Glass plastic airflow separator

An air flow separation and glass-plastic technology, which is used in the separation of solids from solids by air flow, solid separation, chemical instruments and methods, etc., can solve the problems of low work efficiency, time-consuming and laborious, and improve work efficiency and separation effect. Good, long service life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

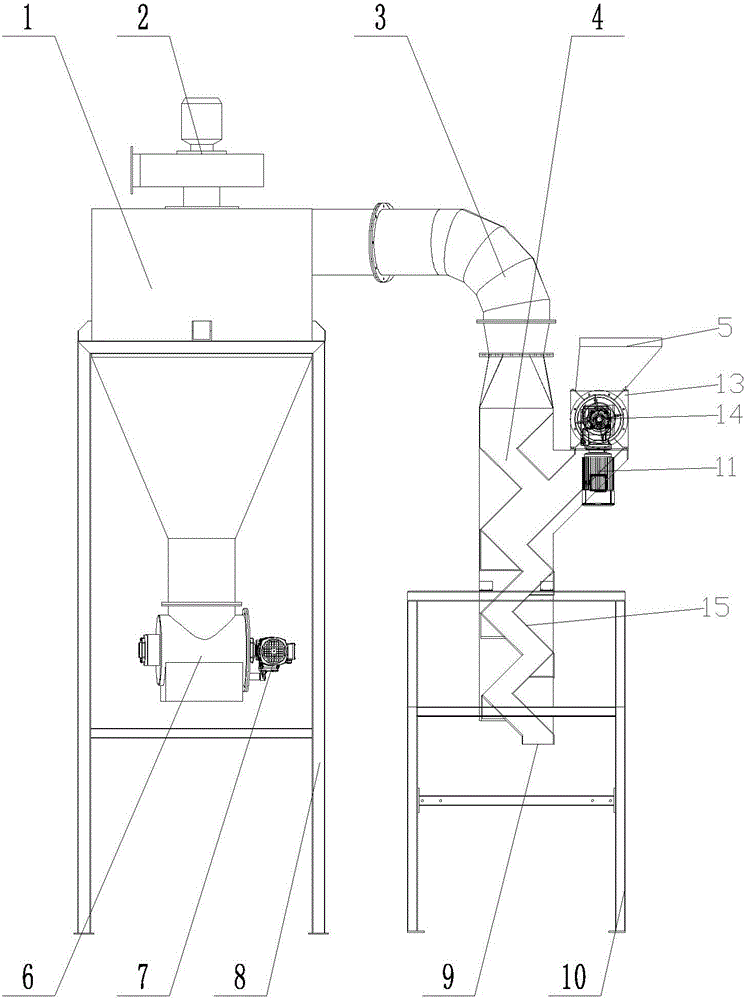

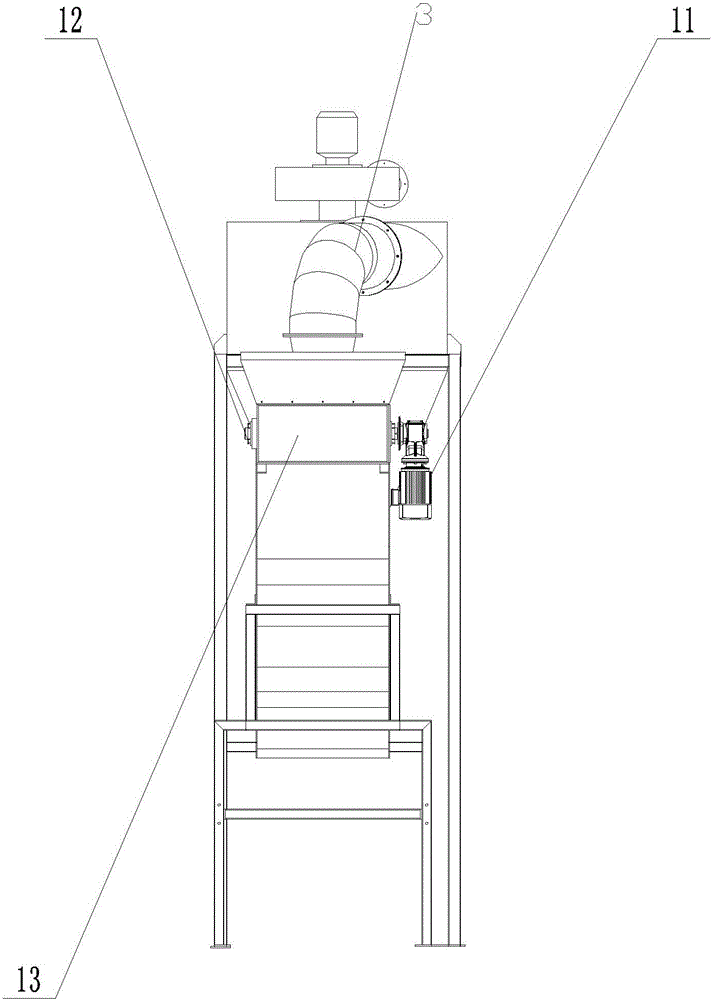

[0016] Such as Figure 1~2 As shown, the present invention mainly comprises plastic collection tube 1, fan 2, elbow 3, separator body 4, unloader 6, bearing holder 12, bulk material box 13, bulk material rotor 14 and separating pipe 15.

[0017] The separator body 4 is fixed on the separator body support 10 , and a separation channel is arranged in the separator body 4 . The separation channel includes a plurality of separation tubes 15 in a zigzag structure, and the plurality of separation tubes 15 are sequentially connected into one body from top to bottom. Even after the separation tube 15 with a Z-shaped structure in the separator body 4 has been in operation for a long time, the upper tube body will be worn through by sharp glass, and the lower tube body will be filled with glass material to prevent the glass from being worn through the second la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com