Tire bead cutting and wire stripping device and method

A bead and cutting technology, applied in the field of waste tires, can solve the problems of low efficiency, high labor cost, no wire stripping system, etc., and achieve the effect of improving the degree of stripping, improving the effect of stripping, and saving manpower and material resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

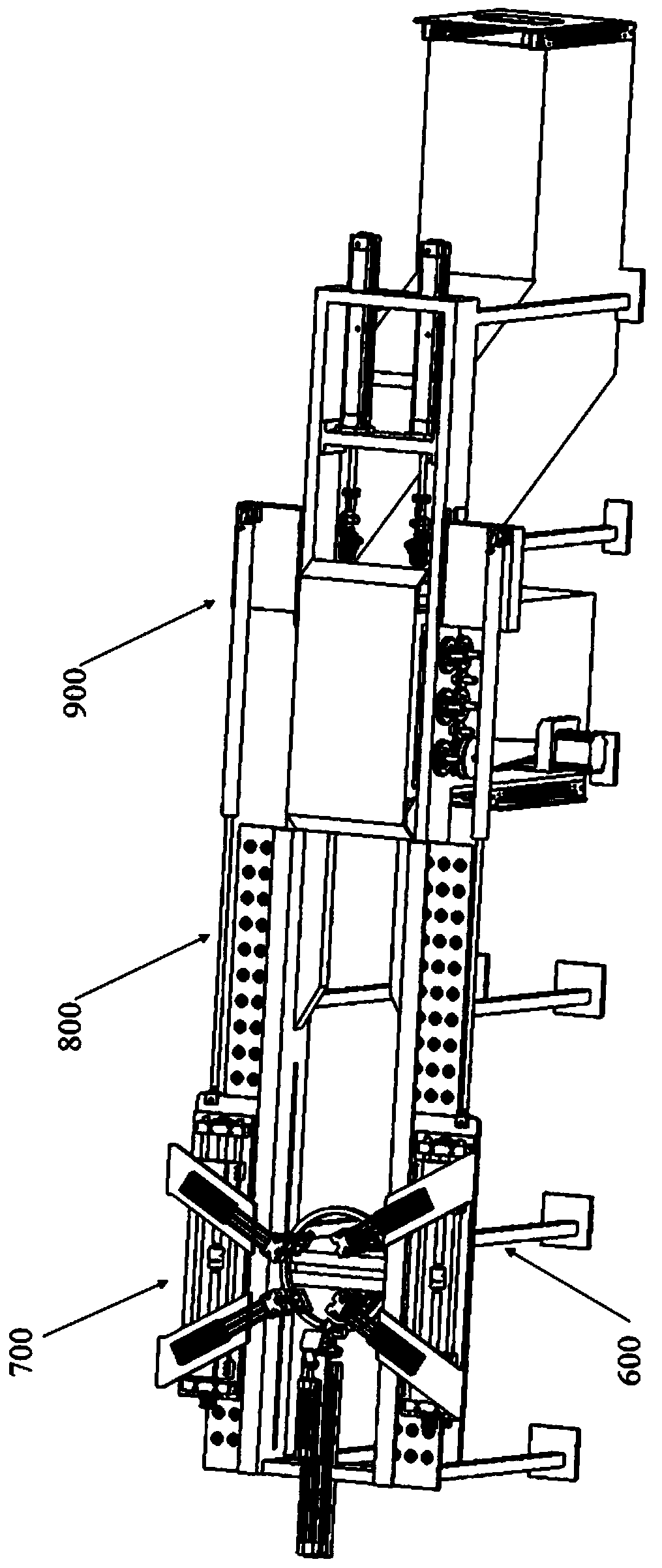

[0042] Such as figure 1 As shown, a bead cutting and stripping device, including

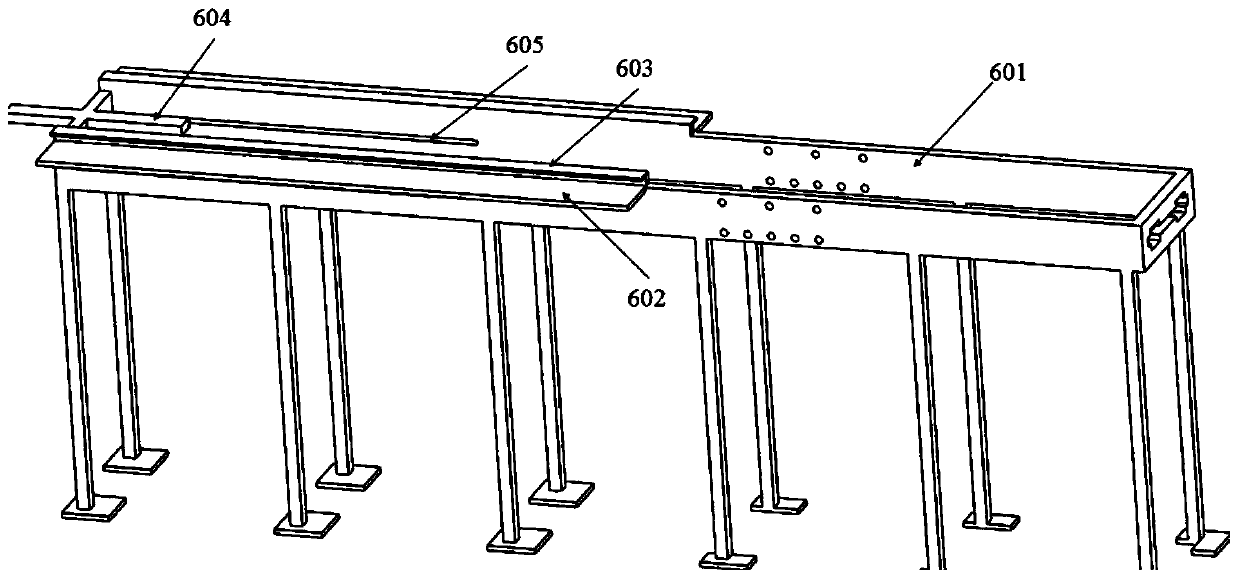

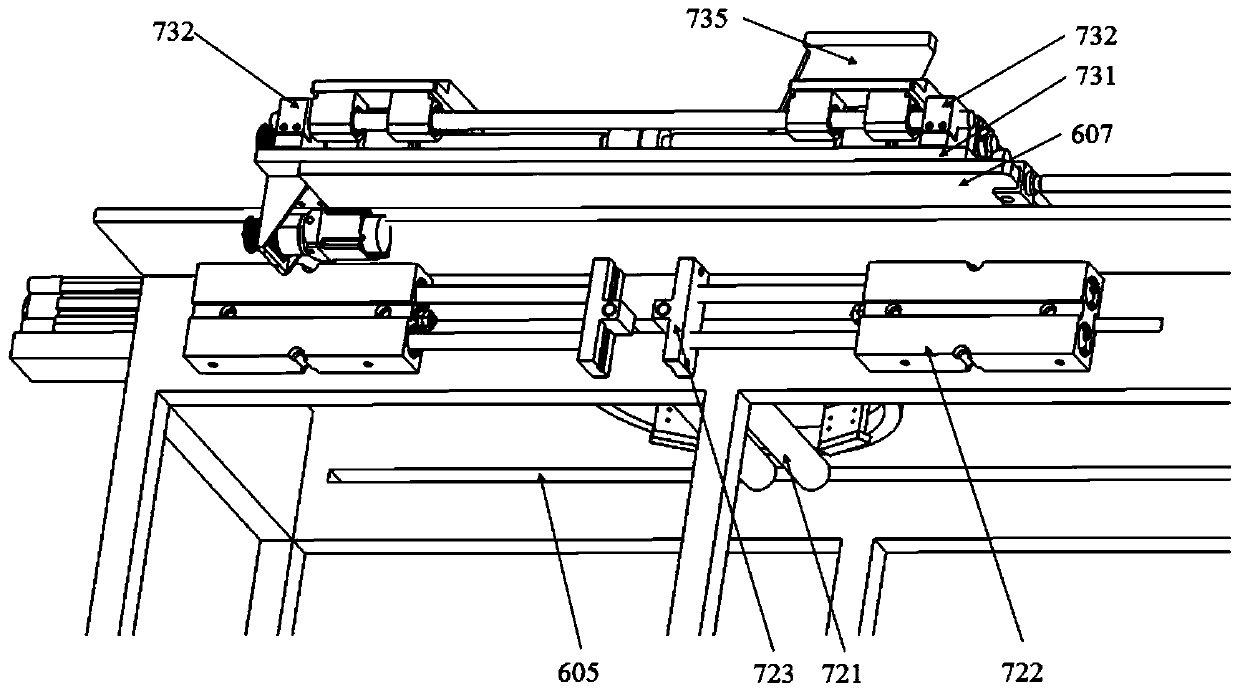

[0043] Workbench mechanism 600, described workbench mechanism comprises workbench body 601, the workbench lower plate 602 that is arranged on the workbench body and the workbench top plate 603, the workbench cross seat that is arranged on the workbench body one end 604, and the workbench slideway 605 that is set on the both side walls of the workbench body, the multi-row bull's-eye wheel 606 that is installed on the workbench lower plate and the workbench upper plate, is arranged on the workbench upper plate and the lower plate. The first layer board 607 that can reciprocate along the bull's-eye wheel between the boards and the layer board cylinder 608 that drives the movement of the first layer board; the first layer board is provided with a horizontally moving slide rail assembly.

[0044] The bead cutting mechanism 700 includes a cutter assembly 710 installed at the end of the workbench mech...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com