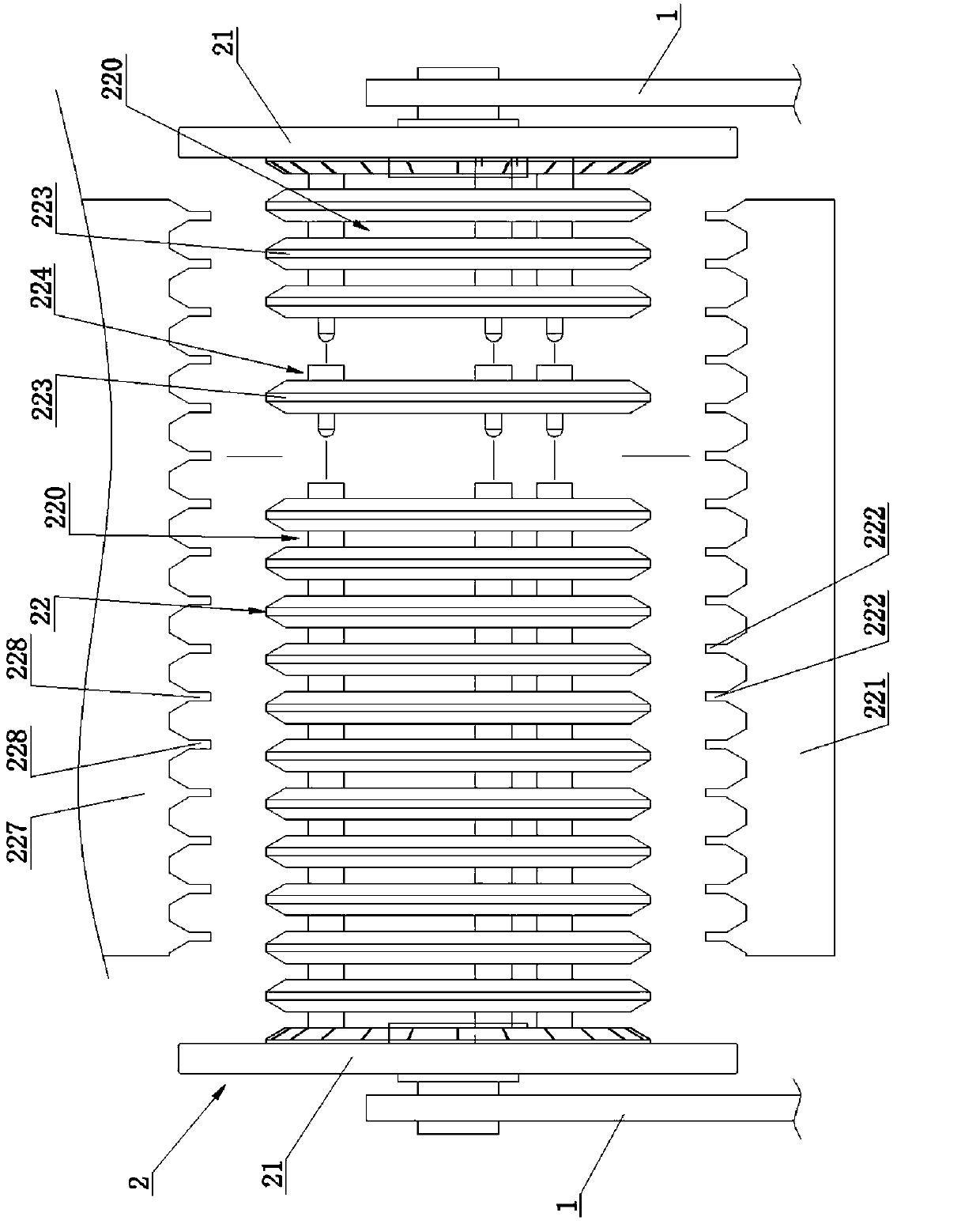

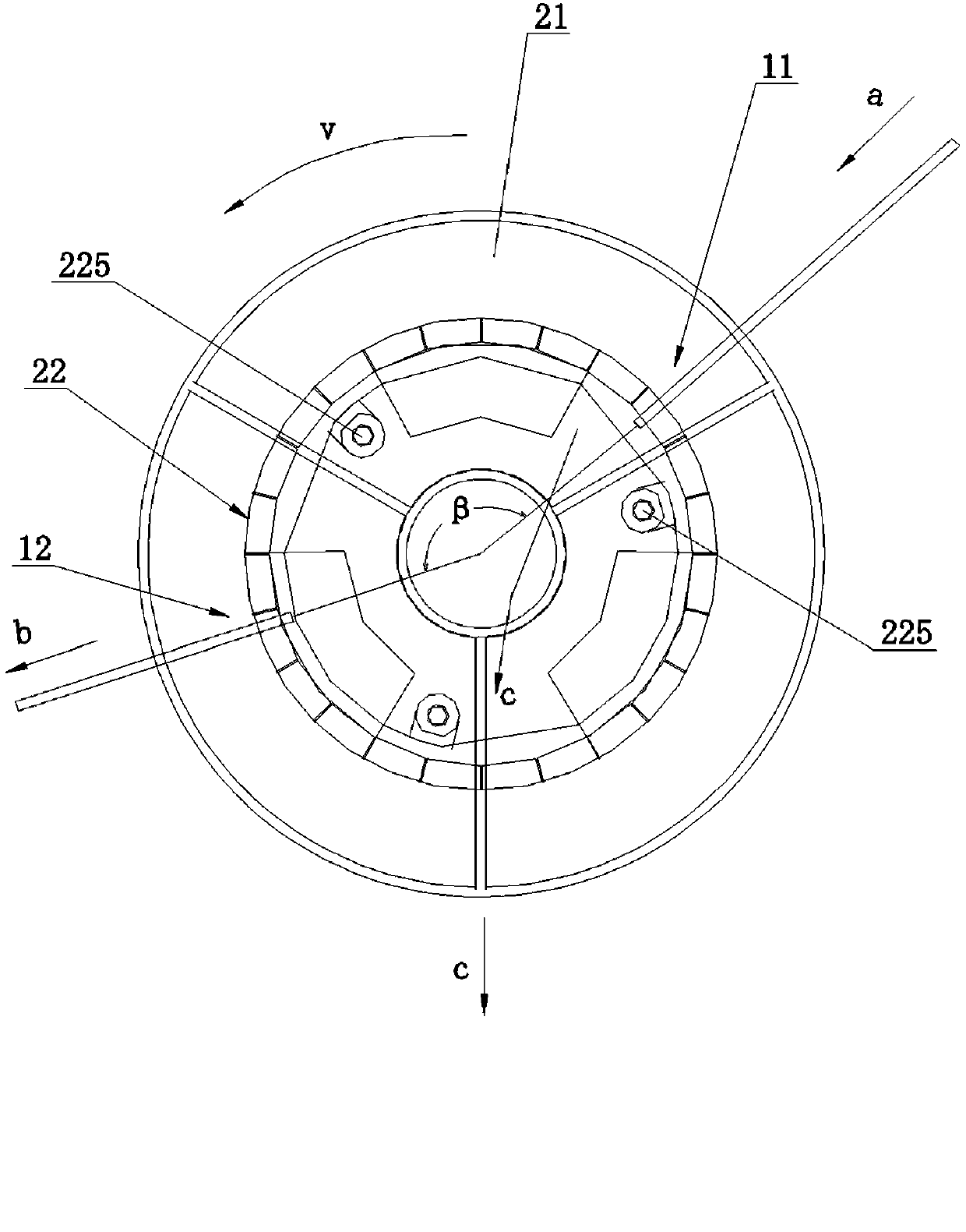

[0017] refer to figure 1 , figure 2 , the non-clogging tea powder sieve device, comprising a main frame body 1, the main frame body 1 is provided with a feed inlet 11, a discharge port 12 and a sieve powder rack 2 that can rotate around the shaft, and the main frame body 1 is equipped with Drive the drive motor that this screen end rack 2 rotates; image 3 Indicated by the direction of the arrow marked v, the sieve rack 2 is set rotatably from the feed port 11 to the discharge port 12 .

[0018] More specifically, continue to refer to figure 1 , figure 2 , the above-mentioned sieve frame 2 includes a support frame 21 connected to the above-mentioned main frame body 1 and a sieve cylinder 22 assembled on the support frame 21, such as figure 1 with figure 2 As shown, the sidewall of the sieve cylinder 22 is provided with sixteen end-to-end connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com