Adhesive tape attaching machine for PCB (printed circuit board) processing

A PCB board and attaching machine technology, which is applied to conveyors, conveyor objects, coating non-metallic protective layers, etc., can solve the problems of large attaching dead angle, small application range, and equipment that cannot match circuit boards of different sizes. , to achieve the effect of fast positioning and easy adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

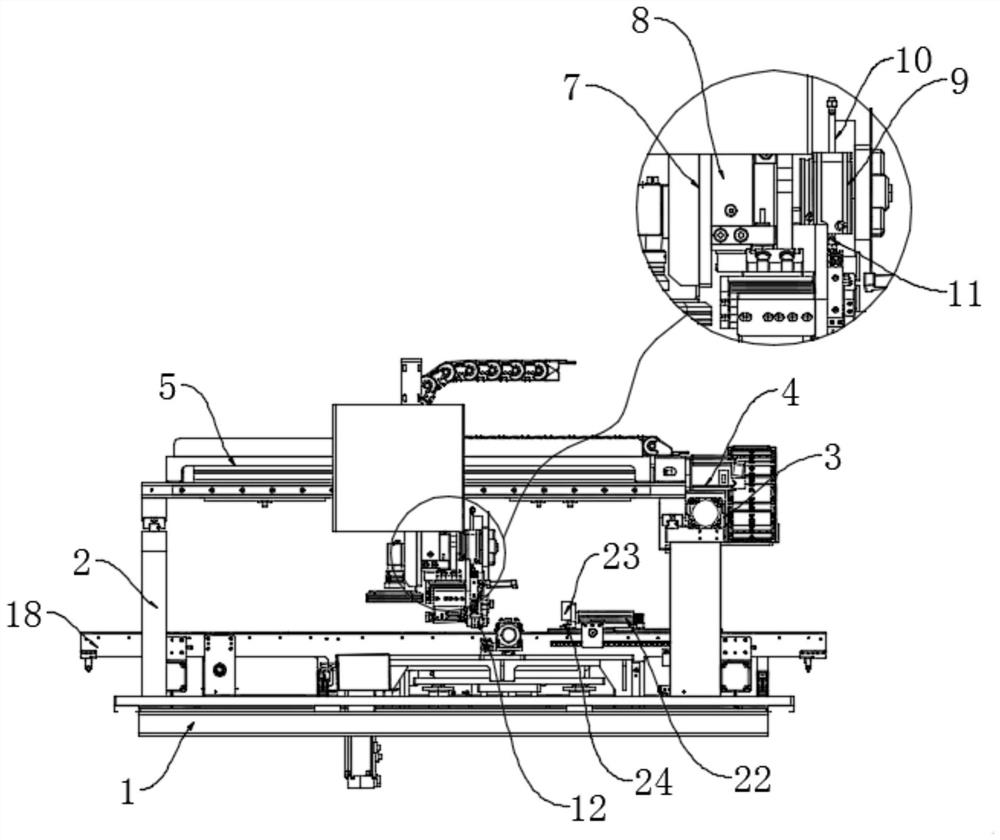

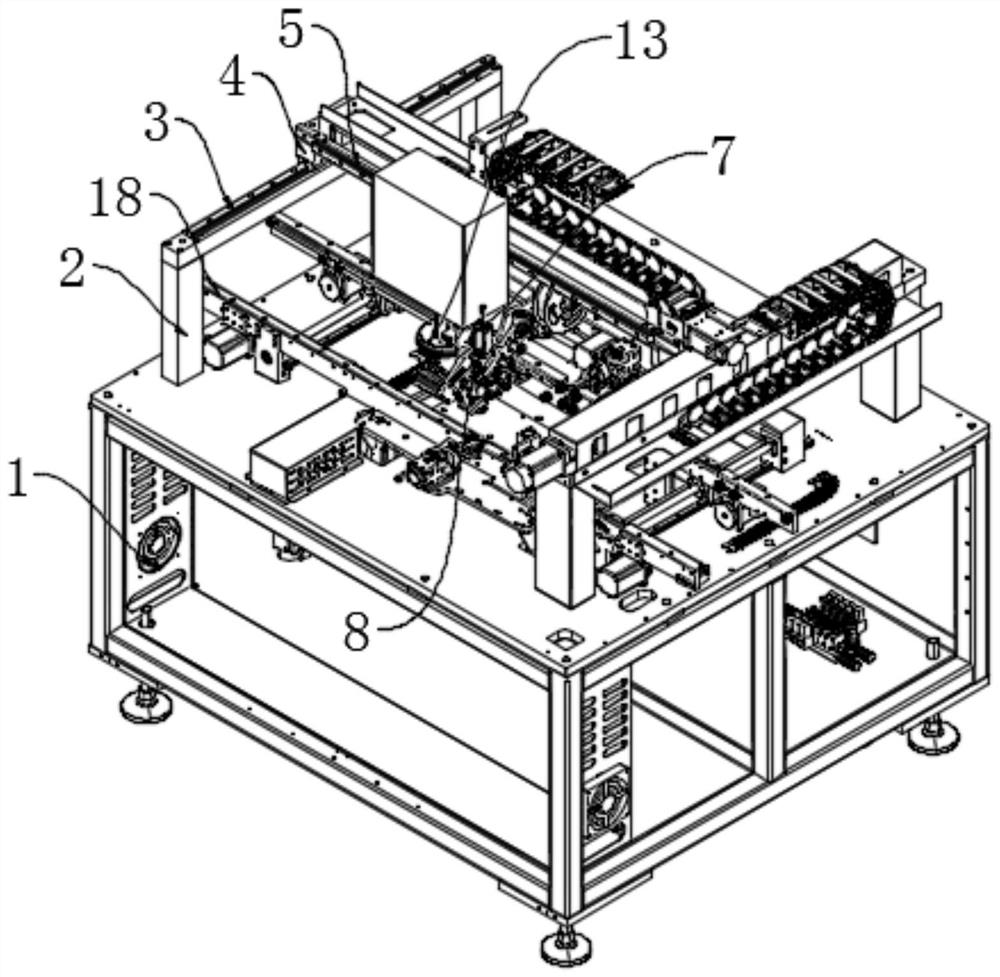

[0027] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

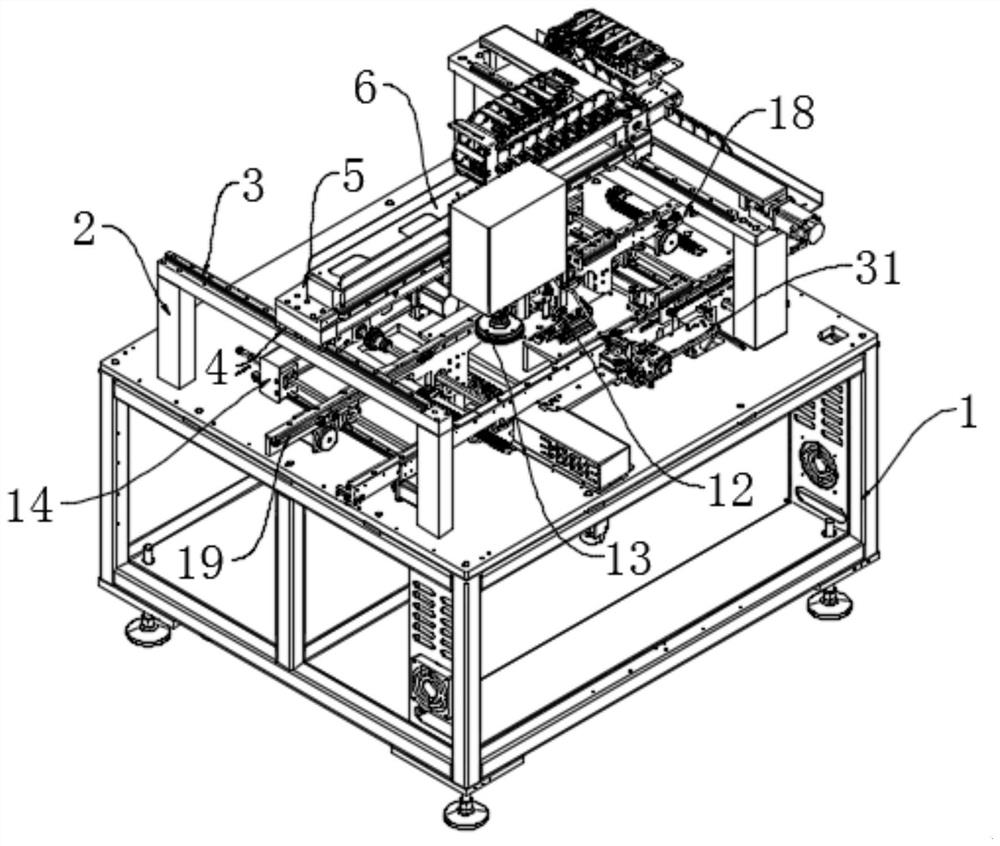

[0028] see Figure 1-7 , the present invention provides a technical solution: a tape attaching machine for PCB board processing, including a frame 1, two sets of reinforcements 2, an adjustment assembly, an attachment assembly, and a feeding assembly, and the reinforcements 2 are symmetrically locked and installed on the machine. On both sides of the upper surface of the frame 1, the adjustment assembly is installed on the reinforcement 2, the attachment assembly is installed on the adjustment assembly, the feeding assembly is installed on the upper surface of the frame 1, and the feeding assembly passes through two sets of reinforcements 2 distribution, and the attachment component and the feeding component are set correspondingly.

[0029] refer to figure 1 , in this embod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com